Professional Documents

Culture Documents

Trim Number Chart API Valve

Uploaded by

René Galbraith BerraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trim Number Chart API Valve

Uploaded by

René Galbraith BerraCopyright:

Available Formats

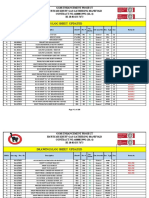

API 600 TRIM NUMBER CHART

STANDARD TRIM CONFIGURATIONS

The following table details standard trim materials available. Special trims are available upon request.

API Trim

Nominal Trim

Trim code

Stem & other trim parts

Disc/Wedge

Number

Seat surface

Trim Material Grade

Old BS

Designation

Service

For oil and oil vapors and general services with heat treated seats and wedges.

General very low erosive or non-corrosive service between -100C and 320C. This

stainless steel material lends itself readily to hardening by heat treatment and is

excellent for contacting parts such as stems, gates, and discs. Steam, gas &

general service to 370C. Oil & Oil vapor 480C.

410

F6

410 (13Cr) (200-275 HBN)

F6 (13Cr) (200 HBN)

410 (13Cr) (250 HBN min)

13Cr-0.75Ni-1Mn

Cr13

304

304

304

304 (18Cr-8Ni)

304 (18Cr-8Ni)

19Cr-9.5Ni-2Mn-0.08C

18-8 Ti

For moderate pressure in corrosive, low erosive service between -265C and

450C.

310

310

(25Cr-20Ni)

310 (25Cr-20Ni)

310 (25Cr-20Ni)

25Cr-20.5Ni-2Mn

25-20

For moderate pressure in corrosive or non corrosive service between -265C and

450C.

410 - Hard

F6H

410 (13Cr) (200-275 HBN)

F6 (13Cr) (200-275 HBN)

F6 (13Cr) (275 HBN min)

13Cr-0.75Ni-1Mn

HF

Seats 275 BHN min. As trim 1 but for medium pressure and more corrosive

service.

410 - Full Hard faced

410+St Gr6 (CoCr Alloy) (350 HBN min)

13Cr-0.5Ni-1Mn/Co-Cr-A

HF

High pressure slightly erosive and corrosive service between -265C and 650C

and higher pressure. Premium trim service to 650C. Excellent for high pressure

water and steam service.

5a

410 - Full Hard faced

HF

As trim 5 where Co is not allowed.

410 and Ni-Cu

F6HFS

410 (13Cr) (200-275 HBN) Monel 400 (NiCu Alloy) (250 HBN min)

410 - Very Hard

F6HF+

410 (13Cr) (200-275 HBN)

410 - Hard faced

F6HFS

8a

410 - Hard faced

Monel

10

316

F6HF

F6HF

410 (13Cr) (200-275 HBN) F6+St Gr6 (CoCr Alloy) (350 HBN min)

410 (13Cr) (200-275 HBN)

F6+Hardf. NiCr Alloy (350 HBN min)

410+Hardf. NiCr Alloy (350 HBN min)

13Cr-0.5Ni-1Mn/Co-Cr-A

Monel 400 (NiCu Alloy) (175 HBN min)

13Cr-0.5Ni-1Mn/Ni-Cu

F6 (13Cr) (250 HBN min)

F6 (13Cr) (750 HB)

13Cr-0.5Ni-1Mo/13Cr-0.5Ni-Mo

410 (13Cr) (200-275 HBN)

410 (13Cr) (250 HBN min)

410+St Gr6 (CoCr Alloy) (350 HBN min)

13Cr-0.75Ni-1Mn/1/2Co-Cr-A

Cr + HF

Universal trim for general service requiring long service life up to 593C. As trim 5

for moderate pressure and more corrosive service. Steam, gas & general service

to 540C. Standard trim for gate valves.

F6HFS

410 (13Cr) (200-275 HBN)

F6 (13Cr) (250 HBN min)

410+Hardf. NiCr Alloy (350 HBN min)

13Cr-0.75Ni-1Mn/1/2Co-Cr-A

Cr + HF

As trim 5a for moderate pressure and more corrosive service.

Monel

Monel (NiCu Alloy)

Monel 400 (NiCu Alloy)

Monel 400 (NiCu Alloy)

70Ni-30Cu

Ni-Cu

316

316 (18Cr-Ni-Mo)

316 (18Cr-Ni-Mo)

316 (18Cr-Ni-Mo)

18Cr-12Ni-2.5Mo-2Mn

18/10/2002

Cr and Cu-Ni As trim 1 and more corrosive service.

