Professional Documents

Culture Documents

(1991) Chaize. Membrane Bioreactor On Domestic Wastewater Treatment Sludge Production and Modeling Approach

Uploaded by

sulihah12Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(1991) Chaize. Membrane Bioreactor On Domestic Wastewater Treatment Sludge Production and Modeling Approach

Uploaded by

sulihah12Copyright:

Available Formats

Waf. Sci. Tech. Vol. 23. Kyoto. pp. 1591-1600. 1991.

Printed in Great Britain. All rights reserved.

0273-1223/91 $000

50

Copyright 1990 IAWPRC

MEMBRANE BIOREACTOR ON

DOMESTIC WASTEWATER

TREATMENT SLUDGE PRODUCTION

AND MODELING APPROACH

S. Chaize and A. Huyard

Laboratoire Central Societe Lyonnaise des Eaux, 38, Rue du President

Wilson, 78230 Le Pecq, France

ABSTRACT

The membrane bioreactor, with an increase of biomass concentration in the aeration tank,

permdt work with low F/M ratio and a reduction in s ludge production. The membrane bioreactor

potentialities have been tested on a laboratory pilo t for domestic wastewater treatment.

Various operating conditions (HRT, SRT) were applied to investigate organic and nitrogen

removal as well as sludge production.

Two modeling approaches were tested (maintenance phenomena, single sludge simulation process)

with unsuccessful1 predictions. Futher investigations are needed to better understand

biological kinetics and phenomena in membrane bioreactor and to obtain higher flux on membrane

processes.

KEYWORDS

wastewater treatment; activated sludge; membrane separation; s ludge production; maintenance.

INTRODUCTION

Conventional biological processes for wastewater treatment use biomass recycling to increase

the microorganism concentration in the aeration tank, and therefore the degradation rate of

organic and nitrogen compounds. Membrane separation techniques have been applied for biomass

recycling in biotechnology (Strathman, 198 5) and in wastewater treatment. Application of

membrane separation to anaerobic digestion was investigated to trea t dairy effluents (000 > 30

g. 1-1 ) (Li et al., 198 5) and domestic wastewater (Grethlein, 1978) . Combination of biological

treatment activated sludge with u ltrafiltration was first

reported by Smith et al.

(1969). The combined process is free from the limitation imposed by the settling tank used-rn

conventional activated sludge process.

Higher biomass concentrations may be used

without

bulking phenomenon problems and no effect of varied

loadings on treatment efficiency. In

Japan, this process was developed for domestic wastewater (Audic et al., 1986), and "in situ"

reclamation in large buildings (Kanayama et al., 1987 ; Arika et aI.:-I977). This process--Is

not cost effective and its application is-lImIted. The high power-consumption is due to the

recirculation pump . Yamamoto et al. (1989) have tested the direct solid-liquid separation

using hollow fiber membrane, out aoalance between surface area and cost, and energy input

has to be made. To predict membrane flux, Fane et al. (1980) developed a computer model of a

combined ultrafiltration and activated s ludge --wastewater treatment system. Regarding the

membrane aspect, the major resistance to flux is provided by the suspended solids. Goma et al.

(1986) and Bouillot et al. (1989) have investigated the biological reactors in a membrane

reactor treating syntnetICdomestic wastewater, incorporating the maintenance "concept". This

paper describes investigations on the effect of SRT and HRT on mbrane bioreactor

potentialities. Sludge production and steady state suspended solids concentration have been

studied. Two biological models for wastewater treatment were tested to evaluate the

performance of membrane._ bioreactor.

159 1

1592

s. CHAIZE and A. HUYARD

MATERIAL AND METHODS

Laboratory pilot plant

The pilot plant, shown in Fiqure I,

is composed of a completly mixed biological reactor

connected to an ultrafiltration module. The concentrate from the ultrafiltration loop was

returned to the tank.

Domesti

c

wastewater

effluent

DDS {tratlonl

I

Treated

Excess permeate

Retentate

1ii

r--

I]

LJ

Fig. 1.

a 4. 5 1

frll

t!:!J

/Reactor J

The reactor (Biolafitte) had

reduce foaming problems.

gH

J Heat exchanger L

Pump

Experimental Set-up

working volume and was

The temperature was maintained at 20C, the air flow rate

was between 800 - 1200 rpm.

was

equipped with a draft tube

80 1

to

h -1 and the mixing speed

The feed supply was regulated by a level regulation in the reactor. The ultrafiltration

module, (De Danske SUkker-fabriker) was a plate and frame module, with four plates in a serial

design, equipped with polysulphone (GR 51PP) and cellulose membrane (ETNA) during run 1 and 2

respectively. Membrane cut-off was around 50 000 d, linear velocity along the membrane was

1. 5 m S-1 and transmembrane pressure was in a range of 1 to 2 bars. The ultrafiltration module

had a surface area of 0.42 m'. The additional loop shown in Figure 1 was used to test the

effect of inverse flow in the ultrafiltration module to prevent membrane clogging during run

1. During all the experiments, excess permeate was returned to the biological reactor.

The laboratory pilot plant had

8 1 total volume. Hydraulic and sludge retention times were

calculated from this total volume. Experimental conditions, for the different run, are

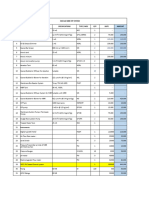

summarized on Table 1.

