Professional Documents

Culture Documents

Industrial Slabs: The Steel Fiber With Industrial-Strength Toughness

Uploaded by

jlcheefei9258Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Industrial Slabs: The Steel Fiber With Industrial-Strength Toughness

Uploaded by

jlcheefei9258Copyright:

Available Formats

INDUSTRIAL SLABS

T HE ST EEL FI B ER W I T H I NDU S TRIAL- S TRENGTH

TOUG H N ESS .

Industrial applications can test the strength and toughness of concrete

floors to their very limits. These heavy-duty floors are often required to perform

under intense static and dynamic loads, impact stresses and flexural fatigue. If improperly

designed and reinforced, concrete slabs can fail, causing significant loss in productivity and

increasing maintenance costs. Fortunately, one family of steel fiber reinforcement products has

been tested and proven time and again in some of the most demanding industrial environments

in the world: Novocon products from Propex Concrete Systems.

Our team consists of highly qualified engineers and fiber reinforced concrete specialists who

will analyze the needs of owners, engineers and end users. We will recommend a highly efficient

and cost-effective solution to optimize long-term performance of your concrete flooring system.

DESIGNED TO PERFORM.

Improves flexural toughness, fatigue endurance, shear strength,

ductility and energy absorption of concrete.

Enables concrete to withstand greater stresses, both prior to

and after cracking.

Provides superior crack width control and unequalled impact

resistance.

Performs under intense loading conditions, including dynamic

wheel loads, static rack loads, uniform distributed loads, impact

from falling loads and vibration from production machines.

Offers three-dimensional homogenous reinforcement which is

always positioned properly.

FIGHTS COSTLY CRACKS AT TRANSFER JOINTS .

High tensile strength fibers create a tighter aggregate interlock

at cracks and contraction joints, which increases load carrying

capacity and provides more stable transfer.

Helps prevent rocking and unstable joints, and loss of filler

material.

Minimizes random cracking between joints to reduce the need

for long-term maintenance of the floor system.

(RESTRAINED SHRINKAGE)

Average Crack Width (mm)

AVERAGE CRACK WIDTH VS . STEEL FIBER VOLUME

33 lb/yd3

20 kg/m3

0.00

66 lb/yd3

40 kg/m3

100 lb/yd3

60 kg/m3

Steel Fiber Volume

IDEAL FOR THESE APPLICATIONS AND OTHERS:

Heavy industrial flooring

Blast-resistant structures

Food processing plants

Joint-free concrete designs

Warehouses

Structural designs

Major distribution centers

Seismic designs

Chemical plants

Hydrodynamic structures

Freezer floors

Equipment foundations

FOR MORE INFORMATION:

See our Product Data Sheets for the NOVOCON family of products.

NORTH AMERICA

Propex Concrete Systems Corp.

6025 Lee Highway, Suite 425

PO Box 22788

Chattanooga, TN 37422

Tel: 800 621 1273

Tel: 423 892 8080

Fax: 423 892 0157

INTERNATIONAL

Propex Concrete Systems Ltd.

Propex House, 9 Royal Court, Basil Close

Chesterfield, Derbyshire, S41 7SL.UK

Tel: +44 (0) 1246 564200

Fax: +44 (0) 1246 465201

www.fibermesh.com

Fibermesh, Novomesh, Novocon, ENDURO and e3 are registered trademarks of Propex Concrete Systems Corp.

THIS PUBLICATION SHOULD NOT BE CONSTRUED AS ENGINEERING ADVICE. WHILE INFORMATION CONTAINED IN THIS PUBLICATION IS ACCURATE TO THE BEST OF OUR KNOWLEDGE, PROPEX DOES NOT WARRANT ITS ACCURACY OR

COMPLETENESS. THE ULTIMATE CUSTOMER AND USER OF THE PRODUCTS SHOULD ASSUME SOLE RESPONSIBILITY FOR THE FINAL DETERMINATION OF THE SUITABILITY OF THE INFORMATION AND THE PRODUCTS FOR THE CONTEMPLATED

AND ACTUAL USE. THE ONLY WARRANTY MADE BY PROPEX FOR ITS PRODUCTS IS SET FORTH IN OUR PRODUCT DATA SHEETS FOR THE PRODUCT, OR SUCH OTHER WRITTEN WARRANTY AS MAY BE AGREED BY PROPEX AND INDIVIDUAL

CUSTOMERS. PROPEX SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, OR ARISING FROM PROVISION OF SAMPLES, A COURSE OF DEALING OR USAGE OF TRADE.