750 BHN min. As trim 1 but for higher pressure and more corrosive/erosive

Cr and Cu-Ni Seats

service.

For corrosive service to 450C such as acids, alkalies, salt solutions, etc. Very

corrosive fluids.

Erosive-corrosive service between -240C and 480C. Resistant to sea water,

acids, alkalies. Has excellent corrosion resistance in chlorine and alkylation

service.

For superior resistance to corrosion for liquids and gases which are corrosive to

410 stainless steel up to 455C. As trim 2 but a higher level of corrosive service.

Provides excellent resistance to corrosive media at high temperatures and

toughness for service at low temperatures. Low temperature service standard for

316SS valves.

11

Monel - Hard faced

MonelHFS

Monel (NiCu Alloy)

Monel 400 (NiCu Alloy)

Monel 400+St Gr6 (350 HBN min)

70Ni-30Cu/1/2Co-Cr-A

HF-Ni

As trim 9 but for medium pressure and more corrosive service.

11a

Monel - Hard faced

MonelHFS

Monel (NiCu Alloy)

Monel 400 (NiCu Alloy)

Monel 400+HF NiCr Alloy (350 HBN min)

70Ni-30Cu/1/2Co-Cr-A

HF-Ni

As trim 9 but for medium pressure and more corrosive service.

12

316 - Hard faced

316HFS

316 (Cr-Ni-Mo)

316 (18Cr-8Ni-Mo)

316+St Gr6 (350 HBN min)

18Cr-12Ni-2.5Mo-2Mn1/2Co-Cr-A

As trim 10 but for medium pressure and more corrosive service.

12a

316 - Hard faced

316HFS

316 (Cr-Ni-Mo)

316 (18Cr-8Ni-Mo)

316 Hardf. NiCr Alloy (350 HBN min)

18Cr-12Ni-2.5Mo-2Mn1/2Co-Cr-A

As trim 10 but for medium pressure and more corrosive service.

13

Alloy 20

Alloy 20

Alloy 20 (19Cr-29Ni)

Alloy 20 (19Cr-29Ni)

Alloy 20 (19Cr-29Ni)

29Ni-19Cr-2.5Mo-0.07C

Very corrosive service. For moderate pressure between -45C and 320C.

14

Alloy 20 - Hard faced

Alloy 20HFS

Alloy 20 (19Cr-29Ni)

Alloy 20 (19Cr-29Ni)

Alloy 20 St Gr6 (350 HBN min)

29Ni-19Cr-2.5Mo-0.07C/1/2Co-Cr-A

As trim 13 but for medium pressure and more corrosive service.

14a

Alloy 20 - Hard faced

Alloy 20HFS

Alloy 20 (19Cr-29Ni)

Alloy 20 (19Cr-29Ni)

Alloy 20 Hardf. NiCr Alloy (350 HBN min)

29Ni-19Cr-2.5Mo-0.07C/1/2Co-Cr-A

As trim 13 but for medium pressure and more corrosive service.

15

304 - Full Hard faced

304HS

304 (18Cr-8Ni-Mo)

304St Gr6

304+St Gr6 (350 HBN min)

19Cr-9.5Ni-2Mn-0.08C/1/2Co-Cr-A

As trim 2 but more erosive service & higher pressure.

16

316 - Full Hard faced

316HF

316 HF (18Cr-8Ni-Mo)

316+St Gr6 (320 HBN min)

316+St Gr6 (350 HBN min)

18Cr-12Ni-2.5Mo-2Mn/Co-Cr-Mo

As trim 10 but more erosive service & higher pressure.

17

347 - Full Hard faced

347HF

347 HF (18Cr-10Ni-Cb)

347+St Gr6 (350 HBN min)

347+St Gr6 (350 HBN min)

18Cr-10Ni-Cb/Co-Cr-A

18-8 Nb

18

Alloy 20 HF

Alloy 20 (19Cr-29Ni)

Alloy 20+St Gr6 (350 HBN min)

Alloy 20+St Gr6 (350 HBN min)

19 Cr-29Ni/Co-Cr-A

As trim 13 but more corrosive service & higher pressure. Combines good corrosion

resistance with high temperature resistance up to 800C.