TABLE 1

Pilot Plant Operating Conditions

PERIOD

HRT

SRT

Run r

o - rliOth

II Fi

roo a

Run 2

o - 28th

28 - 128th

128 - 17 5th

1 7 5 - 190th

8

4

2

2

100

100

50

100

h

h

h

h

d

d

d

d

Analytical methods

SUspended solids were obtained by membrane filtration (Millipore AP 20) or centrifugation and

drying 24 h at llOe. The organic fraction of the suspended solids (MLVSS) were determined

after drying at 5 50C. Kjeldahl nitrogen and chemical oxygen demand (COD) were measured

according to French Standard Methods AFNOR T 90-1 10 and T 90-103. The total organic carbon was

measured in an infrared analyser Tocamaster 9 1 5-B (Beckman).

1593

Domestic wastewater treatment sludge production

After dilution, nitrogen compounds (NH4 , N0 2 ,N03 ) were determined according to the

measurements, drazotation method using colorimetric

Method T 90-013. For NO - NO

and optical density meas ftremen i to 520 nm was made on an autoanalyser (Technicon).

Standard

reaction

Proteins were measured with the Lowry technique (LOWry et al., 1951) and polysaccharides with

the anthrone method (Dubois et al., 19 56). Microorganisms activity was evaluated by

measurement of oxygen consumption mth a respirometer (YSI Model S3 oxygen monitor) and

dehydrogenase activity with INT method (Trevors et al., 1982).

RESULTS AND DISCUSSION

The pilot plant has

run with two operating conditions ; run 1 with a. hydraulic retention

time of 8 h and a sludge retention time of 100 days and run 2 with different values of these

two parameters.

Run 1 with 8 h HRT and 100 days SRT.

The bioreactor was naturally seeded with the microorganisms present in the raw water.

Suspended solid concentrations from the raw water varied from 0. 5 g/l to 0.3 5 gil. Biomass

concentration in the bioreactor and theoretical accumulation of the suspended solids coming

from raw water (see S biomass steady states concentration

) were plotted in Figure 2. After

25 days, the biomass concentration reached a pseudo steady state. Figure 3 shows the TOC

removal efficiency of the bioreactor. The bioreactor efficiency was maximum from the

beginning.In spite of the variations of TOC or COD 9ncentrations in the raw water, the TOC

permeate concentration remained stable at 15 mg 1

This carbon corresponds to organic

compounds with a low molecular weight (inferior to the membrane cut-off), non-degradable by

the microorganisms contained in the bioreactor.

Total nitrification was observed in the operating conditions (SRT, HRT) applied to the

bior,ctor. In the raw water, the nitrogen compounds concentration varied little(NTK - 100

mg.l ). Figure 4 shows the variations of the permeate nitrogen compounds. Nitrification began

after 14 days. The nitrogen organic compounds such as proteins are degraded. The N-NTK

permeate concentration indicated that

part of the effluent TOC

originated from these non

biodegradable compounds. Table 2 summarize the results obtained during run 1.

LE 2

Performance

of the pilot plant

Raw water

Suspended solids mg 1

-1

000 particulate soluble mg 1

-1

200 - 400

Treated water

--- --------------

2 50 - 550

<

30

35 - 80

<

20

Proteins

10 - 12

<

N -

60 -1 50

<

10

<

0. 5

TOC soluble mg 1

-1

NTK

N - NH

Biomass concentration

40 - 80

8 - 10 g 1

-1

-3

-=1

Volumetric load

0.4 5-1. 5 kg 000 m

Massic specific load ( FjM)

0.06-0.10 kg COD kg

SS d

-1

-1

SS d

0. 14 kg O2 kg

O2 consumption (respirometry)

d

-1

-1

1594

s. CHAIZE and A. HUYARD

'0

CI>

'"

:;

E

:J

u

u

'"

'"

50

200

;g

150

CI> Cl

'0 c

CI>

a.

100

"' ...

'O.!.:

'"

:J

fJ)

50

2'"

;;:

;;:

'"

....

