Professional Documents

Culture Documents

Implementation of Pid Control To Reduce Wobbling in A Line Following Robot

Uploaded by

esatjournalsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Implementation of Pid Control To Reduce Wobbling in A Line Following Robot

Uploaded by

esatjournalsCopyright:

Available Formats

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

IMPLEMENTATION OF PID CONTROL TO REDUCE WOBBLING IN A

LINE FOLLOWING ROBOT

Anirudh Sunil Nath 1, Aravind Kumar R2, Tarun Malik3

1

M.Tech Student, Department of Mechanical Engineering, SRM University, Chennai, India, ace.anirudh@gmail.com

B.Tech Student, Department of Telecommunication Engineering, SRM University, Chennai, India, armsr92@gmail.com

3

B.Tech Student, Department of Mechatronics, SRM University, Chennai, India, tarunmalik29@gmail.com

Abstract

A Proportional-Integral-Derivative (PID) Control System provides for controlling the value of a variable, in this case the position of

the robot, so that it is at or near a desired value, called the set-point, in this case on the centre of the line. In contrast to other control

systems this provides for the smoothest type of control with minor deviations and overshooting if implemented correctly. This paper

discusses, the concept, design and implementation of a line following robot that uses the PID control algorithm to govern its motion.

The control algorithm is implemented in real time by a pre-programmed microcontroller.

Keywords: PID, Robot, Sensor, Microcontroller and AI

---------------------------------------------------------------------***------------------------------------------------------------------------1. INTRODUCTION

A line follower robot is a robot that is capable of navigating

while following a line on some terrain with the use of sensors

that tell the robot where it is. Just as we manipulate and

interact with objects through gestures, these robots have to be

taught some way to manipulate and understand its

surroundings to be able understand and comprehensively take

decisions. The decision variables are provided by these

sensors also referred to as the line sensors and the acquired

decision variables are passed through a decision device (in our

case the ATMega328 microcontroller in the Arduino UNO

board). The microcontroller in turn commands the actuators to

move the robot in the desired direction, giving the effect of

following the line. A line in this case is a part of the terrain

with a distinct colour that is in contrast with the background

and is usually of uniform width.

2. ROBOT CONSTRUCTION

The robot consists of the hardware (the tangible components)

and the software (the control logic that runs on the

microcontroller which guides the motion of the robot. The

major sub-systems of the line following robot and their

interactions are shown in Figure 1. The environment is defined

as the surroundings of the robot, with which the robot interacts

with the use of its actuators. The robot in turn can learn about

its surroundings in real time with the use of its sensors that

convert physical parameters of the environment in to electrical

signals that can be understood by the microcontroller. All of

these sub-systems are essential to the functioning of the robot.

Furthermore they must be seamlessly integrated together for

perfect functionality.

Fig-1: The Sub-Systems of the Line Following Robot

2.1 Line Sensor

The line sensors consist of an IR transmitter receiver pair for

differentiating between the line and the background. The

transmitter sends out IR rays and the receiver notes the

amount, or in other words the intensity, of IR rays received

and based on this it calculates if it is over the line or the

surrounding. If the line is of white in colour then it will reflect

more light as compared to any other colour. This difference in

reflected light helps us determine if the sensor is on the line or

on the surroundings. Using IR light reduces the noise due to

ambient light. For our experiment we have tested on a white

line roughly 3cm that runs on coloured backgrounds. Arrays

of such line sensors have been used to form our line sensor as

using just one or few such sensors amounts to very poor

source of information when it comes to following the line at

higher speeds.

__________________________________________________________________________________________

Volume: 02 Issue: 10 | Oct-2013, Available @ http://www.ijret.org

531

IJRET: International Journal of Research in Engineering and Technology

2.2 Decision Device

Decision device is a unit where the decision variables passed

by the line sensors are analysed, processed and then the

appropriate actions/response are initiated. For our robot we

have used the Arduino UNO microcontroller board and

Arduino Programming Language for coding it. The PID

control algorithm, discussed in the next section, is coded to

this microcontroller. It is the brain of the robot and thus it can

be said that the robot, to a certain degree, has artificial

intelligence.

eISSN: 2319-1163 | pISSN: 2321-7308

The bigger problem was to develop an algorithm that would

allow the robot to follow the line smoothly even at high speed.

