Professional Documents

Culture Documents

Be Semester 7 2016-17 Lesson Plan

Uploaded by

api-294538209Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Be Semester 7 2016-17 Lesson Plan

Uploaded by

api-294538209Copyright:

Available Formats

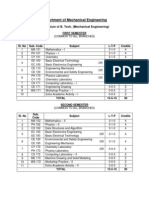

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

VII semester

Sl.

No.

1

2

3

4

6

7

8

9

Course

Course Title

Code

13ME401 Finite Element Methods

13ME402 Microprocessors and

Mechatronics

13ME403 Hydraulics and Pneumatics

Elective Group II

13ME411 Design of Heat Exchangers

13ME412 Vehicle Dynamics

Product Design and

13ME413

Manufacturing

13ME414 Jet and Rocket Propulsion

13ME415 Smart Materials

Probabilistic Methods and

13IE432

Engineering Simulations*

Elective Group III

Analysis and Design of

13ME421

Laminated Composite Structures

13ME422 Surface Engineering

13ME423 Fracture Mechanics

Thermal Management in

13ME424

Electronic Packages and Systems

13IE431 Total Quality Management*

13ME404 Mechanical Vibration Laboratory

13ME405 CAD/CAM Laboratory

13ME406 Mechatronics Laboratory

13ME407 Special Topic 5/Mini Project

Total

L

4

Hours/Week

T P S

0

0

0

Credits

4

4

4

4

0

0

0

0

0

0

0

0

0

4

4

4

4

0

0

0

0

0

0

4

4

4

4

4

0

0

0

0

0

0

4

4

4

0

0

0

-

0

0

0

0

-

0

2

2

2

-

0

0

0

0

-

4

1

1

1

2

25

* A student can NOT take more than ONE institutional elective (which is coded as IE)

through-out the B.E. program.

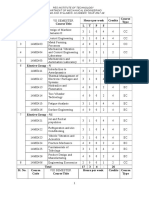

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

PESIT

Department of Mechanical Engineering

7th Semester B. Tech. (Machine design) Lesson Plan

13ME401: Finite Element Methods

Faculty:Dr.SHRIKANTH V. /RAMMOHAN.B

No. of Hours: 52

% Portions covered

Class

Chapter Title / Reference

Topics to be covered

No.

Literature

Lecture Cumulative

1

T2-Chapter 1:

UNIT

Introduction

INTRODUCTION

2

2

Page 1

Introduction to computational methods

FDM, FVM and FEM

2

T1-Chapter 4:

Direct stiffness method

2

4

Page 43

3

T1-Chapter 1:

Integral formulation for numerical

2

6

Page 6

solution Variational method.

4

5

6

7

8

9

10

11

12

T1-Chapter 1:

Page 8

T1-Chapter 1:

Page

10+Krishnamoorthy+Ra

mamurthy

T1-Chapter 2:

Page 17

T1-Chapter 5:

Page 56

***Notes

Method of weighted residuals

T1-Chapter 6:

Page 68

T1-Chapter 7:

Page 87

Global, local and natural coordinate

systems.

UNITII

TWO DIMENSIONAL FIELD

PROBLEMS

Governing differential equations,

integral

equations

for

element

matrices.

Element matrix-triangular element.

T1-Chapter 7:

Page 91

T1-Chapter 8:

Page 100

13

T1-Chapter 8:

Page 105

14

T1-Chapter 9:

Page 126

T1-Chapter 9:

Page 129

T1-Chapter 9:

Page 130

15

16

Potential energy formulation, principle

of virtual work

Division of region into elements, 1-D

linear element

Linear triangular element

Representation of scalar and vector

fields

Torsion of non circular cross sections

General theory, twisting of a square

bar.

Shear stress components, Evaluation of

twisting torque.

Flow of an ideal fluid potential

formulation

Ground water flow

Flow around a cylinder

10

12

14

16

18

20

22

24

26

28

30

32

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

17

18

19

20

21

22

23-24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

T1-Chapter 9:

Page 132

T1-Chapter 9:

Page 134

***Notes

Regional aquifer

T1-Chapter 11:

Page 138

UNITIII

HEAT TRANSFER BY

CONDUCTION

One dimensional fin

Composite wall

T1-Chapter 11:

Page 142

T1-Chapter 11:

Page 144

T1-Chapter 11:

Page 145

T1-Chapter 11:

Page 165

T1-Chapter 11:

Page 166

T1-Chapter 11:

Page 168

T1-Chapter 11:

Page 170

T1-Chapter 11:

Page 176

T1-Chapter 18:

Page 238

T1-Chapter 19:

Page 246

T1-Chapter 19:

Page 250

T1-Chapter 20:

Page 261

T1-Chapter 20:

Page 267

T1-Chapter 21:

Page 277

T1-Chapter 22:

Page 286

T1-Chapter 22:

Page 288

T1-Chapter 23:

Page 293

T1-Chapter 23:

Page 295

Problems.

Introduction to electric and magnetic

problems.

Two dimensional fin

Long

two

dimensional

bodies

-Convective boundary conditions

Axis symmetric field problems

differential equation

Axis symmetric elements

Galerkins method

Element matrices

Problems

UNITIV

STRUCTURAL AND SOLID

MECHANICS

Axial force member element matrix

Truss element element matrices

Analysis of pinned truss

Beam element element matrices

Analysis of statically indeterminate

beam.

Plane frame element element

matrices

Two dimensional stress analysis

Stress strain and Hookes law

Strain displacement equations

Two dimensional elasticity Plane

stress and plane strain.

Displacement equations

34

36

38

40

42

44

48

50

52

54

56

58

60

62

64

66

68

70

72

74

76

78

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

40

41

42

43

44

45

46

47

48

49

50

51

52

T1-Chapter 23:

Page 297

T1-Chapter 23:

Page 304

T1-Chapter 23:

Page 314

T1-Chapter 23:

Page 317

T1-Chapter 23:

Page 320

* **Notes

T2-Chapter 8:

Page 208

T1-Chapter 27:

Page 371

T1-Chapter 27:

Page 375

T1-Chapter 27:

Page 376

T1-Chapter 15:

Page 196

T1-Chapter 27:

Page 380

T1-Chapter 27:

Page 382

Element matrices

Element stresses

Axis symmetric stress analysis

element matrices

Surface loads

Problems

UNITV

HIGHER ORDER ELEMENTS

Iso parametric elements in 1-D and 2D

Use of higher order elements

Changing the variables of integration

1D and 2D

Numerical integration 1D integrals

Quadrilateral regions and triangular

regions

Rectangular and triangular elements

Evaluation of [B] integral, Evaluation

of surface integrals

Pre and post processing, capability of

Fem packages and error analysis

80

82

84

86

88

90

91

93

94

95

97

99

100

Text Books:

T1.Applied finite element analysis by L. J. Segerlind,Wiley, 2 nd edition,1984.

T2. Applied finite element analysis by G. Ramamurthy, IK international

publishing house, 2009.

*** Notes will be provided by the Course instructors.

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

13ME402: Microprocessor and Mechatronics (4-0-0-0-4)

Faculty: D. Sethuram

Class

#

Chapter Title / Reference

Literature

No. of Hours: 52

Topics to be covered

% of Portions covered

Reference Cumulative

chapter

UNIT -1

1

Introduction to Microprocessors

2%

2%

2

3

Microprocessor Instruction set

Microprocessor programming

languages,

The 8085 programming model.

2%

4%

2%

6%

2%

8%

2%

10

2%

12%

2%

14%

2%

16%

2%

18%

2%

20%

2%

22%

2%

2%

24%

26%

2%

28%

2%

30%

2%

32%

2%

34%

2%

36%

4

5

Chapter 1

Introduction

T1

6

7

8

9

10

11

Chapter 2

Microprocessor

Architecture and

Microcomputer systems

T1

12

13

14

15

16

17

18

UNIT II

Chapter: 3

Programming of

Microprocessors

The 8085 programming model

(Continued).

Application:Microprocessor

controlled temperature system

(MCTS).