20 -------

-- Suspended solids

....... Suspended solids accumulated

16

0,

'"

12

"0

'"

'0

CI>

'0

C

CI>

a.

'"

. .

..

:J

en

(lo

a:

. . ' .

.

.. .... .

..

. ..

.. .

40

..

, ... .

.

...

..... .

.

...

..

...

. ..

...

'

120

80

160

200

Time (days)

Fig. 2.

Biomass evolution (Run 1)

200 r------

Raw water rOe

Treated water TOe

160

0,

E

120

()

o

I-

:.I-J.:_.._ ..:.... _.......i............ ..... ...'- ....

0____-4________________

o

40

80

120

160

200

Time (days)

Fig. 3.

TOe removal (Run 1)

140 -------,

0,

E

C'l

o

z

<"II

o

z

..,.

J:

Z

20

. ..

. .i

.

f /_

A

. . ____

A

. __

.. _

o

.

o

80

160

200

40

120

Time (days)

Fig. 4.

N-Compounds in treated water

Domestic wastewater treatment sludge production

1595

Run 2 with HRT And SRT Changes

During the second part of the experiment the HRT varied from 8 h to 2 h and the SRT from 100

to 50 days, in order to study the steady state biomass concentrations at the different

operating conditions. Some problems on pilot operation have caused a loss of biomass (day

97 ). Figure 5 shows the variations of the biomass concentration in the bioreactor and the

accumulation of the suspended solids from raw water ; all the events on pilot operation are

reported in Figure 5.

E!

HRT

SRT

40

300

'C

..

Oi

:;

E

:::J

...

...

240

...

.

en

180

:!:!

'0

II)

01

1/1

:!:!

'0

II)

'C

..

8

100

2

50

100

1ojhours

days

100

- Suspended solids

...... Suspended solids accumulated

32

24

II)

'C

..

120

'C

C

16

..

'C

c

60

a.

1/1

:::J

II)

..

a.

1/1

:::J

II)

8

0

40

80

120

160

200

Time (days)

Biomass evolution (run 2) with different SRT and HRT

Fig. 5.

The biomass concentration increased slowly in the bioreactor (before day 30 ). During this

period a decrease of the membrane permeability was observed (see Figure 10). The influent and

effluent TOe concentrations are plotted in Figure 6.

160

...

.

en

u

TOe treated water

- TOe raw water

._

120

80

I-

40

40

80

120

, 160

200

Time (days)

Fig. 6.

TOe removal (Run 2)

The TOe average concJiltration in the raw water was lower than in previous experiments (TOe

average

0.034 g.l ). Changes in operating conditions (SRT or HRT) had no effect on the

water quality produced (carboneous removal only). Some differences were observed on the

soluble part of the liquor circulating in the bioreactor. TOe, protein and polysaccharide

Figure 7.

(total sugars) concentrations are shown in

=

S. CHAIZE and A. HUYARD

1596

Time

Fig. 7.

(days)

TOe, proteins, polysaccharides on liquor supernatant in reactor

At the beginning, TOe

accumulated on the bioreactor. with the increase

of biomass

concentration, this TOe was degraded. When HRT changed, the TOe, protein and polysaccharide

concentrations increased. This accumulation can be explained by the accumulation of either the

bacterial products (lysies orland excretion) or the raw water components. This phenomenon

became under limitation on soluble substrate. No correlation was found between variations in

TOe concentrations and the accumulation of such compounds in bioreactor liquor. With different

operating conditions, several authors (Yamamoto et al. (1989) ; Bouillot et al. (1989

have

reported this accumulation phenomenon. Changes in-operating conditions disturoed the removal

of nitrogen compounds. These variations are depicted in Figure 8.

..

CI

III

"0

c:

o

0.

o

u

c:

G>

CI

140 r------,

...... NH4

120

N02

- -- N03

100

80

60

..:\;

.

40

Z

Time

Fig. 8.

(days)

N-compounds in treated water (Run 2)

After an adaptation time, the removal of nitrogen compounds was

With an HRT of 2 h, the bioreactor worked with :

- a volumetric load

VL COD

VL NH

- a massic load (F/M)

Measurements of dehydrogenase

plotted on Figure 9.

COD

NH4

activity ( INT

5.04

maximum for each HRT studied.

kg COD

m

-3

-3

0.96

kg

0. 13

kg COD kg

0.026 kg N kg

activity)

N m

and O2

-1

-1

-1

-1

-1

-1

specific

consumption

are

1597

Domestic wastewater treatment sludge production

>;-

en

(/)

&. 12

E

ci

2i='

'?:

>

'"

'"'"

c

CI)

01

0

-0

>.t:

CI)

0

, 01

(/)

--

0.5

.2

0.2 ;

'"

..

