Professional Documents

Culture Documents

Notes On Electron Beam Machining (EBM)

Uploaded by

Arafat MohamedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Notes On Electron Beam Machining (EBM)

Uploaded by

Arafat MohamedCopyright:

Available Formats

5/28/2016

Notes on Electron Beam Machining EBM

Search...

HOME

ABOUT US

TOPIC INDEX

TAG INDEX

CONTRIBUTE

CONTACT

Electron Beam Machining (EBM)

Last updated: Mar 17, 2016

Posted in Manufacturing

Subscribe to our new

notifications of new p

Email *

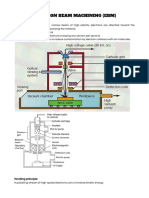

Electron Beam Machining (EBM) is a thermal process. Here a steam of high speed electrons impinges on the

work surface so that the kinetic energy of electrons is transferred to work producing intense heating.

Depending upon the intensity of heating the workpiece can melt and vaporize.

The process of heating by electron beam is used for annealing, welding or metal removal.

During EBM process very high velocities can be obtained by using enough voltage of 1,50,000 V can

produce velocity of 228,478 km/sec and it is focused on 10 200M diameter. Power density can go up to

6500 billion W/sq.mm. Such a power density can vaporize any substance immediately.

Ceramicv

Complex contours can be easily machined by maneuvering the electron beam using magnetic deflection

coils.

corrosionresistan

Quality,LowCost

Subscribe!

To avoid a collision of the accelerating electrons with the air molecules, the process has to be conducted in

vacuum. So EBM is not suitable for large work pieces.

Process is accomplished with vacuum so no possibility of contamination.

No effects on work piece because about 25-50 m away from machining spot remains at room temperature

and so no effects of high temperature on work.

Animation

Casting

Equation

Heat Exchanger

Machine

Thermodynamics Cyc

Vehicle

Schematic diagram of Electron Beam Machining process

MRR in EBM:

Q = area of slot or hole speed of cutting = AV

Where power for Q MRR is P = C.Q

Where,

C = Specific power consumption

Thermal velocity acquired by an electron of the work material due to electron beamis

http://memechanicalengineering.com/electronbeammachiningebm/

1/3

5/28/2016

Notes on Electron Beam Machining EBM

Where, KB= Boltzmann constant

m = mass of one atom of work.

T = rise in temperature

Advantages:

Very small size holes can be produced.

Surface finish produced is good.

Highly reactive metals like Al and Mg can be machined very easily.

Limitations:

Material removal rate is very low compared to other unconventional machining processes.

Maintaining perfect vacuum is very difficult.

The machining process cant be seen by operator.

Workpiece material should be electrically conducting.

Applications:

Used for producing very small size holes like holes in diesel injection nozzles, Air brakes etc.

Used only for circular holes.

Machining Modern Machining Process

RELATED ARTICLES & COMMENTS

ConeCrusherfor

Granite

20986t/hConeCrusherforGranite

To112+Country,AskforPrice!

Fantastic concentrated summary

JACOBUS Oct 10, 2015 3:59 pm

Reply

Nice explanation. if we want to make a small machine ebeam for our lab

purpose how much the cost. Can you guide us who is making this machine

ANAND Oct 29, 2015 10:06 pm

Reply

LEAVE A COMMENT

Last updated 2 months ago

Machinability

0

Last updated 2 months ago

Comment:*

Name:*

Email:*

Abrasive-jet Machining

(AJM)

1

SubmitComment

Last updated 2 months ago

Yes, add me to your mailing list.

Water Jet Machining

(WJM)

0

Last updated 2 months ago

Electro Chemical

Machining (ECM)

1

http://memechanicalengineering.com/electronbeammachiningebm/

2/3

5/28/2016

Notes on Electron Beam Machining EBM

Last updated 3 months ago

Electric Discharge

Machining (EDM)

1

Last updated 6 months ago

Classification of

Unconventional

Machining Processes

1

Home

About Us

Topic Index

Tag Index

Submit Guest Post

Privacy Policy

Contact

Copyright 2016 ME Mechanical

http://memechanicalengineering.com/electronbeammachiningebm/

3/3

You might also like

- Small Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsFrom EverandSmall Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsNo ratings yet

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenFrom EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenRating: 4 out of 5 stars4/5 (2)