CS-503

2006 Propex Concrete Systems Corp.

07/06

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Novomesh 850 PDFDocument2 pagesNovomesh 850 PDFSyawatulshuhada SyawalNo ratings yet

- Modus Operandi - Proflex - Self Supported Roof - All Technical DetailsDocument19 pagesModus Operandi - Proflex - Self Supported Roof - All Technical Detailsuday Ravi100% (1)

- 500plus Reidbar Design ManualDocument42 pages500plus Reidbar Design ManualChristopher GarciaNo ratings yet

- Radtech Man (Fibre Rebar)Document48 pagesRadtech Man (Fibre Rebar)pete0980No ratings yet

- Keller Phi 1000 12E Retaining StructuresDocument16 pagesKeller Phi 1000 12E Retaining StructuresDeepthiNo ratings yet

- REODATA40Document76 pagesREODATA40chanakaNo ratings yet

- Modern Construction Building Methods Techniques MST Connect With Design and Construciton of Pool MANUALDocument86 pagesModern Construction Building Methods Techniques MST Connect With Design and Construciton of Pool MANUALAe R ONNo ratings yet

- Advantages and Benefits of Unbonded Post-TensioningDocument2 pagesAdvantages and Benefits of Unbonded Post-TensioningJc OndoNo ratings yet

- Za Citat DicotechDocument8 pagesZa Citat DicotechEnes S. SejranicNo ratings yet

- Reinforced Concrete Council - Tiltup10Document4 pagesReinforced Concrete Council - Tiltup10Gyorgy AdrienneNo ratings yet

- Shotcrete and UndergroundDocument2 pagesShotcrete and UndergroundSayed Diab AlsayedNo ratings yet

- Blast Resistant Equipment CentersDocument4 pagesBlast Resistant Equipment Centers1mmahoneyNo ratings yet

- 01 - Mortarless Masonry Wall SystemDocument2 pages01 - Mortarless Masonry Wall SystemdiogesodreNo ratings yet

- Report On Precast ElementsDocument17 pagesReport On Precast Elementspradz4No ratings yet

- CVBHW FlexsteelDocument10 pagesCVBHW FlexsteelSrini KumarNo ratings yet

- Manufacturing ProcessDocument6 pagesManufacturing Processbro nawalibmatNo ratings yet

- Essential Technical Data On Steel Reinforcement: InforcingDocument68 pagesEssential Technical Data On Steel Reinforcement: InforcingNil DGNo ratings yet

- Definition, Advantages, Disadvantages, ProcedureDocument35 pagesDefinition, Advantages, Disadvantages, ProcedureRica RegisNo ratings yet

- CVBHW FlexsteelDocument10 pagesCVBHW FlexsteelfranciscocvNo ratings yet

- Prestrest ConcreteDocument6 pagesPrestrest ConcreteWan ImranNo ratings yet

- Floor ManualDocument35 pagesFloor ManualGihan ChathurangaNo ratings yet

- Precast Concrete: University of Duhok Architectural Department Stage: 4th Advance Building TechnologyDocument14 pagesPrecast Concrete: University of Duhok Architectural Department Stage: 4th Advance Building Technologyأحمد خيرالدين عليNo ratings yet

- Duckbill Ground Anchor Systems - Helical Anchors & Anchor Bolts (Feb 2010)Document12 pagesDuckbill Ground Anchor Systems - Helical Anchors & Anchor Bolts (Feb 2010)sandycastleNo ratings yet

- Factors To Consider For Warehouse Construction - Part 1Document8 pagesFactors To Consider For Warehouse Construction - Part 1Usman ShahidNo ratings yet

- Novocon HE1050 DatasheetDocument2 pagesNovocon HE1050 DatasheetviolettaNo ratings yet

- British Precast Drainage AssociationDocument24 pagesBritish Precast Drainage AssociationpaularupNo ratings yet

- Gyprock 513 Party Wall 201205Document28 pagesGyprock 513 Party Wall 201205duckeNo ratings yet

- Architecture Building ConstructionDocument9 pagesArchitecture Building Construction08DALVI PRASHANINo ratings yet

- Aisc InnovativestructuralsteelDocument12 pagesAisc InnovativestructuralsteelJorge perezNo ratings yet

- Abstract Post TensionDocument4 pagesAbstract Post TensionDe Silva ShmapkNo ratings yet

- Hollow Core BushingDocument4 pagesHollow Core BushingAkhileshkumar PandeyNo ratings yet

- Prestressed Concrete Poles: The Solid Alternative To WoodDocument8 pagesPrestressed Concrete Poles: The Solid Alternative To WoodManoj ChaudharyNo ratings yet

- NGNGHDocument17 pagesNGNGHjohnNo ratings yet

- Hollow Core Tech DataDocument1 pageHollow Core Tech Datacr231181100% (1)

- GuideToPost TensionedslabsDocument39 pagesGuideToPost Tensionedslabsyy2010100% (2)

- Tehnologia Posi StrutDocument35 pagesTehnologia Posi Strutdanut_docNo ratings yet

