Professional Documents

Culture Documents

Fiber Ccmposites

Uploaded by

Łukasz SzczypińCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fiber Ccmposites

Uploaded by

Łukasz SzczypińCopyright:

Available Formats

International Symposium on Composite Materials with Textile Reinforcement for use in Building Construction and Related Applications ,

FITAT, Lyon France, 16-18 July 1990, volume 3, pages 387-394.

MANUFACTURING CONCEPTS FOR VOLUME PRODUCTION

OF LARGE COMPOSITE COMPONENTS

Dr John Summerscales

Advanced Composites Manufacturing Centre

School of Manufacturing, Materials and Mechanical Engineering

University of Plymouth

Plymouth PL4 8AA

United Kingdom

Traditionally fibre reinforced plastics have been manufactured using labour intensive methods, such as "bucket and brush"

for boats and civil engineering structures, or "scissors and paste" for aero-space use. The principal constraint on the wider

application of polymer matrix composite materials in the construction industry is the need to develop systems to

manufacture large numbers of parts to accurate tolerances with high quality and consistent appearance.

This paper considers the potential for efficient manufacture of composite components for the building industry, through a

review of processes currently used or in prospect for the creation of large reinforced plastic structures.

ADVANCED POLYMER MATRIX COMPOSITES

MANUFACTURING CONCEPTS

FILAMENT WINDING

RESIN TRANSFER MOULDING

CENTIFUGAL CASTING

FIBRE REINFORCED PLASTICS

PULTRUSION

TAPE LAYING

INTRODUCTION

Traditionally fibre reinforced plastics are manufactured using labour intensive methods, such as "bucket and brush" for

boats and civil engineering structures, or "scissors and paste" for aerospace use. The principal constraint on the wider

application of polymer matrix composite materials in the construction industry is the need to develop systems to

manufacture large numbers of components to accurate tolerances with high quality and consistent appearance.

This paper considers the potential for efficient manufacture of composite components for the building industry, through a

review of processes currently used or in prospect for the creation of large reinforced plastic structures. Finally the

availability of courses on these techniques is addressed.

MANUFACTURING CONCEPTS

Pultrusion

Pultrusion is a continuous process for manufacturing composites that have a continuous cross-sectional shape. The process

consists of pulling the fibre reinforcement through a resin impregnation bath and then through a heated shaping die where

the resin is cured.

Goldsworthy [1982] has described the adaptation of pultrusion for the construction of large diameter tanks on site. The

tank erection system is a pultrusion machine in a 12-metre trailer. The unit is driven to the tank site and the total length of a

specially designed profile (determined by the profile width, tank diameter and tank height) is pultruded into a storage

cannister. The trailer can then move to the next site. The pultrusion has a groove on one edge and a tongue on the other.

The erection machine backfeeds from the cannister, meters bonding resin into the groove and hardener onto

the tongue, and interlocks each layer in a helical fashion to produce the tank. The further potential for continuous

production of submarine pipes and in-situ manufacture in space is noted.

The use of pultrusion in the manufacture of skeletal structures has been extensively studied by Hollaway. Most geometrical

shapes can be produced by this technique, but the application was severely hindered by the inability to effectively join the

pultrusions. Two jointing systems [Green & Phillips, 1982 and Hollaway & Baker, 1984] have now made it possible to join

pultruded sections at any angle allowing the fabrication of plane and space grid structures

Pultrusion technology has been used to produce a 16 000 sq.m. floor suspended below the A19 road Tees viaduct in

Northern England [Head & Churchman, 1989, Wolfendale, 1988]. Five different pultrusions are assembled to produce 3metre by 11-metre panels, which are further combined to produce a structural floor which is used both for maintenance

access and as a protective cladding with a 30-40 year life in an industrial environment. Twenty four kilometres of the main

pultruded section were used.