Microprocessor architecture

Microprocessor operations

Microprocessor memory

Microprocessor Input and output

devices,

Example of a microcomputer

system.

Single chip micro controllers

8085 MPU,

Memory interfacing.

Data Transfer ( copy operations)

Programming of

Microprocessors:Arithmetic

operations,

Programming of

Microprocessors:Arithmetic

operations

Programming of

Microprocessors:Logic operations

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

19

writing assembly Language

programs, Programming techniques:

Looping, Counting and Indexing,

writing assembly Language

programs, Programming techniques

20

21

Assembly Language programs,

Looping,

Assembly Language programs :

Indexing,

Arithmetic operations related to

memory.

Introduction to Mechatronics

systems.

22

21

22

23

24

25

UNIT III

Chapter 4:

Introduction of

Mechatronics systems,

26

27

28

29

30

31

32

33

34

Chapter 5:

Sensors and

Transducers:

Introduction to Mechatronics

measurement system.

Introduction to control systems.

Microprocessor based controllers,

Response of system, Mechatronics

approach.

Introduction to Sensors and

Transducers.

Sensors and Transducers:

Performance terminology

Displacement sensors, Position

sensors

Proximity sensors.

Velocity and motion sensors.

Force sensors.

Fluid pressure sensors.

liquid flow and level sensors,

2%

38%

2%

40%

2%

42%

2%

44%

2%

46%

2%

48%

2%

50%

2%

52%

2%

54%

2%

56%

2%

58%

2%

60%

2%

62%

2%

2%

2%

2%

64%

66%

68%

70%

2%

72%

35

Temperature sensors.

2%

74%

36

Light sensors.

2%

76%

37

Selection of sensors

2%

78%

Introduction to Electrical Actuation

systems.

2%

80%

2%

2%

82%

84%

38

9

40

UNIT IV

Chapter 6:

Electrical Actuation

systems

Mechanical Actuation systems.

Mechanical switches

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

41

Solid state switches

2%

86%

42

Solenoids

2%

88%

43

DC Actuation systems.

2%

90%

44

AC Actuation systems.

1%

91%

45

1%

92%

46

47

Stepper motors and their merits and

demerits

Introduction Actuation systems

Pneumatic Actuation systems .

1%

93%

1%

94%

48

Hydraulic Actuation systems

1%

93%

1%

95%

1%

96%

2%

98%

2%

100%

49

50

51

52

UNIT V

Introduction to Programmable Logic

Chapter 7:

control

Programmable Logic

Basic structure of Programmable

Control and Automation.

Logic control.

Input/ Output processing,

Programming,

Selection of Programmable Logic

control.

Introduction to automation.

Text Books:

1. Microprocessor Architecture, Programming and Applications With 8085/8085A,

R.S. Gaonkar, Penram International Publications, Fifth Edition, 1999.

2. MechatronicsElectronic Control systems in Mechanical and Electrical Engineering,

W.Bolton, Pearson Education Ltd., Third Edition, 2007.

Reference Books:

1. Microprocessor, Rafuquzzaman. M, Prentice-Hall, 1992

2. Automation with Programmable Logic Controllers, Macmillan, 1996

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

13ME403: Hydraulics and Pneumatics (4-0-0-0-4)

Faculty: Dr N Rajesh Mathivanan

Class

1

Chapter Title/

Reference Literature

UNIT 1

1.Introduction

Hydraulic Power:

Portions to be Covered

to

2

3

4

The source of Hydraulic

Power:

5

6

7

8

9

10

11

UNIT II

2.Hydraulic Cylinders:

12-13

14-15

16

17

18

19

3.Hydraulic Motors

20

21-22

23

No. of Hours: 52

UNIT III

4.Control Components in

Hydraulic Systems:

Introduction to Hydraulic Systems and

its practical applications. Pascals law

Problems

on Transmission

and

Multiplication of Forces.

Segments of Hydraulic control systems.

Introduction to hydraulic pumps, pump

flow and pressure.

Pump drive torque and power, pump

efficiency,

Numerical Problems on Pump drive

torque and power, pump efficiency

Pump types-Piston pumps, (Axial piston

pump,

Variable displacement axial pump, Bent

axis axial pump)

Gear pumps (External gear pump),

Vane pumps

Balanced vane pump, Graphic symbols,

Pump specifications

Introduction to hydraulic cylinders,

parts of a cylinder

Numerical problems. cylinder force,

cylinder speed, cylinder power,

Cylinder types Spring return,

telescopic cylinder,

Hydraulic ram. graphic symbols

Numerical on Hydraulic ram.

Cylinder applications problems,

Introduction to Hydraulic motors,

Motor types Gear motor, Balanced

vane motor, Graphic symbols,

Numerical on Motors torque, Motor

speed, Motor power, Motor efficiency,

Introduction to directional control

valves, Check valves, Two-way

directional control valves

% Portions Covered

Reference

Cumulative

Chapter

2%

2%

2%

4%

2%

6%

2%

8%

2%

10

2%

12%

2%

14%

2%

16%

2%

18%

2%

20%

2%

22%

4%

26%

4%

33%

2%

2%

2%

2%

34%

35%

36%

37%

2%

38%

4%

42%

2%

44%

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

24

25

26

Three-way directional control valves,

Four-way directional control valves.

Introduction to pressure control valves,

Pressure relief valves-pilot operated,

sequence valves.

Introduction to flow control valves, flow

control valve types

Needle valve, pressure compensated

flow control valve. Servo control valve

Control of single and double acting

hydraulic cylinder - 3 way DCV,

Control of single and double acting

hydraulic cylinder. (4 way 2 position)

2%

2%

2%

46%

48%

50%

2%

52%

2%

54%

2%

56%

2%

59%

2%

62%

32

Hydraulic cylinder sequencing circuits

2%

64%

33

Clamp and bending circuits, Hydraulic

press circuits.

2%

66%

2%

68%

2%

70%

2%

72%

Accumulator used with a press.

2%

74%

Introduction to Pneumatic Systems,

2%

76%

Structure of Pneumatic control systems

Comparisons of electrical, hydraulic

and pneumatic system. Choices of

working medium, characteristics of

compressed air.

Introduction to pneumatic actuators

Compressor types - Piston compressors,

Screw and rotary compressors.

Dynamic Compressors. Numerical.

Pneumatic

cylinders,

pneumatic

motors.

Pneumatic directional control valves.

2%

78%

4%

82%

2%

84%

2%

86%

2%

88%

2%

90%

2%

92%

27

28

29

30

UNIT IV

5.Hydraulic Circuits:

31

Speed control of hydraulic cylinderMeter-in flow control and Meter-out

flow control circuits.

Ancillary

hydraulic

components:

Accumulators - Diaphragm, spring

loaded

and

weight

loaded

accumulators.

Accumulator graphic symbols.

Accumulator circuits-

34

35

36

37

38

39

40-41

42

43

44

45

47

UNIT V

6.Pneumatic Systems:

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

48

49

50

51

52

7.Air preparation and

distribution:

Pneumatic flow control valves.

2%

94%

Stages of air treatment, Filters,

2%

96%

Air dryers, Lubricators.

Pressure relief valves,

Pressure regulators, Graphical symbols

2%

2%

2%

97%

98%

100%

Reference Books:

1 Introduction to Fluid Power, James L. Johnson, Delmar Thomson Learning, Eswar press,

2003

2 Pneumatics and Hydraulics, Andrew Parr, Jaico Publishing Co. 2005

3 Hydraulic and Pneumatic Controls, R Srinivasan, Vijay Nicole Publications, Second Edition,

2008.

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

14ME411: Design of Heat Exchangers (4-0-0-0-4)

Faculty: Mr. Jyothiprakash K H

No. of Hours: 52

Class #

1-2

3-4

5-6

7-8

9-10

11-12

13-14

Chapter Title /

Reference Chapter

Unit 1 (12hr) Introduction; Classification according to

Chapter1:

transfer process, according to number of

Classification of fluids, according to surface compactness;

Heat Exchangers according to flow arrangements and

according to heat transfer mechanisms.

