Professional Documents

Culture Documents

Chapter 6 PDF

Uploaded by

Santosh IyerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 6 PDF

Uploaded by

Santosh IyerCopyright:

Available Formats

15

CAMTECH/E/2002/AT/1.

CHAPTER 6

CAUSES OF FAILURES AND THEIR REMEDIES

6.1

CAUSES OF FAILURES

In most of the cases the causes of fault can be found by careful observation of the

condition of the windings, e.g. displacement of the turns or coils, coil insulation (brittle

or healthy), evidence of overheating, carbon deposit or flash marks on the core, supports,

the inner surface of the tank or cover. The following notes may be of help in identifying

the cause.

6.2

FAILURE DUE TO LIGHTENING DISCHARGE OR OVER VOLTAGE

This is characteristised by breakdown of the end turns close to the line terminal.

There may be a break in the turns or end lead, and also flash marks on the end coil and

earthed parts close to it, but the rest of the coils will found to be healthy.

6.3

SUSTAINED OVERLOADS

The windings in one or all phase would show signs of overheating and charring;

the insulation would be very brittle and would have lost all its elasticity.

6.4

INTER TURN SHORT, INTER LAYER SHORT, OR INTER COILS SHORT

The same signs as indicated for sustained over load would

be noticed, but only on affected coils, the rest of the coils being

intact.

FIGURE 6.1

INTER - TURN SHORT

CKT OF WINDING

6.5

DEAD SHORT - CIRCUIT

This can be identified by the unmistakable, lateral or axial

displacement of the coils. They may be loose on the core, some

turns on the outermost layer may have burst outwards and broken as

if under tension. If, in addition to these signs, the windings are also

completely charred, it is conclusive evidence that the short circuit

has continued for an appreciable period.

6.6

IF THE OIL SHOWS A LOW BDV

It does not necessarily mean that it has caused the breakdown. At high voltage

ratings, excessive moisture content in the oil may result flashover between the live parts

and earth.

Maintenance Handbook on Auxiliary Transformer

February, 2002

16

CAMTECH/E/2002/AT/1.

6.7

SUGGESTIONS TO AVOID FAILURE

1.

Artisans for maintenance should be well-versed with Aux. transformer and with

proper tools.

2.

Standard materials to be used for maintenance and repair.

3.

To avoid failure due to electricution of bird, primary bushing arching horn gap

should be in two halves.

Proper rating of fuses are to be used on primary and secondary side.

4.

5.

Any type of oil leakage to be attended as early as possible. Oil level on

conservator tank to be checked monthly and to be topped up with same oil if

required.

6.

Breather to be checked thoroughly.

7.

If BDV of oil is less than 30 KV, oil should be filtered by centrifusing plant of

proper size. If colour of oil is not clear then oil should be changed with new oil

(IS:335)

8.

All terminal and earth connection should be properly tightened.

9.

10.

IR value to be checked every three month and comparative record to be

maintained.

Check earth pit resistance in summer season

11.

Motorised Meggers should be used to measure IR values.

12.

Silicagel breather should have capacity of 250 gms at least.

13.

Conservator oil indicator glass should be clear and made of better transparent

sheet.

14.

Complete oil of AT should be changed by fresh oil during POH. Also change all

gaskets.

*****

GO TO CONTENTS

Maintenance Handbook on Auxiliary Transformer

February, 2002

You might also like

- The Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingFrom EverandThe Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingNo ratings yet

- Service Bulletin: - Revision Notice - Added T65 Product To Table1 and 6V - 12V Battery Operating Permission To Table 3Document8 pagesService Bulletin: - Revision Notice - Added T65 Product To Table1 and 6V - 12V Battery Operating Permission To Table 3GutsavoNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Importance of Maintaining Valve RecordsDocument5 pagesImportance of Maintaining Valve Recordsmuthu kujmarNo ratings yet

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Practical Contracts For UTDocument5 pagesPractical Contracts For UTMahade Hasan DipuNo ratings yet

- Rolls Battery ManualDocument42 pagesRolls Battery ManualAVteck AvteckNo ratings yet

- 30 Volt 100 Ah Lead Acid BatteryDocument12 pages30 Volt 100 Ah Lead Acid BatterySandip AhireNo ratings yet

