Professional Documents

Culture Documents

2 Fashion Designer PDF

Uploaded by

raiyanduOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 Fashion Designer PDF

Uploaded by

raiyanduCopyright:

Available Formats

FASHION DESIGNER

SYLLABUS/ CURRICULUM

This program is aimed at training candidates for the job of Fashion Designer, in the Apparel made

ups and home furnishings Sector/ industry (mention name of sector/industry) and by the end of the

program aims at building the following key competencies amongst the learner:

1. Prepare and make a design

collection

3. Evaluate the design development

process

2. Prepare prototype garments for the

collection

4. Maintain work area & tools

5.Maintain health, safety and security at

workplace

This course encompasses 5 out of 5 NOS of Fashion Designer- AMH/ Q1201, Qualification Pack issued

by Apparel Sector Skill Council of India.

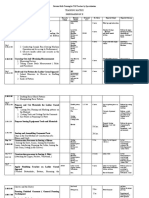

S.No

Module/Topic

Prepare to make

a design

collection

Key Learning

Outcomes

Performance criteria

The learners will be able to :

Research on fashion trends and identify the

emerging theme

Product range and previous designs developed by

the business are reviewed to assess relevance to

current design.

Business processes and client goals are identified.

Research is conducted on target market,

materials, designs, processes and marketing

materials according to the needs of the design

Quality standards for designs are identified.

Design themes and style requirements of

design are determined

Budget, cost points and timing constraints are

identified.

Knowledge & understanding

Organizational Context

The learners will be able to apply knowledge of:

NOS

Code

AMH/N 1201

Prepare

prototype

garments for the

collection

Your organizations policies, procedures,

guidelines and standards for dealing with

buyers/clients

Recognizing and adapting to cultural differences

in the workplace , including modes

of behaviour and interactions

Production capacity and processes of business

are identified.

Identifying improvements.

Completing work systematically with attention to

detail without damage to goods and equipment

Technical knowledge

The learners will be able to apply technical

knowledge of:

Garment construction techniques and processes.

To do the design by hand sketches or by

Computer Aided Design (CAD)

Detailed knowledge of a range of fabrics and

trims

An understanding on the cost process involved in

making an apparel

Costing of created designs / product ensembles

with knowledge of sale ability of a product

designed

Knowledge of Intellectual Property Rights with

respect to designs

Performance criteria

The learners will be able to :

Create techpack which clearly conveys all

guidelines for development of the sample

Appropriate personnel are consulted with to

confirm feasibility and appropriateness of

techpack

Sketches, drawings and samples are used to

Development of sample is monitored to ensure

budget and time constraints

are met

Problems or inconsistencies in sample are

identified and addressed.

AMH/N1202

Evaluate the prototype sample received.

Knowledge & understanding

Organizational Context

The learners will be able to apply knowledge

The organizations policies and procedures

Protocol to obtain more information on work

related tasks

The limits of your role and responsibilities in

relation to IT service requests/incidents

Who to refer problems to when they are outside

the limit of your authority

Your organizations equipments, templates and

processes for preparing the

techpack and how to use these

Details of the job role and responsibilities

Your organizations knowledge base and how to

use and update this

Method of obtaining/ giving feedback related to

performance

Technical knowledge

The learners will be able to apply technical

knowledge of:

Knowledge of fabrics/apparels and garments and

types of fabrics/apparel that require stitching by

hand or machine stitching

Knowledge on Sewing and Pattern making

techniques to make techpack

o Techpacks are made for the range

collection

o Use of CAD or hand sketches

o Feasibility and appropriateness of

o techpack consulted and confirmed

o Techpack finalised internally

Elements of and principles of design and how

they are used to create good design in the

fashion industry

Expertise of personnel

Knowledge on quality and workplace practices

Required involvement of sampling merchandiser,

patternmaker and sampling tailor identified

Evaluate

Design

Development

Processes

Identified personnel for prototype sample

development briefed

Performance criteria

The learners will be able to ::