Exciting new projects, only possible with composites, have been proposed. One such project would be an advanced

composite suspension bridge across the Straits of Gibraltar [Meier, 1983, 1984 1987], although this scheme would consume

the equivalent of several years production of carbon fibres. The technology to produce the tension members is already

established [Yeung & Parker, 1987].

[js] D:\JSdata\papers\FITAT.doc

Page 1 of 5

01-08-16 17:31

International Symposium on Composite Materials with Textile Reinforcement for use in Building Construction and Related Applications ,

FITAT, Lyon France, 16-18 July 1990, volume 3, pages 387-394.

For applications where the transverse strength of a pultrusion would be too low, Shaw-Stewart [1988] has described a

pullwinding technique. One or more winding heads are mounted between the resin impregnation bath and the heated die of

a pultrusion machine. Profiles can have thinner walls than conventional pultrusions.

Sequential moulding

Sequential moulding is a semi-continuous process for moulding continuous profiles from either thermoset or thermoplastic

matrix materials. Feedstock material is alternately pressed between heated dies in the platens of a closed down-stroking

press, or translated along the die length by a distance shorter than the die length during the press open phase. Because

translation occurs with the die open, the forces required are much reduced. It thus becomes possible to mould very thin

profiles of large surface area which would be incapable of taking the tractive forces in pultrusion [Bowen, 1988].

Filament winding

Filament winding is a process for the manufacture of composite structures in which continuous fibre reinforcement is

impregnated with resin then wound onto a rotating mandrel (removable former) in a predetermined pattern. The shape is

usually a surface of revolution. When sufficient material has been wound the mandrel may be transferred to curing oven.

Filament winding is used to produce large diameter cylindrical pipes for water mains, and for effluent drainage. Filament

wound segments have also been used to reline sewerage pipes.

Covington and Baumgardner [1980] reported the development of prototype fibreglass helicopter rotor blades using filament

winding techniques. A Goldsworthy Orbital Pin Winding machine for high volume production of blades with longitudinal

unidirectional reinforcement could lay approximetely 40 kg/hour of fibreglass using 16 strands of 60-end count prepreg

roving. The machine was 14 metre long, 4.5 metres wide and weighed 13 tonnes. Addition of a second winding head

could almost double production rates. A McClean-Anderson tube winding machine could lay in excess of 27 kg/hour of a

similar prepreg roving.

McLarty [1981] analysed the feasibility of filament winding on a hull shaped mandrel in such a way as to cover the

mandrel with fibres at a variety of angles to yield a structure conforming to the contours of the mandrel. The feasibility

was verified by winding a 1/48 scale hull. It was concluded that 62 metre ship hulls could be produced.

Chappelear et al [1983] conducted further study toward the filament winding of a 46-metre glass reinforced plastics ship

hull, and developed a 1/5 scale mandrel for the proposed MSH mine sweeper-hunter for the United States Navy.

Tape laying

Tape-laying is similar to filament winding, except that the substrate is generally stationary. The adjustment of fibre tension

is thus more critical to avoid plies peeling from the substrate.

Holt [1986] has described the development of tape-laying machines at Westland Helicopters for the production of

composite main rotor blade spars. For the Sea King blade project, the tape-laying head traversed an 11-metre flat bedway.

The head removed both the protective front film and the backing paper to lay down 10 plies of the prepreg material. These

plies were hand laid into the tool and consolidated with an inflating mandrel.

To develop a second generation machine the fundamental problem was to automate the laying of material into a twisting

and tapering tool cavity. For the Lynx W30 series BERP blade an extensive programme was undertaken to develop

appropriate material packaging technologies and brush laying techniques. Consolidation of the irregular surfaced stack by

brushes can accommodate tool shapes but required careful control of reinforcement tension and material guidance systems.

The third stage of automation required the elimination of manual intervention in the process at material changeovers or reel

replacement stages. The result was a computer controlled CADAM system which is 16 metre long and will accept a range

of mould tools. Eight cassettes of material, each 'flagged' with faults by the prepreg supplier, are loaded into the machine.