- 01 PTE Unbonded System 02 070909Document9 pages01 PTE Unbonded System 02 070909Aizaz ShaikhNo ratings yet

- Construction EstimateDocument42 pagesConstruction EstimateAngelica GicomNo ratings yet

- Precast FloorDocument8 pagesPrecast FloorjimmydomingojrNo ratings yet

- Epp 1792Document11 pagesEpp 1792burvanovNo ratings yet

- VN Rapid Response Final Rev12 23 PDFDocument40 pagesVN Rapid Response Final Rev12 23 PDFSube OhNo ratings yet

- Modern Construction TechniqueDocument23 pagesModern Construction TechniquerizwanNo ratings yet

- Meyco Waterproofing HR PDFDocument8 pagesMeyco Waterproofing HR PDFFabioSoaresNo ratings yet

- Prefabricated Construction: Shubhaang Goela - 4 Year (Section B)Document7 pagesPrefabricated Construction: Shubhaang Goela - 4 Year (Section B)Shubhaang GoelaNo ratings yet

- Sheet PilingDocument24 pagesSheet PilingniyatiNo ratings yet

- Test 3 FinalDocument8 pagesTest 3 FinaladithyaNo ratings yet

- Gyprock 949 Strata Wall 201202Document24 pagesGyprock 949 Strata Wall 201202duckeNo ratings yet

- 17mc67 (Drsri Precast)Document20 pages17mc67 (Drsri Precast)jagadeshNo ratings yet

- Parrycore Commercial Structures WhatsappDocument3 pagesParrycore Commercial Structures Whatsappapi-342626132No ratings yet

- Light Weight SystDocument4 pagesLight Weight SystRanjan AnchanNo ratings yet

- Keller Phi - 1000 12E - Retaining Structures PDFDocument16 pagesKeller Phi - 1000 12E - Retaining Structures PDFluisNo ratings yet

- Advanced Construction and Materials: Pre-Stressed ConcreteDocument19 pagesAdvanced Construction and Materials: Pre-Stressed ConcreteswethaadusumilliNo ratings yet

- Vibration Serviceability of Long-Span Concrete BuiDocument82 pagesVibration Serviceability of Long-Span Concrete BuiDaniel A. FlorêncioNo ratings yet

- Concrete AssignmentDocument24 pagesConcrete AssignmentPushpesh RanjanNo ratings yet

- Prefabricated ConcreteDocument17 pagesPrefabricated ConcreteNishimaNo ratings yet

- Precast Castinplace ConcreteDocument61 pagesPrecast Castinplace ConcreteNeanderthalNo ratings yet

- Sales Presentation 2016Document25 pagesSales Presentation 2016Matumbi NaitoNo ratings yet

- Tall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966From EverandTall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966A. CoullRating: 5 out of 5 stars5/5 (1)

- Distillation Report - Rotation 1Document1 pageDistillation Report - Rotation 1jlcheefei9258No ratings yet

- Sizing ReceiversDocument1 pageSizing Receiversjlcheefei9258No ratings yet

- Concentration Cheat SheetDocument2 pagesConcentration Cheat Sheetjlcheefei9258No ratings yet

- Sizing ReceiversDocument3 pagesSizing Receiversjlcheefei9258No ratings yet

- Electrical LV Panel Form ClassificationDocument2 pagesElectrical LV Panel Form Classificationjlcheefei9258No ratings yet

- 5066452Document53 pages5066452jlcheefei9258No ratings yet

- Asean Haccp enDocument98 pagesAsean Haccp enzyrtylNo ratings yet

- Abl12e 09Document2 pagesAbl12e 09jlcheefei9258No ratings yet

- Steam Consumption of Jet Pumps: E K Ø 18 Kg/kmol 300 °CDocument2 pagesSteam Consumption of Jet Pumps: E K Ø 18 Kg/kmol 300 °Cjlcheefei9258No ratings yet

- Steam EjectorDocument4 pagesSteam Ejectorjlcheefei9258No ratings yet

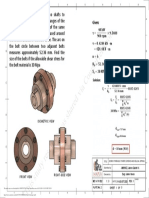

- Adapter SleeveDocument1 pageAdapter Sleevejlcheefei9258No ratings yet

- Chemical Enzymatic InteresterificationDocument37 pagesChemical Enzymatic Interesterificationjlcheefei9258No ratings yet

- Oil Water Separator TheoryDocument3 pagesOil Water Separator Theoryjlcheefei9258No ratings yet

- 0910 8 AbsDocument9 pages0910 8 Absjlcheefei9258No ratings yet

- Stoke's LawDocument6 pagesStoke's Lawjlcheefei9258No ratings yet

- Technical Information TI-011: Insulation Reguirement For Non-Metallic Expansion JointsDocument3 pagesTechnical Information TI-011: Insulation Reguirement For Non-Metallic Expansion Jointsjlcheefei9258No ratings yet

