Professional Documents

Culture Documents

Fracture Anaysis Procedure

Uploaded by

Jimmy Nuñez VarasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fracture Anaysis Procedure

Uploaded by

Jimmy Nuñez VarasCopyright:

Available Formats

Fracture Analysis Procedure

Fracture

Analysis Job Aid

Fracture Analysis

Procedure

Identify Fractures

Brittle Fractures

Ductile Fractures

Fatigue Fractures

Initiation Sites

Stress Raisers

Load Types

These pages are intended to

be a job aid for persons who

must analyze fractures as part of

their daily activities.

These pages are structured

to help anyone learn to look at

broken parts and be able to

determine what type of fracture

took place, where the fracture

started and why it started.

It also contains some brief

knowledge checks and a glossary of

important terms.

Check Your Knowledge

Glossary

Analyzing Fracture Training

[ Close ]

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (1 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Fracture Analysis

[ home | close ]

Fracture Analysis Procedure

Obtain all the fractured parts

Identify all the fracture types and separate the brittle and ductile

fractures from the fatigue fractures

Locate the initiation site of any fatigue fractures present

Determine what stress raiser initiated the fatigue fracture and

whether it is normal or abnormal.

If crack initiated inside the part, look for abnormal stress raisers

such as material or manufacturing problems

If it started on the parts surface, look first for abnormal stress

raisers such as

Wear

Corrosion

Handling

Assembly

Manufacturing

If only normal stress raisers are present, investigate the job

site for application, operation and maintenance practices

Fracture Analysis

[ home | close ]

Identify Fractures

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (2 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Parts break three different ways: brittle fracture, ductile fracture,

and fatigue fracture.

Brittle and ductile fractures usually are the resulting fractures after

some other part has broken.

Fatigue fractures are the most interesting because they are often

closely connected to the root cause of the failure.

Each fracture has distinct characteristics that help identify which

type it is.

One main reason for identifying fracture type is to find the starting

point of the crack called the intiation site.

Initiation sites can be very important and sometimes reveal why the

crack started especially with fatigue fractures.

Initiation sites can also point to the investigation path that must be

followed to arrive at the root cause of the fracture.

Both the fracture type and initiation site location can reveal the kind

of load that caused it.

To learn more about identifying each type of fracture and

obtaining facts about it's cause, click on one of the links at left.

Fracture Analysis

[ home | close ]

Brittle Fractures

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (3 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Brittle fractures can be recognized by their rough surfaces, chevrons, gray

color, sparkles and little or no permanent change in shape called plastic

deformation (see Glossary for definition or go to Ductile Fractures for

examples). If the two parts of the fracture are held close to each other the

part looks almost like it did before breaking.

Brittle fractures are fractures that occur very rapidly with the entire part,

component or structure breaking in two in a fraction of a second to a few

seconds at most. Cracks run in the material at very high speeds of

hundreds of feet or meters per second.

Brittle fractures are usually caused by very sudden excessive loads called

shock or impact loads (see Load Types).

Most brittle fractures are results. This means they are not the cause of a

failure but are actually a result of another part or component failure.

Therefore parts having brittle fractures can be set aside in most

cases as they are not of primary interest.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (4 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Fracture Analysis

[ home | close ]

Ductile Fractures

Ductile fractures can be recognized by their rough surfaces, dark gray or

black color, shear lips and permanent change in shape called plastic

deformation.

Ductile fractures are fractures that occur very rapidly with the entire part,

component or structure breaking in two in a relatively short period of time.

Cracks run in the material at high speeds of several feet or meters per

second. The cracks travel slower than in brittle fractures which allows the

part to distort, twist, bend or deflect to try and carry the excessive load.

Cracking usually starts after the part has been distorted to the limit the

material can withstand and small internal cracks form leaving the outer

circumference to tear apart last.

Most ductile fractures are results. This means they are not the cause of a

failure but are actually a result of another part or component failure.

Therefore parts having ductile fractures can be set aside in most

cases as they are not of primary interest.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (5 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Fracture Analysis

[ home | close ]

Fatigue Fractures

Fatigue fractures can be recognized by their smooth surfaces, light gray or

silvery color, beach marks, ratchet marks and final fracture.