Chapter 2: Analogy between thermal and electrical

Basic Thermal entities; heat exchanger variables and

Design Theory thermal circuit;

for Recuperators NTU method Relation between

and NTU for different flow arrangements

P NTU method relation between P and

NTU; Mean temperature difference

method; correction factor for various flow

arrangements;

Comparison of NTU, P-NTU and

MTD methods .The Psi P and P1 P2

methods.

Solution

methods

for

determining exchanger effectiveness;

Design problems

Effects of longitudinal wall-conduction,

variable overall heat transfer coefficients.

Additional considerations for extended

surface exchangers and shell and tube

heat exchangers.

Unit-2 (10hr)

Chapter 3:

Thermal Design

Theory for

Regenerators

15-16

17-18

19-20

Topics to be covered

Chapter 4:

Heat Exchanger

Pressure Drop

Analysis

% of portions covered

Reference Cumulative

Chapter

2

10

14

16

20

24

28

32

36

Heat transfer analysis;

NTU method; method

Influence of longitudinal and transverse

wall heat conduction.

influence of pressure and carryover

leakages; influence of matrix material,

size and arrangement

Introduction; extended surface heat

exchanger pressure drop; regenerator

pressure drop; tubular heat exchanger

pressure drop

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

21-22

23-24

25-26

27-28

29-30

31-32

33-34

35-36

37-38

39-40

41-42

43-44

45-46

47-48

49-50

51-52

Plate exchanger pressure drop; pressure

drop dependence on geometry and fluid

properties.

Unit-3 (10hr)

Basic concepts; dimensionless groups;

Chapter 5:

analytical and semi-empirical heat

Surface Basic Heat transfer and friction

Transfer and Flow

Friction

Characteristics

Correlations for simple and complex

geometries; influence of temperaturedependent fluid properties

Influence

of

superimposed

free

convection and radiation.

Chapter 6:

Tubular heat exchangers; Tube-fin heat

Heat Exchanger exchangers; plate-fin heat exchangers;

Surface Geometrical Regenerators with continuous cylindrical

Characteristics passages

Shell and tube exchangers with segmental

baffles; gasketed plate heat exchangers.

Unit 4 (10 hr)

Fluid mean temperatures

Chapter 7:

Heat exchanger

Design Procedures

plate-fin heat exchangers

tube-fin heat exchangers

plate heat exchangers

Shell and tube heat exchangers; heat

exchanger optimization.

Unit 5 (10 hr)

Selection criteria based on operating

Chapter 8:

parameters; general guide lines for major

Selection of Heat exchanger types;

Exchangers & Their

Components

selection criteria based on cost estimation

Chapter 9:

Fouling and its effect on exchanger heat

Fouling and

transfer and pressure drop

Corrosion

fouling resistance design approach

prevention and mitigation of fouling;

corrosion in heat exchangers

40

4

42

46

50

54

60

62

4

4

4

66

70

74

80

84

86

91

95

100

Text Book: Fundamentals of Heat Exchanger Design, Ramesh K Shah, Dusan P. Sekulic, John

Wiley & sons , 2003.(Chapters 1, 3 to 10 and 13)

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

13ME412: Vehicle Dynamics (4-0-0-0-4)

Faculty: Mr.BB

Class

#

Chapter Title/

Reference

Literature

No. of Hours: 52

Topics to be Covered

Unit I

Vehicle dynamics Terminology Vehicle,

Driver, Load and Environment, Vehicle

Classifications,

Chapter 1:

ISO and FHWA Classification, Passenger

3-4 Introduction

Car Classifications Vehicle Co-ordinate

T1:page 25-31

Systems, Vehicle inertia properties

Chapter 2:

Axle loads of vehicle and vehicle/trailer

Forward

Vehicle

5-6

combinations static and dynamic

Dynamics

conditions rear wheel, front wheel and

T1:page 39-82

4 wheel drives

Chapter 2:

Axle loads of vehicle and vehicle/trailer

7-8 Forward Vehicle

combinations static and dynamic

Dynamics

conditions rear wheel, front wheel and

T1:page39-82

4 wheel drives

Chapter 2:

Forward Vehicle

9-10

Numerical Examples

Dynamics

T1:page39-82

UNIT 2

Chapter 3:

11-12

Tyre Coordinate Frame and Tyre Force

Tyre Dynamics

System, Tyre Stiffness, Tyre

T3:Page 3-10

Fundamentals

1-2

13-14

15-16

17-18

19-20

Chapter 1:

Introduction

T1:page 20-24

% Portions Covered

Referenc Cumulativ

e Chapter

e

4%

4%

4%

8%

4%

12%

3%

15%

4%

19%

4%

23%

Chapter 3:

Tyre Dynamics

T1: Page 1-21

Tyres and Sidewall Information, Tyre

Components, Radial and non-radial

tyres, Hydroplaning,

4%

27%

Chapter 3:

Tyre Dynamics

T3: Page 30-73

Chapter 4:

Acceleration

PerformanceT2:

Page: 21-28

Chapter 4:

Acceleration

Performance

T2:Page: 28-39

Rolling Resistance and factors affecting

it, Longitudinal Force, Lateral Force,

Camber Force, Numerical Examples

4%

31%

Equation of motion and maximum

tractive effort

4%

35%

Engine characteristics, Traction and

Power limited calculations

3%

38%

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

Chapter 4:

21-22

Acceleration

Performance

T2:Page: 39-42

Chapter 5:

23Braking

24

PerformanceT2:

Page 45-59

Chapter 5:

25Braking

26

Performance

T2:Page 60-74

Chapter 5:

27Braking

28

Performance

T2:Page 67-76

Chapter 6:

29Vehicle

30

AerodynamicsT

3:Page 79-103

Chapter 6:

31Vehicle

32

AerodynamicsT

3:Page 103-123

Chapter 7:

Handling

33Characteristics

34

of Road

VehiclesT3:Page

335-350

Chapter 7:

Handling

35Characteristics

36

of Road Vehicles

T1:Page 350-356

Chapter 7:

Handling

37Characteristics

38

of Road Vehicles

T1:Page 356-363

Chapter 7:

Handling

39Characteristics

40

of Road Vehicles

T1:Page 363-369

Fuel economy calculations, Numerical

Examples.

4%

42%

UNIT 3

Basic equations, Braking forces, Brakes,

Tyre and road friction, stopping distance

4%

46%

Brake Proportioning, Braking efficiency,

Rear wheel lockup

4%

50%

Antilock Brake system, Numerical

Examples.

4%

54%

Aerodynamic, Aerodynamic forces, lift

and drag components

4%

58%

Pitching, yawing, rolling moments, Total

road loads, Numerical Examples

4%

62%

UNIT 4

Steering geometry, Handling

Characteristics of a two axle vehicles.

3%

65%

Steady-State response to steering input,

Testing of handling characteristics such

as Constant Radius Test

4%

69%

Constant speed Test, Constant Steer

Angle Test; Transient Response

Characteristics Road Vehicles

4%

73%

Criteria for Directional Stability,

Numerical Examples.

4%

77%

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

4142

4344

4546

4748

4950

5152

Chapter 7:

Handling

Characteristics

of Road Vehicles

T1:Page 387

Chapter 8:

Ride

Characteristics

of Road

VehiclesT2:page

125-146

T3: Page 431436

Chapter 8:

Ride

Characteristics

of Road

VehiclesT3:page

436-462

Chapter 8:

Ride

Characteristics

of Road

VehiclesT3:page

436-462

Chapter 8:

Ride

Characteristics

of Road

VehiclesT3:page

462-464

Chapter 8:

Ride

Characteristics

of Road

VehiclesT3:page

464-480

Numerical Examples.

4%

81%

UNIT 5

Ride excitation sources, Human response

to vehicle vibration

4%

85%

vehicle ride models quarter car model

and half car model

3%

88%

vehicle ride models quarter car model

and half car model

4%

92%

road profile roughness and modeling,

4%

96%

Evaluation of vehicle vibration in

relation to the ride comfort criterion.