- Admp 6th SemDocument262 pagesAdmp 6th SemmishtisonuNo ratings yet

- Casting DefectsDocument24 pagesCasting DefectsMohamedSabryNo ratings yet

- Exp 2 Total Suspended SolidsDocument3 pagesExp 2 Total Suspended Solidssaras8788% (8)

- Lecture 21 - Electron Beam MachiningDocument26 pagesLecture 21 - Electron Beam MachiningGaurav GodseNo ratings yet

- Ingersoll Rand UP6!25!125 Operators ManualDocument34 pagesIngersoll Rand UP6!25!125 Operators ManualChris LittleNo ratings yet

- Electron Beam Machining (EBM)Document2 pagesElectron Beam Machining (EBM)rs100788No ratings yet

- NTMP - EbmDocument20 pagesNTMP - EbmShuvroneil Sinha RoyNo ratings yet

- Lect 32Document25 pagesLect 32shashankmay18No ratings yet

- Electron Beam MachiningDocument19 pagesElectron Beam MachiningHarshal NilNo ratings yet

- Electron Beam MachiningDocument7 pagesElectron Beam MachiningDiaz LaksmanaNo ratings yet

- Electron Beam Machining: D.Palani Kumar, Assistant Prof. / Mech. Engg., Kamaraj College of Engg. & Tech. VirudhunagarDocument26 pagesElectron Beam Machining: D.Palani Kumar, Assistant Prof. / Mech. Engg., Kamaraj College of Engg. & Tech. VirudhunagarvaniNo ratings yet

- Electron Beam MachiningDocument33 pagesElectron Beam MachiningMr PotatoNo ratings yet

- Elctron Beam MachiningDocument3 pagesElctron Beam MachiningTanu RdNo ratings yet

- Recent Trends in Non-Traditional Machining Processes: Unit - 5Document12 pagesRecent Trends in Non-Traditional Machining Processes: Unit - 5DISHA VNo ratings yet

- NTM Assigment Topic: Electron Beam Machining: Name: Venu Kabra USN: 1RV07ME115 Branch: Mecanical Sem: 7 "C"Document19 pagesNTM Assigment Topic: Electron Beam Machining: Name: Venu Kabra USN: 1RV07ME115 Branch: Mecanical Sem: 7 "C"Venu KabraNo ratings yet

- Electron Beam MachiningDocument5 pagesElectron Beam MachiningpapupassNo ratings yet

- 4A. Electron Beam Machining (EBM)Document3 pages4A. Electron Beam Machining (EBM)Tanu RdNo ratings yet

- Ucmp Unit-5Document77 pagesUcmp Unit-5Rashida BegumNo ratings yet

- ELECTRON BEAM MACHINING PrashanthDocument20 pagesELECTRON BEAM MACHINING PrashanthSurender NarmetaNo ratings yet

- 05 (Ebm Pam)Document26 pages05 (Ebm Pam)ssNo ratings yet

- 261 - MMP Lecture Notes-Ilovepdf-Compressed 66Document7 pages261 - MMP Lecture Notes-Ilovepdf-Compressed 66BABAJINo ratings yet

- NTM Unit4Document8 pagesNTM Unit4saravana kumarNo ratings yet

- Production Technology: Electron Beam MachiningDocument14 pagesProduction Technology: Electron Beam MachiningFuxNo ratings yet

- Ch-12 Unconventional MachiningDocument188 pagesCh-12 Unconventional MachiningAbhishek AroraNo ratings yet

- Assignment Advance Manufacturing Processes: by Vaibhav M. Enroll No. 171E021 May 8, 2020Document11 pagesAssignment Advance Manufacturing Processes: by Vaibhav M. Enroll No. 171E021 May 8, 2020Vaibhav MishraNo ratings yet

- Electron Beam MachiningDocument9 pagesElectron Beam MachiningYunitha RatnadillaNo ratings yet

- MMFM Unit 3 - EBMDocument4 pagesMMFM Unit 3 - EBMadhav1avi0804No ratings yet

- EBM - (Electron Beam Machining)Document11 pagesEBM - (Electron Beam Machining)prankur giriNo ratings yet

- Electron Beam MachiningDocument7 pagesElectron Beam MachiningsatyanitwNo ratings yet

- Some Information About Edm EBM and LBMDocument6 pagesSome Information About Edm EBM and LBMRuchin ChahwalaNo ratings yet

