Professional Documents

Culture Documents

05

Uploaded by

Moaed KanbarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

05

Uploaded by

Moaed KanbarCopyright:

Available Formats

IGNITION TIMING

. 1 7

IGNITION TIMING

Introduction

Ignition timing is the measurement, in degrees of crankshaft rotation, of the point

at which the spark plugs fire in each of the cylinders. It is measured in degrees

before or after Top Dead Center (TDC) of the compression stroke.

Because it takes a fraction of a second for the spark plug to ignite the mixture in

the cylinder, the spark plug must fire a little before the piston reaches TDC.

Otherwise, the mixture will not be completely ignited as the piston passes TDC

and the full power of the explosion will not be used by the engine.

The timing measurement is given in degrees of crankshaft rotation BEFORE the

piston reaches TDC (BTDC). If the setting for the ignition timing is 10 BTDC, the

spark plug must fire 10 before each piston reaches TDC. This only holds true,

however, when the engine is at idle speed.

As the engine speed increases, the pistons go faster. The spark plugs have to

ignite the fuel even sooner if it is to be completely ignited when the piston

reaches TDC. To do this, distributors have various means of advancing the spark

timing as the engine speed increases. On some earlier model vehicles, this is

accomplished by centrifugal weights within the distributor along with a vacuum

diaphragm mounted on the side of the distributor. Models covered by this manual

use signals from various sensors, making all timing changes electronically, and no

vacuum or mechanical advance is used. The 3.0L and 3.2L SHO engines and the

3.0L Flexible Fuel engines use a distributorless electronic ignition system.

Operation of this system allows for full electronic control of the timing.

If the ignition is set too far advanced (BTDC), the ignition and expansion of the

fuel in the cylinder will occur too soon and tend to force the piston down while it

is still traveling up. This causes engine ping. If the ignition spark is set too far

retarded, After TDC (ATDC), the piston will have already passed TDC and started

on its way down when the fuel is ignited. This will cause the piston to be forced

down for only a portion of its travel, and will result in poor engine performance as

well as a lack of power.

The timing marks on the 2.5L engine are visible through a hole in the top of the

transaxle case. The 3.0L and 3.8L engines have the timing marks on the

crankshaft pulley and a timing marker near the pulley. A stroboscopic (dynamic)

timing light is used, which is hooked into the circuit of the No. 1 cylinder spark

plug. Every time the spark plug fires, the timing light flashes. By aiming the

timing light at the timing marks while the engine is running, the exact position of

the piston within the cylinder can be easily read since the stroboscopic flash

makes the mark on the pulley appear to be standing still. Proper timing is

indicated when the notch is aligned with the correct number on the scale.

http://www.chiltondiy.com/content/8687/8687_2_5.html

18.11.2005

IGNITION TIMING

. 2 7

Timing mark on flywheel-2.5L engine with manual transaxle

Timing pointer location-2.5L engine with manual transaxle

Click to enlarge

Timing mark on flywheel-2.5L engine with automatic transaxle

http://www.chiltondiy.com/content/8687/8687_2_5.html

18.11.2005

IGNITION TIMING

. 3 7

Timing pointer location-2.5L engine with automatic transaxle

Timing mark location-3.0L expcept Flexible Fuel and SHO engines

http://www.chiltondiy.com/content/8687/8687_2_5.html

18.11.2005

IGNITION TIMING

. 4 7

Timing mark location-3.0L SHO engine

Click to enlarge

There are three basic types of timing lights available. The first is a simple neon

bulb with two wire connections (one for the spark plug and one for the plug wire,

to connect the light in series). This type of light is quite dim, and must be held

closely to the marks to be seen, but it is quite inexpensive. The second type of

light is powered by the car's battery. Two alligator clips connect to the battery

terminals, while a third wire connects to the spark plug with an adapter. This type

of light is more expensive, but the xenon bulb provides a nice bright flash which

can even be seen in sunlight. The third type replaces the battery source with 110

volt house current, but still attaches to the No. 1 spark plug wire in order to

determine when the plug is fired. Some timing lights have other functions built

into them, such as dwell meters, tachometers, or remote starting switches. These

are convenient, in that they reduce the tangle of wires under the hood, but may

duplicate the functions of tools you already have.