4%

100%

Articles / Books:

T1. Reza N. Jazar, Vehicle Dynamics: Theory and Applications, Springer, First edition,

2008.

T2. Thomas D. Gillespie, Fundamental of Vehicle Dynamics, Society of Automotive

Engineers International, USA 1992.

T3. J. Y. Wong, Theory of Ground Vehicles, John Willey & Sons NY, Third Edition, 2001

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

13ME413: Product Design and Manufacturing (4-0-0-0-4)

Faculty: N. Rajesh Mathivanan

Class

Chapter Title/

Reference

Literature

1

2

3

4-5

UNIT 1

1.Introduction to

product design:

T1: 1.1-1.9.

6

7

8

9-10

2.Product Design

Practice in

industry:

T1: 2.1-2.8, 2.17,

2.18

11

12

13

14

15-16

UNIT II

3.Review of

strength, stiffness

and rigidity

considerations in

product design:

T1: 3.1 - 3.6, 5.1-5.4.

18-19

20

21

22-23

24-25

26

UNIT III

4.Design for

productionmetal

parts:

T1: 6.1 - 6.9, 8.1-8.6.

No. of Hours: 50

Portions to be Covered

Definition of product design, design by

evolution

Design by innovation, Essential factors

of product design, productionconsumption cycle

Flow and value addition in the

production-consumption cycle

Morphology of design (seven phases),

primary design phases and flowcharting

Role of allowance, process capability

and tolerance in detailed design and

assembly.

Introduction, product strategies, time to

market, analysis of the product

The Ss of standardization, Renard

series, simplification

Role of aesthetics in product design,

functional design practice.

Importance of strength, stiffness and

rigidity considerations in product design

Principal stress trajectories (force-flow

lines), balanced design,

criteria and objectives of design,

material toughness: Resilience

Designing for uniform strength, tension

vis--vis compression,

Review of production process:

Introduction, primary processes,

Machining process

non-traditional machining processes

Producibility requirements in the design

of machine components,

Forging design, pressed components

design, casting design,

Design for machining ease, role of

process engineer,

Ease of location casting and special

casting.

% Portions Covered

Reference

Cumulative

Chapter

2%

2%

2%

4%

2%

6%

4%

8%

2%

10%

2%

12%

2%

14%

4%

18%

2%

20%

2%

22%

2%

24%

2%

26%

4%

30%

4%

35%

2%

37%

2%

40%

4%

44%

4%

48%

2%

50%

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

Class

Chapter Title/

Reference

Literature

Designing with plastic, rubber, ceramics

and wood: approach to design with

plastics, plastic bush bearings, gears in

plastics,

Rubber parts, design recommendations

for rubber parts, ceramic and glass parts.

27-28

29-30

31-32

Portions to be Covered

UNIT IV

5. Life cycle of a

product

Life cycle management

% Portions Covered

Reference

Cumulative

Chapter

4%

54%

4%

58%

4%

62%

4%

66%

4%

70%

35-36

Automating information flow -work

flows-.

Creation of work flow templates

37-38

life cycle -work flow integration

4%

75%

39-40

4%

80%

4%

84%

2%

86%

2%

88%

2%

90%

46

Case studies

Product value, Design for safety and

reliability,

Design for environmental considerations

Manufacturing operations in relation to

design,.

Economic analysis, profit and

competitiveness,

Break-even analysis

2%

92%

47

Economics of a new product design

2%

94%

Modern approaches to product design

2%

96%

Concurrent design

2%

98%

Quality Function Deployment (QFD).

2%

100%

33-34

41-42

43

44

45

48

49

50

UNIT V

6.Economic factors

influencing design:

T1: 10.1-10.7.

7.Modern

approaches to

product design:

T1: 14.1-14.2.

Reference Book:

Product Design and Manufacturing, Chitale A K and Gupta R C, PHI, Fourth edition 2002.

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

13ME414: Thermal Management in Electronic Packages and Systems (4-0-0-0-4)

Faculty: Dr K.N.Seetharamu

Class

No.

1-2

3-4

Chapter Title /

Reference

Literature

Topics to be covered

Introduction

UNIT I

R1 (Page 1-14)

Semiconductor

Technology

Trends.

Temperature

Dependent

Failures,

Importance of heat transfer in electronics.

Introduction

Thermal design process. Heat Transfer

mechanisms-conduction, convection and

radiation.

R1 (Page 14-18)

R1 (Page 53-64)

5-6

No. of Hours: 52

Microelectronic

packages and

Thermal Resistance Importance of packaging. Packaging types.

Thermal specifications of packages.

network

% of Portions covered

Reference Cumulativ

chapter

e

4

12

16

20

R1 (Page 103-115)

7-8

Microelectronic

packages and

Thermal Resistance Package thermal resistance network-series

and parallel. General resistance network,

network

Thermal contact resistance,

R1 (Page 204 - 212)

R1 (Page 79-82)

9 - 10

11 12

Microelectronic

packages and

Thermal interface materials, Spreading

Thermal Resistance thermal resistance, Thermal resistance of

network

printed circuit boards.

R1 (Page 85-96)

Heat Conduction

Equation-Fins and

Heat sinks

Radiation Heat

Transfer

UNIT II

General heat Conduction equation.

Boundary and initial conditions. Steady state

one and two dimensional cases.

R1 (Page 169 - 194)

13 - 14

Heat Conduction

Equation-Fins and

Heat sinks

Radiation Heat

Transient heat conduction -. Lumped and

distributed system. Micro scale heat

conduction. Fin equation, fin thermal

resistance, effectiveness and efficiency of

fins.

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

Transfer

R1 (Page 194-204)

Ref (KNS Paper)

R1 (Page 127-150)

15 - 16

Heat Conduction

Equation-Fins and

Heat sinks

Radiation Heat

Transfer

R1 (Page 150-160)

Heat sink thermal resistance, effectiveness

and efficiency Optimization of heat sinks.

Blackbody radiation. Radiation properties of

surfaces.

24

Solar and atmospheric radiation. Stefans

Law, Plancks law, Wiens law and

Kirchhoffs law.

28

View factors, Radiation exchange between

black surfaces, Radiation heat transfer

between nonblack surfaces. Radiation heat

transfer from plate-fin heat sinks.

32

36

External flows. Flat plate and cylinders.

Reynolds number, Prandtl Number, Nusselt

Number.

44

Internal flows. Developing and developed

flows. Fans and pumps. Plate fin heat sinks.

48

Natural convection heat transfer.-Buoyancy

force. Grashoff and Rayleigh numbers.

Vertical plates-. Laminar and turbulent flow.

52

Ref (KNS Paper)

R1 (Page 320-331)

17 - 18

Heat Conduction

Equation-Fins and

Heat sinks

Radiation Heat

Transfer

R1 (Page 331-336)

19 - 20

Heat Conduction

Equation-Fins and

Heat sinks

Radiation Heat

Transfer

R1 (Page 337-349)

21 - 22

23 24

Convective Heat

Transfer

R1 (Page 209-218)

Convective Heat

Transfer

R1 (Page 219-247)

25 - 26

Convective Heat

Transfer

R1 (Page 255-283)

27 - 28

Convective Heat

Transfer

R1 (Page 287-303)

UNIT III

Fundamentals of convection. Velocity

boundary layer. Friction coefficient. Thermal

boundary layer. Heat transfer coefficient.

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

29 - 30

31 - 32

Convective Heat

Transfer

R1 (Page 303-314)

Advanced Cooling

Technologies.

Experimental

Techniques and

Thermal design

Horizontal plates and cylinders. Natural

convection in enclosures. Natural convection

from array of vertical plates. Mixed

convection.