Analyze the prototype sample along with the

design team

Coordinate along with design team to check

sample against the techpack given to the

sampling merchandiser, the look and feel and fit

of the sample

Identify the prototype for the feasibility of the

garment in terms of sourcing of the fabric and

the trims available for the span of production

Identify various product testing to proceed with

prototype

Incorporate modification of the sample until

approved for final production

Get approval on the prototype/final techpack,

agreement finalized with the client

Document Design brief, development processes

and outcomes

Complete Documentation processes, including

filing and storing

Knowledge and understanding

Organizational Context

The learners will be able to apply knowledge

Your organizations policies, procedures and

priorities for your area of work and your role and

responsibilities in carrying out your work

Limits of your responsibilities when coordinating

with other department

Your specific work requirements and who these

must be agreed with

The importance of having a tidy work area and

how to do this

How to prioritize your workload according to

urgency and importance and the benefits of this

AMH/N1203

Your organizations policies and procedures for

dealing with confidential information and the

importance of complying with these

The purpose of keeping others updated with the

progress of your work

Who to obtain guidance from and the typical

circumstances when this may be required

The purpose and value of being flexible and

adapting work plans to reflect change

Technical knowledge

The learners will be able to apply technical knowledge

The importance of understanding of the

development process

Appropriate timescales for completing your work

and the implications of not meeting these for you

and the organization

Ability to strengthen teams awareness

Awareness to reduce development and company

cost

Resources needed for your work and how to

obtain and use these

4.

Maintain Work

Area, Tools and

Machines

Performance criteria

The learners will be able to :

Handle materials, drawing and pattern drafting

tools, equipment and the system for computer

designing with care

Use correct handling procedures.

Use materials to minimize waste

Use of measuring devices effectively

Maintain tools and equipment

Carry out running maintenance within agreed

schedules

Carry out maintenance and/or cleaning within

ones responsibility

Report unsafe equipment and other dangerous

occurrences

Work in a comfortable position with the correct

posture

Use cleaning equipment and methods

AMH/N1204

appropriate for the work to be carried out

Dispose of waste safely in the designated location

Carry out cleaning according to schedules and

limits of responsibility

Request for up gradation of system or softwares

when required for effective working

Always a backup file to be maintained when

working on various design softwares

All soft copies of design work to be maintained in

files as well for future reference

Knowledge and understanding

Organizational ontext

The learners will be able to apply knowledge of:

Personal hygiene and duty of care

Safe working practices and organizational

procedures

Limits of your own responsibility

Ways of resolving with problems within the work

area

The production process and the specific work

activities that relate to the whole Process

5.

Maintain health,

safety and

security at

workplace

PERFORMANCE CRITERIA

The learners will be able to :

Comply with health and safety related

instructions applicable to the workplace

Use and maintain personal protective equipment

as per protocol

Carryout own activities in line with approved

guidelines and procedures

Maintain a healthy lifestyle and guard against

dependency on intoxicants

Follow environment management system related

procedures

Identify and correct(if possible) malfunctions in

machinery and equipment

Report any service malfunctions that cannot be

AMH/N1205

rectified

Store materials and equipment in line with

manufacturers and organizational requirements

Safely handle and move waste and debris

Minimize health and safety risks to self and

others due to own actions

Seek clarifications, from supervisors or other

authorized personnel in case of perceived risks

Monitor the workplace and work processes for

potential risks and threats

Carry out periodic walk-through to keep work

area free from hazards and obstructions, if

assigned

Report hazards and potential risks/ threats to

supervisors or other authorized personnel

Participate in mock drills/ evacuation procedures

organized at the workplace

Undertake first aid ,fire fighting and emergency

response training ,if asked to do so

Take action based on instructions in the event of

fire, emergencies or accidents

Follow organisation procedures for shutdown

and evacuation when required

Knowledge and understanding

Organizational context

The learners will be able to apply knowledge of:

Health and safety related practices applicable at

the workplace

Potential hazards, risks and threats based on

nature of operations

Organizational procedures for safe handling of

tools

Potential risks due to own actions and methods

to minimize these

Environmental management system related

procedures at the workplace

Layout of the plant and details of emergency

exits, escape routes, emergency equipment and

assembly points

Potential accidents and emergencies and

response to these scenarios

Reporting protocol and documentation required

Details of personnel trained in first aid, firefighting and emergency response

Actions to take in the event of a mock drills/

evacuation procedures or actual accident,

emergency or fire

TECHNICAL KNOWLEDGE

The learners will be able to apply technical knowledge

of:

