Professional Documents

Culture Documents

BR-R 000.Dwg Layout1

Uploaded by

Engr Amir Jamal QureshiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BR-R 000.Dwg Layout1

Uploaded by

Engr Amir Jamal QureshiCopyright:

Available Formats

GENERAL NOTES - BRIDGES

1.

6.

DESIGN SPECIFICATIONS:

STANDARD HOOKS

9.10 UNLESS OTHERWISE NOTED THE CYLINDER STRENGTH OF CONCRETE IN

PRESTRESSED CONCRETE POST TENSIONED GIRDER AT TRANSFER

SHALL BE NOT LESS THAN 350 Kg/Sq.CM (5000 psi).

d

1.1 AASHTO STANDARD SPECIFICATIONS FOR HIGHWAY BRIDGES - 1996

9.11 COMPLETE PRESTRESSING TENDONS OR CABLES SHALL CONSIST OF

HIGH TENSILE WIRES OR CABLES AS SPECIFIED IN DRAWINGS,

ALONGWITH CORE HELIX, METAL SHEATHS, COUPLINGS AT ADEQUATE

INTERVALS, PRESTRESSING ANCHORAGES, BINDING TAPE, METAL

SPACERS AND OTHER ACCESSORIES.

90

D

90

D

12d

180

4d

2.

18d

LIVE LOADS:

8d

GENERAL

135

- STIRRUPS AND COLUMN TIE BARS : D = 4d

FOR d < OR = 16mm.

10.2 ALL THE EXCAVATION FOR OPEN FOUNDATIONS SHALL BE SUBJECTED

TO INSPECTION BY ENGINEER PRIOR TO POURING OF CONCRETE.

- OTHER BARS HAVING d < OR = 32mm :

10.3 EACH EXPLORATORY/CONFIRMATORY BORE HOLE SHALL BE DRILLED

UPTO 25 METER DEPTH MINIMUM OR 3 METER BELOW THE TIP LEVEL

OF THE PILE AT THAT LOCATION WHICHEVER IS GREATER. IN CASE

ROCK IS ENCOUNTERED THE CORE DRILLING SHALL BE DONE 15 METER

DEEP OR 3 METER BELOW THE TIP LEVEL OF THE PILE AT THAT

LOCATION WHICHEVER IS GREATER OR AS DIRECTED BY THE ENGINEER.

GRADE 60 : D = 8 x d

3.1 ALL DIMENSIONS ARE IN MILLIMETERS UNLESS OTHERWISE NOTED.

ELEVATIONS ARE IN METERS.

11.

3.2 ALL ELEVATIONS SHOWN ON DRAWINGS ARE FINISHED SURFACE

LEVELS UNLESS OTHERWISE NOTED.

7.

3.3 ALL EXPOSED CONCRETE CORNERS, EDGES AND ANGLES SHALL BE

CHAMFERED OR FILLETED 20 x 20 mm UNLESS OTHERWISE SPECIFIED.

8.

MATERIALS:

28 DAYS (15 X 30 CM) COMPONENT

CYLINDER STRENGTH KG/Sq.Cm

--------------------------------------------------REINFORCED

A1

210 (3000 psi) APPROACH SLAB, BARRIER,ABUTMENT, & PILECAP

REINFORCED

A3

280 (4000 psi) DECK SLAB,DIAPHRAGM & PILES

LEAN

100 (1400 psi)

PRESTRESSED

D

350 (5000 psi) PRESTRESSED CONCRETE

CLASS

STRUCTURAL STEEL

9.

THE FOLLOWING MINIMUM CONCRETE COVER SHALL BE PROVIDED ON

STEEL UNLESS OTHERWISE NOTED,

CLIENT:

PILES ...........................................

75 mm

PIER MAIN BARS .............................

PIER AND COLUMN TIES,

BEAM STIRRUP..................................... 40 mm

APPROACH SLAB,

BOTTOM ................................. 50 mm

TOP ................................. 30 mm

(Transportation Engineering Services Division)

45 - L BLOCK MODEL TOWN (EXTENSION) LAHORE - 54700

GOVERNMENT OF KHYBER PAKHTUNKHWA

PAKHTUNKHWA HIGHWAYS AUTHORITY

(PKHA), PESHAWAR

in association with

C. JT.

CL

=

=

CONSTRUCTION JOINT

CENTRELINE

C/C

DIA.