A detector on the machine recognises the flags 11-metres ahead of the fault and can discard unsuitable material before

beginning to lay a complete ply.

Evans [1988] has described a two-stage tape-layer for the processing of 75 mm preimpregnated unidirectional carbon fibre

tapes. An off-line tape-processor inspects the tape and uses ultrasonic knives to prepare a reel of backing paper on which

only good usable fault-free material is retained. Cutting may be straight, angled of contoured. The reel is logged into a

computer for use by the second stage applicator. The applicator does not carry cutting heads or ancillary equipment, and

hence may be lightweight and very fast. Tape is laid in one direction, with the substrate table rotated for oriented plies.

Lay-up speeds of up to 15 kg prepreg/hr are claimed

[js] D:\JSdata\papers\FITAT.doc

Page 2 of 5

01-08-16 17:31

International Symposium on Composite Materials with Textile Reinforcement for use in Building Construction and Related Applications ,

FITAT, Lyon France, 16-18 July 1990, volume 3, pages 387-394.

Fibre arranging process

The use of robots for composite manufacture offers considerable potential. Automation of fibre cutting, textile handling,

preform placement, bonding, painting and component machining are all amenable to automatic control. Boyce [1989] has

recently considered the use of robots in the winding of resin-impregnated fibres around pins to preform the reinforcement

before compression moulding.

Centrifugal casting

Centrifugal casting is a production technique for fabricating cylindrical components, such as pipes. The resin and fibres are

rotated inside a hollow mandrel, which is rotated and heated to effect cure.

Centrifugal casting is used to produce large diameter cylindrical pipes for water mains, and for the manufacture of

telegraph poles, [Cheshire, 1988].

Resin transfer moulding

Resin Transfer Moulding (RTM) is a closed mould technique in which the mould is loaded with dry fibres before catalysed

resin is injected under pressure or caused to flow into the mould by vacuum. RTM has been used for some time in the

production of motor car bodies [Adams & Roberts, 1985], boat hulls [Anon, 1986 a,b] and the Laser 28 deck [Pittman,

1985].

Le Comte bV [Anon, 1986 c,d] produce a series of simple versatile reinforced plastic landing craft up to 22 metres long

using vacuum-assisted injection moulding (VAIM) and has proposed that the 5 ton hulls of 34 metre surface effect ships

will be produced using the VAIM technique.

THE ADVANCED COMPOSITES MANUFACTURING CENTRE

In November 1986, the United Kingdom Department of Education and Science offered start-up funding for new courses in

Advanced Manufacturing Technology. The University of Plymouth (then Plymouth Polytechnic) responded with a

proposal for continuing professional education (CPE) to address the needs of the fibre composites manufacturing industry.

The Advanced Composites Manuafacturing Centre (ACMC) was set up in 1987 to deliver these CPE courses and to be a

focus for research, development and consultancy.

ACMC is the only establishment in Europe providing regular Short Courses for industry on manufacture of continuousfibre reinforced plastic matrix composites. The Centre also organises Workshop meetings where experts gather to discuss

the underlying science of composite fabrication. During the first 27 months there were 440 delegates from 192 companies,

with 24% representation from overseas (EEC, Scandinavia, Austria, Switzerland, South Africa, Japan, Brazil, USA and

Canada).

For the future ACMC intends to run at least eight short courses and three workshops in each year. Short course topics are

repeated each year. The workshop meetings address current 'hot' topics in composites manufacture. Recent meetings have

addressed Thermoplastic Composites, Resin Transfer Moulding, Boatbuilding, Textiles and Preforms, Mould Tools, and

Machining, Bonding and Repair.