56

60

Liquid immersion cooling, Thermo-syphons,

Loop heat pipes, Thermoelectric coolers,

piezoelectric fans, Electro hydrodynamic

flow, Synthetic Jets,

64

Single phase and two phase flow micro

channels- Thermal design, Cooling of 3

dimensional vertical stacks, Cooling of array

of boards

68

System cooling, Flow rate measurements,

System impedance measurement, Fans and

pump curves, Velocity measurements

72

Temperature

measurement

methods,

Acoustic Noise measurements, Importance

of Experimental measurements in Thermal

Design.

76

80

84

UNIT IV

Heat pipes, Micro heat pipes, Heat pipe heat

sinks, Heat pipe selection and modeling, Jet

impingement on flat surfaces and heat sinks

R1 (Page 421-435)

33 34

Advanced Cooling

Technologies.

Experimental

Techniques and

Thermal design

R1 (Page 435-452)

35 - 36

Advanced Cooling

Technologies.

Experimental

Techniques and

Thermal design

Ref (KNS Papers)

37 - 38

Advanced Cooling

Technologies.

Experimental

Techniques and

Thermal design

R1 (Page 401-414)

39 - 40

Advanced Cooling

Technologies.

Experimental

Techniques and

Thermal design

R1 (Page 414-420)

41 - 42

Computer

Simulation and

Thermal Design

R7 & R8

Heat transfer and fluid flow equations.Summary. Fundamentals of computer

simulation, Finite difference, Finite volume

and Finite element methods-Basic ideas

Computer

Solution

R1 (Page 353-362)

43 44

UNIT V

of

one

and

two

dimensional

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

Simulation and

Thermal Design

R1 (Page 356-373)

45 - 46

Computer

Simulation and

Thermal Design

R1 (Page 373-381)

47 - 48

Computer

Simulation and

Thermal Design

conduction problems. - Steady and transient

states, Fluid flow and energy equations

Laminar and turbulent flows- introduction.

Solution of problems using Ansys and Fluent

(or Comsol)

88

Case studies from electronic packages, boards

and systems

92

Case studies from electronic packages, boards

and systems

96

Case studies from electronic packages,

boards and systems

100

Ref (KNS Papers)

49 - 50

Computer

Simulation and

Thermal Design

Ref (KNS Papers)

51 - 52

Computer

Simulation and

Thermal Design

Ref (KNS Papers)

Reference Books:

R1. Heat Transfer-Thermal Management in Electronics by Shabany Younes CRC press,2010

R2. Fundamentals of Thermal management. Avram Bar Cohen, Abhay Watwe and K N

Seetharamu. Chapter 6 in the book Fundamentals of Microsystems Packaging, Rao R.

Tummala, McGrawhill. 2001

R3. Cooling of Electronic Equipment. Chapter in the book Introduction to Thermodynamics

and Heat Transfer Y A Cengel, McGrawhill,1997.

R4. Cooling Technologies for Electronic Equipment,D S Steinberg, John Wiley, 1980.

R5. Thermal Analysis and Control of Electronic Equipment.\, A D Kraus and A Bar

Cohen, Mc GrawHill, Hemisphere, 1983

R6. Thermal Computations for Electronic Equipment, G N Ellison, Van Nostrand

Reinhold,1984.

R7. Fundamentals of Finite Element methods for heat and fluid flow. R W Lewis, P Nithiarasu

and K N Seetharamu, John Willey, 2004.

R8. Computational Fluid Dynamics. The Finite Volume Method, Veer Steg and Malla Shekara,

Cambridge University Press

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

13ME415: Smart Materials (4-0-0-0-4)