As trim 13 but more corrosive service & higher pressure. Water, gas or low

pressure steam to 230C.

Special

Alloy 20 - Full Hard

faced

Bronze

Bronze

410 (CR13)

Bronze

Bronze

Water, oil, gas, or low pressure steam to 232C.

Special

Alloy 625

Alloy 625

Alloy 625

Alloy 625

Alloy 625

NACE

Specially treated 316 or 410 trim combined with B7M bolts and 2HM nuts to meet NACE MR-01-75 requirements.

Full Stellite Full Hardfaced trim, suitable for abrasive & severe services up to 1200F (650C).

Important Note: Data provided in this chart is for informational purposes only. Always consult current API publications to verify information and trim date. Australian Pipeline Valve recommend that customers engineers analyse service requirements and specify the materials they consider optimum

for their service conditions. Temperatures shown will vary depending on service applications, pressure and media type.

~ Short lead time valve manufacturer ~

If you find this website information useful tell your Plant Manager and Procurement Manager about us!

www.australianpipelinevalve.com.au

70-78 Stanbel Road Salisbury Plain, South Australia 5109 Telephone +61 (0)8 8285 0033 Fax +61 (0)8 8285 0044 admin@australianpipelinevalve.com.au

TRIM MATERIAL EQUIVALENT GRADES

TRIM

UNS

TYPE

GRADE (forged)

ASTM (wrought)

DIN

DIN W No.

F6

UNS S41000

13Cr

ASTM A182 F6a

A4276-410

DIN X12Cr13

1.4006

304

UNS S30400

18-8 Cr-Ni

ASTM A182 F304

A276-304

DIN X5CrNi 18 10

1.4301

316

UNS S31600

18-8 Cr-Ni (18-10-2)

ASTM A182 F316

A276-316

DIN X5CrNiMo 18 10

1.4401

321

UNS S32100

18 Cr-10 Ni-Ti

ASTM A182 F321

A276-321

DIN X6CrNiTi 18 10

1.4541

347

UNS S34700

18 Cr-10 Ni-Cb

ASTM A182 F347

A276-347

DIN X6CrNiNb 18 10

1.455

MONEL

UNS N04400

67Ni-30Cu

ASTM B564-N04400

B164-N04400

DIN 17743

2.436

ALLOY 20

UNS N08020

28Ni-19Cr-Cu-Mo

ASTM A182-F20*

ASTM B473

DIN 14500

2.466

ALLOY 625

UNS N06625

60Ni-22Cr-9Mo-3.5Cb

ASTM B564-N06625

ASTM B564-N06625

DIN 17361

2.4865

C276

UNS N10276

54Ni-15Cr-16Mo

ASTM B564-N10276

ASTM B574-N10276

DIN NiMo 16 Cr 15 W

2.4819

17/4PH

UNS S17400

0C417Ni4Cu4Nb

ASTM A4750 UNS S17400

ASTM A4705 UNS S17400

X5CrNiCuNb17-4-4

1.4548

St. Gr6

UNS R30006

Co Cr-A

AMS 5894

Stellite Gr6

* No longer listed in ASME B16.34 - 2009.

For technical references and ASTM/ASME cross reference information on stainless, duplex, chrome-moly and alloy steel used in valves & piping systems in the petrochemical and refining go to

our website: www.australianpipelinevalve.com.au.

We can manufacture exotic grades like Nickel, Super Duplex F55 (6A/CD3MWCuN), F51 (4A/CD3MN), Monel (ASTM A494-M35-1), Hastealloy C (ASTM A-494 C12MW), F317 (CG8M), etc., in

short lead-time.

