Professional Documents

Culture Documents

Udimet Alloy 720

Uploaded by

AnishNairCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Udimet Alloy 720

Uploaded by

AnishNairCopyright:

Available Formats

www.specialmetals.

com

Chromium..................................................................15.5-16.5

Cobalt ........................................................................14.0-15.5

Molybdenum..............................................................2.75-3.25

Tungsten ....................................................................1.00-1.50

Titanium.....................................................................4.75-5.25

Aluminum...................................................................2.25-2.75

Carbon.......................................................................0.01-0.02

Zirconium.................................................................0.025-0.05

Boron.........................................................................0.01-0.02

Nickel..........................................................................Balance*

Typical Mechanical Properties

*Reference to the balance of a composition does not guarantee

Table 3 - 1000-Hour Rupture Strength of PrecipitationHardened UDIMET alloy 720

this is exclusively of the element mentioned but that it predominates

and others are present only in minimal quantities.

Rupture Strength

Temperature

C

ksi

MPa

1200

1300

1400

1600

1800

649

704

760

871

982

102

73

70

32

10

700

500

480

219

68

Physical Constants

Table 2 - Physical Constants

Density, lb/in3 ...................................................................0.292

g/cm3 ....................................................................8.08

Melting Range, F....................................................2180-2440

C ...................................................1194-1338

Coefficient of Expansion, 70-200F, 10-6 in/inF................6.8

21-93C, m/mC ................12.24

UDIMET alloy 720

Table 1 - Limiting Chemical Composition, %

UDIMET alloy 720 is a nickel base alloy, solid

solution strengthened with tungsten and molybdenum

and precipitation-hardened with titanium and

aluminum. The alloy combines high strength with

metallurgical stability as demonstrated by excellent

impact strength retention after long exposures at

elevated temperatures. Good oxidation and corrosion

resistance combined with high strength make the alloy

useful in gas turbine blade and disc applications.

Available Products

and Specifications

Temperature, C

100

200

300

400

500

600

700

800

900

1000

1600

200

1400

Tensile Strength

1200

160

1000

120

800

Yield Strength (0.2% offset)

600

80

UDIMET alloy 720 is available

as forging billet and bar.

Stress, MPa

Stress, ksi

Elongation, %

0

240

Major specifications:

EMS 55477

EMS 73105

MSRR 7252

C50TF105

MTS 5013

400

40

200

Elongation

0

0

0

200

400

600

800

1000

1200

1400

1600

1800

2000

Temperature, F

Figure 1. Typical mechanical properties of precipitation-hardened UDIMET alloy 720

Publication Number SMC-106

Copyright Special Metals

Corporation, 2004 (Sept 04)

UDIMET is a trademark of the

Special Metals Corporation

group of companies.

www.specialmetals.com

U.S.A.

France

Affiliated Companies

Special Metals Services SA

17 Rue des Frres Lumire

69680 Chassieu (Lyon)

Phone

+33 (0) 4 72 47 46 46

Fax

+33 (0) 4 72 47 46 59

Special Metals Welding

Products

Special Metals Corporation

Billet, rod & bar, flat

& tubular products

3200 Riverside Drive

Huntington, WV 25705-1771

Phone

+1 (304) 526-5100

+1 (800) 334-4626

Fax

+1 (304) 526-5643

Billet & bar products

4317 Middle Settlement Road

New Hartford, NY 13413-5392

Phone

+1 (315) 798-2900

+1 (800) 334-8351

Fax

+1 (315)798-2016

Atomized powder products

100 Industry Lane

Princeton, KY 42445

Phone

+1 (270) 365-9551

Fax

+1 (270) 365-5910

Shape Memory Alloys

4317 Middle Settlement Road

New Hartford, NY 13413-5392

Phone

+1 (315) 798-2939

Fax

+1 (315) 798-6860

United Kingdom

Special Metals Wiggin Ltd.