Never pierce a spark plug wire in order to attach a timing light or

perform tests. The pierced insulation will eventually lead to an electrical

arc and related ignition troubles.

Since your car has electronic ignition, you should use a timing light with an

inductive pickup. This pickup simply clamps onto the No. 1 spark plug wire,

eliminating the adapter. It is not susceptible to cross-firing or false triggering,

which may occur with a conventional light, due to the greater voltages produced

by electronic ignition.

Timing

INSPECTION & ADJUSTMENT

Except 3.0L Flexible Fuel (FF), 3.0L and 3.2L SHO Engines

The timing marks on the 2.5L engine are located on the flywheel and are visible

through a hole in the transaxle case for manual transaxles. To view the timing

marks, a cover plate on top of the transaxle must be removed. For 2.5L engines

equipped with automatic transaxles, the timing marks are visible through a hole

http://www.chiltondiy.com/content/8687/8687_2_5.html

18.11.2005

IGNITION TIMING

. 5 7

in the transaxle case.

The 3.0L and 3.8L engines have the timing marks on the crankshaft pulley and a

timing pointer near the pulley. To check and adjust the ignition timing:

Timing mark location-3.0L except Flexible Fuel and SHO engines

1.

Place the transaxle in the P (AT) or N (MT) position. The air conditioner and heater

must be in the OFF position.

2.

Open the hood, locate the timing marks and clean them with a stiff brush or

solvent. On vehicles equipped with a manual transaxle, it will be necessary to

remove the transaxle cover plate which allows access to the timing marks.

3.

Using a white chalk or paint, highlight the specified timing mark and pointer.

4.

Near the distributor, detach the inline Spark Output (SPOUT) connector or remove

the shorting bar from the double wire SPOUT connector. The spout connector is

the center wire between the Electronic Control Assembly (ECA) connector and the

Thick Film Integrated (TFI) or Ignition Control (ICM) module.

5.

Connect an inductive-type timing light, Rotunda tool No. 059-00006 or equivalent,

to the No. 1 spark plug wire. DO NOT puncture the ignition wire with any type of

probing device.

The high ignition coil voltage generated in the EEC-IV ignition system

may falsely trigger the timing lights with capacitive or direct connect

pick-ups. It is necessary that an inductive type timing light be used in

http://www.chiltondiy.com/content/8687/8687_2_5.html

18.11.2005

IGNITION TIMING

. 6 7

this procedure.

6.

Connect a suitable tachometer, Rotunda tool No. 099-00003 or equivalent, to the

engine. The ignition coil connector allows a test lead with an alligator clip to be

connected to the Distributor Electronic Control (DEC) terminal without removing

the connector.

The ignition coil electrical connector allows a test lead with an alligator

clip to be connected to its dark green/yellow dotted wire terminal

without removing the connector. Be careful not to ground the alligator

clip, for permanent damage to the ignition coil will result.

7.

Start the engine, using the ignition key, and allow it to run until it reaches normal

operating temperature.

Only use the ignition key to start the vehicle. Do NOT use a remote

starter, as disconnecting the start wire at the starter relay will cause the

TFI or ICM to revert back to the start mode timing, after the vehicle is

started. Reconnecting the start wire after the vehicle is running will not

correct the timing.

8.

Check the engine idle rpm; if it is not within specifications, adjust as necessary.

Idle speed is not adjustable on 1991-95 vehicles. After the rpm has been adjusted

or checked, aim the timing light at the timing marks. If they are not aligned, loosen

the distributor clamp bolts slightly and rotate the distributor body until the marks

are aligned under the timing light illumination.

9.

Tighten the distributor clamp bolts and recheck the ignition timing. Readjust the

idle speed, if necessary or possible.

10.

Turn the engine OFF, remove all test equipment, reconnect the inline SPOUT

connector to the distributor and, if necessary, reinstall the cover plate on manual

transaxle vehicles.

3.0L Flexible Fuel (FF), 3.0L and 3.2L SHO Engines

The base ignition timing is set at 10 Before Top Dead Center (BTDC) and is not

adjustable.