Copyright Australian Pipeline Valve 2013

API 600 Trim Number Chart R8 - AS

www.australianpipelinevalve.com.au

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- CAT CSV 09 18aDocument28 pagesCAT CSV 09 18aMiyka'el PaunNo ratings yet

- 180 19 Seat Selection PDFDocument4 pages180 19 Seat Selection PDFmoorthymech1979No ratings yet

- List4 PDFDocument29 pagesList4 PDFmoorthymech1979No ratings yet

- Valve Material EquivalentsDocument3 pagesValve Material EquivalentsAndre Villegas Romero100% (1)

- Fugative EmmissionDocument35 pagesFugative EmmissionAhmed MansourNo ratings yet

- The Benefits of Using Die-Formed Packing Rings and Sets: by Ralf Vogel, ESA MemberDocument2 pagesThe Benefits of Using Die-Formed Packing Rings and Sets: by Ralf Vogel, ESA Membermoorthymech1979No ratings yet

- Fugative EmmissionDocument35 pagesFugative EmmissionAhmed MansourNo ratings yet

- Valve MaintenanceDocument6 pagesValve Maintenancemoorthymech1979No ratings yet

- Flare System PDFDocument41 pagesFlare System PDFAzar Deen100% (1)

- GRP Installation GuideDocument13 pagesGRP Installation GuidepparreraNo ratings yet

- Ductile Iron Versus Steel PDFDocument1 pageDuctile Iron Versus Steel PDFmoorthymech1979No ratings yet

- 20140331WFIProduct-BRANCH FITTINGS PDFDocument20 pages20140331WFIProduct-BRANCH FITTINGS PDFmoorthymech1979No ratings yet

- Designing Steam Pressure Reducing StationsDocument7 pagesDesigning Steam Pressure Reducing StationsMohammed Hassan B KorainaNo ratings yet

- Geothermal Pipe Line DesignDocument15 pagesGeothermal Pipe Line DesignjohnjuantamadNo ratings yet

- Aço Sa 537 cl1Document23 pagesAço Sa 537 cl1pcorreia68100% (1)

- C1 ENGINEERING PRINCIPLES AND PRACTICES for Retrofitting Flood-Prone HomesDocument37 pagesC1 ENGINEERING PRINCIPLES AND PRACTICES for Retrofitting Flood-Prone HomesAnonymous mcHqIfbnV1No ratings yet

- Hdpe DimensionDocument2 pagesHdpe Dimensionmoorthymech1979No ratings yet

- Butterfly Valve PDFDocument2 pagesButterfly Valve PDFmoorthymech1979No ratings yet

- Designing Steam Pressure Reducing StationsDocument7 pagesDesigning Steam Pressure Reducing StationsMohammed Hassan B KorainaNo ratings yet

- Geosynthetics Guide to Original FRANK Puddle FlangesDocument16 pagesGeosynthetics Guide to Original FRANK Puddle FlangesDuzzysNo ratings yet

- 04 Gander Corrosion Control Liza BallantyneDocument27 pages04 Gander Corrosion Control Liza Ballantynemoorthymech1979No ratings yet

- C1 ENGINEERING PRINCIPLES AND PRACTICES for Retrofitting Flood-Prone HomesDocument37 pagesC1 ENGINEERING PRINCIPLES AND PRACTICES for Retrofitting Flood-Prone HomesAnonymous mcHqIfbnV1No ratings yet

- Non-Asbestos Gasket: Catalogue No. Zy03Document24 pagesNon-Asbestos Gasket: Catalogue No. Zy03Wh NgNo ratings yet

- KTR Kat99pp01 Coupling GuardDocument20 pagesKTR Kat99pp01 Coupling Guardmoorthymech1979100% (1)

- 04 Gander Corrosion Control Liza BallantyneDocument27 pages04 Gander Corrosion Control Liza Ballantynemoorthymech1979No ratings yet

- 04 Gander Corrosion Control Liza Ballantyne PDFDocument69 pages04 Gander Corrosion Control Liza Ballantyne PDFmoorthymech1979No ratings yet

- Hdpe DimensionDocument2 pagesHdpe Dimensionmoorthymech1979No ratings yet

- Aço Sa 537 cl1Document23 pagesAço Sa 537 cl1pcorreia68100% (1)

- Valve Material EquivalentsDocument3 pagesValve Material EquivalentsAndre Villegas Romero100% (1)

- Thermoplastic Valves PDFDocument8 pagesThermoplastic Valves PDFmoorthymech1979No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Kiwiprop K4 Boss Assembly v2.4Document15 pagesKiwiprop K4 Boss Assembly v2.4adul sungkatinNo ratings yet

- Tube Cutter: MS-TC-308Document1 pageTube Cutter: MS-TC-308Claudio SavazziNo ratings yet

- GGM Enhancement Project Drawings Log Sheet UpdatedDocument198 pagesGGM Enhancement Project Drawings Log Sheet UpdatedJohn BuntalesNo ratings yet

