Professional Documents

Culture Documents

ACH-remove Airbone Contaminan PDF

Uploaded by

Faizal AchmadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACH-remove Airbone Contaminan PDF

Uploaded by

Faizal AchmadCopyright:

Available Formats

72

MMWR

October 28, 1994

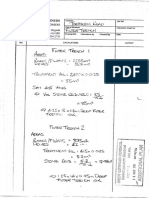

TABLE S3-1. Air changes per hour (ACH) and time in minutes required for removal

efficiencies of 90%, 99%, and 99.9% of airborne contaminants*

Minutes required for a removal efficiency of:

ACH

90%

99%

99.9%

1

2

3

4

5

138

69

46

35

28

276

138

92

69

55

414

207

138

104

83

6

7

8

9

10

23

20

17

15

14

46

39

35

31

28

69

59

52

46

41

11

12

13

14

15

13

12

11

10

9

25

23

21

20

18

38

35

32

30

28

16

17

18

19

20

9

8

8

7

7

17

16

15

15

14

26

24

23

22

21

25

30

35

40

45

50

6

5

4

3

3

3

11

9

8

7

6

6

17

14

12

10

9

8

*This table has been adapted from the formula for the rate of purging airborne contaminants

(99 ). Values have been derived from the formula t1 = [In (C2 C1) (Q V)] 60, with T1 = 0

and C2 C1 (removal efficiency 100), and where:

t1

C1

C2

Q

V

QV

=

=

=

=

=

=

initial timepoint

initial concentration of contaminant

final concentration of contaminants

air flow rate (cubic feet per hour)

room volume (cubic feet)

ACH

The times given assume perfect mixing of the air within the space (i.e., mixing factor = 1).

However, perfect mixing usually does not occur, and the mixing factor could be as high as 10

if air distribution is very poor (98 ). The required time is derived by multiplying the appropriate

time from the table by the mixing factor that has been determined for the booth or room. The

factor and required time should be included in the operating instructions provided by the

manufacturer of the booth or enclosure, and these instructions should be followed.

You might also like

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Numerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityFrom EverandNumerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityNo ratings yet

- Air Changes Per Hour (ACH) and Time in Minutes Required For RemovalDocument1 pageAir Changes Per Hour (ACH) and Time in Minutes Required For RemovalalbrgmailNo ratings yet

- 5 Centrifugal CompressorsDocument48 pages5 Centrifugal CompressorsWeins GemerlapNo ratings yet

- Air _ Appendix _ Environmental Guidelines _ Guidelines Library _ Infection Control _ CDCDocument14 pagesAir _ Appendix _ Environmental Guidelines _ Guidelines Library _ Infection Control _ CDCSergio Motta GarciaNo ratings yet

- Step and RP EditedDocument12 pagesStep and RP EditedTezza Keizel FutalanNo ratings yet

- AKM Metallurgical BalancesDocument38 pagesAKM Metallurgical BalancesPrakshal GangwalNo ratings yet

- CL 333 Chemical Engineering Lab-2 (2019) : Experiment Number FM 302 TitleDocument31 pagesCL 333 Chemical Engineering Lab-2 (2019) : Experiment Number FM 302 TitleAkshat PunekarNo ratings yet

- Feed composition screening calculations g=9.81m/s2 do=4.5mm dp=9mmDocument4 pagesFeed composition screening calculations g=9.81m/s2 do=4.5mm dp=9mmPrashant DasNo ratings yet

- Design of Cooling TowerDocument17 pagesDesign of Cooling TowerMohan VarkeyNo ratings yet

- Appendix B. Air: Infection ControlDocument15 pagesAppendix B. Air: Infection ControlNMP Kumar UNo ratings yet

- Air91co24 2Document11 pagesAir91co24 2gsv988No ratings yet

- Bosch HFM5 SensorsDocument2 pagesBosch HFM5 Sensorsrestinho100% (1)

- Correlation Between Entry Velocity, Pressure Drop and Collection Efficiency in A Designed Stairmands CycloneDocument7 pagesCorrelation Between Entry Velocity, Pressure Drop and Collection Efficiency in A Designed Stairmands CycloneAJER JOURNALNo ratings yet

- Classes and Comparisons Between CompressorsDocument48 pagesClasses and Comparisons Between CompressorsVijay MeenaNo ratings yet

- McCabe-Thiele Method ExplainedDocument1 pageMcCabe-Thiele Method ExplainedRamazan TosunNo ratings yet

- Process Dynamics and Control SolutionsDocument15 pagesProcess Dynamics and Control Solutionsciotti620940% (5)

- Hydrological Analysis Part OfreportDocument7 pagesHydrological Analysis Part OfreportSakar ShresthaNo ratings yet

- Heat Transfer through a Glass WindowDocument4 pagesHeat Transfer through a Glass WindowAlexander Yauri Gomez50% (2)

- Tehno A4Document4 pagesTehno A4calinNo ratings yet

- Analisa Peralatan Mekanis GMS PasuruanDocument13 pagesAnalisa Peralatan Mekanis GMS PasuruanBang RegarNo ratings yet

