Professional Documents

Culture Documents

Risk Assesment Tie-In (Mechanical)

Uploaded by

Galih SukmaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assesment Tie-In (Mechanical)

Uploaded by

Galih SukmaCopyright:

Available Formats

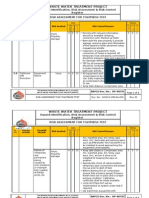

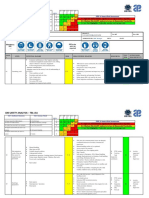

ORF TIE-IN HAZARD/RISK ASSESSMENT

Hazard / Risk Assessment and Control Record

Revision:

Task/Process Assessed:

Tie-in ORF 1 & 2

Date:

06 August 2010

Rev 0.0

Location:

North East Sumatra - Indonesia

Operation:

Kambuna Field Operations

Assessment Team:

See attendant list attached

Owner:

Project & Operations Managers

Approved:

Salamander Energy Country Manager Indonesia and Regional Operations Director

HAZARD

INITIAL RISK

CONTROLS

RESIDUAL RISK

Risk Level

Mitigation

Likelihood

Prevention

Consequence

Consequence

Risk Level

Hazard Description

and Effect

Loss

Category/

Population

at Risk

Likelihood

(Items highlighted in

yellow have

Undesirable Risk thus

require additional

ALARP)

Consequence

Activity Steps

Kambuna Field Operations Risk Assessment - Draft Version V0.1

Acceptable (-4)

Permit to work / JSA (Specific equipm ent

entry)

Toolbox meeting

Procedures

Proper PPE

Certified Gas tester

Standby paramedic (SOS), First aid kit

Acceptable (-4)

Proper manual handling/ correct lifting

All vehicles must diesel engine and

provided with spark arrestor

Train and experience personnel

Equipm ent pre inspection

Fire fighting equipment in place

Gas sniffer ( LEL ), repeat testing

Restricted area should be marked by

marking tape, sign board and flagman

1 of 16

Permit to work / JSA (Specific)

Toolbox meeting

Procedures

Proper PPE

Certified Gas tester

Standby param edic (SOS), First aid kit

MSDS Paint stripper

Unlikely (-2)

Unlikely (-2)

Fire fighting equipment in place

Gas sniffer ( LEL ), repeat testing

Proper manual handling

Non sparking tools/equipment

Water curtain/spray

Provide proper access/egress, platform

as required.

Experienced and competent personnel

only

Serious (-2)

Serious (-2)

People

Environment

Asset

Reputation

Intolerable (-12)

Struck by moving

equipment, Bodily

injury

Pinch point Hand, leg

injury (caught in

between )

Spark from vehicle

exhaust

Intolerable (-12)

Equipment

Mobilization to

site

Likely (-4)

People

Environment

Asset

Reputation

Likely (-4)

Pinch point Hand, leg

injury (caught in

between )

Gas-exposure, gas

toxic, explosion, fire

Slip, fall and trip

Access impact

Energy release

Major (-3)

Hot Bolting

Major (-3)

ACTIVITIES PRIOR TO SHUTDOWN

25-1-09

HAZARD

INITIAL RISK

CONTROLS

RESIDUAL RISK

Permit to work / JSA

Toolbox meeting

Procedures & method statement

Proper PPE

Certified Gas tester

Standby paramedic (SOS), First aid kit

Risk Level

Consequence

Likelihood

Unlikely (-2)

Acceptable (-4)

Acceptable (-2)

Improbable (1)

Load shall not over the SWL of the

lifting gear

Trained and experienced personnel

Lifting gear shall have valid certificate

Do not stand under suspended material

Using tag line

Watch for swinging material

Layout equipment lifting plan

Access & egress layout

Restricted area and maximum lift radius

should be marked by marking tape

(demarcation red- white)

Signals and means of communication

between operator and signalman.

Permit to work / JSA

Toolbox meeting

Procedures

Proper PPE

Certified Gas tester

Standby param edic (SOS), First aid kit

Serious (-2)

Risk Level

Intolerable (-12)

Likelihood

Unlikely (-2)

Proper manual handling/ correct lifting

technique.