Faculty: BKK

Clas

s#

1

10

Chapter Title /

Reference Literature

Chapter: 1

Introduction

R1

Chapter: 1

Introduction

T1: Chapter 1

Page 4 - 6

Chapter: 1

Introduction

T1: Chapter 1

Page 7 - 8

Chapter: 2

Piezoelectric Materials

T1: Chapter 1

Page 113

Chapter: 2

Piezoelectric Materials

T1: Chapter 2

Page 117 118

Chapter: 2

Piezoelectric Materials

T1: Chapter 2

Page 119 - 122

Chapter: 2

Piezoelectric Materials

T1: Chapter 2

Page 145

Chapter: 2

Piezoelectric Materials

T1: Chapter 2

Page 146 - 149

Chapter: 2

Piezoelectric Materials

T1: Chapter 2

Page 149 - 153

Chapter: 2

Piezoelectric Materials

T1: Chapter 2

Page 154 - 156

No. Of Hours: 50

Topics to be covered

% of Portions covered

Reference

Cumulative

chapter

UNIT 1

Introduction to Smart Materials

2%

2%

UNIT 1

Smart Material Actuators and Sensors

2%

4%

UNIT 1

Smart Actuators, Sensors

2%

6%

UNIT 1

Fundamentals of Piezoelectricity

2%

8%

2%

10%

UNIT 1

Basic Piezoceramic Characteristics

2%

12%

UNIT 1

Hysteresis and Nonlinearities in

Piezoelectric Materials

2%

14%

UNIT 1

Piezoceramic Actuators - Behavior

under Static Excitation Fields

2%

16%

UNIT 1

Piezoceramic Actuators - Behavior

under Static Excitation Fields

2%

18%

UNIT 1

Behavior under Dynamic Excitation

Fields

2%

20%

UNIT 1

Piezoceramic

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

11

12

13

14

Chapter: 3

Shape Memory Alloys

T1: Chapter 3

Page 146 - 149

Chapter: 3

Shape Memory Alloys

T1: Chapter 3

Page 198 - 199

Chapter: 3

Shape Memory Alloys

T1: Chapter 3

Page 200 202

Chapter: 3

Shape Memory Alloys

T1: Chapter 3

Page 208 211

15

Chapter: 3

Shape Memory Alloys

T1: Chapter 3

Page 214 216

16

Chapter: 3

Shape Memory Alloys

T1: Chapter 3

Page 229 232

17

Chapter: 3

Shape Memory Alloys

T1: Chapter 3

Page 233 237

18

Chapter: 3

Shape Memory Alloys

T1: Chapter 3

Page 238 242

19

20

Chapter: 3

Shape Memory Alloys

T1: Chapter 3

Page 256 258

Chapter: 3

Shape Memory Alloys

T1: Chapter 3

Page 281 283

UNIT 2

Fundamentals of Shape Memory Alloy

(SMA) Behavior, Phase Transformation

2%

22%

UNIT 2

Lattice Structure and

Mechanism

Deformation

2%

24%

UNIT 2

Low Temperature Stress-Strain Curve,

Origin of the One-Way Shape Memory

Effect

2%

26%

UNIT 2

Two-Way Shape Memory Effect

2%

28%

2%

30%

2%

32%

2%

34%

2%

36%

2%

38%

2%

40%

UNIT 2

Constrained Behavior of SMA - Free

Recovery, Constrained Recovery,

Effective Load-Lines of an SMAWire

Actuator

UNIT 2

Testing of SMA wires - Sample

Preparation, Cycling and Annealing,

Transformation Temperatures under Zero

Stress

UNIT 2

Testing of SMA wires - Variation of

Transformation Temperatures with

Stress, Stress-Strain Behavior at

Constant Temperature

UNIT 2

Testing of SMA wires - StressTemperature Behavior at Constant Strain,

Comparison of Resistive Heating and

External Heating

UNIT 2

Damping Capacity of SMA, Differences

in Stress-Strain Behavior in Tension and

Compression

UNIT 2

Composite Structures with Embedded

SMA Wires - Variable Stiffness

Composite Beams

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

21

22

23

24

25

26

27

28

29

Chapter: 3

Shape Memory Alloys

T1: Chapter 3

Page 284 288

Chapter: 3

Shape Memory Alloys

T1: Chapter 3

Page 294 298

Chapter: 4

Electrorheological

Fluids

T1: Chapter 7

Page 685 688

Chapter: 4

Electrorheological

Fluids

T1: Chapter 7

Page 689 - 692

Chapter: 4

Electrorheological

Fluids

T1: Chapter 7

Page 700 703

Chapter: 4

Electrorheological

Fluids

R1

Chapter: 5

Magnetorheological

Fluids

T1: Chapter 7

Page 685 688

Chapter: 5

Magnetorheological

Fluids

T1: Chapter 7

Page 689 692

Chapter: 5

Magnetorheological

Fluids

T1: Chapter 7

Page 700 703

UNIT 2

SMA-in-Sleeve Concept, Beams with

Embedded SMA Wires

2%

42%

UNIT 2

Experimental Testing of Variable

Stiffness Beams

2%

44%

UNIT 3

Fundamental Composition and Behavior

of Electrorheological fluids

2%

46%

UNIT 3

Fundamental Composition and Behavior

of Electrorheological fluids

2%

48%

UNIT 3

Electrorheological fluids dampers

2%

50%

UNIT 3

Applications of ER fluids

2%

52%

UNIT 3

Fundamental Composition and Behavior

of Magnetorheological fluids

2%

54%

UNIT 3

Fundamental Composition and Behavior

of Magnetorheological fluids

2%

56%

UNIT 3

Magnetorheological fluids dampers

2%

58%

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

30

31

32

33

34

35

36

37

38

Chapter: 5

Magnetorheological

Fluids

T1: Chapter 7

R1

Chapter: 6

Electrostrictive

Materials

T1: Chapter 6

Page 662 - 664

Chapter: 6

Electrostrictive

Materials

T1: Chapter 7

Page 670 - 672

Chapter: 6

Electrostrictive

Materials

T1: Chapter 7

Page 673 - 675

Chapter: 6

Electrostrictive

Materials

T1: Chapter 6

Page 676 - 677

Chapter: 7

Magnetostrictive

Materials

T1: Chapter 6

Page 581 583

Chapter: 7

Magnetostrictive

Materials

T1: Chapter 6

Page 584 - 587

Chapter: 7

Magnetostrictive

Materials

T1: Chapter 6

Page 587 - 590

Chapter: 7

Magnetostrictive

Materials

T1: Chapter 6

Page 599 - 600

UNIT 3

Applications of MR fluids

2%

60%

2%

62%

UNIT 4

Behavior under Static Excitation Fields

2%

64%

UNIT 4

Behavior under Dynamic Excitation

Fields

2%

66%

UNIT 4

Effect of Temperature, Polarization

2%

68%

UNIT 4

Magnetostriction

2%

70%

UNIT 4

Review of Basic Concepts in Magnetism

2%

72%

UNIT 4

Review of Basic Concepts in Magnetism

2%

74%

UNIT 4

Mechanism of Magnetostriction Definition of Crystal Axes and Magnetic

Anisotropy

2%

76%

UNIT 4

Electrostrictives

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

39

40

41

42

43

44

45

46

47

48

Chapter: 7

Magnetostrictive

Materials

T1: Chapter 6

Page 604 - 606

Chapter: 7

Magnetostrictive

Materials

T1: Chapter 6

Page 607 - 608

Chapter: 8

Fiber Optics

T2 : Chapter 7

Page 140

Chapter: 8

Fiber Optics

T2 : Chapter 7

Page 140 142

Chapter: 8

Fiber Optics

T2 : Chapter 7

Page 144 146

Chapter: 8

Fiber Optics

T2 : Chapter 7

Page 146 - 148

Chapter: 8

Fiber Optics

T2 : Chapter 7

Page 148 - 150

Chapter: 9

Smart Systems and

Control

T2 : Chapter 8

Page 157

Chapter: 9

Smart Systems and

Control

T2 : Chapter 8

Page 158 - 165

Chapter: 9

Smart Systems and

Control

T2 : Chapter 8

Page 165 - 169

UNIT 4

Effect of Magnetic Field Polarity, Effect

of External Stresses

2%

78%

UNIT 4

Effect of Temperature, Strain Hysteresis

2%

80%

UNIT 5

Introduction to fiber optics

2%

82%

UNIT 5

Discussion of fundamental principles

2%

84%

UNIT 5

Fiber optic sensors especially in the

measurement of Strain

2%

86%

UNIT 5

Fiber optic sensors especially in the

measurement of Strain

2%

88%

UNIT 5

Fiber optic sensors especially in the

measurement of Strain

2%

90%

UNIT 5

Introduction to Smart Systems and

Control

2%

92%

UNIT 5

Principles of Active control of Structures

2%

94%

UNIT 5

Principles of Active control of Structures

2%

96%

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

49

50

Chapter: 9

Smart Systems and

Control

R1

Chapter: 9

Smart Systems and

Control

R1

UNIT 5

Sensors and Actuators to control Fatigue

Crack propagation in Aircraft

2%

98%

UNIT 5

Sensors and Actuators to control Fatigue

Crack propagation in Aircraft

2%

100%

Text Books:

T1: Smart Structures Theory, Inderjit Chopra, Jayant Sirohi, Cambridge University Press,

2013

T2: Smart Structures, Analysis and Design, A V Srinvasan, Michael McFarland, Cambridge

University Press, 2001.

Reference:

R1: Notes prepared by the department staff member

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

13IE432: Probabilistic Methods and Engineering Simulations (4-0-0-0-4)

Faculty: Dr. Anirban Chakraborty

No. of Hours: 52

Unit

1

Lecture

1-2

3-4

5-6

7-8

9-10

11-12

2

13-14

15-16

17-18

19-20

3

21-22

23-24

25-26

27-28

29-30

31-32

33-34

35-36

Topics

Random variables; Mean, Variance

and Covariance; Chebyshev's

inequality; Law of Large Numbers

Discrete random variables

Binomial, Poisson,

Geometric, Negative Binomial

random variables, Hypergeometric

random variables, Numerical

problems

Continuous random variables

Uniform, Normal, Exponential

Poisson process; Conditional

Expectation and Conditional

Variance

Moment generating functions;

Stochastic processes, Project Work

(First Phase)

Pseudo-random number generation,

Generating discrete random variables

Inverse transform method

Acceptance rejection technique,

Composition approach, Generating

random vectors

Generating continuous random

variables Inverse transform

algorithm, Continuous random

variables - Rejection method,

Polar method for generating

normal random variables, Problems

Monte Carlo Integration

Importance sampling, Correlated

sampling

Control variates, Stratified sampling

Antithetic variates, Partition of the

region

Conditional Monte Carlo, Random

Quadrature Method

Markov Chains; ChapmanKolmogorov equations

Classification of states; Limiting

probabilities;

Applications

% Portions

4

% Cumulative

4

11

15

19

23

27

31

35

38

4

4

42

46

4

3

50

53

57

61

65

69

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

37-38

39-40

41-42

5

43-44

45-46

47-48

49-50

51-52

Mean time spent in transient states;

Branching processes

Time reversible Markov Chains;

Markov Chain Monte Carlo Methods

Markov Decision Processes, Project

Work (Third Phase)

Project work: Theoretical

background

Project work: Algorithm building

Project work: Computer

programming

Project work: Analysis of results

Project work: Report discussions

73

77

81

85

4

4

89

93

3

4

96

100

Textbook:

Simulation, Sheldon M. Ross (Academic Press, Elsevier, 2011)

References:

1. Introduction to Probability Models, Sheldon M. Ross (Academic Press, Elsevier, 2003)

2. Probability and Random Processes, Scott Miller and Donald Childers (Academic Press,

Elsevier, 2012)

3. Simulation and the Monte Carlo Method, Reuven Y. Rubinstein (John Wiley and Sons, Inc.

1981)

4. Lecture Notes

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

13ME421: Analysis and Design of Laminated Composite Structures (4-0-0-0-4)

Faculty: SA

Class

No.