The provisional calendar to the end of 1991 includes both Short Courses (SC) and Industrial Workshops (W):

17-21 Sep 90

10-12 Oct 90

5-8 Nov 90

20-22 Nov 90

10-12 Dec 90

SC17

SC18

SC19

W13

SC20

Introduction

Composites in motor racing

Filament winding

Offshore composites

Cure monitoring

21-24 Jan 91

11-15 Feb 91

4-8 Mar 91

18-22 Mar 91

22-26 Apr 91

13-17 May 91

3-7 Jun 91

17-21 Jun 91

SC21

SC22

W14

SC23

SC24

SC25

SC26

W15

Advanced thermoplastic composites

Improved and automated manufacture

Textiles and preforms

Practical composite tooling

Resin transfer moulding

Pultrusion

Foams and sandwich structures

Sandwich structures

16-20 Sep 91

7-11 Oct 91

21-25 Oct 91

11-15 Nov 91

9-13 Dec 91

SC27

SC28

W16

SC29

SC30

Introduction

Machining, bonding and repair

Manufacture of FRP boats

Filament winding

Process monitoring and control

[js] D:\JSdata\papers\FITAT.doc

Page 3 of 5

01-08-16 17:31

International Symposium on Composite Materials with Textile Reinforcement for use in Building Construction and Related Applications ,

FITAT, Lyon France, 16-18 July 1990, volume 3, pages 387-394.

The Centre has recently developed a Composites Engineering degree which was validated in June 1989. The first students

on this unique B.Eng.(Hons) Composites Engineering course will graduate in academic year 1990/91. During the first two

years the students will have gained a solid foundation in either Mechanical Engineering or Systems Engineering. The third

year will be spent in industrial training. The final year concentrates on Composites Engineering with four 45-hour taught

modules, a 60-hour practical module and a 160-hour research project.

SUMMARY

The manufacture of continuous fibre reinforced plastics as large structural components is practical using currently available

techniques. The paper has reviewed the most probable methods which may be used to produce such structures in large

numbers with the consistency of appearance necessary for large projects. The provision of education in these various

techniques is also addressed

REFERENCES

Adams A.A. & Roberts J.H., 1985, "Vacuum impregnation", Proc.Conf.'Hands off GRP II', Coventry, 14 May 1985,

Paper 5.

Anon., 1986a, "Resin injection used in USA for moulding 21 foot cruiser hull", Reinforced Plastics, February 1986,

30(2), 48.

Anon., 1986b, "Resin injection (RTM) powers off", International Reinforced Plastics Industry, Jan/Feb 1986, 5(3), 18.

Anon., 1986c, "Injection moulding for large craft", Ship and Boat International, January/February 1986, 43-44.

Anon., 1986d, "Solid skirts for smoother sailing", Ship and Boat International, January/February 1986, 25-26.

Bowen D.H., Thorpe T., Hammond A. & Brabon S., 1988, "Sequential moulding- a process for continuous production

of reinforced plastic profiles", Proc.2nd.Int.Conf.Automated Composites, PRI/BCS/USAF, Leeuwenhorst NL, 26-28

September 1988, paper 27.

Boyce G.S., 1989, "Development of a volume production technique for the manufacture of complex shaped

components in continuous fibre composites", Proc.Mass Production Composites Symposium, Imperial College,

London, 19-20 September 1989.

Chappelear D.N, Aochi T. & Milligan R.J., 1983, "Filament winding of a ship hull", Lockheed report LMSC-D945

402, October 1983. AD A134 577.

Cheshire E.J., 1988, "The rise and fall of the Lampro telephone pole", Proc.16th Reinforced Plastics Congress, BPF,

Blackpool, 7-10 November 1988, Paper 36, pp 163-166.

Covington C.E. & Baumgardner, P.S., 1980, "Design and production of fibreglass helicopter rotor blades", In Lenoe,

E.M., Oplinger D.W. & Burke J.J. (editors), "Fibrous Composites in Structural Design", Plenum, NY & London, 1980,

pages 497-513.