- Electron Beam Machining 1Document9 pagesElectron Beam Machining 1Anonymous NUIEgENo ratings yet

- 04 Non Traditional Machining 4Document22 pages04 Non Traditional Machining 4Mas ArifinNo ratings yet

- Document 1Document8 pagesDocument 1sadiqali4244No ratings yet

- Submitted To:-Er - Sunil Kumar Baghla: Submitted By: - Gurpreet Singh R.NO-21803012 B.tech7 Sem (M.E)Document37 pagesSubmitted To:-Er - Sunil Kumar Baghla: Submitted By: - Gurpreet Singh R.NO-21803012 B.tech7 Sem (M.E)GURPREET SINGHNo ratings yet

- Electron Beam Machining:: Principle of EBMDocument5 pagesElectron Beam Machining:: Principle of EBMZaky MuzaffarNo ratings yet

- Ch-12 Unconventional MachiningDocument135 pagesCh-12 Unconventional MachiningSaumil ShahNo ratings yet

- Electron Beam MachiningDocument9 pagesElectron Beam MachiningductuanvvNo ratings yet

- Electrochemical Machining (ECM) Is A Non-Traditional Machining (NTM) Process Belonging ToDocument11 pagesElectrochemical Machining (ECM) Is A Non-Traditional Machining (NTM) Process Belonging ToMd Sultan AhemadNo ratings yet

- Electron Beam WeldingDocument20 pagesElectron Beam WeldingkumarNo ratings yet

- Electron Beam MachiningDocument30 pagesElectron Beam Machiningmehedi hasanNo ratings yet

- Electron Beam WeldingDocument10 pagesElectron Beam WeldingStefanie WilsonNo ratings yet

- ECDMDocument9 pagesECDMRobert NayakNo ratings yet

- Micro-Machining Techniques (Document30 pagesMicro-Machining Techniques (FirozNo ratings yet

- Electron Beam Machining: Principle of EBMDocument4 pagesElectron Beam Machining: Principle of EBMPragyan Kumar PradhanNo ratings yet

- Electron Beam Welding of Micro-Housings With Dissimilar Metals For Electronic CircuitsDocument3 pagesElectron Beam Welding of Micro-Housings With Dissimilar Metals For Electronic CircuitsAbhishek KumarNo ratings yet

- Electron Beam MachineDocument23 pagesElectron Beam MachineMQ ZerooNo ratings yet

- Reference: Diffusion Bonded EDM Electrode With Micro Holes For Jetting Dielectric Liquid, CIRP Annals - Manufacturing Technology, 2006Document11 pagesReference: Diffusion Bonded EDM Electrode With Micro Holes For Jetting Dielectric Liquid, CIRP Annals - Manufacturing Technology, 2006EdinNo ratings yet

- Ucmp - Assignment 15P31A0383Document5 pagesUcmp - Assignment 15P31A0383Sài TejaNo ratings yet

- AMP Microproject Grp-12Document16 pagesAMP Microproject Grp-12Sandeep JaiswalNo ratings yet

- COPEN-9 Full Paper Upload 77Document6 pagesCOPEN-9 Full Paper Upload 77aghosh704100% (1)

- Lecture 24 - ECMDocument32 pagesLecture 24 - ECMDivyam GargNo ratings yet

- Electron Beam WeldingDocument19 pagesElectron Beam WeldingRajan BhadoriyaNo ratings yet

- A.K.das - Resistance WeldingDocument26 pagesA.K.das - Resistance WeldingAsad Bin Ala QatariNo ratings yet

- Electron Beam: MachiningDocument37 pagesElectron Beam: MachiningraghurockramNo ratings yet

- Non-Traditional MachiningDocument24 pagesNon-Traditional MachiningNikhil PrasannaNo ratings yet

- EBMDocument6 pagesEBManeesh19inNo ratings yet

- Non Conventional MachiningDocument19 pagesNon Conventional MachiningTooling ganeshNo ratings yet

- Comparative Analysis of Mild Steel Before and After Stabilization and Evaluate Machine Parameters Using EcmDocument13 pagesComparative Analysis of Mild Steel Before and After Stabilization and Evaluate Machine Parameters Using Ecmk eswariNo ratings yet

- Chapter 26Document13 pagesChapter 26april heramizNo ratings yet

- Msds Colateric Jbs (16 Section)Document6 pagesMsds Colateric Jbs (16 Section)mndmattNo ratings yet