'0

[}j

CI)

(;

. .

'

: l::

.

fl

.0.

,:.

; .'

!=:

./ .

0.1

...

i i

:l

consumption

.

activity

!\ ' f

.

::

L .f:..; :: :

.... : :. . ;':.:= .. :;.:

:f ....

-. .

'.'''' : .i!_.:: :! '!

.

::: :l:.."

E 0.4

N

0

E 0.3

02

INT

01

<>

CI)

.

(/)

.. i

.....

..

O-------------L------________L-____

80

40

120

Time (days)

160

200

0, comsumption and INT activity (Run 2)

Fig. 9.

These two activities are a good indicator of the active fraction of the biomass. During the

"growth" phase of this biomass, values for these parameters were higher than during steady

state. At the beginning, the biomass active fraction w as high.As the biomass aged, the specific

activities decreased, which can be explained by the decrease of the ratio of active/inactive

fraction of the biomass. The active fraction became only a small fraction of suspended solids

in the bioreactor.

Biomass steady state concentrations

and sludge production

Figures 2 and 5 report the biomass concentration in the reactor and the theorical accumulation

of suspended solids from the raw water

the calculation is the daily accumulation of

suspended solids.

SSac

E ([inf SS conc.) x 24jHRT) - wastage

TOe

The biomass generated by the removal of soluble

was not taken . into account. The

difference between theoretical and experimental suspended solids concentrations s mainly due

to the conversion of organic matter into biomass and CO,.

The model developed by the IAWPRC task group (Henze et a1. 1986). on mathematical modeling for

design and operation of biological wastewater treatment was used to evaluate the performance

of the membrane bioreactor. Operating conditions and results of simulation are reported in

Table 3.

run

The kinetics parameters were those proposed by the IAWPRC task group. Feed characteristics used

for the simulation are an average of the raw water characteristics during

2. The predicted

effluent COD of 0.002 g 1 '1 is slightly lower than experimental value 0.030 g 1 -1), whereas

the predicted

effluent concentration was very close to the experimental value.

NTK

The major disagreement between modeling and experimental approach is on biomass concentration

(suspended solids). Whereas the modeling approach predicted MLVSS concentration of 16 and 6 5

g 1 -1, for a n HR T o f 8 and 2 h respectively, the S S experimental values were around 1 0

36

g 1 -I (MLVSS

7 5 % of suspended solids concentration). This difference can be explained by

the large SRT (100 days) and the low HRT used in the experiment. Indeed the IAWPRC model,

which was valid

with results from typical activated sludge plant, does not incorporate

maintenance phenomena, important for processes w i

a low F/M ratio.

and

th

The maintenance concept was introduced by Pirt (196 5). It expressed the energy consumption

necessary for the endogeneous respiration of the microorganisms. The observed yield (Yobs) and

the specific growth rate (p) are related by the following equation

l/Y

obs

where

ms

is the

maintenance coefficient

l/Y

lim

and Y

lim

m /p

s

the maximum yield

in batch

experiments.

s. CHAIZE and A. HUY ARD

1598

TABLE 3

Results From Simulation with IAWPRC Model

HRT*

SRT*

COMPOUNDS

mg 1-1

CHARACTERISTICS

8 h

2 h

100 d

100 d

FEED

------

Heterotrophic organisms

1. 743

6.982

0. 0

Autotrophic organisms

0.189

0. 761

0.0

Particulate products

8. 81 5

3 5.273

0.0

Inert particulate

9 COD 1-1

5.2 50

21.000

0.03 5

Organics Particulate

0.146

0. 58 5

0.226

Soluble organics

9 COD . l - l

0.002

0.002

0.193

Soluble ammonia N

0.0003

0.0003

0.059

Soluble nitrate/

nitrite N 9 N 1-1

0.068

0.068

0.001

Soluble organics N

0.0004

0.0004

0.006 5

Biodeg. particulate

organics N 9 N 1-1

0.045

0. 045

0.009 5

4.0

4.0

16.145

64.6

9 COD 1-1

9 COD 1-1

9 COD 1-1

9 COD 1-1

9 N 1-1

9 N 1 -1

OXygen

mg O2 1-1

MLV5S

9 COD 1-1

9. 0

* Calculated on aeration tank for modeling simulation

Bouillot et al. (1989) using a soluble synthetic substrate have demonstrated the validity of

this conceptr membrane bioreactor application. The steady state biomass concentration (X)

is given in the equation below :

(1)

X -

+ 1Ils

Ylim

with Dh - l/HRT and Dp

l/SRT. Using synthetic

domestic wastewater and the strain

Pseudomonas fluorescens, a maintenance oefficient and a growth yield were determined :

- 0.56 g.Ss.g.- COD

Ills - 0.035 h-i arid Y

lim

During run 1 and run 2, steady states biomass was detenn.ined

results are reported in Table 4.