Fatigue fractures are fractures that occur very slowly over a period of

hours, weeks or months and usually go undetected until the part finally

breaks completely in two. This event is called final fracture and is either

ductile, brittle or both.

The most interesting fact about fatigue fractures is that cracks will start at

areas of high stress. These areas are stress raisers and can be

something as simple as a dimensional change or as complex as heat

treatment residual stress.

Fatigue fractures, when found, are usually closely connected to the

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (6 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

root cause of failure making them the most interesting and useful

fracture.

Fracture Analysis

[ home | close ]

Initiation Sites

The initiation site is one of the most important sites on any fracture

as it is the location where cracks first started.

The initiation site of a brittle fracture can be just about anywhere on

the surface.

The initiation site of a ductile fracture usually occurs at the part's

smallest cross section and is of little importance.

Initiation sites of fatigue fractures are stress raisers and are very

important to helping identify why the fatigue crack started.

Once a stress raiser has been identified, the next step is to

determine whether it is a normal stress raiser or abnormal stress

raiser.

Fracture Analysis

[ home | close ]

Stress Raisers

Stress raisers are physical changes in a part that results in an increase of

internal stress in the part at the location of the physical change. This

change can be a simple dimensional change such as a reduction in

diameter of a rod, it can be a design feature such as a keyway or it can be

something more subtle such as residual tensile stress due to heat

treatment.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (7 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Stress raisers that are part of the design and manufacturing of the

component are considered normal stress raisers while stress raisers due to

wear, corrosion, excessive residual stress, dents, cracks or material

problems are abnormal stress raisers.

When analyzing fatigue fractures, once the initiation site is located, the

stress raiser starting the fatigue should be identified and investigated to

see if it is normal or abnormal.

Abnormal Stress Raisers

Normal Stress Raisers

Fracture Analysis

[ home | close ]

Load Types

Fracture Analysis

[ home | close ]

Knowledge Checks

Analyzing Fractures

Fracture Analysis

[ home | close ]

Glossary of Terms

A

B

Brittle fractures are fractures that occur very rapidly with the entire part,

component or structure breaking in two in a fraction of a second to a few

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (8 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

seconds at most. Cracks run in the material at very high speeds of

hundreds of feet or meters per second.

C

Chevrons are ridges on brittle fractures that usually get closer together as

they approach the initiation site of a brittle fracture.

D

Ductile fractures are fractures that occur very rapidly with the entire part,

component or structure breaking in two in a relatively short period of time.

Cracks run in the material at high speeds of several feet or meters per

second. The cracks travel slower than in brittle fractures which allows the

part to distort, twist, bend or deflect to try and carry the excessive load.

Cracking usually starts after the part has been distorted to the limit the

material can withstand and small internal cracks form leaving the outer

circumference to tear apart last.

E

F

Fatigue

G

H

I

The initiation site is the location where cracks start.

J

K

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (9 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

L

Load

M

N

O

P

Plastic deformation occurs when parts are loaded beyond their normal

strength and are forced to bend, twist, distort or stretch changing the shape

of the part noticeably and permanently.

Q

R

S

Shear lips are jagged rough edges extending part or all of the way around

the circumference of ductile fractures. The shear lip is formed when the last

material to fracture finally tears apart on about a 45 degree angle.

Sparkles means a fracture surface glitters when it is moved in the light. It

appears to have tiny diamonds embedded in the surface. It is typical of

fractures of steel and cast aluminum and indicates a brittle fracture

occurred. Sparkles are caused by crystals of the metal fracturing along flat

crystalline surfaces. It is also referred to as crystalline fracture.

Stress is the internal force that exists on each small cross sectional area of

material in a part and is caused by the external applied load.

Stress raisers are physical changes in a part that results in an increase of

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (10 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

internal stress in a part at the location of the physical change. This change

can be a simple dimensional change such as a reduction in diameter of a

rod, it can be a design feature such as a keyway or it can be something

more subtle such as residual tensile stress due to heat treatment. Wear,

corrosion or other surface damage can also be stress raisers.

T

U

V

W

X

Y

Z

Fracture Analysis

home

Analyzing Fractures Training - To Proceed with the Training Click

Here!

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (11 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

In this module we will learn the basics of identifying the three different

types of fractures that occur in metals. Then will will learn how to use these

fractures to locate the starting point of the crack. Once we have this

information we can usually find the reason why cracking started.