Occupational health and safety risks and

methods

Personal protective equipment and method of

use

Identification, handling and storage of hazardous

substances

Proper disposal system for waste and byproducts

Signage related to health and safety and their

meaning

Importance of sound health, hygiene and good

habits

Ill-effects of alcohol, tobacco and drugs

You might also like

- TR - Fashion Design (Apparel) NC IIIDocument71 pagesTR - Fashion Design (Apparel) NC IIIJMiguel Abueg100% (2)

- Three Steps of PressingDocument4 pagesThree Steps of PressingELAD27- GAMINGNo ratings yet

- Grade 8 TLE Module on Dressmaking and TailoringDocument44 pagesGrade 8 TLE Module on Dressmaking and TailoringJoan Jambalos Tuerto100% (1)

- Module For Dress Making ExploratoryDocument1,781 pagesModule For Dress Making Exploratory202350154No ratings yet

- Fashion Design Technology CTSDocument13 pagesFashion Design Technology CTSiqbal1439988No ratings yet

- Drafting The Back and Front Skirt Basic PatternDocument1 pageDrafting The Back and Front Skirt Basic PatternMargie Ballesteros ManzanoNo ratings yet

- Educ-321 PPT (Seesion Plan)Document19 pagesEduc-321 PPT (Seesion Plan)Dave Vertucio OfficialNo ratings yet

- Binding options for unique vestsDocument3 pagesBinding options for unique vestsmaggiehsuehNo ratings yet

- Cad Assig (Tuka) 1 AnanyaDocument66 pagesCad Assig (Tuka) 1 AnanyaAnanya KarnNo ratings yet

- Introduction to Fashion and Global TextilesDocument45 pagesIntroduction to Fashion and Global TextilesHarsh AwanaNo ratings yet

- TleDocument7 pagesTleJeh-u Bayani100% (1)

- Garment Pressing GuideDocument16 pagesGarment Pressing GuideMd. Asiqul AlamNo ratings yet

- Draft Ladies Trousers PatternDocument5 pagesDraft Ladies Trousers PatternlhenNo ratings yet

- Sewing Tools and Sewing Machine Operations: NtroductionDocument29 pagesSewing Tools and Sewing Machine Operations: Ntroductiongeorge odoyoNo ratings yet

- Pre TestDocument13 pagesPre TestVince AzaresNo ratings yet

- Art of Fashion Draping Techniques & Tools ExplainedDocument3 pagesArt of Fashion Draping Techniques & Tools ExplainednovertaNo ratings yet

- Las-Draft Basicblock PatternDocument14 pagesLas-Draft Basicblock PatternGwy Hipolito100% (1)

- Taking Body MeasurementDocument3 pagesTaking Body MeasurementHarrycel Rycel Chesry PalganNo ratings yet

- Draft basic skirt patternDocument18 pagesDraft basic skirt patternJanine Hope VinsonNo ratings yet

- Clothing ConstructionDocument1 pageClothing ConstructionJoseph Fayomi0% (1)

- Classroom and Lab Area - Job Roles WiseDocument115 pagesClassroom and Lab Area - Job Roles Wiseneedurheed90No ratings yet

- PowerPoint Presentation - Sewing ToolsDocument48 pagesPowerPoint Presentation - Sewing ToolsSherile Ann Tapalla100% (2)

- Lesson 1.types of Necklines and Facing PDFDocument8 pagesLesson 1.types of Necklines and Facing PDFJuliana PalomaNo ratings yet

- Neck: Instructions - Women's Body MeasurementsDocument4 pagesNeck: Instructions - Women's Body MeasurementsSitti SaymaNo ratings yet

- Lesson Plan - Sewing A HemDocument3 pagesLesson Plan - Sewing A Hemapi-366587339No ratings yet

- Recommendation For ImprovementDocument3 pagesRecommendation For ImprovementAmmLawlier100% (1)

- LO1 - Pattern DraftingDocument5 pagesLO1 - Pattern DraftingcharmaineNo ratings yet

- Skirt VariationsDocument31 pagesSkirt VariationsARYAN RATHORENo ratings yet

- Parts of Body To Be Measured Can BeDocument16 pagesParts of Body To Be Measured Can BeSantillan PrincessNo ratings yet