(Fig. 2 and Fig. 5).

These

When the SRT is very high, therefore Dp is very low, equation 1 can be simplified:

Dh (COD inf - COD effl)

(2)

X - -------

ms

From Equation 2 the maintenance

of COD removal.

coefficient Ills can be estimated by plotting

as a function

Domestic wastewater treatment sludge production

TABLE 4

Steady State

1599

Analysis

TOe

SS

SS

Raw water

Reactor

g 1-1

g 1 -1

-- - ----- -- -- ---- ----- --- ---37- 50th

Bh

100d

35.6 (14.9)

0. 25 (0.09)

10.07 (0.77)

5B- 72th

1

40.2 (9.4)

0. 33 (0.12)

10. 3 (0.79)

101- 115th

40.4 (21.7)

0.7B (0.03)

B.34 (0.75)

120-134th

39. 4 (11.6)

0.79 (0.05)

12. B6 (1.42)

---6-20th

Bh

100d 20

(7.67)

0. 20 (0.11)

2.0B (0.24)

4h

2B -42th

20.74 (4.67)

0.2B (0.07)

4.95 (2.03)

73-94th

2

5 5. 15 (B.33)

0.29 (0. 13)

27.43 (1.43)

160-l7Sth

2h

SOd SLOB (17.3)

O.lB (0.07)

25.BB (2.20)

100d

17B-1BBth

100. 32 (29. 54) 0.23 (0.06)

36.3 (3. 5 1)

Run

Period

HRT

SRT

Removal

mg 1-1

) indicates the standard deviation of the P mean value calculated

'!his approach was applied by using the experimental results summarized in Table 4, but a

maintenance coefficient cannot be estimated due to the important dispersion of values. This

result can be explained by the high concentration of suspended solids in raw water, which is

not considered separately in

Equation 1. The incorporation of the maintenance concept

into the IAWPRC model should solve this limitation.

Membrane flux

Membrane with different organic composition were used in these experiments.

Regardless of

rating conditions (suspended solids concentration) comparison seems difficult. Figure 10

the permeability variation of each membrane.

90 r-------

PS (Run 1)

ETNA (Run 2)

:c

..

CII

E

Cii

Co

CII

C

..

.c

E

CII

::!!

45

30

15

1\

:i

INV

ll

..'.,:,- .1.1..

... ":'"

".

OL-----------------

200

160

120

BO

40

o

Time (days)

INV - change of recirculation flow direction

Fig. 10. Membrane permeability (RunS 1 and 2)

The GR 5 1 PP membranes have a lower initial permeability than E'lNA membranes. During run 1

changes:.in recirculation flow direction have a slight effect on the membrane permeability. With

a higher biomass concentration, ETNA membranes seem to give a higher flux after 1 50 days.

COOCLUSICN

Membrane bioreactor is a very attractive process. High sludge retention

excess sludge production were obtained because of the membrane efficiency.

time and very

With a SRT of 100 days and a HRT of 2 hours, a good effluent quality is obtained.

low

1600

s. CHAIZE and A. HUYARD

The major inconvenience for the developnent

of this process is not favoured by the high

operating cost due to the recirculation loop.

With regard to the results obtained, it is

necessary to optimize the process with the following operating conditions

- biomass concentration (determinated by SRT and HRT)

- membrane flux and surface area

- power consumption (0. transfer - recirculation loop).

In order to better understand the biological reactions involved in this process, it is

necessary to further develop the maintenance concept and its application to conventional

wastewater treatment prediction models.

ACKNCl4LEDGEMENT

Acknowledgement to G.M. Faup, Head Ingenior of the Central Laboratory and J. Mamen for helpful

discussion, to M. Le Digabel and M. Hurtrez for typing and illustrations of this paper. Thanks

to C.P. Leslie Grady for providing the SSSP program (Simulation of Single Sludge Process).

This work was funded by EUREKA project with the collaboration of Lyonnaise des !aux and DDS

Company.

REFERENCES

Arika, M., Kobayashi, H., Kimara, H. (1977). pilot plant test of an activated sludge

ultrafiltration combined process for domestic wastewater reclamation. Desalination, 23,

77-86.

Audic, J.M., Fugita, Y. and Faup, G.M. (1986). Le couplage boues activees - membrane : une

realite au Japon. T.S.M., 6, 297-300.

Bouillot, P., canales-;X:-;- Pareilleux, A., Huyard, A., Goma, G. (1989). Membrane bioreactor

for the evaluation of maintenance phenomena in wastewater treatment. Accepted for

publication in J. Fenn. Tech.