Evans G.J., 1988, "The processing of pre-impregnated composite materials", Proc.2nd.Int.Conf.Automated

Composites, PRI/BCS/USAF, Leeuwenhorst NL, 26-28 September 1988, paper 8.

Goldsworthy W.B., 1982, "Continuous manufacturing processes", Chapter 17 in Lubin G. (editor), "Handbook of

Composites", Van Nostrand Reinhold, 1982, pages 479-490.

Green A.K. & Phillips L.N., 1982, "Crimp bonded end fittings for use in pultruded composite sections", Composites,

July 1982, 13(3), 219-224.

Head P.R. & Churchman A., 1989, "Design, specification and manufacture of pultruded composite floor", Proc.Mass

Production Composites Symposium, Imperial College, 19-20 September 1989.

Hollaway L. & Baker S., 1984, "The development of nodal joints suitable for double layer skeletal systems made from

fibre/matrix composites", Proc.3rd.Int.Conf.Space Structures, Guildford, September 1984.

Holt D., 1986, "Mechanised manufacture of composite main rotor blade spars", Proc.2nd.Int.Conf.Fibre Reinforced

Composites, IMechE/PRI/IProdE/RAeS, Liverpool, April 1986, 125-131.

McLarty J.L., 1981, "Feasibility of filament winding large ship hulls", McClean-Anderson report J2016, December

1981. AD A125 771.

Meier U., Muller R. & Puck A., 1983, "FRP-box beams under static and fatigue loading", Proc.Int.Conf.Testing,

Evaluation and Quality Control of Composites, Guildford, 13-14 September 1983, pp 324-336.

Meier U., 1984, "Multiplication of the critical span of suspension bridges through the use of high performance

composites", Proc.14th.Reinforced Plastics Congress, BPF, Brighton, 5-7 November 1984, Paper 40, pages 185-187.

Meier U., 1987, "Proposal for a carbon fibre reinforced composite bridge across the Strait of Gibraltar at its narrowest

site",Proc.Institution of Mechanical Engineers, 1987, 201(B2), 73-78.

Pittman K.L., 1985, "Breaking the old moulds", Sail, January 1985, 76-81.

Shaw-Stewart D.E., 1988, "Pullwinding", Proc.2nd.Int.Conf.Automated Composites, PRI/BCS/USAF, Leeuwenhorst

NL, 26-28 September 1988, paper 15.

Wolfendale R., 1988, "The A19 GRP enclosure - a highly visible GRP project", Proc.16th.Reinforced Plastics

Congress, BPF, Blackpool, 7-10 November 1988, Paper 35, p 161.

[js] D:\JSdata\papers\FITAT.doc

Page 4 of 5

01-08-16 17:31

International Symposium on Composite Materials with Textile Reinforcement for use in Building Construction and Related Applications ,

FITAT, Lyon France, 16-18 July 1990, volume 3, pages 387-394.

Yeung Y.C.T. & Parker B.E., 1987, "Composite tension members for structural applications", Proc.4th.Int

Conf.Composite Structures, Paisley, 27-29 July 1987, volume 1, pages 309-320.

[js] D:\JSdata\papers\FITAT.doc

Page 5 of 5

01-08-16 17:31

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Understanding Power Dynamics and Developing Political ExpertiseDocument29 pagesUnderstanding Power Dynamics and Developing Political Expertisealessiacon100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HRM Assignment Final - Case StudyDocument7 pagesHRM Assignment Final - Case StudyPulkit_Bansal_2818100% (3)

- U1L2 - Definitions of 21st Century LiteraciesDocument19 pagesU1L2 - Definitions of 21st Century LiteraciesJerry Glenn Latorre CastilloNo ratings yet

- Sulzer MC EquipmentDocument12 pagesSulzer MC EquipmentsnthmlgtNo ratings yet

- Chemical Engineering Assignment SubmissionDocument10 pagesChemical Engineering Assignment SubmissionFahad KamranNo ratings yet