All vehicles / equipm ent must diesel

engine and provided with spark arrestor

Communication

Trained and experienced personnel

Fire fighting equipment in place

Gas sniffer ( LEL ), repeat testing

No sparking tools/equipment

Layout equipment lifting plan

Access & egress layout

Stabilization of grade

Mitigation

Serious (-2)

Lifting gear capacity

not adequate

Lifting over existing

pipe and equipments

Material drop

Prevention

Serious (-2

Possible (-3)

People

Environment

Asset

Undesirable (-6)

Handling

materials to and

from working

area

People

Environment

Asset

Reputation

Consequence

Possible (3)

Struck by moving

equipment, Bodily

injury

Pinch point Hand, leg

injury (caught in

between )

Gas-exposure, gas

toxic, explosion, fire

Slip, fall and trip

Access impact

Loss

Category/

Population

at Risk

Serious (-2)

Set-up

equipment on

site

Hazard Description

and Effect

Catastrophic (-4)

(Items highlighted in

yellow have

Undesirable Risk thus

require additional

ALARP)

Consequence

Activity Steps

Kambuna Field Operations Risk Assessment - Draft Version V0.1

Proper manual handling.

Isolation List (Electrical & Blinding)

Communication / coordination

Gas sniffer ( LEL ), repeat testing

No sparking tools

Fire fighting equipment in place

Oil pollution containment (receptacle tray)

in place

Electrical de-energization (except lighting)

Provide proper access/egress, platform

as required.

2 of 16

Permit to work / JSA

Toolbox meeting

Isolation / MCC-LOTO/ Blinding

Procedures

Proper PPE

Certified Gas tester

Grounding and bonding

Standby param edic (SOS), First aid kit

Standby fire truck (Ops ERP)

Standby vacuum truck (Ops ERP)

Standby evacuation car

Acceptable (-4)

People

Environment

Asset

Reputation

Intolerable (-12)

Pinch point Hand, leg

injury (caught in

between.

Gas-exposure, gas

toxic, explosion, fire

Pollution

Energy release

Slip, fall and trip

Possible (-3)

Isolation the

system, install

blind spade,

electrical

isolation

Catastrophic (-4)

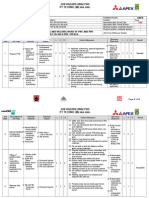

Hand over from Operations hydro carbon free and de-energized (ZEP)

25-1-09

HAZARD

INITIAL RISK

CONTROLS

RESIDUAL RISK

Kambuna Field Operations Risk Assessment - Draft Version V0.1

Proper manual handling/ correct lifting

All vehicles must diesel engine

Train and experience personnel

Equipm ent pre inspection

3 of 16

Permit to work / JSA

Toolbox meeting

Procedures

Likelihood

Consequence

Risk Level

Acceptable (-4)

Permit to work / JSA

Toolbox meeting

Procedures

Proper PPE

Standby param edic (SOS), First aid kit

Standby evacuation car

Acceptable (-4)

Acceptable (-4)

Proper manual handling.

Isolation List (Electrical & Blinding)

Communication / coordination

Provide proper access/egress, platform

as required.

Restricted area and maximum lift radius

should be marked by marking tape

(demarcation red- white)

Unlikely (-2)

Permit to work / JSA

Toolbox meeting

Procedures and matrix

Isolation / LOTO/ Blinding Procedures

Proper PPE

Certified Gas tester

Standby fire truck (Ops ERP)

Standby vacuum truck (Ops ERP)

Standby evacuation car

Standby param edic (SOS), First aid kit

Unlikely (-2)

Unlikely (-2)

Proper manual handling.

Isolation / Blinding list

Communication / coordination

Gas sniffer ( LEL ), repeat testing

Non sparking tools

Fire fighting equipment in place (water

curtain)

Provide proper access/egress, platform

as required.

Shelter (rain, wind)

continuous lighting illumination

Standby fire truck

Serious (-2

Risk Level

Intolerable (-12)

Likelihood

Possible (-3)

Catastrophic (-4)

Mitigation

Serious (-2

People

Environment

Asset

Reputation

Undesirable (-6)

Struck by moving

equipment, Bodily

injury

Pinch point Hand, leg

injury (caught in

between )

Spark from vehicle

exhaust

Possible (3)

People

Asset

Reputation

Prevention

Serious (-2)

Demobilization

Pinch point Hand, leg

injury (caught in

between.

Energy release

Slip, fall and trip

Intolerable (-12)

Precommissioni

ng, N2 Leak

Test

People

Environment

Asset

Reputation

Consequence

Likely (-4)

Tie-in, fit - up

Pinch point Hand, leg

injury (caught in

between.