- UAE University College of Engineering Training and Graduation Project UnitDocument100 pagesUAE University College of Engineering Training and Graduation Project UnitPortia ShilengeNo ratings yet

- CdA CalculatorDocument8 pagesCdA CalculatorSyahrizal NPNo ratings yet

- Moc of Air and NitrogenDocument4 pagesMoc of Air and NitrogenlogicvirusNo ratings yet

- CO O N CO O: Calculation of Heater Efficiency: Laboratory Analysis of Gas SampleDocument2 pagesCO O N CO O: Calculation of Heater Efficiency: Laboratory Analysis of Gas SamplerawadNo ratings yet

- Potencia especifica v/s Presion de salidaDocument2 pagesPotencia especifica v/s Presion de salidaMaritza PomaNo ratings yet

- Chapter 9 Natural Convection 9-32 A Fluid Flows Through A Pipe in Calm Ambient Air. The Pipe Is Heated Electrically. The Thickness of TheDocument23 pagesChapter 9 Natural Convection 9-32 A Fluid Flows Through A Pipe in Calm Ambient Air. The Pipe Is Heated Electrically. The Thickness of TheKerem GönceNo ratings yet

- FinalDocument3 pagesFinalMiko Ong TanNo ratings yet

- Jabatan Kejuruteraan Loji dan Automotif Fakulti Kejuruteraan Mekanikal dan Pembuatan Universiti Tun Hussein Onn MalaysiaDocument9 pagesJabatan Kejuruteraan Loji dan Automotif Fakulti Kejuruteraan Mekanikal dan Pembuatan Universiti Tun Hussein Onn MalaysiawanpudinNo ratings yet

- Heat Chap07 099Document10 pagesHeat Chap07 099Kerem GönceNo ratings yet

- DR Quek Time Area KL - MSMA2Document5 pagesDR Quek Time Area KL - MSMA2Wan MahiramNo ratings yet

- LAB 1 ICON SimulatonDocument13 pagesLAB 1 ICON SimulatonnursyakirahrahimNo ratings yet

- Basic Pneumatic SystemDocument95 pagesBasic Pneumatic SystemRoyal Ritesh SharmaNo ratings yet

- Accumulator Sizing DataDocument6 pagesAccumulator Sizing DataSubham GhantaNo ratings yet

- Rotary Dryer Design for Dicalcium Phosphate ProductionDocument10 pagesRotary Dryer Design for Dicalcium Phosphate ProductionNess Sanchez87% (15)

- SOLUTIONS FOR TUTORIAL - 4 (September 13,2012) : CN S PDocument7 pagesSOLUTIONS FOR TUTORIAL - 4 (September 13,2012) : CN S PRahulRandyNo ratings yet

- Aircraft PropulsionDocument23 pagesAircraft Propulsionmentalxfiction100% (2)

- Nilai OptimumDocument10 pagesNilai OptimumAgista KarmeliaNo ratings yet

- Tutorial 6 - Solution Mixtures Winardi Sani : CO N 2 O 2Document13 pagesTutorial 6 - Solution Mixtures Winardi Sani : CO N 2 O 2wanpudinNo ratings yet

- Tutorial 4 - Solution 4.2-4.7Document2 pagesTutorial 4 - Solution 4.2-4.7ngoc.nguyennhuNo ratings yet

- Cat C280-12 Spec SheetsDocument16 pagesCat C280-12 Spec SheetsThan Htet100% (1)

- E1 - Head Losses in Pipes: Middle East Technical University Department of Civil EngineeringDocument5 pagesE1 - Head Losses in Pipes: Middle East Technical University Department of Civil EngineeringOnur SolmazNo ratings yet

- Air Cooled Heat Exchanger Preliminary SelectionDocument4 pagesAir Cooled Heat Exchanger Preliminary SelectionAA GGNo ratings yet

- Section26 14Document11 pagesSection26 14nervthcNo ratings yet

- Q C Q C: 6.3.2 Effect of Filter Efficiency On The Airborne Microbial Concentration in Non-Unidirectional CleanroomsDocument5 pagesQ C Q C: 6.3.2 Effect of Filter Efficiency On The Airborne Microbial Concentration in Non-Unidirectional CleanroomsThisIs MyCatNo ratings yet

- Tugas 3Document13 pagesTugas 3Arif Kurnia IhsanudinNo ratings yet

- Final Report 7Document8 pagesFinal Report 7Ahmad SalehiNo ratings yet

- Dear Capital Gas Egypt: Yours Sincerely ..Document11 pagesDear Capital Gas Egypt: Yours Sincerely ..Omar WardehNo ratings yet

- Tut-7-Quality Management-SolutionDocument3 pagesTut-7-Quality Management-Solutionantarctica809No ratings yet

- Irrigation ExamDocument19 pagesIrrigation ExamZerihun IbrahimNo ratings yet

- UTM Flow Measurement Lab Report AnalysisDocument20 pagesUTM Flow Measurement Lab Report AnalysisKhairil IkramNo ratings yet