Chapter Title /

Reference

Literature

Unit 1: Chapter 1:

Preliminaries

3

4

5

8

9

Unit 1: Chapter 1:

Preliminaries

Unit 1: Chapter 1:

Preliminaries

Unit 1: Chapter 1:

Preliminaries

Unit 1: Chapter 1:

Preliminaries

Unit 1: Chapter 2:

Introduction to

composite materials

and lamina

mechanics

Unit 1: Chapter 2:

Introduction to

composite materials

and lamina

mechanics

Unit 1: Chapter 2:

Introduction to

composite materials

and lamina

mechanics

Unit 2: Chapter 3:

No. of Hours: 52

Topics to be covered

Vector and tensor transformations; Isotropic

elasticity equations; kinematics, kinetics and

constitutive equations generalized Hookes

law, monoclinic, orthotropic, transversely

isotropic and isotropic materials; Equations

of thermo-elasticity, hygro-thermal elasticity

and electro-elasticity;

Virtual

work

principles:

Virtual

displacement and forces, Internal and

external virtual work;

Variational operator and functionals,

extrema of functionals fundamental lemma

of variational calculus and Euler-Lagrange

equations

Variational methods; Weighted residual

methods;

Principle of virtual displacements and the

Principle of minimum total potential energy;

Various types of fiber-reinforced composite

laminate, laminate construction and lay-up;

Tensor

and

contracted

notations;

Engineering constants of orthotropic

materials;

Characterization of a unidirectional lamina; Transformation of coordinates, stress, strain and material coefficients,

Plane-stress

constitutive

relations;

Simple problems

% of Portions covered

Reference Cumulativ

chapter

e

2%

2%

2%

4%

2%

6%

2%

8%

2%

10%

2%

12%

1%

13%

2%

15%

2%

17%

Simple problems

Classical laminated plate theory:

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

10

11

12

13

14

15

16

17

18

19

20

21

Theories of

laminated composite

plates CLPT and

FSDT

Unit 2: Chapter 3:

Theories of

laminated composite

plates CLPT and

FSDT

Unit 2: Chapter 3:

Theories of

laminated composite

plates CLPT and

FSDT

Unit 2: Chapter 3:

Theories of

laminated composite

plates CLPT and

FSDT

Unit 2: Chapter 3:

Theories of

laminated composite

plates CLPT and

FSDT

Unit 2: Chapter 3:

Theories of

laminated composite

plates CLPT and

FSDT

Unit 2: Chapter 4:

Layer wise theories

Unit 2: Chapter 4:

Layer wise theories

Unit 2: Chapter 4:

Layer wise theories

Unit 2: Chapter 4:

Layer wise theories

Unit 2: Chapter 4:

Layer wise theories

Unit 2: Chapter 4:

Layer wise theories

Unit 3: Chapter 5:

1D analysis of

laminates

composites

assumptions, displacements and strains,

lamina constitutive relations, laminate

constitutive equations, laminate stiffnesses

for selected laminates

Coupling and Decoupling

2%

19%

2%

21%

2%

23%

2%

25%

2%

27%

2%

29%

2%

31%

2%

33%

2%

35%

2%

37%

1%

38%

2%

40%

Equations of motion; Equations of motion in

terms of displacements

Equations of motion; Equations of motion in

terms of displacements

First-order shear deformation theory

First-order shear deformation theory

An overview of layer-wise theories, Layerwise theory of Reddy

Layer-wise theory of Reddy: Displacement

field, strains and stresses, Laminate

constitutive equations

Layer-wise theory of Reddy: Equations of

motion

Simple problems

Simple problems

Simple problems

Bending analysis using CLPT

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

22

23

24

25

26

27

28

29

30

31

Unit 3: Chapter 5:

1D analysis of

laminates

composites

Unit 3: Chapter 5:

1D analysis of

laminates

composites

Unit 3: Chapter 6:

Analysis of

laminates

composites plates

using CLPT

Unit 3: Chapter 6:

Analysis of

laminates

composites plates

using CLPT

Unit 3: Chapter 6:

Analysis of

laminates

composites plates

using CLPT

Unit 3: Chapter 6:

Analysis of

laminates

composites plates

using CLPT

Unit 3: Chapter 6:

Analysis of

laminates

composites plates

using CLPT

Unit 3: Chapter 6:

Analysis of

laminates

composites plates

using CLPT

Unit 3: Chapter 6:

Analysis of

laminates

composites plates

using CLPT

Unit 3: Chapter 6:

Analysis of

laminates

Buckling analysis using CLPT

2%

42%

2%

44%

2%

46%

2%

48%

2%

50%

2%

52%

2%

54%

2%

56%

2%

58%

2%

60%

Vibration analysis using CLPT

Bending of simply supported rectangular

plates, Navier solution,

Navier solution, Bending of plates with two

opposite edges simply supported, analytical

solutions

Bending of plates with two opposite edges

simply supported, analytical solutions

Vibration of simply supported plates

Vibration of simply supported plates

Simple problems

Simple problems

Simple problems

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

32

33

34

35

36

37

38

39

40

41

42

43

44

45

composites plates

using CLPT

Unit 3: Chapter 6:

Analysis of

laminates

composites plates

using CLPT

Unit 4: Chapter 7:

Composite failure

theories and failures

Unit 4: Chapter 7:

Composite failure

theories and failures

Unit 4: Chapter 7:

Composite failure

theories and failures

Unit 4: Chapter 7:

Composite failure

theories and failures

Unit 4: Chapter 7:

Composite failure

theories and failures

Unit 4: Chapter 7:

Composite failure

theories and failures

Unit 4: Chapter 7:

Composite failure

theories and failures

Unit 4: Chapter 8:

Design

considerations

Unit 4: Chapter 8:

Design

considerations

Unit 4: Chapter 8:

Design

considerations

Unit 4: Chapter 8:

Design

considerations

Unit 4: Chapter 8:

Design

considerations

Unit 4: Chapter 9:

Simple problems

2%

62%

Maximum stress and Maximum strain

theory, Tsai-Hill failure criterion

1%

63%

Tsai-Wu failure criterion, Tensile strength of

a uni-directional lamina

2%

65%

Shear strength of a uni-directional lamina;

Simple numerical problems

2%

67%

2%

69%

2%

71%

2%

73%

2%

75%

2%

77%

2%

79%

2%

81%

2%

83%

2%

85%

2%

87%

Simple numerical problems

Simple numerical problems

Free-edge effect (J N Reddy), Interlaminar

stresses (Jones, Pg. 260): experimental

confirmation (Jones, Pg. 269) and

implications (Jones, Pg. 272);

Failure modes of a laminated composite:

Matrix crushing, fiber breaking and debonding,

delaminations:

Free

edge

delamination suppression (Jones, Pg. 274)

Fiber and matrix selection factors (Jones);

Importance of constituents

Configuration

structures

selection

Stiffened

Laminate joints; Design of a composite

piece (Daniel Jones);

Optimization of a composite laminate

Helicopter blade (Daniel Jones Pg. 347)

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

46

47

48

49

50

51

52

Design of laminated

composites

structures

Unit 4: Chapter 9:

Design of laminated

composites

structures

Unit 4: Chapter 9:

Design of laminated

composites

structures

Unit 4: Chapter 9:

Design of laminated

composites

structures

Unit 4: Chapter 9:

Design of laminated

composites

structures

Unit 4: Chapter 9:

Design of laminated

composites

structures

Unit 4: Chapter 9:

Design of laminated

composites

structures

Unit 4: Chapter 9:

Design of laminated

composites

structures

Transmission shafts for trucks

1%

88%

2%

90%

2%

92%

2%

94%

2%

96%

2%

98%

2%

100%

Filament wound vessel winding angle

First-ply failure of a laminate ultimate

rupture

Optimum laminate for isotropic stress state

Determination of elastic characteristics of a

Carbon/Epoxy uni-directional layer using

tensile test;

Quasi-isotropic laminate

Sandwich structures (Chapter 4 in Daniels

book), Post-curing shapes of un-symmetric

laminates (Jones. Ph. 356), Environmental

effects

Text books:

T1 Text Book: Mechanics of Laminated Composite Plates and Shells: Theory and Analysis. J.