Gas-exposure, gas

toxic, explosion, fire

Slip, fall and trip

weather (rain, wind,

sun)

Low visibility (night)

Loss

Category/

Population

at Risk

Serious (-2)

Hazard Description

and Effect

Major (-3)

(Items highlighted in

yellow have

Undesirable Risk thus

require additional

ALARP)

Consequence

Activity Steps

25-1-09

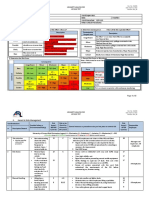

RISK MATRIX

-25 to -20

BLACK

NON-OPERABLE:

Evacuate the zone and or area/country

-16 to -10

RED

INTOLERABLE:

Do not take this risk

-9 to -5

YELLOW UNDESIRABLE: Demonstrate ALARP before proceeding

-4 to -2

GREEN

-1

BLUE

ACCEPTABLE:

Proceed carefully, with continuous improvement

NEGLIGIBLE:

Safe to proceed

Probable

Likely

Unlikely

Possible

Improbable

LIKELIHOOD

-1

Serious

-2

Major

-3

Catastrophic

-4

MultiCatastrophic

-5

CONSEQUENCE

Light

-1

-2

-3

-4

-5

L1

L2

L3

L4

L5

-2

-4

-6

-8

-10

S1

S2

S3

S4

S5

-3

-6

-9

-12

-15

M1

M2

M3

M4

M5

-4

-8

-12

-16

-20

C1

C2

C3

C4

C5

-5

-10

-15

-20

-25

MC1

MC2

MC3

MC4

MC5

White arrow indicates decreasing risk

HAZARD / RISK RATING

CONSEQUENCE

Category

People

Asset

Including

Exploration

Operations

First Aid Case

Negligible damage

Negligible damage

Light

No lost time

$1 $1,000

Small leak 1-200L

Minor damage

Minor damage

$1,000 $5,000

Minor spill 200-500L

2

Serious

1 to 3 days lost time

Major Injury

Partial shut-down

Major

3 Days Lost Time

$5,000 $50,000

4

Catastrophic

MultiCatastrophic

Multiple fatalities

Staff on

Site

Localised spill

Major spill

2

Unlikely

3

Possible

4

Likely

5

Probable

100% shut-down

Massive damage

>$500,000

>10,000L

Never heard in the industry

Has happened in the industry

Happens every year in the industry

Happens periodically on crew / on site

Happens every day on crew / on site

If unsure, choose the middle of the matrix i.e. 3x3 = 6

National

Media

5,000-10,000L

Category

Improbable

Location

Media

Severe damage

LIKELIHOOD

Immediate

vicinity

500-5,000L

$50,000 $500,000

Reputation

Significant damage

Major shut-down

Single fatality

Environment

Internationa

l Media

You might also like

- 002 Working at Height Risk AssessmentDocument4 pages002 Working at Height Risk Assessmentgangadharan000100% (14)

- (EDIT) F-SAF-0046.11 Bolt Torquing Risk Assessment (Generic)Document10 pages(EDIT) F-SAF-0046.11 Bolt Torquing Risk Assessment (Generic)ainun mardiah75% (4)

- Excavation Risk AssessmentDocument3 pagesExcavation Risk Assessmentrashid zaman57% (7)

- 20) Pumping of WaterDocument7 pages20) Pumping of WaterMobin Thomas Abraham75% (12)

- Risk Assessment For Tightness TestDocument8 pagesRisk Assessment For Tightness TestAriel Dela Cruz100% (1)

- Risk Assessment for Scaffolding OperationsDocument5 pagesRisk Assessment for Scaffolding OperationsAnonymous iI88Lt0% (1)

- Excavation Risk Assessment KTPS - 8 PAGESDocument7 pagesExcavation Risk Assessment KTPS - 8 PAGESrajalingam100% (1)

- Working at Height Risk AssessmentDocument2 pagesWorking at Height Risk Assessmentvismay83% (6)

- ConfinedSpace RiskAssessmentDocument9 pagesConfinedSpace RiskAssessmentrashid zaman100% (4)

- JSA-020 Fence InstallationDocument4 pagesJSA-020 Fence InstallationMoaatazz Nouisri75% (4)

- Hydro Test (Rev 01)Document4 pagesHydro Test (Rev 01)Binay100% (5)

- Water Tank Base Construction Hazard Identification and Risk ControlDocument5 pagesWater Tank Base Construction Hazard Identification and Risk Controlramod100% (2)