Most product failures are a result of improper operation, application or

maintenance and the fractures can identify this. Less frequently, product

problems can cause fractures and we can discover this also by knowing

how to analyze the fracture surfaces. The final purpose is to help arrive at

the events that can be used to build a time line to arrive at the root cause

of failure.

Eight Steps of Applied Failure Analysis

In This Presentation

Basic Terminology

Different Rates of Loading

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (12 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Brittle Fracture Characteristics

Fractured Component

Track Tensioner Spring Fracture

Fractured Piston Skirt

Fractured Gear Tooth

Fractured Gear

Brittle Crack Growth

Brittle Fracture Explained

Brittle Fracture

Ductile Fracture Characteristics

Fracture Analysis

home

Brittle Fractures

Chevrons

Chevrons are ridges on brittle fractures that usually get closer together as

they approach the initiation site of a brittle fracture.

Chevrons on this fracture point to the upper right.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (13 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Chevrons on this piston fracture point to the lower center.

Chevrons point to the left in this fractured gear.

Fracture Analysis

home

Brittle Fractures

Sparkles

sparklesmeans means a fracture surface glitters when it is moved in the

light. It appears to have tiny diamonds embedded in the surface. It is

typical of fractures of steel and cast aluminum and indicates a brittle

fracture occurred. Sparkles are caused by crystals of the metal fracturing

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (14 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

along flat crystalline surfaces. It is also referred to as crystalline fracture.

This fractured steel shows a sparkly condition and no shape change

This valve head also shows sparkles and no shape change.

Fracture Analysis

home

Ductile Fractures

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (15 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Shear Lips

Shear lips are jagged rough edges extending part or all of the way around

the circumference of ductile fractures. The shear lip is formed when the last

material to fracture finally tears apart on about a 45 degree angle.

A shear lip on this connecting rod bolt can be seen sticking out at the lower

edge of the bolt.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (16 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

A closer look at the bolt shows a shear lip extends all the way around the

bolt.

The shear lip is largest at the bottom and also at the more difficult to see

top area of the bolt where it is still down in the bolt hole.

Fracture Analysis

home

Ductile Fractures

Plastic Deformation

Plastic deformation occurs when parts are loaded beyond their normal

strength and are forced to bend, twist, distort or stretch changing the shape

of the part noticeably and permanently.

This connecting rod bolt has stretched very noticeably

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (17 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

This connecting rod has been twisted and distorted.

Fracture Analysis

home

Fatigue Fractures

Beach Marks

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (18 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Beach marks are similar to growth rings in a tree and usually expand out

and away from the initiation site. They focus on the starting point of the

fracture. The beach marks on this fracture point to the lower edge as the

initiation site.

Fracture Analysis

home

Fatigue Fractures

Ratchet Marks

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (19 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

The two bright radial features on this fracture at the initiation site are

ratchet marks. Ratchet marks form when two fatigue fractures are growing

at the same time at approximately the same location with one being just a

little above or below the other. At some point in time the material

separating the two fractures breaks vertically between them producing a

vertical wall or ratchet mark.

Fracture Analysis

home

Fatigue Fractures

Final Fracture

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (20 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

The large area on this fracture above the beach marks is the final fracture.

This portion of the fracture occurred in just a fraction of a second when the

part could no longer carry the repeated cyclic loading. Final fracture size

can tell a lot about the applied load. A large final fracture indicates a very

high applied load.

Fracture Analysis

home

Stress Raisers

Abnormal Stress Raisers

Abnormal stress raisers generally are of five kinds

Material problems

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (21 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Pre-cracks in parts

Surface damage such as corrosive pitting, unusual wear,

dents, nicks, or scratches

Improper manufacturing processes

The first two will produce fatigue cracks starting subsurface.

The others will start fatigue cracks on the surface.

Fracture Analysis

home

Abnormal Stress Raisers

Material Problems

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (22 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

This large crankshaft has fractured at a main journal fillet. A closeup of the

initiation site located by the arrow is to the right.