(1956). Colorimetric method

Dubois, M., Gilles, K.A., Hamilton, J.K., Rebers, B.A., Smith, F.

the determination of sugars and related substances. Anal. Chem., 28, 350-356.

Fane, A.G., Fell, C.J.D., Nor, M.T. (1980). Ultraflltration(activated sludge

system.

R.

Development of a predictive model. ultrafiltration membranes and applications. Edito[

Cooper.

plenum Press, London-N.York.

Goma , G., Bouillot, P. (1986). wastewater treatment by bioreactor coupled with membrane

filtration. Presented paper at Biofair Conference, Tokyo, Japon.

Grethlein, H.E. (1978). Anaerobic digestion and membrane separation of domestic wastewater.

JWPCF, 50, 4, 754-763.

Henze, M.,Grady Jr, C.P.L., Gujer, W., Marais, G.V.R., Matsud, T. (1986). IAWPRC Task Group

on Mathematical MOdelling for Design and Operation of Biological Wastewater Treatment,

"Final report : Activated sludge model". IAWPRC Scientific and Technical Reports, 1.

(1987). water treatment by -use of

Kanayama, H.,

Tomoyasu, T. and

Katayama,

S.

membrane/bioreactor system. Presented paper at the 1987 Int. congress on membrane processes

lCOM 87.

Li, A., Kothari, D. and Corrado, J. (1985). Application of membrane anaerobic reactor system

for the treatment of industrial wastewater. 39th Proc. Ind. waste Conference, 627-636.

Lowry, O.M., Rosebrough, N.J., Fan, A.L. and Randall, R.J. (1951). Protein measurements with

the folin phenol reagent. J. BioI. Chem., 193, 265-275.

Pirt, S.J. (1965). The maintenance energy of oacteria in growing cultures. Proc. Soc. London,

l63-B, 224-231.

Smir.C.V., Gregorio, D.O., Talcott, R.M. (1969). The use of ultrafiltration membrane for

activated sludge separation. Presented paper at 24th Annual Purdue Industrial Waste

Conference.

Strathmann, H.

(1985). Membranes and membrane processes in biotechnology. Trends

in

biotechnology, 3, 5, 112-118. Proc. 39th Ind. Waste Conf. Perdue Univ., 627-636.

Trevors , J.T., Mayfield, C.I., Iniss, W.E. (1982). Measurement of electron transport system

(E.T.5.) activity in soil. Microbiol. Ecol., , 163-168.

Yamamoto, K., Hiasa, M., MahmoOd, T., Matsuo, T. (1989). Direct solid-liquid separation using

hollow fiber membrane in an activated sludge aeration tank.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pe-501003-009 STPDocument9 pagesPe-501003-009 STPJeyakumar ArumugamNo ratings yet

- Free PPT Templates: LogotypeDocument34 pagesFree PPT Templates: LogotypeOdiliaDeaNovenaNo ratings yet

- Impact of Aeration On Mixed Liquor in Submerged‐ Membrane Bioreactors For Wastewater Treatment PDFDocument13 pagesImpact of Aeration On Mixed Liquor in Submerged‐ Membrane Bioreactors For Wastewater Treatment PDFsulihah12No ratings yet

- 2018 A Novel Bio-Electrochemical System With Sandactivated Carbon Separator, PDFDocument11 pages2018 A Novel Bio-Electrochemical System With Sandactivated Carbon Separator, PDFsulihah12No ratings yet

- A Review of Fouling Mechanisms, Control Strategies and Real Time Fouling Monitoring Techniques in Forward Osmosis PDFDocument37 pagesA Review of Fouling Mechanisms, Control Strategies and Real Time Fouling Monitoring Techniques in Forward Osmosis PDFsulihah12No ratings yet

- Impact of Aeration On Mixed Liquor in Submerged‐ Membrane Bioreactors For Wastewater Treatment PDFDocument13 pagesImpact of Aeration On Mixed Liquor in Submerged‐ Membrane Bioreactors For Wastewater Treatment PDFsulihah12No ratings yet

- A Study On MBR For Water ReuseDocument8 pagesA Study On MBR For Water Reusesulihah12No ratings yet

- Environment Footprint of MBR Using LCA AnalysisDocument13 pagesEnvironment Footprint of MBR Using LCA Analysissulihah12No ratings yet

- Photocatalytic Degradation of P-Nitrophenol in An Annular Column Photoreactor and The IntermediatesDocument7 pagesPhotocatalytic Degradation of P-Nitrophenol in An Annular Column Photoreactor and The Intermediatessulihah12No ratings yet