- JSA Fitting and Welding Work For Pipe Trench InstalationDocument6 pagesJSA Fitting and Welding Work For Pipe Trench InstalationAzmi Fauzi78% (9)

- 6-Steel Work Risk Assessment ReportDocument7 pages6-Steel Work Risk Assessment ReportSyed Ali Hassan67% (3)

- Risk Asses 65-Piping Fabricated and Assembly - H03Document11 pagesRisk Asses 65-Piping Fabricated and Assembly - H03Rochdi BahiriNo ratings yet

- HIRA (Pipeline Construction Work)Document28 pagesHIRA (Pipeline Construction Work)sheerazali90% (10)

- 3-REV.1 - Hot Work - Risk Assessment JHADocument16 pages3-REV.1 - Hot Work - Risk Assessment JHAnaiyar100% (1)

- RISK ASSESSMENT FORM FOR POTABLE WATER WORKSDocument44 pagesRISK ASSESSMENT FORM FOR POTABLE WATER WORKSloveson709No ratings yet

- JSA-GF-008 Jacket Deck InstallationDocument9 pagesJSA-GF-008 Jacket Deck InstallationAmy Alvarez San RomanNo ratings yet

- JSA006 - Vacuum Box TestingDocument5 pagesJSA006 - Vacuum Box TestingLaohan LiuNo ratings yet

- Risk Assessment - Drain Pipe Connection at MLSDocument8 pagesRisk Assessment - Drain Pipe Connection at MLS逍逾No ratings yet

- 3263 - Transfer of Diesel JSA-R76!02!202-01Document1 page3263 - Transfer of Diesel JSA-R76!02!202-01cmrig74No ratings yet

- JHA Pump CreteDocument2 pagesJHA Pump CretePopo EaldamaNo ratings yet

- JHA Civil WorksDocument2 pagesJHA Civil Worksethelchudi100% (11)

- JSA For Fabrication WorksDocument11 pagesJSA For Fabrication Workssurendra behera100% (3)

- Job Safety Analysis Lifting and RiggingDocument17 pagesJob Safety Analysis Lifting and RiggingSam Seed100% (1)

- Risk Assessment For Cable LayingDocument5 pagesRisk Assessment For Cable Layingpopamino50% (2)

- Radiography Testing Safety AnalysisDocument1 pageRadiography Testing Safety AnalysisHussein Adnan Fneish100% (1)

- What Is Dissociation and What To Do About It?Document2 pagesWhat Is Dissociation and What To Do About It?Tommy ThompsonNo ratings yet

- RISK ASSES-106-Erection of Steel Structure BuildinDocument4 pagesRISK ASSES-106-Erection of Steel Structure BuildinRochdi Bahiri50% (2)

- Electric Hand Drill Risk AssessmentDocument4 pagesElectric Hand Drill Risk AssessmentTariq AkhtarNo ratings yet

- Jsa Nitrogen PurgingDocument2 pagesJsa Nitrogen PurgingKanthimathinathan Krishnan100% (5)

- JSA-018 Lifting With Mobile CraneDocument5 pagesJSA-018 Lifting With Mobile CraneOmar Dhieb100% (1)

- Jsa FormDocument3 pagesJsa Formmiaicarba100% (1)

- Hyundai Engineering & Construction Co., Ltd. HAMAD MEDICAL CITY Construction Package CP-300B Hospital Fit Out ProjectDocument4 pagesHyundai Engineering & Construction Co., Ltd. HAMAD MEDICAL CITY Construction Package CP-300B Hospital Fit Out ProjectYounis Khan100% (1)

- Project Hazard Identification and Risk Assessment FormDocument5 pagesProject Hazard Identification and Risk Assessment FormAsad RazaNo ratings yet

- Risk Assessment Lifting OperationsDocument5 pagesRisk Assessment Lifting OperationsHưng Hoàng Duy100% (1)

- Job Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa ReviewDocument4 pagesJob Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa ReviewMoaatazz Nouisri100% (1)

- 007 - Risk Ass. - CE-0994-MEP WorksDocument9 pages007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- Welding and Radiography Risk AssessmentDocument11 pagesWelding and Radiography Risk AssessmentAldrin75% (8)

- BargeDocument4 pagesBargeanon_222140886No ratings yet

- Jsa For Lifting Crane 016Document6 pagesJsa For Lifting Crane 016kiran kumar100% (1)