Holmer Road

Hereford HR4 9SL

Phone

+44 (0) 1432 382200

Fax

+44 (0) 1432 264030

Germany

Special Metals Deutschland Ltd.

Postfach 20 04 09

40102 Dsseldorf

Phone

+49 (0) 211 38 63 40

Fax

+49 (0) 211 37 98 64

Hong Kong

Special Metals Pacific Pte. Ltd.

Unit A, 17th Floor, On Hing Bldg

1 On Hing Terrace

Central, Hong Kong

Phone

+852 2439 9336

Fax

+852 2530 4511

Canada House

Bidavon Industrial Estate

Waterloo Road

Bidford-On-Avon

Warwickshire B50 4JN, U.K.

Phone

+44 (0) 1789 491780

Fax

+44 (0) 1789 491781

Controlled Products Group

590 Seaman Street, Stoney Creek

Ontario L8E 4H1, Canada

Phone

+1 (905) 643-6555

Fax

+1 (905) 643-6614

A-1 Wire Tech, Inc.

India

Special Metals Services Ltd.

No. 60, First Main Road, First

Block

Vasantha Vallabha Nagar

Subramanyapura Post

Bangalore 560 061

Phone

+91 (0) 80 2666 9159

Fax

+91 (0) 80 2666 8918

Italy

Special Metals Wire Products

Holmer Road

Hereford HR4 9SL

Phone

+44 (0) 1432 382556

Fax

+44 (0) 1432 352984

Special Metals Services SpA

Via Assunta 59

20054 Nova Milanese (MI)

Phone

+390 362 4941

Fax

+390 362 494224

China

The Netherlands

Special Metals Pacific Pte. Ltd.

Room 1802, Plaza 66

1266 West Nanjing Road

Shanghai 200040

Phone

+86 21 3229 0011

Fax

+86 21 6288 1811

Special Metals Service BV

Postbus 8681

3009 AR Rotterdam

Phone

+31 (0) 10 451 44 55

Fax

+31 (0) 10 450 05 39

Singapore

Special Metals Pacific Pte. Ltd.

Room 910, Ke Lun Mansion

12A Guanghua Road

Chaoyang District

Beijing 100020

Phone

+86 10 6581 8396

Fax

+86 10 6581 8381

1401 Burris Road

Newton, NC 28658, U.S.A.

Phone

+1 (828) 465-0352

+1 (800) 624-3411

Fax

+1 (828) 464-8993

Special Metals Pacific Pte. Ltd.

24 Raffles Place

#27-04 Clifford Centre

Singapore 048621

Phone

+65 6532 3823

Fax

+65 6532 3621

A Special Metals Company

4550 Kishwaukee Street

Rockford, IL 61109, U.S.A.

Phone

+1 (815) 226-0477

+1 (800) 426-6380

Fax

+1 (815) 226-0537

Rescal SA

A Special Metals Company

200 Rue de la Couronne des Prs

78681 Epne Cdex, France

Phone

+33 (0) 1 30 90 04 00

Fax

+33 (0) 1 30 90 02 11

DAIDO-SPECIAL METALS

Ltd.

A Joint Venture Company

Daido Shinagawa Building

6-35, Kohnan 1-chome

Minato-ku, Tokyo 108-0057, Japan

Phone

+81 (0) 3 5495 7237

Fax

+81 (0) 3 5495 1853

The data contained in this publication is for

informational purposes only and may be

revised at any time without prior notice. The

data is believed to be accurate and reliable,

but Special Metals makes no representation

or warranty of any kind (express or implied)

and assumes no liability with respect to the

accuracy or completeness of the information

contained herein. Although the data is

believed to be representative of the product,

the actual characteristics or performance of

the product may vary from what is shown in

this publication. Nothing contained in this

publication should be construed as

guaranteeing the product for a particular use

or application.