EXP. JT.

E.F

EL.

F.F

GI

GUTS

=

=

=

=

=

=

=

=

ID

I.F

m

mm

N.F

NSL.

PGL.

SYM.

T

TH.

TYP.

=

=

=

=

=

=

=

=

=

=

=

CENTER TO CENTER

DIAMETER

EXPANSION JOINT

EACH FACE

ELEVATION

FAR FACE

GALVANIZED IRON

GUARANTEED ULTIMATE STRENGTH

(OF PRESTRESSING CABLES)

INTERNAL DIAMETER

INNER FACE

METER

MILLIMETER

NEAR FACE

NATURAL SURFACE LEVEL

PROFILE GRADE LEVEL

SYMMETRICAL

TOP

THICK

TYPICAL

FINISHED ROAD LEVEL

R C C ABUTMENT/ WING WALL

16.1.

16.2.

16.3.

16.4.

16.5.

9.8 INTERMEDIATE GROUT VENTS SHALL BE PROVIDED NEAR THE LOWEST

PARTS OF THE CABLE PROFILE AT ABOUT MID-LENGTH OF THE

CABLES. CABLES SHALL BE GROUTED AFTER STRESSING WITH FEBFLOWCABLE/ FLOWCABLE-50 OR EQUIVALENT AS APPROVED BY THE

ENGINEER. ANCHORAGE POCKETS SHALL BE FILLED WITH 210

KG/SQ. CM (3000 Psi) CONCRETE USING 10 MM. DOWN AGGREGATE,

16.6.

16.7.

16.8.

D= DIAMETER OF SMALLER BAR IN LAP

16.9.

9.9 THE FOLLOWING SHALL BE ASSUMED IN THE CALCULATION OF

THEORETICAL ELONGATION, Ao:

- MODULUS OF ELASTICITY, E = 193,000 MPa. (28000 ksi)

- COEFFICIENT OF FRICTION = 0.25 / radian.

- WOBBLE COEFFICIENT

= 0.0033 /meter.

- DRAW-IN OF WEDGES FOR,

0.5" (12.7mm) STRAND

= 5 mm.

16.10.

PROJECT:

ASSOCIATED CONSULTING

ENGINEERS- ACE (PVT.) LTD.

THEORETICAL ELONGATION OF

PRESTRESSING TENDON

BOTTOM

BORE HOLE

16.

9.7 PROVISIONS SHALL BE MADE IN THE END ANCHORAGES FOR GROUTING

THE CABLE DUCTS IMMEDIATELY AFTER TENSIONING. AFTER

SECURING THE END ANCHORAGES, ALL CABLES SHALL BE PRESSURE

GROUTED IN THEIR DUCTS IN ACCORDANCE WITH THE

SPECIFICATIONS.

50 mm

CONSULTANT:

=

=

F.R.L

9.6 SUITABLE STEEL CHAIRS/ FRAMES TO HOLD THE PRESTRESSING

CABLE DUCTS AND REINFORCEMENT IN TRUE POSITION AT ADEQUATE

INTERVALS (RANGING FROM 0.8 TO 1.2 METER) SHALL BE

PROVIDED.

CONCRETE COVER:

30 mm

POST-TENSIONING

9.5 THE CABLE AXIS MUST COINCIDE WITH THE ANCHORAGE AXIS

BEHIND THE ANCHORAGE FOR A LENGTH OF AT LEAST 400mm OR

TRUMPET LENGTH, WHICHEVER IS GREATER.

ALL STEEL TUBES SHALL CONFORM TO ASTM A-501 HAVING MINIMUM

YIELD STRENGTH OF 248 N/mm2 (36,000 psi).

BARRIER

TOP, BOTTOM & SIDES .............

B

B.H

9.4 THE JACKING FORCE, CABLE ELONGATION AND LOCKING SLIPPAGE

SHALL BE IN ACCORDANCE WITH THE DRAWINGS. ANY DEVIATION OR

VARIATION MUST BE REPORTED TO THE ENGINEER BEFORE

CONTINUING STRESSING WORK.