- Family and Consumer Management: Body MeasurementDocument21 pagesFamily and Consumer Management: Body MeasurementDeidre Donaldson100% (1)

- Traditional Lesson PlanDocument3 pagesTraditional Lesson PlanMerr FloranoNo ratings yet

- TLE 10 Q1 Week1 3 TLE HEDM9 12SK Ia C 1 Tangonan Corazon Darrel TangonanDocument52 pagesTLE 10 Q1 Week1 3 TLE HEDM9 12SK Ia C 1 Tangonan Corazon Darrel TangonanJoey BalicaoNo ratings yet

- Laffzlh - 1589236092.tailoringDocument582 pagesLaffzlh - 1589236092.tailoringAdriana Raquel Raquel Lopez Bard100% (2)

- Welt Pocket Sewing InstructionsDocument19 pagesWelt Pocket Sewing InstructionsanewnothingNo ratings yet

- Tape MeasureDocument11 pagesTape MeasureSBME Computershop100% (1)

- K To 12 Dressmaking and Tailoring Learning ModulesDocument21 pagesK To 12 Dressmaking and Tailoring Learning ModulesMicah Maulit RamosNo ratings yet

- Footwear Technology GuideDocument20 pagesFootwear Technology GuideumidgrtNo ratings yet

- Functional ClothingDocument5 pagesFunctional ClothingravikantNo ratings yet

- Dressmaking 9: Project Plan For Sleeping GarmentsDocument4 pagesDressmaking 9: Project Plan For Sleeping GarmentsMeriam AmoraNo ratings yet

- Std12 Voc TDD emDocument239 pagesStd12 Voc TDD emreemmerNo ratings yet

- Safety in The Sewing LabDocument10 pagesSafety in The Sewing LabmrForestbellNo ratings yet

- Clothing Textiles and Fashion 10-30-2000Document75 pagesClothing Textiles and Fashion 10-30-2000morshed_mahamud7055100% (1)

- Fabric Design TechniquesDocument28 pagesFabric Design TechniquesMae-maeGarmaNo ratings yet

- Dressmaking Three Day Skill TrainingDocument58 pagesDressmaking Three Day Skill TrainingANTONIA NABISES MANCILITANo ratings yet

- Fastener Lesson PlanDocument3 pagesFastener Lesson Planapi-352669853100% (1)

- Competency Based Curriculum for Dress MakingDocument44 pagesCompetency Based Curriculum for Dress MakingGhouseNo ratings yet

- Dressmaking TrainingDocument3 pagesDressmaking TrainingLawson SohNo ratings yet

- Lesson 11 Placket and OpeningDocument11 pagesLesson 11 Placket and OpeningEmerson John Rosete100% (2)

- Simple Seam Finishes Guide Under 40 CharactersDocument2 pagesSimple Seam Finishes Guide Under 40 CharactersAbdul Azis100% (1)

- The History of The Sewing MachineDocument4 pagesThe History of The Sewing MachineNe CKa0% (1)

- Principles of Design for ClothingDocument30 pagesPrinciples of Design for ClothingSharlyn GalonoNo ratings yet

- Manipulating Basic PatternsDocument12 pagesManipulating Basic PatternsJhon Dhael MontanoNo ratings yet

- Principleof DesignDocument31 pagesPrincipleof DesignJay CastNo ratings yet

- Dressmaking 11 LO 2.3Document20 pagesDressmaking 11 LO 2.3Wendy ArnidoNo ratings yet

- QuizDocument2 pagesQuizKirbyCrozzle PablitoNo ratings yet

- LAS Grade 10 DressmakingDocument16 pagesLAS Grade 10 DressmakingRoberto MabulacNo ratings yet

- Carr and Latham's Technology of Clothing ManufactureFrom EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerRating: 4 out of 5 stars4/5 (1)

- 3 Advance Pattern Maker PDFDocument6 pages3 Advance Pattern Maker PDFraiyanduNo ratings yet

- Maintain Production EfficiencyDocument4 pagesMaintain Production EfficiencyFaizan ArshadNo ratings yet