The solution to this is to implement the PID control algorithm

to control the motion of the robot.

4. LINE FOLLOWING WITH PID

PID is widely used control algorithm, mostly used in

industries, Robotics and other areas. The following is a brief

explanation of PID. The PID algorithm is explained with

taking a simple line following robot as an example, however

its application may not be only limited by this.

2.3 Actuators

The actuators in this robot are brushed DC motors with a

reduction gearbox that operate at 60 RPM and have sufficient

torque to carry the robot. They are directly connected to the

wheels of the robot and cause the robot to move in the desired

direction. We have two motors controlling the two wheels.

Motion is achieved using the concept of differential drive.

Thus we can achieve motions of moving front, back and

turning left and right. The motion is controlled from the

microcontroller.

The two motors are used to drive the robot using the concept

of differential drive. In this the speed and direction of rotation

of the individual wheels are used to both move and turn the

robot.

2.4 Power Source

The power source provides electrical power to the robot and

all its components. It also consists of a set of regulators that

provide the required voltages to the various parts of the robot.

We choose a LiPo battery for this purpose because it has the

highest power to weight ratio. Regulators are used to provide

different levels of voltages for all the various components.

Our goal is to make the Robot follow the black line on the

white surface. For it to follow the line with less number of

errors and in a smooth manner we use PID Algorithm. It uses

an IR sensor to detect the change in the colour of the place it is

on. If it is a black, the sensor is on the line. If it is white, it is

on the background.

The sensor gives a HIGH value when it is on the black line &

a LOW if it is on the white background. We can use any

number of line sensors but for this example we will take 3

sensors into consideration. We will refer them as the Left,

Middle & Right Sensor.

First we will start off by describing the normal behavior of a

robot while following a line. While the robot moves over the

line it may come into the following conditions, if the line is

detected by the Left Sensor, then the robot is programmed to

go towards Left, if it is detected by the Right sensor, then it

goes towards right and similarly for center position of the line

it will go straight. The disadvantage in using this is that the

robot may wobble a lot, and if going too fast then it may lose

control and stop following the line, as discussed in the

previous section.

3. LINE FOLLOWING WITHOUT PID

After construction of the robot we programmed it follow the

line without the PID control algorithm. The method that was

used was to check the sensor condition and according to that

move the robot in the appropriate direction such that the robot

tries to centre itself over the line this was repeated by the

microcontroller hundreds of times a second. This was the

implementation of a direct mapping of the sensor condition to

the motion of the robot. The code was written so that the robot

follows a black line on a white background.

The result of this was that the robot followed the line. The

deviations observed were immense. In certain cases the line

sensors would all be off the line. This confused the robot since

it did not correspond to any condition of the robot. The robot

would continue in its last motion. This problem was solved by

figuring out which direction the robot was moving when it

moved off the line. This helped put it back on track.

Fig -2: Comparison of robot with and without PID following a

line

__________________________________________________________________________________________

Volume: 02 Issue: 10 | Oct-2013, Available @ http://www.ijret.org

532

IJRET: International Journal of Research in Engineering and Technology

When we introduce PID into the motion of Robot then it takes

the following factors into consideration: the speed with which

the robot is moving from side to side, is the robot centred over

the line and how long the robot is not centred on the line. By

introducing these, we can get a line following robot which will

be very smooth in its motion and can follow it at high speeds

as well.

eISSN: 2319-1163 | pISSN: 2321-7308

4.5 Integral Component

This component measures the error that builds up over time.

This involves adding up the error after every step. The integral

value keeps building up after every sensor scan cycle of the

microcontroller.

In Figure 2, we can see that the line following robot without

PID follows the line with a lot of wobbling, whereas on the

other hand the one with PID is much smoother as compared to

the one without PID.

The understanding of PID is necessary for its proper

implementation. For this we need to look at the following

terms.

This is basically used to tell that the output given by the

algorithm is not sufficiently changing the value of the error

and the output given needs to be varied more drastically to

reduce the error value. This is done for both positive and

negative errors.

4.1 Target Position (Set-Point)

4.6 Derivative Component

It is the required position for the robot to be in. For a line

following robot, it is over the center of the line. It is set to

zero. It is basically the mean position/the desired position. It is

set as a set point in the program, and all the positions of the

robot will be with respect to the target position.