N. Reddy

T2 Text Book: Composite materials: Design and applications, Third edition. Daniel Gay. CRC

Press, Taylor and Francis Group

T3 Text Book: Mechanics of composite materials. Robert M Jones. Mc-Graw Hill

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

13ME422: Surface Engineering (4-0-0-0-4)

Faculty: Dr. MS

Class #

Chapter Title /

Reference

Literature

Chapter: 1

Introduction to

Surface

engineering:

T1:Chapter 2,

page 14-18

Chapter: 1

Introduction to

Surface

engineering:

T1:Chapter 2,

page 14-18

Chapter: 1

Introduction to

Surface

engineering:

T1:Chapter 2,

page 19-20

Chapter: 1

Introduction to

Surface

engineering:

T2:Chapter 1,

page 10-14

Chapter: 1

Introduction to

Surface

engineering:

T1:Chapter 2,

page 10-14

Chapter: 1

Introduction to

Surface

engineering:

T1:Chapter 2,

page 10-14

No. of Hours: 52

Topics to be covered

% of Portions covered

Reference

Cumulative

chapter

Unit 1

Introduction to surface engineering,

basic concepts, surfaces

2%

2%

surface energy, composition, surface

structure, modification of surfaces

2%

4%

Importance of Surface Processing in

Modifying the Properties of engineering

components

3%

7%

Surface modification of Components

Subjected to Abrasion

2%

9%

Surface modification of Components

Subjected to Wear

2%

11%

Surface modification of Components

Subjected to Corrosion

2%

13%

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

10

11

12

13

Chapter: 1

Introduction to

Surface

engineering:

T1:Chapter 2,

page 10-14

Chapter: 1

Introduction to

Surface

engineering:

T1:Chapter 3,

page 108-119

Chapter: 1

Introduction to

Surface

engineering:

T1:Chapter 3,

page 108-119

Chapter: 1

Introduction to

Surface

engineering:

T2:Chapter 4,

page 121-134

Chapter: 1

Introduction to

Surface

engineering:

T2:Chapter 4,

page 121-134

Chapter: 2

Various methods

of surface

modification:

T1:Chapter 1,

page 14-35

Chapter: 2

Various methods

of surface

modification:

T1:Chapter 1,

page 26-29

Surface modification of Components

Subjected to Fatigue.

1%

14%

Substrates for Surface Processing:

Various materials and advantages

2%

16%

Preparation of Substrate for Surface

Processing: Physical methods.

2%

18%

Preparation of Substrate for Surface

Processing: Chemical methods.

2%

20%

Preparation of Substrate for Surface

Processing: Electrochemical methods.

2%

22%

Unit 2

Introduction to Various Methods of

Surface Modifications

1%

23%

Physical

Vapour

Deposition

(Chromium, Nickel, Titanium, Copper,

etc.)

1%

24%

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

14

15

16

17

18

19

20

Chapter: 2

Various methods

of surface

modification:

T1:Chapter 1,

page 26-29

Chapter: 2

Various methods

of surface

modification:

T1:Chapter 1,

page 26-29

Chapter: 2

Various methods

of surface

modification:

T1:Chapter 1,

page 25-26

Chapter: 2

Various methods

of surface

modification:

T1:Chapter 1,

page 25-26

Chapter: 2

Various methods

of surface

modification:

T1:Chapter 1,

page 25-26

Chapter: 2

Various methods

of surface

modification:

T1:Chapter 1,

page 29-30

Chapter: 2

Various methods

of surface

modification:

T1:Chapter 1,

page 29-30

PVD: Substrates, deposition process,

characteristics, parameters

2%

26%

PVD

coatings

:

Advantages,

Limitations and Applications

2%

28%

Chemical

Vapour

Deposition

(Chromium, Nickel, Titanium, Copper,

etc.)

1%

29%

CVD: substrates, deposition process,

characteristics, parameters

2%

31%

CVD

coatings

:

Advantages,

Limitations and Applications

2%

33%

Surface modification

Implantation Methods,

1%

34%

2%

36%

using

Ion

Ion Implantation process, parameters

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

21

22

23

24

25

26

27

Chapter: 2

Various methods

of surface

modification:

T1:Chapter 1,

page 29-30

Chapter: 2

Various methods

of surface

modification:

T1:Chapter 2,

page 14-18

Chapter: 2

Various methods

of surface

modification:

T1:Chapter 7,

page 280-287

Chapter: 2

Various methods

of surface

modification:

T1:Chapter 7,

page 280-287

Chapter: 3

Electrochemical

and Spark

Discharge

Processes:

T1:Chapter 1,

page 17-19

Chapter: 3

Electrochemical

and Spark

Discharge

Processes:

T1:Chapter 2,

page 17-19

Chapter: 3

Electrochemical

and Spark

Discharge

Processes:

T1:Chapter 1,

page 17-19

Ion implantation coatings : Advantages,

Limitations and Applications

2%

38%

High temperature performance of

engineering

component

surfaces:

necessity and importance

1%

39%

Various Coatings for High Temperature

Performance.

2%

41%

Advantages,

limitations

and

applications of high temperature

performance coatings

2%

43%

UNIT 3

Electrochemical Processes :

concepts, surface preparation

Basic

2%

45%

electroplating, electro less plating,

electro polishing, other methodologies

2%

47%

Different Methods, reagents and

parameters for electro chemical

methods

2%

49%

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

28

29

30

31

32

33

Chapter: 3

Electrochemical

and Spark

Discharge

Processes:

T2:Chapter 1,

page 20-24

Chapter: 3

Electrochemical

and Spark

Discharge

Processes:

T2:Chapter 2,

page 31-53

Chapter: 3

Electrochemical

and Spark

Discharge

Processes:

T2:Chapter 2,

page 31-53

Chapter: 3

Electrochemical

and Spark

Discharge

Processes:

T2:Chapter 2,

page 31-53

Chapter: 3

Electrochemical

and Spark

Discharge

Processes:

T2:Chapter 2,

page 31-53

Chapter: 3

Electrochemical

and Spark

Discharge

Processes:

T2:Chapter 7,

page 270-279

Different Methods, reagents and

parameters for electro chemical

methods

2%

51%

Spark Discharge Processes: Methods,

Characteristics, Applications

2%

53%

Spark Discharge Processes: Methods,

Characteristics, Applications

2%

55%

Plasma

Coating

:

Methods,

Characteristics, Applications

3%

58%

Organic and Powder Coatings :

Methods, Characteristics, Applications

2%

60%

Thermal Barrier Coating : Methods,

Characteristics, Applications

2%

62%

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

34

35

36

37

38

39

40

41

Chapter: 3

Electrochemical

and Spark

Discharge

Processes:

T2:Chapter 7,

page 270-279

Chapter: 4

Advanced

Techniques:

T3:Chapter 2,

page 54-73

Chapter: 4

Advanced

Techniques:

T3:Chapter 2,

page 54-73

Chapter: 4

Advanced

Techniques:

T3:Chapter 2,

page 54-73

Chapter: 4

Advanced

Techniques:

T3:Chapter 2,

page 54-73

Chapter: 4

Advanced

Techniques:

T1:Chapter 2,

page 14-18

Chapter: 4

Advanced

Techniques:

T1:Chapter 2,

page 54-73

Chapter: 4

Advanced

Techniques:

T1:Chapter 2,

page 54-73

Thermal Barrier Coating : Methods,

Characteristics, Applications

2%

64%

2%

66%

Laser Surface Processing : Various

methods, key parameters, advantages

2%

68%

Laser

Ablation

methods,

parameters, advantages

2%

70%

2%

72%

EMI shielding coatings : necessity,

performance, advantages , applications

2%

74%

RF Shielding coatings : necessity,

performance, advantages , applications

2%

76%

Specialty

coatings:

necessity,

performance, advantages , applications

2%

78%

UNIT 4

Advanced Electron Beam Techniques :

Various methods, key parameters,

advantages

key

Coating on Plastics : Various methods,

key parameters, advantages

PES INSTITUTE OF TECHNOLOGY

B.E- Mechanical Engineering (Batch 2013-17)

42

43

44

45

46

47

48

49

50

Chapter: 5

Applications of

various methods:

T1:Chapter 7,

page 243-265

Chapter: 5