A typical material problem produced the abnormal stress raiser that started

a subsurface fatigue crack in the crankshaft. This type of fatigue fracture is

sometimes called a bull's eye since it produces a target like appearance

with the impurity at the center.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (23 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

This piston pin contains a material impurity which started a fatigue fracture

which eventually produced a major engine failure. The picture to the right is

a closeup view of the material problem.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (24 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

The straight line running from left to right near the center of the picture is

the material impurity. Beach marks can be seen growing upward and

downward fromt this area.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (25 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

This steel casting shows another material problem that sometimes occurs

in castings. The closeup at the right is of the problem area.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (26 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

The closeup shows a cavity or large hole in the casting caused by improper

pouring practices. It is called a shrinkage cavity. This hole was so large

that it failed abruptly very early in its life.

Fracture Analysis

home

Abnormal Stress Raisers

Pre-Cracks

Sometimes parts are cracked due to manufacturing processes. These

cracked parts produce another type of abnormal stress raiser. This is

usually referred to as a pre-crack. The precrack in this connecting rod is

the dark area at the center. Ratchet marks can be seen starting along the

lower edge. This indicates fatigue started inside the part, not at the surface.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (27 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

This picture has the various areas mentioned in the previous picture

identified to help locate the pre-crack and the other features of the fracture.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (28 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

The arrow points to another example of a pre-crack.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (29 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

This marked up image shows the location of the pre-crack and the ratchet

marks and beach marks starting inside the part at the bottom edge of the

pre-crack.

Fracture Analysis

home

Abnormal Stress Raisers

Surface Damage

This shaft has surface damage on a bearing seat caused by improper

disassembly practice. A cutting torch was used to remove the bearing and

during the removal, the shaft was nicked by the torch. The resulting

abnormal stress raiser started a fatigue fracture.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (30 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

This closer view shows the abnormal stress raiser and the initiation site of

the fatigue crack.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (31 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

This bolt has not fractured yet but has a high risk of a fatigue crack starting

at the reddish stained area of fretting corrosion. This type of surface

damage produces surface pitting which can be a severe stress raiser

resulting in fatigue fracture. The source of the vibration that caused the

fretting should be identified and corrected

Fracture Analysis

home

Abnormal Stress Raisers

Improper Manufacturing

This ground engaging tool had a fatigue fracture start from a dent. In this

case the dent was intentional. It is the letter "T" in the word CAT. The

trademark location had to be moved as it created an abnormal stress raiser

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (32 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

resulting in fatigue fractures.

The fillet radius on this cylinder rod was machined much too small creating

a very abnormal stress raiser

Fracture Analysis

home

Stress Raisers

Normal Stress Raisers

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (33 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Splines on shafts are normal stress raisers by design

Keyways are also normal stress raisers if machined to print

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (34 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Dimensional changes of many types are normal stress raisers

Threads are normal stress raisers existing on most fasteners

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (35 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Radii such as at the root of gear teeth are normal stress raisers

Residual stress due to heat treatment is a normal stress raiser.

One of the most difficult jobs is to determine if normal stress raisers are

really produced to specification or have been machined wrong making

them abnormal stress raisers.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (36 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Fracture Analysis

home

Tests

Analyzing Fractures

For each question below, click on the circle next to the correct answer.

When you are finished with the test, push the 'Score my test' button at the

bottom of the page. Good luck!

Question #1

Which of the following answers best describes the various types of

fracture?

A. Brittle and ductile

B. Fatigue and brittle

C. Fatigue and ductile

D. Brittle, ductile and fatigue

E. All of the above

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (37 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Question #2

Which type of fracture is usually a result and not the root cause of a

failure?

A. Brittle

B. Ductile

C. Both brittle and ductile

D. Fatigue

E. All of the above

Question #3

Which of the following are characteristics of brittle fracture?