- Photocatalytic Degradation of P-Nitrophenol in An Annular Column Photoreactor and The IntermediatesDocument7 pagesPhotocatalytic Degradation of P-Nitrophenol in An Annular Column Photoreactor and The Intermediatessulihah12No ratings yet

- Environment Footprint of MBR Using LCA AnalysisDocument13 pagesEnvironment Footprint of MBR Using LCA Analysissulihah12No ratings yet

- Specific Energy Consumption of Membrane Bioreactor (MBR) For SewageDocument14 pagesSpecific Energy Consumption of Membrane Bioreactor (MBR) For Sewagesulihah12No ratings yet

- Towards Energy Positive Wastewater Treatment PlantsDocument9 pagesTowards Energy Positive Wastewater Treatment Plantssulihah12No ratings yet

- Towards Energy Positive Wastewater Treatment PlantsDocument9 pagesTowards Energy Positive Wastewater Treatment Plantssulihah12No ratings yet

- Membrane Bioreactor - Applications and Limitations in Treating High Strength Industrial WastewaterDocument11 pagesMembrane Bioreactor - Applications and Limitations in Treating High Strength Industrial Wastewatersulihah12No ratings yet

- Bio-Fouling Reducers For Improving The Performance of An Aerobic Submerged Membrane Bioreactor Treating Palm Oil Mill EffluentDocument8 pagesBio-Fouling Reducers For Improving The Performance of An Aerobic Submerged Membrane Bioreactor Treating Palm Oil Mill Effluentsulihah12No ratings yet

- Jawapan Lengkap Matematik Tingkatan 1 Bahagian ADocument6 pagesJawapan Lengkap Matematik Tingkatan 1 Bahagian Asulihah12No ratings yet

- Challenges in The Application of Microbial Fuel Cells To Wastewater Treatment and Energy Production - A Mini ReviewDocument11 pagesChallenges in The Application of Microbial Fuel Cells To Wastewater Treatment and Energy Production - A Mini Reviewsulihah12No ratings yet

- Photocatalytic Degradation of P-Nitrophenol in An Annular Column Photoreactor and The IntermediatesDocument7 pagesPhotocatalytic Degradation of P-Nitrophenol in An Annular Column Photoreactor and The Intermediatessulihah12No ratings yet

- Bio-Fouling Reducers For Improving The Performance of An Aerobic Submerged Membrane Bioreactor Treating Palm Oil Mill EffluentDocument8 pagesBio-Fouling Reducers For Improving The Performance of An Aerobic Submerged Membrane Bioreactor Treating Palm Oil Mill Effluentsulihah12No ratings yet

- A Review of Anaerobic Membrane Bioreactors For Municipal Wastewater Treatment - Integration Options, Limitations and ExpectationsDocument16 pagesA Review of Anaerobic Membrane Bioreactors For Municipal Wastewater Treatment - Integration Options, Limitations and Expectationssulihah12No ratings yet

- 04 FunctionsDocument26 pages04 Functionssulihah12No ratings yet

- PPyAQS (9, 10-Anthraquinone-2-Sulfonic Acid) and PPyARS Modified Stainless Steel MeshDocument8 pagesPPyAQS (9, 10-Anthraquinone-2-Sulfonic Acid) and PPyARS Modified Stainless Steel Meshsulihah12No ratings yet

- Conductive and Hydrophilic Polypyrrole Modified Membrane Cathodes in MBRDocument7 pagesConductive and Hydrophilic Polypyrrole Modified Membrane Cathodes in MBRsulihah12No ratings yet

- 01 1 Intro To ComputerDocument32 pages01 1 Intro To Computersulihah12No ratings yet

- Regulating Sewage Pollution of Malaysian RiversDocument6 pagesRegulating Sewage Pollution of Malaysian Riverssulihah12No ratings yet

- Cathodic Fluidized Granular Activated Carbon Assisted-Membrane Bioelectrochemical Reactor For Wastewater TreatmentDocument6 pagesCathodic Fluidized Granular Activated Carbon Assisted-Membrane Bioelectrochemical Reactor For Wastewater Treatmentsulihah12No ratings yet

- Winery Wastewater Treatment For Water Reuse Purpose - Conventional Activated Sludge Versus Membrane Bioreactor MBR PDFDocument7 pagesWinery Wastewater Treatment For Water Reuse Purpose - Conventional Activated Sludge Versus Membrane Bioreactor MBR PDFsulihah12No ratings yet

- (2005) de Feo. Treatment of High Strength Wastewater With Vertucal Wetland FilterDocument8 pages(2005) de Feo. Treatment of High Strength Wastewater With Vertucal Wetland Filtersulihah12No ratings yet