This component acts as the inverse of the integral component

in the PID control algorithm.

4.2 Measured Position

This component prevents the overshooting of the robot from

the line when correcting the error. This means that when the

error is reduces it stops the robot from moving so that it does

not continue its motion to produce error by moving to the

other side of the line.

This is a value depending upon the position of the robot with

respect to the line. It can either be positive or negative. It

involves calculating the distance between the current position

of the robot and the target position. It can either be to the right

or to the left of the target position, and based on that it is given

a positive or negative value.

4.3 Error

This is the difference between the Target Position and the

Measured Position. So the more far away the robot will be

from the Target position, the more the value of the error. The

magnitude of error depends on which side of the line the robot

is in. This also has positive and negative values.

4.4 Proportional Component

This component of the PID control, tells us how far away the

robot is from the line. A sensor condition of 011 tells us the

robot is closer to the line than the sensor position of 001. This

component is proportional to the position of the robot with

respect to the target position and proportionally varies the

output speed of the robot to bring it back to its intended

position.

4.7 PID Constants

There are 3 constants used in this algorithm. These are the

Proportional Constant (Kp), Integral Constant (Ki) and the

Derivative Constant (Kd). The values of these constant are set

beforehand by the programmer. The values of these constant

depend on various thing ranging from weight of the robot to

the size of it. The robot dimensions and the actuation system

also play an important role in determining the value of these

constants.

5. PID IMPLEMENTATION IN THE ROBOT

For our robot, we used Arduino as the microcontroller board,

with an ATMega328 on board. We initialized the various

constants such as Kp, Ki and Kd. We also give a value to the

Tp Variable, which is the maximum speed given to the wheels

for straight condition. Also we initialize last error, which is the

previous error value & other variables such as integral,

derivative and proportional. We set the value of the Measured

Position Variable for each sensor condition. These are the

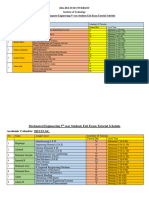

values we set are as in Table 1.

A high proportional value would require a large change in the

output value, to correct the error.

__________________________________________________________________________________________

Volume: 02 Issue: 10 | Oct-2013, Available @ http://www.ijret.org

533

IJRET: International Journal of Research in Engineering and Technology

Table -1: Value for Measured Position

Sensor

Position

0-0-0

0-0-1

0-1-1

0-1-0

1-1-0

1-0-0

1-1-1

Measured

Given Value

100

2

1

0

-1

-2

0

Then we calculated the error value as

Error = Measured Value Target Position

A higher error value tells us that the robot is farther away from

the line, than a lower error value. We then set the integral

value as sum of current integral value & the error. The

derivative value was updated to the sum of current derivative

value & the last error.

We then calculated TURN Value as the sum of the product of

ERROR Value & the Kp constant, product of Ki constant and

integral and the product of Kd constant & the derivative. We

then give the output to the left wheel and the right wheel as a

PWM (Pulse Width Modulation) output, which directly

controls the speed of the motor.

LeftPWM = Tp + TURN

eISSN: 2319-1163 | pISSN: 2321-7308

PID can be further improved by increasing the number of

sensors, which would cause the robot to go faster at curves

and follow it more efficiently. The reason to this is that at

curves the corner sensors will sense the line and proportionally

are able to come back to the line, whereas for lesser number of

sensors the robot may just come off the line.

CONCLUSIONS

Before using the PID, the problem we faced were that the

robot did not follow the line smoothly. It wasnt efficiently

following the line, so to improve this we implemented the PID

logic. We started with implementing the proportional part, and

wrote down the code for it. After running the robot we noticed

that while following the wobbling of the robot was lesser than

before, but it was still a big issue. We then added the integral

part to the code, and the robot was now following the line

much more efficiently with very less wobbling. The line

following was further improved after adding the differential

part to the code, which reduced the overshooting of the robot

while trying to return to the line. The robot developed and

used for testing by us is shown in Figure 3.

While implementing PID, we faced a major problem in setting

up the constants for the Proportional, Integral and Differential.

We started by setting each value as 1 and then made the

changes by either increasing it or decreasing it, and seeing the

changes in the behavior of the robot. The constants had to be

changed to many times before arriving at the perfect values.