- Master Hazards Risks RegisterDocument113 pagesMaster Hazards Risks RegisterIvanNo ratings yet

- RISK ASSESSMENT Demolation and Making of New Pump Foundation BDocument33 pagesRISK ASSESSMENT Demolation and Making of New Pump Foundation BAriel Dela CruzNo ratings yet

- DLF PCC HiraDocument6 pagesDLF PCC HiraskfahimuddinNo ratings yet

- Jsa SKDocument10 pagesJsa SKEngr Tahir UL Haq100% (2)

- Battery FillingDocument3 pagesBattery FillingMajdiSahnounNo ratings yet

- Job Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentDocument5 pagesJob Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentMoaatazz NouisriNo ratings yet

- JHA General Maintenance Activity PDFDocument5 pagesJHA General Maintenance Activity PDFdede SinbadNo ratings yet

- Tie - in Mechanical Installation JHADocument7 pagesTie - in Mechanical Installation JHAmalik jahanNo ratings yet

- Lifting Bridge JSADocument8 pagesLifting Bridge JSAeslamNo ratings yet

- Risk Assessment - Lifting OperationsDocument3 pagesRisk Assessment - Lifting Operationsdnmule100% (1)

- NSRP Project: Confined Space Entry CertificateDocument1 pageNSRP Project: Confined Space Entry CertificateThanh Tung DongNo ratings yet

- 009 Installation of Pumps Risk AssessmentDocument2 pages009 Installation of Pumps Risk AssessmentRadhaKrishnan RNo ratings yet

- Job Safety Analysis for Pipeline LoadingDocument8 pagesJob Safety Analysis for Pipeline LoadingMoaatazz NouisriNo ratings yet

- RA For High Pressure Cleaning Using HPCE 520-330Document3 pagesRA For High Pressure Cleaning Using HPCE 520-330George CristianNo ratings yet

- Risk Assessment For Hot WorksDocument4 pagesRisk Assessment For Hot Workseldho100% (1)

- HIRA FormatDocument2 pagesHIRA FormatSachin Yashwant kumbharNo ratings yet

- Risk assessment electrical workDocument2 pagesRisk assessment electrical workErni Tri LestariNo ratings yet

- QHSE Risk Register for ONGC Drilling Rig in MumbaiDocument24 pagesQHSE Risk Register for ONGC Drilling Rig in Mumbaivikrant911100% (2)

- F-Sp-Hse06-01 Rev 03 Hira NewDocument14 pagesF-Sp-Hse06-01 Rev 03 Hira Newvishal bailurNo ratings yet

- Ohsas: Guide To Implementing A Health & Safety Management SystemDocument72 pagesOhsas: Guide To Implementing A Health & Safety Management SystemJennifer Mae CastroverdeNo ratings yet

- ISBBDocument8 pagesISBBmufid00No ratings yet

- Bleve: Boiling Liquid Expanding Vapor ExplosionDocument54 pagesBleve: Boiling Liquid Expanding Vapor ExplosionGalih Sukma100% (3)

- OSHA 3114 - HazardousWaste Operations and Emergency ResponseDocument47 pagesOSHA 3114 - HazardousWaste Operations and Emergency ResponseWahed Mn ElnasNo ratings yet

- Praxair Material Safety Data Sheet: Product: Nitrogen, Compressed P-4631-H Date: July 2007Document8 pagesPraxair Material Safety Data Sheet: Product: Nitrogen, Compressed P-4631-H Date: July 2007Galih SukmaNo ratings yet

- Lockout TagoutDocument27 pagesLockout TagoutMohammed Al-OdatNo ratings yet

- Zika ReviewDocument7 pagesZika ReviewGalih SukmaNo ratings yet

- Lockout TagoutDocument27 pagesLockout TagoutMohammed Al-OdatNo ratings yet

- Fire Alarm Manual: Training GuideDocument34 pagesFire Alarm Manual: Training Guideganeshakce100% (1)

- Bleve: Boiling Liquid Expanding Vapor ExplosionDocument54 pagesBleve: Boiling Liquid Expanding Vapor ExplosionGalih Sukma100% (3)

- Fire Water Requirement Philosophy #1Document2 pagesFire Water Requirement Philosophy #1Galih SukmaNo ratings yet

- Bleve: Boiling Liquid Expanding Vapor ExplosionDocument54 pagesBleve: Boiling Liquid Expanding Vapor ExplosionGalih Sukma100% (3)