- The Influence of Teleworking On Performance and Employees Counterproductive BehaviourDocument20 pagesThe Influence of Teleworking On Performance and Employees Counterproductive BehaviourCHIZELUNo ratings yet

- Silicon ManufacturingDocument132 pagesSilicon ManufacturingAndrea SottocornolaNo ratings yet

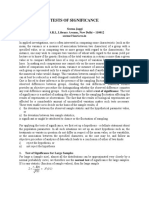

- 5 Tests of Significance SeemaDocument8 pages5 Tests of Significance SeemaFinance dmsrdeNo ratings yet

- Brake System PDFDocument9 pagesBrake System PDFdiego diaz100% (1)

- Adb Wind ConeDocument4 pagesAdb Wind ConeSulistyo WidodoNo ratings yet

- 2VAA001695 en S Control NTCS04 Controller Station Termination UnitDocument43 pages2VAA001695 en S Control NTCS04 Controller Station Termination UnitanbarasanNo ratings yet

- An Introduction To Community DevelopmentDocument21 pagesAn Introduction To Community DevelopmentThuyAnh NgnNo ratings yet

- Kuliah 1 - Konservasi GeologiDocument5 pagesKuliah 1 - Konservasi GeologiFerdianNo ratings yet

- 123 The Roots of International Law and The Teachings of Francisco de Vitoria As A FounDocument23 pages123 The Roots of International Law and The Teachings of Francisco de Vitoria As A FounAki LacanlalayNo ratings yet

- Ninja's Guide To OnenoteDocument13 pagesNinja's Guide To Onenotesunil100% (1)

- Exp-1. Evacuative Tube ConcentratorDocument8 pagesExp-1. Evacuative Tube ConcentratorWaseem Nawaz MohammedNo ratings yet

- ASIA INTERNATIONAL FURNITURE MATERIALS CONTRACTDocument2 pagesASIA INTERNATIONAL FURNITURE MATERIALS CONTRACTSALOME URUCHI AGUILARNo ratings yet

- SEW Motor Brake BMGDocument52 pagesSEW Motor Brake BMGPruthvi ModiNo ratings yet

- Guimaras State CollegeDocument5 pagesGuimaras State CollegeBabarianCocBermejoNo ratings yet

- The Eukaryotic Replication Machine: D. Zhang, M. O'DonnellDocument39 pagesThe Eukaryotic Replication Machine: D. Zhang, M. O'DonnellÁgnes TóthNo ratings yet

- wt-and-fds-practical-slipsDocument32 pageswt-and-fds-practical-slipsRohidas SapkalNo ratings yet

- Confirmation Form: Pillar Regional Conference (NCR)Document1 pageConfirmation Form: Pillar Regional Conference (NCR)Llano Multi-Purpose CooperativeNo ratings yet

- Seminar - Review 2 FinalDocument12 pagesSeminar - Review 2 FinalBhaskaruni Sai TarunNo ratings yet

- Course-PM SSY135 Wireless Communications 21-22Document7 pagesCourse-PM SSY135 Wireless Communications 21-22Amirhossein MohsenianNo ratings yet

- Non-Destructive Examination & Standard CF Acceptance For - Forgsd - Pipe Work Stub PiecesDocument2 pagesNon-Destructive Examination & Standard CF Acceptance For - Forgsd - Pipe Work Stub PiecesveeramalaiNo ratings yet

- Managerial Performance Evaluation ProceduresDocument3 pagesManagerial Performance Evaluation Procedures1robcortesNo ratings yet

- Ancon Channel & Bolt FixingsDocument20 pagesAncon Channel & Bolt FixingsatiattiNo ratings yet

- Movement Joints (NHBC)Document5 pagesMovement Joints (NHBC)hemendraengNo ratings yet

- Plenaristas León 2022xDocument6 pagesPlenaristas León 2022xGloria MontielNo ratings yet

- Final System DocumentationDocument31 pagesFinal System DocumentationEunice AquinoNo ratings yet