- Bowman Installation and Maintenance HydraulicsDocument10 pagesBowman Installation and Maintenance HydraulicsAshish YadavNo ratings yet

- Mazda m4-121g EngineDocument31 pagesMazda m4-121g EngineKevine Khaled89% (9)

- Marine Fuel Oil, Its Iso Standard, Analysis and Corrective ActionDocument151 pagesMarine Fuel Oil, Its Iso Standard, Analysis and Corrective ActionMariyath Muraleedharan KiranNo ratings yet

- Monarch Repair ManualDocument21 pagesMonarch Repair ManualZeck0% (1)

- Kaukan Oil Cooler Instruction HandbookDocument14 pagesKaukan Oil Cooler Instruction HandbooksunhuynhNo ratings yet

- Rolls Battery ManualDocument46 pagesRolls Battery ManualJosé Alejandro VargasNo ratings yet

- IRS S 88-93 - For Low Maintenance Lead Acid Stationary Sec CeDocument10 pagesIRS S 88-93 - For Low Maintenance Lead Acid Stationary Sec CeVikas Srivastav100% (1)

- RTA-09 Cylinder Covers With Erosion and Corrosion Resistant CladdersDocument5 pagesRTA-09 Cylinder Covers With Erosion and Corrosion Resistant CladdersCatalin CataNo ratings yet

- Plante BatteriesDocument16 pagesPlante Batteriessureshnfcl0% (1)

- The Truth About Batteries-White PaperDocument13 pagesThe Truth About Batteries-White PaperRahul ShelkeNo ratings yet

- 2602-0018 Aviation CMM - Hawker VRLA (Rev 5)Document19 pages2602-0018 Aviation CMM - Hawker VRLA (Rev 5)VMNo ratings yet

- Procedure of Maintenance of DG SETDocument8 pagesProcedure of Maintenance of DG SETVatsavai Appala Narasimha RajuNo ratings yet

- Technical Information BS 6290 PDFDocument23 pagesTechnical Information BS 6290 PDFVinh TrươngNo ratings yet

- LAC English PDFDocument30 pagesLAC English PDFArumugam RajendranNo ratings yet

- Opamp Basic KnowledgeDocument30 pagesOpamp Basic KnowledgeTanmay HazraNo ratings yet

- Troubleshooting & Maintenance Piston-Type Hydraulic AccumulatorsDocument4 pagesTroubleshooting & Maintenance Piston-Type Hydraulic AccumulatorsqwureyquweryNo ratings yet

- Electrical Installations: The Boat Safety Scheme Essential GuideDocument18 pagesElectrical Installations: The Boat Safety Scheme Essential GuideCostin RotaruNo ratings yet

- Crane 1 2 HH400-1518-4Document244 pagesCrane 1 2 HH400-1518-4cengiz kutukcu100% (1)

- Instructions For Continued Airworthiness Maintenance Manual Supplement Concorde Valve Regulated Lead-Acid Main BatteryDocument11 pagesInstructions For Continued Airworthiness Maintenance Manual Supplement Concorde Valve Regulated Lead-Acid Main BatteryESAVENo ratings yet

- IRS S-93-96 (A) (Amd. 1)Document41 pagesIRS S-93-96 (A) (Amd. 1)vineet.navrang7882No ratings yet

- Battery User Manual: Recommended Charging, Equalization and Preventive Maintenance Procedures For Rolls BatteriesDocument72 pagesBattery User Manual: Recommended Charging, Equalization and Preventive Maintenance Procedures For Rolls Batteriesmad659No ratings yet

- KEUMDUK KDW PumpDocument17 pagesKEUMDUK KDW PumpThairanil AbduljaleelNo ratings yet

- Crane 3 GP160-0516-2Document222 pagesCrane 3 GP160-0516-2cengiz kutukcuNo ratings yet

- G700TM-Manual-1.0, 16 HP 2ndDocument20 pagesG700TM-Manual-1.0, 16 HP 2ndMohan Charanchath0% (1)

- Alfa Laval SB Carlsberg Flask Instruction Manual Ese02966enDocument18 pagesAlfa Laval SB Carlsberg Flask Instruction Manual Ese02966enpacocurroNo ratings yet

- Preliminary Progress 2Document2 pagesPreliminary Progress 2Mourad BenderradjiNo ratings yet