- MSDS - 134aDocument9 pagesMSDS - 134aUpul Samantha LiyanaarachchiNo ratings yet

- Chem Ass 3084357142010Document2 pagesChem Ass 3084357142010kidaneNo ratings yet

- Maintenance Solutions For Hvac Systems: Belzona Protective Coatings and Engineering CompositesDocument12 pagesMaintenance Solutions For Hvac Systems: Belzona Protective Coatings and Engineering CompositesSUHEL NEVREKARNo ratings yet

- Extraction of Copper and Gold From Anode Slime of Sarcheshmeh Copper Complex by M.H.Dehghanpoor PDFDocument5 pagesExtraction of Copper and Gold From Anode Slime of Sarcheshmeh Copper Complex by M.H.Dehghanpoor PDFFerudun AkyolNo ratings yet

- Biosorption of Heavy Metals: Department of Biotechnology and Environmental SciencesDocument25 pagesBiosorption of Heavy Metals: Department of Biotechnology and Environmental SciencesYen BumNo ratings yet

- Horizontal Laminar Flow HoodDocument3 pagesHorizontal Laminar Flow HoodRichard Balicat Jr.No ratings yet

- A B C D Answer: B, A, D, C: O O BR 1 Eq Br2 Febr3Document3 pagesA B C D Answer: B, A, D, C: O O BR 1 Eq Br2 Febr3Quốc NguyễnNo ratings yet

- TOS General Chemistry 1 2021-2022Document2 pagesTOS General Chemistry 1 2021-2022ariane lagatic100% (1)

- ArmaFlex Application UkDocument36 pagesArmaFlex Application UkDave StaelensNo ratings yet

- Molecules: Synthesis and Bioactivity of A-Aminophosphonates Containing FluorineDocument7 pagesMolecules: Synthesis and Bioactivity of A-Aminophosphonates Containing FluorineThomas CharmNo ratings yet

- Assignment 1 - Chapter 3 AnswerDocument9 pagesAssignment 1 - Chapter 3 AnswerHarryzam MartelNo ratings yet

- Interview With DR Nelly Grosjean - EditDocument2 pagesInterview With DR Nelly Grosjean - Editkc_liew_4No ratings yet

- P70 80 Sealed Filter DriersDocument11 pagesP70 80 Sealed Filter Driersghostz0rNo ratings yet

- Biological Molecules: Grade 9 BiologyDocument28 pagesBiological Molecules: Grade 9 BiologyHeyitsyasi xoxNo ratings yet

- Material Price ListDocument43 pagesMaterial Price ListSathish RagavanNo ratings yet

- Chemical Bonding 2Document16 pagesChemical Bonding 2yvg95100% (1)

- Corrosion New Jul20Document66 pagesCorrosion New Jul20hafiz aimanNo ratings yet

- Investigation of Mechanical Properties of Rice Straw Fiber Epoxy CompositeDocument8 pagesInvestigation of Mechanical Properties of Rice Straw Fiber Epoxy CompositeAnson DsouzaNo ratings yet

- Toyota Forklift FBM 16-20-25 30 Repair ManualDocument22 pagesToyota Forklift FBM 16-20-25 30 Repair Manualdrroybarreramd141203wcr100% (110)

- Questionbank AS5640Document9 pagesQuestionbank AS5640Saurav KumarNo ratings yet

- Bioinspiration and BiomimeticsDocument7 pagesBioinspiration and BiomimeticsAyush 100niNo ratings yet

- ASTUDYONAMYLASEREVIEWDocument9 pagesASTUDYONAMYLASEREVIEWzaharo putriNo ratings yet

- SD - Cupric Tartrate TS, Alkaline (Fehling's Solution) (B) (USP204) (EU)Document7 pagesSD - Cupric Tartrate TS, Alkaline (Fehling's Solution) (B) (USP204) (EU)atikah razakNo ratings yet

- Evaluation and Preparation of Guava Jam Stored at Ambient TemperatureDocument10 pagesEvaluation and Preparation of Guava Jam Stored at Ambient Temperatureiftikhar AhmedNo ratings yet

- Pra Un Ing 2013-Paket 7Document14 pagesPra Un Ing 2013-Paket 7adela_97lineNo ratings yet

- Commpany Profile - Hipack LabelprinDocument4 pagesCommpany Profile - Hipack LabelprinAzharul FuadNo ratings yet