A. Rough

B. Little or no permanent change in shape

C. Chevrons

D. Crystalline fracture

E. All of the above

Question #4

Ductile fractures will usually have:

A. Beach marks

B. Ratchet marks

C. Chevrons

D. Little or no plastic deformation

E. Shear lips

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (38 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Question #5

Beach marks show the:

A. Origin of a fatigue fracture

B. Location where the part finally failed

C. Location of least interest

D. Fracture was due to a sudden overload

E. None of the above

Question #6

Fatigue fracture origins can be of special interest because:

A. Fatigue starts at a stress raiser

B. They always indicate the root cause of failure

C. They indicate the part has been in service far too long

D. They indicate the part was used in an abusive manner

E. All of the above

Question #7

Once a stress raiser has been identified on a fatigue fracture, the next

thing to do is:

A. Examine all other failed parts

B. Determine if abuse caused the failure

C. Decide if wear played a role in failure

D. Determine if it is abnormal

E. Look for evidence of corrosion

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (39 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Question #8

Fatigue starting inside the part at a well defined and localized area

indicates:

A. The part was used far too long

B. The part was subjected to a corrosive environment

C. The part may have been abused during service

D. The part is fine

E. None of the above

Question #9

Beach marks and ratchet marks that do not extend all the way to a part's

surface indicate:

A. The part was cracked before going into service

B. The part was not the cause of the problem

C. The part was subjected to a corrosive environment

D. The failure was related to excessive part wear

E. None of the above

Question #10

Fatigue that starts at a normal stress raiser indicates:

A. The application should be investigated

B. The part is the root cause

C. The part was used far too long

D. A material flaw caused the failure

E. The manufacturing process produced a cracked part

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (40 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

This test was made with free online software from Merex Corporation.

Analyzing Fractures

Fracture Analysis

home

Analyzing Fractures

Eight Steps of Applied Failure Analysis

State the problem clearly

Get organized

Observe and record facts

Think logically with the facts

Determine most probable root cause

Communicate

Correct the problem

Follow up

Fracture identification and analysis is fundamental to Step 3, Observing

and Recording facts. A digital camera is a great tool to use for this step.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (41 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Fracture Analysis

home

Analyzing Fractures

In This Presentation

Brittle fracture characteristics

Ductile fracture characteristics

Fatigue fracture characteristics

Stress raisers

Metal strength

Loads on parts

Now we will learn to identify the three fracture types and look for stress

raisers at the starting point of the cracking. We will learn the role stress

raisers play in causing fracture.

Fracture Analysis

home

Analyzing Fractures

Basic Terminology

There are three basic fracture types, brittle, ductile and fatigue.

Both brittle and ductile fractures occur rapidly, traveling thousands of

meters per second through metal in some instances. They produce rough

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (42 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

fracture surfaces.

Fatigue usually occurs over a much longer period of time, maybe days,

weeks, months or years. It usually leaves a smooth fracture surface.

We might already guess that as we build time lines in Step 4, we would

expect fatigue fractures to be involved with events that occur early on the

time line and brittle and ductile fractures will be associated with events that

occur very close or at the end of the time line. For this reason we will say

that fatigue fractures are usually closely related to root causes, while

brittle and ductile fractures are usually related to results.

Initiation sites are the locations where fatigue cracking starts and this is

where we will find the stress raiser that started it.

Stress raisers are areas of physical differences contained by all parts that

cause the applied loads to be concentrated more heavily at certain

locations. We will give some examples later.

After a crack grows a certain distance through a part, the remaining cross

sectional area can no longer carry the loads and the remaining material

fractures. This area is called final fracture.

Fracture Analysis

home

Analyzing Fractures

Different Rates of Loading

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (43 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Just a reminder that there are three basic loading rates which have an

effect in producing the three fracture types. Both impact and overloads are

single load applications. Cyclic loads are repeated. Remember to

distinguish between a single overload which usually causes ductile fracture

and cyclic overload which causes fatigue fracture

Fracture Analysis

home

Analyzing Fractures

Brittle Fracture Characteristics

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (44 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Now lets learn to identify brittle fractures. They have four characteristics.

They are rough.

They do not deform much at the edges during fracture, bend, twist,

shear called plastic deformation. This means you can put the two

halves of the fracture back together and the part looks very similar to

the way it looked before breaking.

Brittle fractures either sparkle like diamonds are embedded on the

fracture surface or ...

they have ridges forming chevrons or v-shaped structures on the

surface. Harder steels form sparkles while softer steels form chevrons.

This gives us a hint about the parts hardness. These characteristics

hold true for steel, aluminum and most other crystalline materials but

does not hold true for cast iron. Cast iron fracture is extremely difficult

to analyze, even by expert metallurgists.

The most important thing to remember about brittle fractures is they are

usually results.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (45 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Fracture Analysis

home

Analyzing Fractures

Fractured Component

What do you see on this fracture? No deformation at the edges, sparkly

surface and rough texture. What kind of fracture is it?