- O & M MANUAL - Volt AmpDocument31 pagesO & M MANUAL - Volt Amp2003vinay60% (5)

- Fixed Fuel Systems and Permanently Installed Engines: The Boat Safety Scheme Essential GuideDocument38 pagesFixed Fuel Systems and Permanently Installed Engines: The Boat Safety Scheme Essential GuideCostin RotaruNo ratings yet

- Lecture On Battery and Battery Charger at Ehv SDocument7 pagesLecture On Battery and Battery Charger at Ehv Spareshpawar.pmpNo ratings yet

- Maintenance and Charging of BatteriesDocument4 pagesMaintenance and Charging of Batteries2023seee004No ratings yet

- Transformer Manual PDFDocument31 pagesTransformer Manual PDFpitamberverma56% (16)

- Bep 2Document4 pagesBep 2RK KNo ratings yet

- MANUALrev Fviewing 1Document12 pagesMANUALrev Fviewing 1saleossNo ratings yet

- Gill Battery VRLA Service ManualDocument48 pagesGill Battery VRLA Service ManualtheoNo ratings yet

- VRLA SpecDocument41 pagesVRLA SpecsdvijayNo ratings yet

- MODELS: G 1006T/SS316: Operating Instructions, Installation & Maintenance Manual Including Spare Parts ListDocument13 pagesMODELS: G 1006T/SS316: Operating Instructions, Installation & Maintenance Manual Including Spare Parts ListjaimeNo ratings yet

- Installation Operation & Maintenance Manual For Shallow Well/ Surface / Monoblock PumpDocument16 pagesInstallation Operation & Maintenance Manual For Shallow Well/ Surface / Monoblock PumpPrashanth KumarNo ratings yet

- Chloride Brochure Plante YAP - YCP - .YHP - PDFDocument4 pagesChloride Brochure Plante YAP - YCP - .YHP - PDFsqh_uetNo ratings yet

- G554T-Manual-1.5, 10HPDocument21 pagesG554T-Manual-1.5, 10HPMohan CharanchathNo ratings yet

- TRJN0109 UsersGuide PDFDocument24 pagesTRJN0109 UsersGuide PDFBijuNo ratings yet

- Pages From Rescue Boat Engine Mercury 25Document11 pagesPages From Rescue Boat Engine Mercury 25Prajesh T VNo ratings yet

- 2B40208-2 Capacity TestDocument8 pages2B40208-2 Capacity Testameya gawadeNo ratings yet

- 100r Motor Ac Cms 100rDocument4 pages100r Motor Ac Cms 100ramariei_niculinaNo ratings yet

- Lead Acid Storage BatteryDocument9 pagesLead Acid Storage BatteryAchu DeepuNo ratings yet

- Bushings Monitoring Actis Maina Tumiatti v4 FinalDocument6 pagesBushings Monitoring Actis Maina Tumiatti v4 FinalNorbertoNo ratings yet

- General Srvice Bulletin GSB - 0417Document22 pagesGeneral Srvice Bulletin GSB - 0417Ruben CervantesNo ratings yet

- Honda EM 3500 XDocument56 pagesHonda EM 3500 XDokhtar SaidiNo ratings yet

- Buchholz Relays For Power Transformers PDFDocument4 pagesBuchholz Relays For Power Transformers PDFDiego Ruben PalavecinoNo ratings yet

- OF600 Oximiser601 InstructionsDocument52 pagesOF600 Oximiser601 InstructionsBrod ChatoNo ratings yet

- Neddeck Marine Oand MDavit SCHDocument54 pagesNeddeck Marine Oand MDavit SCHGabriel Nogueira67% (3)

- Sop Welding & Gas CuttingDocument9 pagesSop Welding & Gas CuttingvinodsnNo ratings yet

- C&D BateriasDocument45 pagesC&D BateriasAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- 542 FormationDocument1 page542 FormationSantosh IyerNo ratings yet

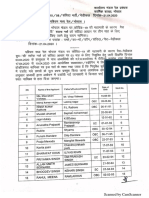

- App. Supervisor PostingDocument1 pageApp. Supervisor PostingSantosh IyerNo ratings yet