You might also like

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Brightray Alloy 35Document2 pagesBrightray Alloy 35SANKET SINGHNo ratings yet

- Nimonic Alloy 115Document4 pagesNimonic Alloy 115mvanzijpNo ratings yet

- Special Metals Corp - Global Supplier Special Alloy ProductsDocument1 pageSpecial Metals Corp - Global Supplier Special Alloy ProductsjlplazaolaNo ratings yet

- Russel Metals Data BookDocument522 pagesRussel Metals Data Bookdsantol100% (1)

- 2013 CuttingToolsCatalogDocument282 pages2013 CuttingToolsCatalogHeru SaNo ratings yet

- Inconel - Alloy 050 - UNS N06950Document2 pagesInconel - Alloy 050 - UNS N06950Javeed A. KhanNo ratings yet

- Surat UnitsDocument35 pagesSurat UnitsRitesh Chudasama80% (5)

- Prelims 1Document10 pagesPrelims 1M Ry ZealNo ratings yet

- High Tensile Steel: Nearest StandardDocument3 pagesHigh Tensile Steel: Nearest StandardAnonymous dvrhf5No ratings yet

- Alpine Metal Tech - List of Subsidiaries & Representatives - SteelDocument5 pagesAlpine Metal Tech - List of Subsidiaries & Representatives - SteelMbamali ChukwunenyeNo ratings yet

- Widia Technical PSEinch 544-560Document0 pagesWidia Technical PSEinch 544-560hugobscottNo ratings yet

- Maska Catalogo SDocument195 pagesMaska Catalogo Ssajuro1989No ratings yet

- Jfe Steel - Sulpuric Steel C1e-013Document8 pagesJfe Steel - Sulpuric Steel C1e-013Harsh AgarwalNo ratings yet

- Global Headquarters: North America - SalesDocument10 pagesGlobal Headquarters: North America - SalesvvkguptavoonnaNo ratings yet

- Top 100 Yorkshire CompaniesDocument1 pageTop 100 Yorkshire CompaniesAjinkya KulkarniNo ratings yet

- MaskaDocument195 pagesMaskavare222No ratings yet

- List 5 Approved Manufacturers of Iron Castings: As at 06 November 2012Document36 pagesList 5 Approved Manufacturers of Iron Castings: As at 06 November 2012wyvren88No ratings yet

- Gas Turbine ManufacturersDocument5 pagesGas Turbine ManufacturersManikandan SenthilNo ratings yet

- HardwareDocument152 pagesHardwarepolicia101No ratings yet

- TopSteelmakers2013 PDFDocument32 pagesTopSteelmakers2013 PDFgobe86No ratings yet

- Steel Directory 2018Document84 pagesSteel Directory 2018Nisarg ShahNo ratings yet

- Company contact details and product informationDocument5 pagesCompany contact details and product informationMuralidhara PrasadNo ratings yet

- Heavy Duty Conveyor Pulley Catalog PDFDocument84 pagesHeavy Duty Conveyor Pulley Catalog PDFJoel MooreNo ratings yet

- Injection MouldingDocument16 pagesInjection Mouldingramesh.rao3192No ratings yet

- ST Dimen Prop 2007Document118 pagesST Dimen Prop 2007b_wooNo ratings yet

- SteelforgecatalogDocument38 pagesSteelforgecatalogStephen MaxeyNo ratings yet

- Excel Series - Radial Ball BearingsDocument4 pagesExcel Series - Radial Ball BearingspibearingNo ratings yet

- 21Document72 pages21James CapplemanNo ratings yet

- List of Stainless Steel Development AssociationsDocument5 pagesList of Stainless Steel Development AssociationszuudeeNo ratings yet

- Encon Industrial Price List 2013Document84 pagesEncon Industrial Price List 2013Ferdie BautistaNo ratings yet

- PF 320 FS 2100N 4x00DN PL UKDocument9 pagesPF 320 FS 2100N 4x00DN PL UKChad HicksNo ratings yet