Brittle.

Is it most likely a cause of a failure?

No, it is usually a result.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (46 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Fracture Analysis

home

Analyzing Fractures

Track Tensioner Spring Fracture

What do you see on this fractured track tensioner spring?

Little deformation, rough surfaces and a distinct pattern of chevrons.

What kind of fracture is it?

Brittle of course meaning this part fractured as a result of something else

occurring previously.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (47 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Fracture Analysis

home

Analyzing Fractures

Fractured Piston Skirt

What do you see on the skirt of this broken piston?

A rough surface, no deformation and a distinct set of chevrons.

What kind of fracture is it?

Brittle.

What caused it?

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (48 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

A sudden impact load.

Is this fracture a cause or a result?

A result.

Fracture Analysis

home

Analyzing Fractures

Fractured Gear Tooth

What do you see on the skirt of this broken piston?

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (49 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

A rough surface, no deformation and a distinct set of chevrons.

What kind of fracture is it?

Brittle.

What caused it?

A sudden impact load.

Is this fracture a cause or a result?

A result.

Fracture Analysis

home

Analyzing Fractures

Fractured Gear

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (50 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

What do you see here?

Rough fracture, no deformation and chevrons.

This is a brittle fracture that is a result of a shock load. The shock load

occurred in the area of the gear teeth at the left.

What is the lighter gray area?

This is the harder metal around the surface of the gear called the case.

This was produced by heat treating the gear during manufacturing.

Fracture Analysis

home

Analyzing Fractures

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (51 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Brittle Crack Growth

Brittle cracks are most frequently caused by impact or shock loads. The

individual grains of steel making up the part have no time to deform and try

to carry this sudden extra load.

In most instances the grains fracture along the layers of unit cells. This is

known as cleavage.

If the metal is very hard and fractures almost entirely by cleavage, the

cleaved grains reflect light creating the sparkle on certain fractures.

Fracture Analysis

home

Analyzing Fractures

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (52 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Brittle Fracture Explained

A deck of playing cards illustrates brittle fracture very well.

Imagine the deck represents a single grain of steel and each card within

the deck represents a layer of unit cells.

Fracture Analysis

home

Analyzing Fractures

Brittle Fracture

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (53 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Brittle fracture along the layers of unit cells is equivalent to cutting the

deck or separating it as pictured. Notice the grain or deck has not changed

its original shape meaning no plastic deformation occurred during the

fracture.

Fracture Analysis

[ home | close ]

Ductile Fracture Characteristics

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (54 of 55) [14/02/2003 0:15:41]

Fracture Analysis Procedure

Ductile fractures are similar to brittle fractures in that they are usually

results of a single excessive load being applied. But in this case the load is

not applied fast enough to prevent the part from bending and deforming to

carry the load. This kind of fracture might occur in a connecting rod bolt if

the other bolt in the pair should come loose and fall out of the rod. The

remaining tight bolt is now overloaded and stretches, bends and breaks

due to the overload.

Ductile fractures are rough with dark surfaces, show lots of deformation

usually with a shear lip at the edges, occur rapidly and may have a woody

texture if the fracture runs in the direction of grain flow.

file:///C|/Documents%20and%20Settings/cmunoz/E...pia%20de%20Fracture%20Analysis%20Procedure.htm (55 of 55) [14/02/2003 0:15:41]