- CementDocument1 pageCementSantosh IyerNo ratings yet

- Government of India (Bharat Sarkar) Mantralaya) Board) : Ministry of Railways (RailDocument2 pagesGovernment of India (Bharat Sarkar) Mantralaya) Board) : Ministry of Railways (RailSantosh IyerNo ratings yet

- Gopal Udhyog: Plot No. 5&6, Suruchi Nagar, Bhopal (M.P) - 462003 Daily Progress Report of Foundation WorkDocument1 pageGopal Udhyog: Plot No. 5&6, Suruchi Nagar, Bhopal (M.P) - 462003 Daily Progress Report of Foundation WorkSantosh IyerNo ratings yet

- Viewnitpdf 2641980 1Document24 pagesViewnitpdf 2641980 1Santosh IyerNo ratings yet

- Model Processor RAM Storage GraphicsDocument6 pagesModel Processor RAM Storage GraphicsSantosh IyerNo ratings yet

- Model SOP 2018Document421 pagesModel SOP 2018B KRISHNA RAONo ratings yet

- Conferencing With Google MeetDocument9 pagesConferencing With Google MeetSantosh IyerNo ratings yet

- E-Mobility in Indian Railways: Railway Electrification: R K Pandey Tata Projects Limited 04th Sep'2018, New DelhiDocument16 pagesE-Mobility in Indian Railways: Railway Electrification: R K Pandey Tata Projects Limited 04th Sep'2018, New DelhiSantosh IyerNo ratings yet

- Traction Distribution Management System (TDMS) : ObjectivesDocument1 pageTraction Distribution Management System (TDMS) : ObjectivesSantosh IyerNo ratings yet

- Technical Paper - IPWE 2018 PDFDocument410 pagesTechnical Paper - IPWE 2018 PDFSantosh IyerNo ratings yet

- Earthing Practices For 25Kv/50Kv Railways - Engineering ChangeDocument8 pagesEarthing Practices For 25Kv/50Kv Railways - Engineering ChangeSantosh IyerNo ratings yet

- Form 26AS: Annual Tax Statement Under Section 203AA of The Income Tax Act, 1961Document4 pagesForm 26AS: Annual Tax Statement Under Section 203AA of The Income Tax Act, 1961Santosh IyerNo ratings yet

- 812652file1 PDFDocument3 pages812652file1 PDFSantosh IyerNo ratings yet

- KPTL Senior Engineer OHEDocument1 pageKPTL Senior Engineer OHESantosh IyerNo ratings yet

- Date Transaction Description Amount (In RS.)Document2 pagesDate Transaction Description Amount (In RS.)Santosh IyerNo ratings yet

- Core Approve List PDFDocument42 pagesCore Approve List PDFSantosh IyerNo ratings yet

- Breifcase PolicyDocument1 pageBreifcase PolicySantosh IyerNo ratings yet

- Final Handbook On OHE InspectionDocument36 pagesFinal Handbook On OHE InspectionSantosh Iyer100% (1)

- TRF - Policyunion BearerDocument14 pagesTRF - Policyunion BearerSantosh IyerNo ratings yet

- Causes and Impact of Emi in Power Systems Part 2Document46 pagesCauses and Impact of Emi in Power Systems Part 2naiad09No ratings yet

- Ch04 Bipolar Junction Transistors (BJTS) (41 PP) PDFDocument21 pagesCh04 Bipolar Junction Transistors (BJTS) (41 PP) PDFjunaidnazir100% (1)

- Annual Tower Inspection ReportDocument2 pagesAnnual Tower Inspection ReportL14R100% (1)

- W 1000064Document24 pagesW 1000064Adrian RodriguesNo ratings yet

- Step2000 Busway-Siemens PDFDocument96 pagesStep2000 Busway-Siemens PDFMokr AchourNo ratings yet

- Certificado de Calidad - Cable 8010Document2 pagesCertificado de Calidad - Cable 8010JuanNo ratings yet

- 1.1K - 3.3KTL-G3 User Manual20210519Document72 pages1.1K - 3.3KTL-G3 User Manual20210519Maureu Jefferson BenvenhoNo ratings yet

- 230VAC Air Compressor Wiring Instructions: Electrical Connections For Permanently Connected Electric CompressorsDocument2 pages230VAC Air Compressor Wiring Instructions: Electrical Connections For Permanently Connected Electric CompressorsNabeel MohammedNo ratings yet