- English)Document193 pagesEnglish)vladijaraNo ratings yet

- AustraliaDocument18 pagesAustraliaNikunj SatraNo ratings yet

- Metallic: TIGER DrylacDocument8 pagesMetallic: TIGER DrylacAmin ThabetNo ratings yet

- Exibitor List - As of 28nov08Document6 pagesExibitor List - As of 28nov08Soldier MayNo ratings yet

- Catalogo Sanvik 2008 Suppl - 081 (Completo)Document213 pagesCatalogo Sanvik 2008 Suppl - 081 (Completo)Michelle CordovaNo ratings yet

- Gen IvarDocument6 pagesGen IvarahmkriponNo ratings yet

- Pacific Steel Locations GuideDocument70 pagesPacific Steel Locations Guidekimyt250651No ratings yet

- KANDLAUNITSDocument18 pagesKANDLAUNITSAshwani Verma100% (1)

- Welding ConsumablesDocument5 pagesWelding ConsumablesSwetang RathodNo ratings yet

- Inconel - Alloy 330 - UNS N08330Document8 pagesInconel - Alloy 330 - UNS N08330Javeed A. KhanNo ratings yet

- Heating RotiDocument5 pagesHeating RotiSwetang RathodNo ratings yet

- Underwater Welding Electrodes GuideDocument26 pagesUnderwater Welding Electrodes GuideMirnes HodzićNo ratings yet

- CanadaDocument45 pagesCanadaRishabh GoyalNo ratings yet

- Grafitos ShunkDocument5 pagesGrafitos ShunkBruno Golem Azuara100% (2)

- ADIDAS Service Centers March 2014Document7 pagesADIDAS Service Centers March 2014Charles GarrettNo ratings yet

- Cases on the Enforcement of Construction Adjudication AwardsFrom EverandCases on the Enforcement of Construction Adjudication AwardsNo ratings yet

- The Blacksmith's Craft - An Introduction To Smithing For Apprentices And CraftsmenFrom EverandThe Blacksmith's Craft - An Introduction To Smithing For Apprentices And CraftsmenNo ratings yet

- Alumina to Zirconia: The History of the CSIRO Division of Mineral ChemistryFrom EverandAlumina to Zirconia: The History of the CSIRO Division of Mineral ChemistryRating: 1 out of 5 stars1/5 (1)

- TODAY Tourism & Business Magazine, Volume 22, December, 2015From EverandTODAY Tourism & Business Magazine, Volume 22, December, 2015No ratings yet

- Die Casting Metallurgy: Butterworths Monographs in MaterialsFrom EverandDie Casting Metallurgy: Butterworths Monographs in MaterialsRating: 3.5 out of 5 stars3.5/5 (2)

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Wrought Ironwork - A Manual of Instruction for Rural CraftsmenFrom EverandWrought Ironwork - A Manual of Instruction for Rural CraftsmenRating: 5 out of 5 stars5/5 (1)

- Basic Thermodynamic CyclesDocument4 pagesBasic Thermodynamic Cyclesapi-3830954No ratings yet

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocument4 pagesA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16No ratings yet

- AmmA - 2015 Abstract TemplateDocument1 pageAmmA - 2015 Abstract TemplateAnishNairNo ratings yet

- 2011 JournalDocument6 pages2011 JournalAnishNairNo ratings yet

- PVC Drainage Pipe & FittingsDocument19 pagesPVC Drainage Pipe & FittingsKenneth MooreNo ratings yet

- Control Joint Waterstop Installation GuideDocument1 pageControl Joint Waterstop Installation GuideED WARMONDNo ratings yet

- Fischer Catalogue INT en Complete 088220Document562 pagesFischer Catalogue INT en Complete 088220smasNo ratings yet

- Civil V Structural Analysis II (10cv53) NotesDocument90 pagesCivil V Structural Analysis II (10cv53) NotesGagan NagpalNo ratings yet