Timing mark location-3.0L SHO engine

http://www.chiltondiy.com/content/8687/8687_2_5.html

18.11.2005

IGNITION TIMING

. 7 7

Click to enlarge

TACHOMETER HOOKUP

On distributor-equipped models with an "E'' type ignition coil, the tachometer

connection is made at the back of the wire harness connector. A cut-out is

provided and the tachometer lead wire alligator clip can be connected to the dark

green/yellow dotted wire of the electrical harness plug.

Chilton Automotive Information Systems. 2004 Thomson Delmar Learning.

http://www.chiltondiy.com/content/8687/8687_2_5.html

18.11.2005

You might also like

- Ignition Timing PDFDocument7 pagesIgnition Timing PDFStephen DiandaNo ratings yet

- Snap-On MT2261A User ManualDocument8 pagesSnap-On MT2261A User ManualAndrew Dickens67% (6)

- Timing Light With Advance Feature PDFDocument8 pagesTiming Light With Advance Feature PDFstevencychenNo ratings yet

- D AdjustmentsDocument11 pagesD Adjustmentsdguruge8No ratings yet

- BMW - K1200 - Throttle-Valve-Actuator TVA (Version 1-2) - 1Document5 pagesBMW - K1200 - Throttle-Valve-Actuator TVA (Version 1-2) - 1steveNo ratings yet

- Description: Report A Problem With This ArticleDocument5 pagesDescription: Report A Problem With This ArticleFaroukNo ratings yet

- Starting Sys PDFDocument42 pagesStarting Sys PDFAnonymous 8GJQCGaeNo ratings yet

- Alt I Installation GuideDocument10 pagesAlt I Installation GuidegustavoespinosamNo ratings yet

- 1.9l 4-Cylinder Turbo DieselDocument26 pages1.9l 4-Cylinder Turbo Dieselfloresf5100% (1)

- Model Identification: WarningDocument11 pagesModel Identification: Warningoz23No ratings yet

- 3500 Governer Fuel Ratio ControlDocument32 pages3500 Governer Fuel Ratio ControlaliNo ratings yet

- Basic Testing Pajero 1991Document12 pagesBasic Testing Pajero 1991nadaNo ratings yet

- Ignition TimingDocument7 pagesIgnition TimingdonlynNo ratings yet

- Maintenance and Tune-Up Idle Speed and Mixture AdjustmentDocument5 pagesMaintenance and Tune-Up Idle Speed and Mixture AdjustmentFarabi ArdhiantoNo ratings yet

- Effect of Valve ClearanceDocument13 pagesEffect of Valve Clearanceabdu0% (1)

- D - Adjustments: 1991 Mitsubishi MonteroDocument10 pagesD - Adjustments: 1991 Mitsubishi MonteronadaNo ratings yet

- DLE-35RA: Operator's ManualDocument24 pagesDLE-35RA: Operator's ManualМаксим ИващенкоNo ratings yet

- Camry 2013Document406 pagesCamry 2013Aldo Monteon100% (1)

- Easy Fast Smart Installation ManualDocument26 pagesEasy Fast Smart Installation Manualsagarisltd100% (3)

- Dellorto Carb Install Instructions For 13bDocument7 pagesDellorto Carb Install Instructions For 13bBrent Z. BaileyNo ratings yet

- 3412C Fuel System Pruebas y AjustesDocument13 pages3412C Fuel System Pruebas y AjustesJuan Carlos Inga VasquezNo ratings yet

- PVL Ignition Installation & Operating Instructions: Warning!!Document4 pagesPVL Ignition Installation & Operating Instructions: Warning!!nenadNo ratings yet

- MPI 5 Port Kit Fitting Instructions Aug 2020Document3 pagesMPI 5 Port Kit Fitting Instructions Aug 2020Angi RomanoNo ratings yet

- Idle Speed ControlDocument4 pagesIdle Speed ControlRichard Dela PeñaNo ratings yet

- DLE 55 G0055-ManualDocument24 pagesDLE 55 G0055-ManualAbel Gonzalez OnrubiaNo ratings yet

- Tune-Up Guide For Geo Metro 1.0 Liter CarsDocument8 pagesTune-Up Guide For Geo Metro 1.0 Liter CarsDerek JewettNo ratings yet