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- CAT Ground Engaging ToolsDocument35 pagesCAT Ground Engaging ToolsJimmy Nuñez VarasNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- An Evaluation of Biomass Co-Firing in EuropeDocument10 pagesAn Evaluation of Biomass Co-Firing in EuropeJimmy Nuñez VarasNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Optimal Design of An Air-Cooled Condenser For Flue Gas From A PowDocument316 pagesOptimal Design of An Air-Cooled Condenser For Flue Gas From A PowJimmy Nuñez VarasNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Dew Point of The Flue Gas of Boilers Co-FiringDocument8 pagesDew Point of The Flue Gas of Boilers Co-FiringJimmy Nuñez VarasNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Biomass MITDocument9 pagesBiomass MITJimmy Nuñez VarasNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Nugen Mobility Inc.: Scm150-Xxx Axial Flux, Brushless PM MotorDocument4 pagesNugen Mobility Inc.: Scm150-Xxx Axial Flux, Brushless PM MotorJimmy Nuñez VarasNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 2011ARDocument72 pages2011ARMika AurelioNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Road CoastingDocument145 pagesRoad CoastingBhavsar NilayNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- 710713RA Solenoid ValvesDocument2 pages710713RA Solenoid ValvesEDUARDOMTZNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Front Elevation Side Elevation: E.W.S. HousingDocument1 pageFront Elevation Side Elevation: E.W.S. HousingsahilNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A786a786m PDFDocument11 pagesA786a786m PDFleroy2007No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Alluminium Composite Panel-FlexibondDocument4 pagesAlluminium Composite Panel-Flexibondedars08No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Chapter 5CDocument6 pagesChapter 5Cnishant361No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Se Sovent Design Manual 101o New011007Document24 pagesSe Sovent Design Manual 101o New011007jomy_pj8106No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

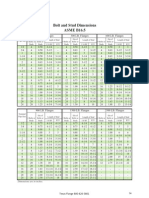

- Bolt and Stud DimentionDocument1 pageBolt and Stud DimentionwhngomjNo ratings yet

- Case Study On Ground Improvement by High Pressure Jet GroutingDocument6 pagesCase Study On Ground Improvement by High Pressure Jet Groutingnagy_andor_csongorNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Access Hardware Architectural CatalogueDocument87 pagesAccess Hardware Architectural CatalogueAccess HardwareNo ratings yet

- Sun Temple, GujratDocument11 pagesSun Temple, GujratSejal MengajiNo ratings yet

- En 01542 - 1999 Pull OffDocument10 pagesEn 01542 - 1999 Pull OffPriceMarkNo ratings yet

- Ga 37-7,5 (Aii 382713)Document146 pagesGa 37-7,5 (Aii 382713)Mohamad Bahrodin100% (1)

- Addendum To Standard Bidding Document Procurement of Civil WorksDocument29 pagesAddendum To Standard Bidding Document Procurement of Civil WorksvivekNo ratings yet

- Sand Treatment Package (Asabi-A-3401) 34665 Ponticelli - Al Shaheen PWTDocument3 pagesSand Treatment Package (Asabi-A-3401) 34665 Ponticelli - Al Shaheen PWTTĩnh Hồ TrungNo ratings yet

- Fire Tube Boilers PDFDocument16 pagesFire Tube Boilers PDFG.SWAMI67% (3)

- A. Tes BQ StrukturDocument1 pageA. Tes BQ Strukturdian faniNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- BIM and Sustainability in Terms of Philippine StandardsDocument6 pagesBIM and Sustainability in Terms of Philippine Standardsraifel100% (1)

- DSS Design of Steel BeamsDocument14 pagesDSS Design of Steel Beamsrashmi ashtekarNo ratings yet

- Constructability Concepts Significance and ImplemeDocument11 pagesConstructability Concepts Significance and ImplemeHari Dwi KisbiyantoroNo ratings yet

- Engineer's Report On Collapse of South Alabama Football FacilityDocument22 pagesEngineer's Report On Collapse of South Alabama Football Facilitycreg1973100% (1)

- 2nd PPT Torsional IrregulartitiesDocument20 pages2nd PPT Torsional IrregulartitiesAnkit DalviNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- 06.5 - Section 02300-Earthwork (Add 1)Document6 pages06.5 - Section 02300-Earthwork (Add 1)Danny SiagianNo ratings yet

- Chapter 4 GlassDocument51 pagesChapter 4 Glassaman sudiNo ratings yet

- 54450b13e6c55 Dutypoint Dosing Pots DetailsDocument2 pages54450b13e6c55 Dutypoint Dosing Pots DetailsMohammed KhaledNo ratings yet

- The Transformation of Vernacular Architecture in Indonesia in Relation To Colonisation by The DutchDocument6 pagesThe Transformation of Vernacular Architecture in Indonesia in Relation To Colonisation by The DutchDavid TolentinoNo ratings yet

- B V DoshiDocument30 pagesB V DoshiJeeva Z FedricoNo ratings yet

- Brazing Procedure 1Document5 pagesBrazing Procedure 1Tina MillerNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)