After setting up P constant, and setting the Integral Constant,

even the P constant had to be varied a little.

RightPWM = Tp TURN

This results in both the wheels moving at different speed,

which depends on the sensor input and is computed above. At

the end of the program we set the last error value as current

error value.

This algorithm keeps repeating in a loop to give an effective

PID algorithm. The above explained computation happens

many times in a second to give an efficient line following

robot.

Another essential part of a PID algorithm is the setting of the

PID Constants, that are Kp, Ki and Kd values. The best way to

determine the perfect constant value would be to start from 0,

and then look for the best output after continuously

incrementing them. From the program execution, the robot

first checks the sensor input, and calculates the error

accordingly. The error value tells us how far our robot is from

the line. Then the derivative is calculated which tells us how

fast are we moving towards or away from the line. The

integral is then calculated which sums up the distance from the

lines edge. Using this TURN value is calculated which is

added to the PWM values of the wheel.

Fig-3: The Robot

REFERENCES

[1]. Electrical Power Systems by Wadhwa C L

[2]. Modern Control Systems by Richard C Dorf and Bishop

[3]. Robotics modeling planning and control by Bruno

Siciliano, Lorenzo Sciavicco, Luigi Villani, Giuseppe Oriolo.

__________________________________________________________________________________________

Volume: 02 Issue: 10 | Oct-2013, Available @ http://www.ijret.org

534

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

[4]. Robot Buildings for Beginners by David Cook

BIOGRAPHIES

Anirudh is currently pursuing his M.Tech in

Robotics from SRM University, Chennai. His area

of interest is AI and Robotics

Aravind is currently pursuing his B.Tech in

Telecommunication Engineering from SRM

University, Chennai. Area of interest is Robotics

and Networking.

Tarun is currently pursuing his B.Tech in

Mechatronics from SRM University. His area of

interest is Robotics and Machine Learning.

__________________________________________________________________________________________

Volume: 02 Issue: 10 | Oct-2013, Available @ http://www.ijret.org

535

You might also like

- PTE 3 Week Study ScheduleDocument3 pagesPTE 3 Week Study ScheduleesatjournalsNo ratings yet

- Analysis of Cylindrical Shell Structure With Varying Parameters PDFDocument6 pagesAnalysis of Cylindrical Shell Structure With Varying Parameters PDFesatjournalsNo ratings yet

- Analysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFDocument4 pagesAnalysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFesatjournalsNo ratings yet

- Analysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFDocument7 pagesAnalysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFesatjournalsNo ratings yet

- Analysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFDocument6 pagesAnalysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFesatjournalsNo ratings yet

- A Review On Fake Biometric Detection System For Various ApplicationsDocument4 pagesA Review On Fake Biometric Detection System For Various ApplicationsesatjournalsNo ratings yet

- A Servey On Wireless Mesh Networking ModuleDocument5 pagesA Servey On Wireless Mesh Networking ModuleesatjournalsNo ratings yet

- A Review Paper On Smart Health Care System Using Internet of ThingsDocument5 pagesA Review Paper On Smart Health Care System Using Internet of ThingsesatjournalsNo ratings yet

- A Study and Survey On Various Progressive Duplicate Detection MechanismsDocument3 pagesA Study and Survey On Various Progressive Duplicate Detection MechanismsesatjournalsNo ratings yet

- A Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesDocument9 pagesA Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesesatjournalsNo ratings yet

- A Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemDocument8 pagesA Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemesatjournalsNo ratings yet

- A Women Secure Mobile App For Emergency Usage (Go Safe App)Document3 pagesA Women Secure Mobile App For Emergency Usage (Go Safe App)esatjournalsNo ratings yet

- A Survey On Identification of Ranking Fraud For Mobile ApplicationsDocument6 pagesA Survey On Identification of Ranking Fraud For Mobile ApplicationsesatjournalsNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Android Controlled Notice Board: Prof. Neha TiwariDocument4 pagesAndroid Controlled Notice Board: Prof. Neha TiwariNayan SolanKiNo ratings yet

- AB Pushbutton 800T FXJT6A5 Cut D704Document9 pagesAB Pushbutton 800T FXJT6A5 Cut D704Rory HillNo ratings yet

- SpeedStile Installation Guidlines Rev 1Document14 pagesSpeedStile Installation Guidlines Rev 1WERMERMNo ratings yet