- Corolla L 2014 2zr FaeDocument526 pagesCorolla L 2014 2zr Faeelizardo macias condoriNo ratings yet

- Carburetor Troubleshooting Repair Guide For HondaDocument9 pagesCarburetor Troubleshooting Repair Guide For HondaRoyal ENo ratings yet

- G4123 - Instructions Lanpara Avance Gunson InstrucionesDocument19 pagesG4123 - Instructions Lanpara Avance Gunson InstrucionesJean CarlosNo ratings yet

- 5 Engine and Its ComponentsDocument16 pages5 Engine and Its ComponentsMoisés MartinezNo ratings yet

- Ondemandware - Staticsites Horizon Us SiteSites Horizon masterdefaultManualsDLEG0020 Manual ENDocument24 pagesOndemandware - Staticsites Horizon Us SiteSites Horizon masterdefaultManualsDLEG0020 Manual ENpaulo_gallina_2No ratings yet

- Fuel PumpDocument4 pagesFuel PumpRajesh Kumar100% (2)

- 2.0l EngineDocument312 pages2.0l EngineMike Sumaya Jr.No ratings yet

- Service Information and Use of 8T5300 Engine Timing Indicator Group (0782)Document56 pagesService Information and Use of 8T5300 Engine Timing Indicator Group (0782)Luis OcampoNo ratings yet

- Timing The RotaxDocument3 pagesTiming The RotaxARMILITENo ratings yet

- ME Manual AppendixDocument641 pagesME Manual AppendixAnonymous uTO1WI0% (1)

- DLE60 User ManualDocument24 pagesDLE60 User ManualkingNo ratings yet

- How - To Engine Tune-Up BasicsDocument6 pagesHow - To Engine Tune-Up Basicsimplode32No ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Fire Boy Shumdown SystemDocument9 pagesFire Boy Shumdown SystemHector Jose Espinoza PerezNo ratings yet

- Ford Think Service Manual - Section 3 PowertrainDocument16 pagesFord Think Service Manual - Section 3 PowertrainDennis Jason AntiNo ratings yet

- Dleg0085 ManualDocument24 pagesDleg0085 ManualEdgar Alexander Grisales VallejoNo ratings yet

- Charging 2001-04 PDFDocument19 pagesCharging 2001-04 PDFoz23No ratings yet

- 05 Fuel Injection SystemDocument42 pages05 Fuel Injection SystemVishal JohaheerNo ratings yet

- Venza 1AR FEDocument268 pagesVenza 1AR FEDiego49650% (2)

- (PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 Ingles PDFDocument34 pages(PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 Ingles PDFtrastornadojhonNo ratings yet

- (PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 InglesDocument34 pages(PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 Inglesjorge Angel LopeNo ratings yet

- Testing and Adjusting Cat 3412 SN 3fzDocument21 pagesTesting and Adjusting Cat 3412 SN 3fzEd Calhe100% (11)

- 4runner Limited 2009 2UZ FEDocument314 pages4runner Limited 2009 2UZ FEarmotrixmecNo ratings yet

- Engine Identification: 1998-2000 ENGINES 3.0L V6 1998-2000 ENGINES 3.0L V6Document49 pagesEngine Identification: 1998-2000 ENGINES 3.0L V6 1998-2000 ENGINES 3.0L V6Rafael Enrique Grijalva GarciaNo ratings yet

- Electrical System EngineDocument87 pagesElectrical System EngineGreg HannaNo ratings yet

- Engine IdentificationDocument47 pagesEngine Identificationgerber damianNo ratings yet

- Motec Gear Change Ignition CutDocument16 pagesMotec Gear Change Ignition CutOutlawRNo ratings yet

- Ajuste Avance Encendido Chevy 5.7 LDocument1 pageAjuste Avance Encendido Chevy 5.7 LRomulo Correa RuizNo ratings yet

- Installing The Hot-Spark SVDA 034 Distributor With 3BOS4U1 Electronic IgnitionDocument4 pagesInstalling The Hot-Spark SVDA 034 Distributor With 3BOS4U1 Electronic IgnitionIsaias PrestesNo ratings yet