- EN SFV 128 TotDocument59 pagesEN SFV 128 TotsrinivasNo ratings yet

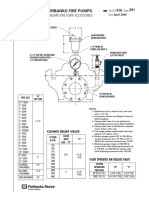

- Ds FlowserveDocument5 pagesDs FlowservejmeleNo ratings yet

- 2386 7 1963 Reff2021Document32 pages2386 7 1963 Reff2021Raghav TiwaryNo ratings yet

- The Fire Resistant Solution For Steel Conduit: Cable DescriptionDocument10 pagesThe Fire Resistant Solution For Steel Conduit: Cable DescriptionBhagoo HatheyNo ratings yet

- GREE CATALOGO Cac 2011Document162 pagesGREE CATALOGO Cac 2011lasNo ratings yet

- Tower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsDocument1 pageTower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsKenan AvdusinovicNo ratings yet

- SOPs To Work Maunal 2019 20 March 2019 PDFDocument274 pagesSOPs To Work Maunal 2019 20 March 2019 PDFAbhishek Choudhary100% (5)

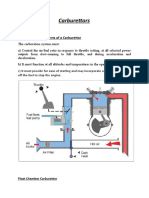

- CarburettorsDocument12 pagesCarburettorsrohitNo ratings yet

- 2034 Kshirsagar Kunal (Cafeteria)Document32 pages2034 Kshirsagar Kunal (Cafeteria)RISHABH JAISWAL0% (1)

- Imw 50 Single Con CabinaDocument1 pageImw 50 Single Con CabinaIgnacio LopezNo ratings yet

- Data Center Projects: Establishing A Floor Plan: White Paper 144Document21 pagesData Center Projects: Establishing A Floor Plan: White Paper 144Abrham GidayNo ratings yet

- Thesis On Construction Technology and Management PDFDocument8 pagesThesis On Construction Technology and Management PDFpsmxiiikdNo ratings yet

- Water and Waste Systems OverviewDocument18 pagesWater and Waste Systems OverviewJOSUÉ CABRERANo ratings yet

- Tubulacao Dimensioes Globais Valvulas e ConexoesDocument3 pagesTubulacao Dimensioes Globais Valvulas e ConexoesDouglas Fernandes Dos SantosNo ratings yet

- Hvac Duct Static Pressure CalculationDocument9 pagesHvac Duct Static Pressure CalculationSharifur RehmanNo ratings yet

- Masterseal 621 TdsDocument2 pagesMasterseal 621 TdsJulesNo ratings yet

- The New Age of Engineering and Construction Technology PDFDocument13 pagesThe New Age of Engineering and Construction Technology PDFLIEGENo ratings yet

- Astm F2620Document22 pagesAstm F2620Ricardo Peralta100% (1)

- Aksesoris PumpDocument10 pagesAksesoris PumpDido AlexanNo ratings yet

- Pump SCE B 2Document8 pagesPump SCE B 2Zankar R ParikhNo ratings yet

- Petronas Technical Standards: Passive Fire and Cryogenic Protection For Structural SteelDocument27 pagesPetronas Technical Standards: Passive Fire and Cryogenic Protection For Structural SteelvinothNo ratings yet

- Adts 2732005Document2 pagesAdts 2732005Tejas PatilNo ratings yet

- EN ASME RuryDocument3 pagesEN ASME RuryGentelmanOnlyNo ratings yet

- Reinforced Concrete: Introduction To The CourseDocument11 pagesReinforced Concrete: Introduction To The CourseChristian James MontebonNo ratings yet

- Calculation of Septic Tank & Sock PitDocument11 pagesCalculation of Septic Tank & Sock Pitakram1978No ratings yet

- J4011 - PNEUMATIC & HYDRAULIC (Hydraulic Basic)Document43 pagesJ4011 - PNEUMATIC & HYDRAULIC (Hydraulic Basic)Boy LiverpoolNo ratings yet