- Electronique - Audio - Microphone Valve PreampDocument7 pagesElectronique - Audio - Microphone Valve PreampkoukihamedNo ratings yet

- DatasheetDocument13 pagesDatasheetdanielNo ratings yet

- Lec 6-7 TransformerDocument92 pagesLec 6-7 TransformerTajammul NasiriNo ratings yet

- NIC Components NRSA SeriesDocument7 pagesNIC Components NRSA SeriesNICCompNo ratings yet

- Sigma2 Alarms CompleteListDocument4 pagesSigma2 Alarms CompleteListPhạm Xuân HảiNo ratings yet

- OSI With OMM-2 Multiple Optical Probe Interface System: Data SheetDocument8 pagesOSI With OMM-2 Multiple Optical Probe Interface System: Data SheetHubert Vásquez CuevaNo ratings yet

- F411U2 2 Relay Actuator 10A: DescriptionDocument4 pagesF411U2 2 Relay Actuator 10A: DescriptionOscar Payan ViamonteNo ratings yet

- Semiconductor Interview Questions & Answers: Copper Indium Gallium SeleniumDocument2 pagesSemiconductor Interview Questions & Answers: Copper Indium Gallium SeleniumsmydyNo ratings yet

- Power System Protection: Dr. Lionel R. Orama Exclusa, PE Week 4Document12 pagesPower System Protection: Dr. Lionel R. Orama Exclusa, PE Week 4anuragpugaliaNo ratings yet

- Three Phase SystemDocument4 pagesThree Phase Systempepenapao1217No ratings yet

- ABB VFD EN - ACS320 - SFUM - A - A4 User ManualDocument44 pagesABB VFD EN - ACS320 - SFUM - A - A4 User ManualRahul GuptaNo ratings yet

- SpecificationsDocument4 pagesSpecificationsBawantha Prasad MihirangaNo ratings yet

- IE Buck Converter Application NoteDocument14 pagesIE Buck Converter Application NoteJoseph JeremyNo ratings yet

- L800/L1400/L1800/ L2400/L3000: Professional Power AmplifierDocument4 pagesL800/L1400/L1800/ L2400/L3000: Professional Power AmplifierKruno KisicNo ratings yet

- Panasonic Trouble Shooting GuideDocument27 pagesPanasonic Trouble Shooting GuideSSLBOX Event NotificationNo ratings yet

- Basic of Electrical & Electronic EngineeringDocument5 pagesBasic of Electrical & Electronic Engineeringamir11601No ratings yet

- 4-Wire FansDocument4 pages4-Wire FansPhan Anh TuanNo ratings yet

- Lab-04 DC Electronics Part 2Document8 pagesLab-04 DC Electronics Part 2pioneer boysNo ratings yet

- TC 20KL03Document26 pagesTC 20KL03davidNo ratings yet

- OSI-RS Imager Reset Station: FeaturesDocument2 pagesOSI-RS Imager Reset Station: FeaturesErick HdezNo ratings yet

- 4008a en PDFDocument45 pages4008a en PDFHamsuddin TeknikNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Electric Motor Control: DC, AC, and BLDC MotorsFrom EverandElectric Motor Control: DC, AC, and BLDC MotorsRating: 4.5 out of 5 stars4.5/5 (19)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingFrom EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingNo ratings yet

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceFrom EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceNo ratings yet

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Renewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningFrom EverandRenewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningRating: 5 out of 5 stars5/5 (4)

- Renewable Energy Finance: Theory and PracticeFrom EverandRenewable Energy Finance: Theory and PracticeRating: 4 out of 5 stars4/5 (1)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Thermal Power Plant: Design and OperationFrom EverandThermal Power Plant: Design and OperationRating: 4.5 out of 5 stars4.5/5 (23)

- Electric Motors and Drives: Fundamentals, Types and ApplicationsFrom EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsRating: 4.5 out of 5 stars4.5/5 (12)

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsFrom EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsNo ratings yet

- The Truth About Solar Panels The Book That Solar Manufacturers, Vendors, Installers And DIY Scammers Don't Want You To ReadFrom EverandThe Truth About Solar Panels The Book That Solar Manufacturers, Vendors, Installers And DIY Scammers Don't Want You To ReadRating: 4.5 out of 5 stars4.5/5 (10)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)