- Apply Quality StandardDocument24 pagesApply Quality StandardAbubeker AbduNo ratings yet

- Walton Digitech Industries LTDDocument4 pagesWalton Digitech Industries LTDraiyanduNo ratings yet

- GH8 Closing Report 1st Lot 8k: SL Item Name Item CodeDocument8 pagesGH8 Closing Report 1st Lot 8k: SL Item Name Item CodeMohammad KamruzzamanNo ratings yet

- Gauge Dash Boar Final V 1Document27 pagesGauge Dash Boar Final V 1raiyanduNo ratings yet

- E SchoolDocument12 pagesE SchoolMahalakshmi ParthasarathyNo ratings yet

- Gar 3Document15 pagesGar 3raiyanduNo ratings yet

- Gar 4Document24 pagesGar 4raiyanduNo ratings yet

- Textiles and Garment Production GuideDocument29 pagesTextiles and Garment Production Guidezeeshan_220No ratings yet

- Gar 2Document31 pagesGar 2Nit VictorNo ratings yet

- Quality - SWOT AnalysisDocument2 pagesQuality - SWOT AnalysisraiyanduNo ratings yet

- 7949 37085 3 PBDocument11 pages7949 37085 3 PBAman ChaudharyNo ratings yet

- School Management SystemDocument7 pagesSchool Management SystemNelson DevasagayamNo ratings yet

- SWOT Analysis: StrengthDocument2 pagesSWOT Analysis: StrengthraiyanduNo ratings yet

- Chapter03 PDFDocument3 pagesChapter03 PDFraiyanduNo ratings yet

- Edur1001eb Eduswift School Management SystemDocument11 pagesEdur1001eb Eduswift School Management Systemdg_samrat6595No ratings yet

- SWOT Analysis Course - 3hrs .3CEUDocument2 pagesSWOT Analysis Course - 3hrs .3CEUraiyanduNo ratings yet

- Executive Director and Manager Strengths and WeaknessesDocument4 pagesExecutive Director and Manager Strengths and WeaknessesraiyanduNo ratings yet

- 7009 20565 1 PB PDFDocument9 pages7009 20565 1 PB PDFraiyanduNo ratings yet

- Yousef Almulla: This Is A Complete Research On Effective Communication With More Emphasis On WorkplaceDocument109 pagesYousef Almulla: This Is A Complete Research On Effective Communication With More Emphasis On WorkplaceraiyanduNo ratings yet

- Setting The Buyer in Motion Ho PDFDocument11 pagesSetting The Buyer in Motion Ho PDFraiyanduNo ratings yet

- Ie 27Document7 pagesIe 27raiyanduNo ratings yet

- Leanprogramme 160704100830 PDFDocument61 pagesLeanprogramme 160704100830 PDFraiyanduNo ratings yet

- 5.isca RJMS 2013 041 PDFDocument5 pages5.isca RJMS 2013 041 PDFraiyanduNo ratings yet

- 3 2Document31 pages3 2huongthuy1811No ratings yet

- Ie 27Document7 pagesIe 27raiyanduNo ratings yet

- Itil Problem Management Process Poster Series Part 1Document1 pageItil Problem Management Process Poster Series Part 1raiyanduNo ratings yet

- 02 Whole PDFDocument385 pages02 Whole PDFraiyanduNo ratings yet

- Researchpaper/design and Implementation of Cellular Manufacturing in A Sewing Floor PDFDocument16 pagesResearchpaper/design and Implementation of Cellular Manufacturing in A Sewing Floor PDFraiyanduNo ratings yet

- 20167246Document10 pages20167246raiyanduNo ratings yet

- Pos022 Itil Poster 9 PDFDocument1 pagePos022 Itil Poster 9 PDFraiyanduNo ratings yet

- Of The: Clear View Waste-LineDocument3 pagesOf The: Clear View Waste-LineraiyanduNo ratings yet

- BB Genuine Engine Oil 15W-40Document10 pagesBB Genuine Engine Oil 15W-40Santosh WamaneNo ratings yet

- The Project Report Entitle A Study On Employee's Absenteeism Is Intended To Determine TheDocument85 pagesThe Project Report Entitle A Study On Employee's Absenteeism Is Intended To Determine TheMOHAMMED KHAYYUMNo ratings yet