- C12-Surface BOPSDocument119 pagesC12-Surface BOPSmissaoui100% (1)

- WEMA S3 Senders - Installation ManualDocument2 pagesWEMA S3 Senders - Installation ManualAbraham Márquez PaxtiánNo ratings yet

- Pricelist 5 Juni 2023 (Toko Tempo 90 Hari)Document12 pagesPricelist 5 Juni 2023 (Toko Tempo 90 Hari)Dwi WicaksonoNo ratings yet

- RCC41 Continuous Beams (A & D)Document17 pagesRCC41 Continuous Beams (A & D)Amit Kumar Paul0% (1)

- RMS RMZ ITH ToolsDocument2 pagesRMS RMZ ITH ToolsDhanaNo ratings yet

- Bendi - B3-30 - AC - Maintenance - Check Lists PDFDocument9 pagesBendi - B3-30 - AC - Maintenance - Check Lists PDFChristian BedoyaNo ratings yet

- Rotating Cleaners - Sanitor: - Slow Constant Rotation - Low Volume Flow - Working Pressure Up To 20 Bar - No ElastomersDocument1 pageRotating Cleaners - Sanitor: - Slow Constant Rotation - Low Volume Flow - Working Pressure Up To 20 Bar - No ElastomerspollodoboxNo ratings yet

- Carrir 50TJM Data Sheet Eng PDFDocument28 pagesCarrir 50TJM Data Sheet Eng PDFomar farukNo ratings yet

- PSN Test ToolDocument1 pagePSN Test ToolRobert GonzalezNo ratings yet

- RMQLP-4120-H10 (Assembly)Document3 pagesRMQLP-4120-H10 (Assembly)Debabrata SahaNo ratings yet

- Cp-005-Calibration of Internal MicrometerDocument5 pagesCp-005-Calibration of Internal MicrometerSUNILNo ratings yet

- Atlas Copco: Parts ListDocument100 pagesAtlas Copco: Parts ListMuhammad Tariq100% (1)

- 1200x800 Column DesignDocument4 pages1200x800 Column DesignrameshkaaNo ratings yet

- Greenheck Damper GuideDocument2 pagesGreenheck Damper GuideStefan WeissNo ratings yet

- Answer Key IWCF 3-4 Student ManualDocument8 pagesAnswer Key IWCF 3-4 Student ManualIgorCencičNo ratings yet

- Thread Disk ReportDocument1 pageThread Disk Reportgabe.sotoNo ratings yet

- Technical Data: Diameter - Pitch Combinations For Class of FitDocument1 pageTechnical Data: Diameter - Pitch Combinations For Class of FitecavalinNo ratings yet

- Isometric View: JIMENEZ, James Gabriel VDocument1 pageIsometric View: JIMENEZ, James Gabriel VHansyyy CarantoNo ratings yet

- Design of Jigs, Fixtures and Press Tools: Muruganandam Arunachalam Vijayaraghavan G.KDocument19 pagesDesign of Jigs, Fixtures and Press Tools: Muruganandam Arunachalam Vijayaraghavan G.Kniharika kadiriNo ratings yet

- Comparison of PD 5500, EN 13445, ASME VIII PDFDocument4 pagesComparison of PD 5500, EN 13445, ASME VIII PDFviki_gpNo ratings yet

- M 441422 Service ManualDocument67 pagesM 441422 Service ManualThomas FennellNo ratings yet

- NTPC Revised Vendor ListDocument33 pagesNTPC Revised Vendor ListSandeep NarayananNo ratings yet

- Investigation of Mechanical Properties of GFRP NanopartclesDocument9 pagesInvestigation of Mechanical Properties of GFRP NanopartclesAnup BetageriNo ratings yet

- Dynapac v6030tv Spare Parts CatalogueDocument20 pagesDynapac v6030tv Spare Parts Cataloguestanley100% (56)

- Piston Pump: PD LDDocument8 pagesPiston Pump: PD LDMohammad Jahid AlamNo ratings yet

- Borewell Details1Document10 pagesBorewell Details1BRCO meerutNo ratings yet

- Komatsu Crawler Excavator Pc300hd 8 Shop ManualDocument20 pagesKomatsu Crawler Excavator Pc300hd 8 Shop ManualMarlon100% (49)

- Nomenclature of Face and End Milling CutterDocument4 pagesNomenclature of Face and End Milling CutterIsmael AibisNo ratings yet

- Chain and Sprocket PDFDocument64 pagesChain and Sprocket PDFmalanadu KanjirapallyNo ratings yet

- 2022A MECD413 DeberII1Document2 pages2022A MECD413 DeberII1Alexis YepezNo ratings yet