- Energy Company Fire Emergency TeamDocument29 pagesEnergy Company Fire Emergency TeamGalih SukmaNo ratings yet

- HRADocument53 pagesHRAGalih Sukma100% (1)

- APSACS Summer Holiday Homework Guide Warm Region 2023 24 Dated 02 June 2023 - CompressedDocument17 pagesAPSACS Summer Holiday Homework Guide Warm Region 2023 24 Dated 02 June 2023 - CompressedGaming 7HawkNo ratings yet

- Macronutrients ProteinsDocument2 pagesMacronutrients ProteinsEllice O. MonizNo ratings yet

- Grade 4 WINS OrientationDocument2 pagesGrade 4 WINS OrientationChristine FranciscoNo ratings yet

- 10 Simple Yoga Poses For Increasing Your HeightDocument24 pages10 Simple Yoga Poses For Increasing Your HeightVimal AnanthNo ratings yet

- Cholera FinalDocument57 pagesCholera FinalBinayaNo ratings yet

- What is pancytopenia and its causesDocument33 pagesWhat is pancytopenia and its causesDabogski FranceNo ratings yet

- Challenges and Opportunities in Preventive and Social MedicineDocument3 pagesChallenges and Opportunities in Preventive and Social MedicineIJAR JOURNALNo ratings yet

- Bio SaftyDocument7 pagesBio Saftyapi-283956320No ratings yet

- Nursing Care Plan UlcerDocument2 pagesNursing Care Plan Ulcerxrampley2100% (2)

- Serial number verification formDocument1 pageSerial number verification formArjelyNo ratings yet

- Inflammation - The Silent Killer - Terra Health EssentialsDocument6 pagesInflammation - The Silent Killer - Terra Health EssentialshighlanderoneNo ratings yet

- 2016 3 23 9 12 47tapchi-Dhdn-So12 (97) .2015-Color-WebDocument128 pages2016 3 23 9 12 47tapchi-Dhdn-So12 (97) .2015-Color-WebThọ Nguyễn Văn100% (1)

- Umesh Pharma 1507821908 - 365Document22 pagesUmesh Pharma 1507821908 - 365Training and PlacementNo ratings yet

- NHS Diabetic Eye Screening Programme: Essential Free NHS ChecksDocument2 pagesNHS Diabetic Eye Screening Programme: Essential Free NHS ChecksEsanNo ratings yet

- Assisted SuicideDocument30 pagesAssisted SuicideAlex Mini AndraNo ratings yet

- Middle Childhood Physical Development (6-11 YearsDocument13 pagesMiddle Childhood Physical Development (6-11 YearsAngela YlaganNo ratings yet

- Education Solutions, Edunsol@gmail - Com, 09996522162Document170 pagesEducation Solutions, Edunsol@gmail - Com, 09996522162edphrNo ratings yet

- Kindergarten q1 Week10 v2Document33 pagesKindergarten q1 Week10 v2Aryan Angela Dela CruzNo ratings yet

- Ethical Decision Making in ResearchDocument2 pagesEthical Decision Making in ResearchChandraKurniawanNo ratings yet

- Veterans Handbook 2020Document69 pagesVeterans Handbook 2020Senator Cory BookerNo ratings yet

- Details of Positive Cases in Kurnool DistrictDocument60 pagesDetails of Positive Cases in Kurnool DistrictSohail MullaNo ratings yet

- Definition of Sexual Abuse of ChildrenDocument2 pagesDefinition of Sexual Abuse of ChildrenRadhika RathoreNo ratings yet

- Generic PfPan Job AidDocument1 pageGeneric PfPan Job AidSilvia SatoNo ratings yet

- Single/ Exam Zone Centre DetailsDocument5 pagesSingle/ Exam Zone Centre DetailsHarsh AroraNo ratings yet

- Fibre Cement Slates Fixing GuideDocument26 pagesFibre Cement Slates Fixing GuideMuhammad HafizuddinNo ratings yet

- Tugas Jurnal TeksolDocument6 pagesTugas Jurnal TeksolNovita IndahNo ratings yet

- Principles of Health AdminDocument42 pagesPrinciples of Health AdminAnne BattulayanNo ratings yet

- High Yield Surgery Compatible VersionDocument77 pagesHigh Yield Surgery Compatible Version17kimpNo ratings yet

- Adhaota Vasica (Malabar Nut)Document7 pagesAdhaota Vasica (Malabar Nut)ABHINABA GUPTANo ratings yet