- Risk Assessment Determining Control: Prosedur Hazard Identification, (Hiradc)Document4 pagesRisk Assessment Determining Control: Prosedur Hazard Identification, (Hiradc)Muhammad Naim Abd Wahab100% (1)

- What Is Organizing ?Document28 pagesWhat Is Organizing ?Sarahjane TerradoNo ratings yet

- Telekom Zadovoljstvo Final Version After Language Editing For PublishingDocument31 pagesTelekom Zadovoljstvo Final Version After Language Editing For PublishingSara PancicNo ratings yet

- HAZRECDocument18 pagesHAZRECArshath FleminNo ratings yet

- A Critical Review of Shipbreaking Literature Reveals Shortcomings in Dimensions Considered For SustainabilityDocument32 pagesA Critical Review of Shipbreaking Literature Reveals Shortcomings in Dimensions Considered For SustainabilityptkfernandesNo ratings yet

- Checklist, Annual Inspection GuideDocument3 pagesChecklist, Annual Inspection GuideKasimiro BukayoNo ratings yet

- Manual Task/Handling: Yoursafety@Irp - Toolbox DiscussionDocument1 pageManual Task/Handling: Yoursafety@Irp - Toolbox DiscussionRoman StreliaievNo ratings yet

- Geismar Tensor Hidráulico TH 120 SVL Manual e Certificado CEDocument55 pagesGeismar Tensor Hidráulico TH 120 SVL Manual e Certificado CEAndre Filipe0% (1)

- Coke Msds (Opal)Document6 pagesCoke Msds (Opal)Viral PatelNo ratings yet

- Organizational Structure Within The Act 514Document2 pagesOrganizational Structure Within The Act 514Khairun Najibah Mohd SaidNo ratings yet

- D-1964 InkDocument8 pagesD-1964 InkYotselys LópezNo ratings yet

- Indg290 - A Simple Guide To LOLERDocument8 pagesIndg290 - A Simple Guide To LOLERDarko ZovkoNo ratings yet

- Construction Safety Plan GuideDocument13 pagesConstruction Safety Plan Guideemmanueloboh92% (24)

- Msds L-Ascorbic Acid 500gDocument6 pagesMsds L-Ascorbic Acid 500gsy strongNo ratings yet

- Method Statement - Asphalt Road Rectification Completion Rev. 1Document7 pagesMethod Statement - Asphalt Road Rectification Completion Rev. 1anon_759550912No ratings yet

- WSHGuidelines Safe Use of Lorry CraneDocument38 pagesWSHGuidelines Safe Use of Lorry CraneSaravanaah VJNo ratings yet

- Chapter 3Document124 pagesChapter 3dhindsa096No ratings yet

- Safety Science Methodology Improves Construction SafetyDocument7 pagesSafety Science Methodology Improves Construction SafetyMelekot MengistuNo ratings yet

- Xylene 28975Document14 pagesXylene 28975cv k3 tulus karena vulusNo ratings yet

- 06LOLERCompetentPersonCompAssessment Rev0 Amend1Document17 pages06LOLERCompetentPersonCompAssessment Rev0 Amend1Ronny AndalasNo ratings yet

- Computer Programming GuideDocument12 pagesComputer Programming GuideRhayan Dela Cruz DaquizNo ratings yet

- Antiscalant MSDS GuideDocument2 pagesAntiscalant MSDS GuideKumbang KambingNo ratings yet

- Chemical Management PlanDocument6 pagesChemical Management Planjulieta budionganNo ratings yet

- Official Business Studies p1 Eng Memo Final-09 September 2023Document28 pagesOfficial Business Studies p1 Eng Memo Final-09 September 2023owethumatsebulaNo ratings yet

- Safety RecordDocument1 pageSafety RecordSani Adipura WinataNo ratings yet

- DW Module 1Document11 pagesDW Module 1Khiyal HussainNo ratings yet

- Health & Safety Lectures: Risk AssessmentDocument25 pagesHealth & Safety Lectures: Risk Assessmenteladio30No ratings yet

- GL-T11R Im 96M12530 GB WW 1076-2Document8 pagesGL-T11R Im 96M12530 GB WW 1076-2Alec DyerNo ratings yet