- HD64180Z Hardware Manual 4th EdDocument224 pagesHD64180Z Hardware Manual 4th EdAngga GintaraNo ratings yet

- Substation TheoryDocument69 pagesSubstation Theorykvrgms100% (2)

- Zener Diode+regulationDocument10 pagesZener Diode+regulationammadm540No ratings yet

- Typical MRP ProblemDocument4 pagesTypical MRP Problemashwin josephNo ratings yet

- Energizer L92: Product Datasheet Product DatasheetDocument2 pagesEnergizer L92: Product Datasheet Product DatasheetDot N SpotNo ratings yet

- Pioneer PDP 433PEDocument108 pagesPioneer PDP 433PEPaulo GardelNo ratings yet

- IOT Exit Exam ScheduleDocument6 pagesIOT Exit Exam ScheduleabdulazizNo ratings yet

- IS 8783 (Part-4-Sec.1) - 1995 - HR PVC Insulated - Winding Wires For Submersible MotorsDocument10 pagesIS 8783 (Part-4-Sec.1) - 1995 - HR PVC Insulated - Winding Wires For Submersible Motorsshivam dwivediNo ratings yet

- Coil-Lock ... Hold-in-Device: From Power Quality Solutions IncDocument2 pagesCoil-Lock ... Hold-in-Device: From Power Quality Solutions IncvelizarkoNo ratings yet

- SCX-6345n Service ManualDocument322 pagesSCX-6345n Service ManualAnonymous gn8qxxNo ratings yet

- Siemens Micromaster Eco ManualDocument181 pagesSiemens Micromaster Eco ManualMohammad Imtiaz ChowdhuryNo ratings yet

- WWW - MK-Electronic - De: FRU (Field Replaceable Unit) ListDocument7 pagesWWW - MK-Electronic - De: FRU (Field Replaceable Unit) ListCarlos EduardoNo ratings yet

- CI 8038 - CI 555 FinalDocument10 pagesCI 8038 - CI 555 Finalmaria diazNo ratings yet

- Icaro - Instruction ManualDocument10 pagesIcaro - Instruction ManualJonatan Fuenmayor ArteagaNo ratings yet

- Daikin Applied UK D AHU Modular Product BrochureDocument6 pagesDaikin Applied UK D AHU Modular Product BrochurejorgecascalesNo ratings yet

- TP Modulation Sous Matlab CorrigéeDocument37 pagesTP Modulation Sous Matlab CorrigéeELmokhtar HamrouniNo ratings yet

- WO 9840960-Giampaolo MACCANTI Electromagnetic DeviceDocument1,099 pagesWO 9840960-Giampaolo MACCANTI Electromagnetic DeviceemiltzvetanovNo ratings yet

- IDAM Internship ReportDocument47 pagesIDAM Internship Reportvivekanand_bonalNo ratings yet

- Instrumentation PDFDocument1 pageInstrumentation PDFFerliemNo ratings yet

- M05 Q&aDocument139 pagesM05 Q&aversineNo ratings yet

- User Guide: Tracer™ TD7 With UC 800Document24 pagesUser Guide: Tracer™ TD7 With UC 80001666754614No ratings yet

- 80 Channel System For Various Interior Measurement ScenariosDocument2 pages80 Channel System For Various Interior Measurement ScenariosXVJNo ratings yet

- Learn PLC Programming Relay SequencesDocument108 pagesLearn PLC Programming Relay SequencesIppiNo ratings yet

- Cell Reselection ProcedureDocument4 pagesCell Reselection ProcedureAbhay U. NagraleNo ratings yet

- 05a - MSM 86 - e PDFDocument2 pages05a - MSM 86 - e PDFMuhammad Nur CahyadiNo ratings yet

- GB-Statys 100A Rack-Operating ManualDocument41 pagesGB-Statys 100A Rack-Operating Manualxuyen tranNo ratings yet

- PS18/28/35/38/48 Series Iii Bass Module Dsp/Amp Boardpcb P/N 309887 Rev 01 Sheet 1 of 12Document14 pagesPS18/28/35/38/48 Series Iii Bass Module Dsp/Amp Boardpcb P/N 309887 Rev 01 Sheet 1 of 12Sv KoNo ratings yet