- How Cathay Pacific Leveraged IT to Support Business GrowthDocument2 pagesHow Cathay Pacific Leveraged IT to Support Business Growthranjeeeth8569100% (1)

- Cylinders FullDocument110 pagesCylinders FulltnvishNo ratings yet

- Presentation ON Rural Marketing Mix: Presented By: Aradhana Bhopte Ravneet KaurDocument23 pagesPresentation ON Rural Marketing Mix: Presented By: Aradhana Bhopte Ravneet KaurRavneet Kaur100% (1)

- Drilling PDFDocument32 pagesDrilling PDFاحمد عمر حديدNo ratings yet

- Esfigmomanômetro Aneróide Manual - WelchAllyn (Manual de Serviço) PDFDocument67 pagesEsfigmomanômetro Aneróide Manual - WelchAllyn (Manual de Serviço) PDFBrunoNo ratings yet

- METHOD STATEMENT PRESSURE SWITCH UAE Univ.Document2 pagesMETHOD STATEMENT PRESSURE SWITCH UAE Univ.Muhamed RasheedNo ratings yet

- SKF SM 20 - CSTR SpecificationDocument3 pagesSKF SM 20 - CSTR SpecificationPaweł HejmowskiNo ratings yet

- Quotations FormatDocument3 pagesQuotations FormatRakeshNo ratings yet

- Airbus Vs BoeingDocument8 pagesAirbus Vs BoeingPrajwal Rajiv ShettyNo ratings yet

- Metering For Linemen: Current TransformersDocument3 pagesMetering For Linemen: Current TransformersEBENo ratings yet

- Inventor ReportDocument7 pagesInventor Report2cekal50% (2)

- Maruti SuzukiDocument33 pagesMaruti SuzukiNaman Arya100% (4)

- An Integrated Lean Approach To Process Failure ModDocument12 pagesAn Integrated Lean Approach To Process Failure ModLeoo Cotrina FranciaNo ratings yet

- DESIGN AND FABRICATION OF WIRE ROPE MAKING MACHINE Ijariie12690Document5 pagesDESIGN AND FABRICATION OF WIRE ROPE MAKING MACHINE Ijariie12690Tanishq ShettyNo ratings yet

- Tesla v. Xpeng's Cao ComplaintDocument14 pagesTesla v. Xpeng's Cao ComplaintmashablescribdNo ratings yet

- Dockomo Heavy Machinery EquipmentDocument11 pagesDockomo Heavy Machinery Equipmentchokx0080% (2)

- Module 7 (Maintenance Practices) Sub Module 7.1 (Safety Precautions-Aircraft and Workshop) PDFDocument42 pagesModule 7 (Maintenance Practices) Sub Module 7.1 (Safety Precautions-Aircraft and Workshop) PDFshareyhou100% (1)

- Engineering Economics Chapter 2 & 3Document14 pagesEngineering Economics Chapter 2 & 3byun baekNo ratings yet

- Electronic Government - Concepts, Tools, Methodologies, and Applications - Introductory ChapterDocument35 pagesElectronic Government - Concepts, Tools, Methodologies, and Applications - Introductory ChapterСтаменић МаринаNo ratings yet

- SCHLENKER Katalog 2022 EN - WEBDocument136 pagesSCHLENKER Katalog 2022 EN - WEBhosseinNo ratings yet

- FSC-Interpretations-Chain of Custody-2016-11-11 PDFDocument32 pagesFSC-Interpretations-Chain of Custody-2016-11-11 PDFRazvan IonescuNo ratings yet

- Building EstimateDocument16 pagesBuilding EstimateMrinal TalukdarNo ratings yet

- Tower Signal BoqDocument2 pagesTower Signal Boqrafael velardeNo ratings yet

- E PKS: Control Builder Parameter ReferenceDocument3,341 pagesE PKS: Control Builder Parameter ReferenceAnkoosh MandanNo ratings yet

- DOE-0359 Hanford Site Electrical Safety ProgramDocument59 pagesDOE-0359 Hanford Site Electrical Safety Programandresboy123No ratings yet

- 1 - SAP BPC NW 10.0 Script Logic Implementation Guide V18Document84 pages1 - SAP BPC NW 10.0 Script Logic Implementation Guide V18Angel Ammulu100% (1)