- Starter Chevrolet S10Document22 pagesStarter Chevrolet S10Maxi SardiNo ratings yet

- Ignition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.From EverandIgnition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Rating: 3 out of 5 stars3/5 (4)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Ford Manual for Owners and Operators of Ford Cars and Trucks (1919)From EverandFord Manual for Owners and Operators of Ford Cars and Trucks (1919)No ratings yet

- اسئلة تمهيدي انكليزي من 2014 -2020Document114 pagesاسئلة تمهيدي انكليزي من 2014 -2020Moaed KanbarNo ratings yet

- Manual Transmission: (M5/6Cfx-1)Document10 pagesManual Transmission: (M5/6Cfx-1)Moaed Kanbar100% (2)

- الأزمنة في الإنكليزيDocument23 pagesالأزمنة في الإنكليزيMoaed KanbarNo ratings yet

- PB AT A4CF1 EngDocument19 pagesPB AT A4CF1 EngMoaed KanbarNo ratings yet

- PB Air Conditioning EngDocument18 pagesPB Air Conditioning EngMoaed KanbarNo ratings yet

- PB MDPS EngDocument9 pagesPB MDPS EngMoaed KanbarNo ratings yet

- PB SRS EngDocument18 pagesPB SRS EngMoaed KanbarNo ratings yet

- Continuous Variable Valve Timing (CVVT), FunctionDocument2 pagesContinuous Variable Valve Timing (CVVT), FunctionMoaed KanbarNo ratings yet

- PB AT A4CF1 EngDocument19 pagesPB AT A4CF1 EngMoaed KanbarNo ratings yet

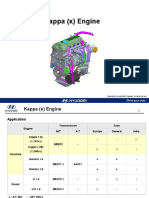

- PB Engine Gamma EngDocument14 pagesPB Engine Gamma EngMoaed Kanbar100% (3)

- PB Engine Kappa EngDocument15 pagesPB Engine Kappa EngMoaed Kanbar50% (2)

- In-Vehicle Repair: Timing Drive Components - Hydraulic Chain Tensioner, RHDocument1 pageIn-Vehicle Repair: Timing Drive Components - Hydraulic Chain Tensioner, RHMoaed Kanbar100% (1)

- Mitsubishi Galant 4g63 Engine Repair ManualDocument29 pagesMitsubishi Galant 4g63 Engine Repair ManualMoaed Kanbar100% (1)

- Cross Section F8M F8Q Engine Repair (Motor Diesel F8M F8Q Dacia Papuc Solenza 1307)Document107 pagesCross Section F8M F8Q Engine Repair (Motor Diesel F8M F8Q Dacia Papuc Solenza 1307)bogdanxp2000100% (4)

- Hydraulic & Workshop PDFDocument19 pagesHydraulic & Workshop PDFMoaed Kanbar100% (3)

- Karcher Pressure Washer Parts and Basic Repair Service Manual Pump SM9120 0140 G3025BH G3025OH G3050OH PDFDocument8 pagesKarcher Pressure Washer Parts and Basic Repair Service Manual Pump SM9120 0140 G3025BH G3025OH G3050OH PDFMoaed Kanbar100% (1)

- Clean and Cool PDFDocument4 pagesClean and Cool PDFMoaed KanbarNo ratings yet

- 0288sportage Brochure 2011 PDFDocument6 pages0288sportage Brochure 2011 PDFMoaed KanbarNo ratings yet

- Deteqstandart PDFDocument4 pagesDeteqstandart PDFMoaed KanbarNo ratings yet

- How To Install Guide: Prepare, Install & Care For Your New Vinyl SidingDocument13 pagesHow To Install Guide: Prepare, Install & Care For Your New Vinyl SidingMoaed Kanbar100% (1)

- Lubrication System (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) )Document2 pagesLubrication System (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) )grivaskachiswe40No ratings yet

- EDC Lesson PlanDocument3 pagesEDC Lesson PlanboobalanapNo ratings yet

- Yzf R15 Service PDFDocument347 pagesYzf R15 Service PDFbamboo wifi100% (3)

- H Generator Set Data SheetDocument4 pagesH Generator Set Data SheetKatya RodriguezNo ratings yet