- Report MalaysiaDocument6 pagesReport Malaysiafarid_23101531No ratings yet

- Optimal WWTP Process Selection For Treatment of Domestic WastewaterDocument12 pagesOptimal WWTP Process Selection For Treatment of Domestic Wastewatersulihah12No ratings yet

- Microbial Production of Homogeneously Layered Cellulose Pellicles in A Membrane BioreactorDocument4 pagesMicrobial Production of Homogeneously Layered Cellulose Pellicles in A Membrane BioreactorEndarto YudoNo ratings yet

- Chapter Different Types of Bioreactors in Bioprocesses PDFDocument37 pagesChapter Different Types of Bioreactors in Bioprocesses PDFmaye100% (1)

- Meng 2017Document30 pagesMeng 2017Yongmei WangNo ratings yet

- Biological Nutrient RemovalDocument23 pagesBiological Nutrient RemovalvijayendraNo ratings yet

- Literature Review On Palm Oil Mill EffluentDocument4 pagesLiterature Review On Palm Oil Mill Effluentfvgneqv8100% (1)

- Grey Water Characterization and Treatment For ReuseDocument8 pagesGrey Water Characterization and Treatment For ReuseWai Phyo AungNo ratings yet

- H2O - Biowheel ConfigurationsDocument2 pagesH2O - Biowheel ConfigurationsDouglas CostaNo ratings yet

- Wilf Book2 FlyerDocument4 pagesWilf Book2 FlyerunconformistNo ratings yet

- Birzeit Water Drops 7Document60 pagesBirzeit Water Drops 7AhmadNo ratings yet

- Treatment On Petrochemical Industry Waste WaterDocument28 pagesTreatment On Petrochemical Industry Waste WaterRimeli RoychoudhuryNo ratings yet

- 2007 Kebriae PresentationDocument47 pages2007 Kebriae PresentationrezaNo ratings yet

- MBR Membrane BioreactorDocument3 pagesMBR Membrane Bioreactorjpsingh75No ratings yet

- Pharmaceutical Waste-Water: Parth Naik ICT, MumbaiDocument48 pagesPharmaceutical Waste-Water: Parth Naik ICT, MumbaiShraddha MalveNo ratings yet

- Boltzetal 2010MOP8-Chap 13BiofilmReactorTechnologyandDesign PDFDocument260 pagesBoltzetal 2010MOP8-Chap 13BiofilmReactorTechnologyandDesign PDFAlina PlescanNo ratings yet

- CaseStudies PharmezZLDDocument2 pagesCaseStudies PharmezZLDYang SunmanNo ratings yet

- Types of FermenterDocument24 pagesTypes of FermenterANJALI100% (2)

- D16 - Cost Analysis, Literature Data (Incl. Pilot Plant Trials Conducted by Partners)Document23 pagesD16 - Cost Analysis, Literature Data (Incl. Pilot Plant Trials Conducted by Partners)rasheed_tech2012No ratings yet

- Aeration System in BioreactorDocument9 pagesAeration System in BioreactorlovleshrubyNo ratings yet

- Stow Main CopiedDocument71 pagesStow Main CopiedBinaebi DoubraNo ratings yet

- Innovation in Water-Singapore - Volume 1Document40 pagesInnovation in Water-Singapore - Volume 1VJ GeoNo ratings yet

- Water Filtration: Nonwoven Fabric FiltersDocument15 pagesWater Filtration: Nonwoven Fabric FiltersMark Roger Huberit IINo ratings yet

- Decentralized Wastewater Treatment Highlights BrochureDocument20 pagesDecentralized Wastewater Treatment Highlights BrochureSulaiman Mohsin AbdulAzizNo ratings yet

- Treated Effluent Discharge MethodDocument2 pagesTreated Effluent Discharge MethodarshadNo ratings yet

- Methods For Removing Ammonical NitrogenDocument13 pagesMethods For Removing Ammonical Nitrogenshanku_bietNo ratings yet

- Complete and Simple Solutions For Industrial Process Water and Wastewater TreatmentDocument3 pagesComplete and Simple Solutions For Industrial Process Water and Wastewater TreatmentElena GilNo ratings yet

- 1 s2.0 S0045653522009559 MainDocument7 pages1 s2.0 S0045653522009559 MainEdwin Josué EspinaNo ratings yet

- Design Manual For Small Wastewater Works 2009-1Document62 pagesDesign Manual For Small Wastewater Works 2009-1VichekaNo ratings yet

- The Anodising Industry Wastewater Considerations of Its Treatment For Environmental ProtectionDocument14 pagesThe Anodising Industry Wastewater Considerations of Its Treatment For Environmental ProtectionSururuki CaninaniNo ratings yet

- MBR Design SheetDocument9 pagesMBR Design SheetVenkatesh SivaramanNo ratings yet