- South Africa Algo Used For Pavement TemperatureDocument10 pagesSouth Africa Algo Used For Pavement TemperatureVivek KumarNo ratings yet

- Concentration Changes in A CSTR (Continuous Stirred Tank Reactor)Document10 pagesConcentration Changes in A CSTR (Continuous Stirred Tank Reactor)pekanselandarNo ratings yet

- Paper 4 - Energy Auditor - Set B Key: General InstructionsDocument12 pagesPaper 4 - Energy Auditor - Set B Key: General InstructionsRichard RegidorNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Drake Low Temp ChillersDocument4 pagesDrake Low Temp ChillersFaizal AchmadNo ratings yet

- Engine HP and Exhaust FlowDocument2 pagesEngine HP and Exhaust FlowFaizal AchmadNo ratings yet

- Terminal Unit Sys - Danger of Oversizing Heating CoilsDocument3 pagesTerminal Unit Sys - Danger of Oversizing Heating CoilsmajortayNo ratings yet

- RINNAI Infinity Oporation ManualDocument40 pagesRINNAI Infinity Oporation ManualFaizal AchmadNo ratings yet

- 16.10 Energy Conservation Aspects in Compressed Air System Rev-0Document8 pages16.10 Energy Conservation Aspects in Compressed Air System Rev-0Faizal AchmadNo ratings yet

- BS Standards for Offshore StructuresDocument4 pagesBS Standards for Offshore StructuresFaizal AchmadNo ratings yet

- 16.8 Valves and Acessories Rev-0Document6 pages16.8 Valves and Acessories Rev-0Faizal AchmadNo ratings yet

- Engine Exhaust Flow Rate CalculationDocument8 pagesEngine Exhaust Flow Rate CalculationMani Kumar50% (2)

- 16.9 Compressor Air Dryer Rev-0Document9 pages16.9 Compressor Air Dryer Rev-0Faizal AchmadNo ratings yet

- 16.3 Compressed Air Demand Rev-0Document4 pages16.3 Compressed Air Demand Rev-0Faizal AchmadNo ratings yet

- Natural Gas Installation Standards PDFDocument80 pagesNatural Gas Installation Standards PDFFaizal AchmadNo ratings yet

- Swimming Pool Design-A PDFDocument135 pagesSwimming Pool Design-A PDFFaizal Achmad100% (1)

- Civil Road PDFDocument9 pagesCivil Road PDFFaizal AchmadNo ratings yet

- 5 Mining Sector and Air Pollution PDFDocument33 pages5 Mining Sector and Air Pollution PDFFaizal AchmadNo ratings yet

- Supp Notes HospitalsDocument38 pagesSupp Notes HospitalsFaizal AchmadNo ratings yet

- Space Design Load Summary for Packaged Rooftop AHUDocument3 pagesSpace Design Load Summary for Packaged Rooftop AHUFaizal AchmadNo ratings yet

- One Minute ManagerDocument13 pagesOne Minute Managerapi-3825047100% (1)

- Xs Absolute: Setting The Standard For HEPA Filters For Over 40 YearsDocument2 pagesXs Absolute: Setting The Standard For HEPA Filters For Over 40 YearsFaizal AchmadNo ratings yet

- One Minute ManagerDocument13 pagesOne Minute Managerapi-3825047100% (1)

- Cleanrooms, Laboratories and Specialist HVAC Design and Build SolutionsDocument12 pagesCleanrooms, Laboratories and Specialist HVAC Design and Build SolutionsFaizal AchmadNo ratings yet

- Civil RoadDocument9 pagesCivil RoadFaizal AchmadNo ratings yet

- Viking Release - K17 ESFRDocument1 pageViking Release - K17 ESFRFaizal AchmadNo ratings yet

- VRV Single Outdoor Part 1Document226 pagesVRV Single Outdoor Part 1Faizal AchmadNo ratings yet

- Using Lysaght Roofing Walling 26 Aug 08Document70 pagesUsing Lysaght Roofing Walling 26 Aug 08Faizal AchmadNo ratings yet

- BS Standards for Offshore StructuresDocument4 pagesBS Standards for Offshore StructuresFaizal AchmadNo ratings yet

- Shell BoilersDocument7 pagesShell BoilersFaizal AchmadNo ratings yet

- Federal Cleanroom StandardsDocument6 pagesFederal Cleanroom StandardsmarkNo ratings yet

- 5 Mining Sector and Air Pollution PDFDocument33 pages5 Mining Sector and Air Pollution PDFFaizal AchmadNo ratings yet

- HVAC Design for Cleanroom Facilities CourseDocument55 pagesHVAC Design for Cleanroom Facilities CourseMadhu Gajulapalli100% (1)

- Miscellaneous Boiler Types, Economisers and SuperheatersDocument3 pagesMiscellaneous Boiler Types, Economisers and SuperheatersFaizal AchmadNo ratings yet