- Maintenance-Engine Oil Type - 01Document2 pagesMaintenance-Engine Oil Type - 01jarbasNo ratings yet

- A. R. Gunaki, "Analysis of Diesel Engine Turbocharger & Its Optimization", International Journal For Scientific Research & Development PDFDocument6 pagesA. R. Gunaki, "Analysis of Diesel Engine Turbocharger & Its Optimization", International Journal For Scientific Research & Development PDFvignesh ranaNo ratings yet

- Lincoln: 81713, 81713A, 81770-1, 2, 3, 4, 5 Sl-I Injector SeriesDocument2 pagesLincoln: 81713, 81713A, 81770-1, 2, 3, 4, 5 Sl-I Injector SeriesJimmy CmNo ratings yet

- Sebp7383 05 00 Allcd - 9Document837 pagesSebp7383 05 00 Allcd - 9Roland Culla100% (1)

- Motorcraft Antifreeze CoolantsDocument6 pagesMotorcraft Antifreeze CoolantsRogerio EduardoNo ratings yet

- AlternatorDocument3 pagesAlternatorVatsal PatelNo ratings yet

- RevTech2013 WcollectionDocument44 pagesRevTech2013 Wcollectionhandoko pocaNo ratings yet

- MODULE-14 Previous Questions: World'$ of AmeDocument50 pagesMODULE-14 Previous Questions: World'$ of AmeRobNo ratings yet

- Vespa Jetting Guide: Allstyles ScootersDocument4 pagesVespa Jetting Guide: Allstyles ScootersLuas LineNo ratings yet

- MAN D2866E Manual PDFDocument64 pagesMAN D2866E Manual PDFAleksanrd Mihailov85% (27)

- Stock Card KMM PRD Mei 2022Document9 pagesStock Card KMM PRD Mei 2022Lavexia GamingNo ratings yet

- 950H - Sebp3866-24 - K5K - Vol 2Document735 pages950H - Sebp3866-24 - K5K - Vol 2Nilder Rojas100% (4)

- KSZ 70-125BDocument690 pagesKSZ 70-125Bcengiz kutukcu100% (1)

- Tata Hitachi EX-200 Parts ManualDocument164 pagesTata Hitachi EX-200 Parts ManualBALA100% (11)

- Fault Codes C13 C15 C18Document51 pagesFault Codes C13 C15 C18inforlex71% (7)

- Iveco Cursor 13 Brochure FinalDocument2 pagesIveco Cursor 13 Brochure FinalkarijosephNo ratings yet

- EN DX420LC-7K DX490LC-7K DX530LC-7K Brochure D4600693 07-2022 LowResDocument28 pagesEN DX420LC-7K DX490LC-7K DX530LC-7K Brochure D4600693 07-2022 LowResBilal VURALNo ratings yet

- DB 01.01.26.04 Pump S200 SSDocument2 pagesDB 01.01.26.04 Pump S200 SSPRAMOD KUMARNo ratings yet

- 30 Kva Cummins Generators PDFDocument3 pages30 Kva Cummins Generators PDFManu Khanna100% (1)

- Axial Piston Closed Circuit Pumps: Parts ManualDocument24 pagesAxial Piston Closed Circuit Pumps: Parts Manualjon fredyNo ratings yet

- 4TNV98T GgeDocument35 pages4TNV98T Ggeagung sailorNo ratings yet

- QuickServe Online - (4310591) N14 Base Engine (STC, Celect™, Celect Plus™) Service ManualDocument10 pagesQuickServe Online - (4310591) N14 Base Engine (STC, Celect™, Celect Plus™) Service Manualcarlosar1477No ratings yet

- EOLCS Directory - NASCO GROUP LLCDocument2 pagesEOLCS Directory - NASCO GROUP LLCRafael LuqueNo ratings yet

- Diagrama Electrico D8L PDFDocument1 pageDiagrama Electrico D8L PDFdanflocaNo ratings yet

- Tugas Mesin-Mesin FluidaDocument5 pagesTugas Mesin-Mesin FluidaAgeng TaslimNo ratings yet

- Iveco Vehicle CardDocument57 pagesIveco Vehicle CardthantNo ratings yet