4.8 STEEL TUBES.

PRESTRESSED GIRDER

TOP ........................................... 25 mm

BOTTOM ..................................... 40 mm

STIRRUPS AND TIES .................. 40 mm

9.3 CABLE EXTENSION INCLUDES A PULL-IN MARGIN OF 5 mm AT EACH

STRESSING END. CONE PULL-IN AT BOTH ENDS, DURING TENSIONING

AND AFTER ANCHORGAE SHALL BE RECORDED AND COMMUNICATED TO

THE ENGINEER FOR ANY DEVIATION.

DUCTS FOR PRESTRESSING

LIST OF SYMBOLS AND ABBREVIATIONS:

Ao

9.2 ALL CABLES SHALL BE STRESSED, SIMULTANEOUSLY FROM BOTH

ENDS, IN THE ORDER SPECIFIED ON THE DRAWINGS. MAXIMUM

PERMISSIBLE STRESS BEFORE LOCKING SHALL BE 0.765 OF

GUARANTEED ULTIMATE TENSILE STRENGTH (GUTS).

BEARING PADS.

DECK SLABS,

TOP OF SLABS............................ 40 mm

BOTTOM OF SLAB........................ 25 mm

15.

9.1 A MULTI-STRAND POST TENSIONING SYSTEM SHALL BE USED.

PRESTRESSING CABLES.

PROTECTION WORKS:

THE LIMITS OF PROTECTION WORKS SHALL BE AS SHOWN IN THE

DRAWINGS AND AS DIRECTED BY THE ENGINEER.

8.8 BEHIND THE ABUTMENT AND WING WALLS A SELECTED GRANULAR FILL

SHALL BE PROVIDED, AS SHOWN IN THE DRAWINGS.

- FOR CABLE 11/0.5" , ID SHALL BE > or = 75 mm

- FULLY GALVANIZED SHEATH TH > or = 0.5mm SHALL BE USED

5.

14.

8.7 ALL EXPOSED SURFACES SHALL HAVE FAIR FACED FINISH UNLESS

OTHERWISE SPECIFIED.

BEARING PADS SHALL CONFORM TO SECTION 14, "ELASTOMERIC

BEARINGS" OF AASHTO SPECIFICATIONS FOR HIGHWAY BRIDGES,

1996

4.7

EMBEDDED ITEMS

ALL EMBEDDED ITEMS SHALL BE SECURED IN POSITION ACCORDING

TO THE DRAWINGS BEFORE PROCEEDING WITH THE CONCRETING

8.6 ALL FACES OF CONCRETE IN ABUTMENTS AND WING WALLS IN

CONTACT WITH SOIL SHALL BE DAMP PROOFED WITH TWO LAYERS OF

BITUMINOUS MATERIAL. WITH NO EXTRA COST.

STEEL REINFORCEMENT

PRESTRESSING STEEL SHALL BE NORMAL RELAXATION STRAND

CONFORMING TO AASHTO M203 (ASTM A-416), GRADE 270 HAVING

MINIMUM ULTIMATE TENSILE STRENGTH OF 1862 N/mm2 (270 Ksi).

4.6

13.

8.5 IF LAUNCHING IS USED THE MAXIMUM CANTILEVER OVERHANG SHALL

NOT EXCEED 3 m.

ALL STRUCTURAL STEEL SHALL CONFORM TO ASTM A-36 HAVING

MINIMUM YIELD STRENGTH OF 248 N/mm2 (36,000 psi). BOLTS AND

NUTS SHALL CONFORM TO ASTM A-307 OR EQUIVALENT. ALL WELDS

SHALL CONFORM TO A.W.S (AMERICAN WELDING STANDARDS).

4.5

DETAIL BAR BENDING SCHEDULE

DETAILED BAR BENDING SCHEDULE SHALL BE PREPARED BY THE

CONTRACTOR AND SUBMITTED FOR ENGINEER'S APPROVAL.

8.4 IF LIFTING METHOD IS USED, GIRDERS SHALL BE LIFTED FROM

BOTH ENDS USING LIFTING HOLES / SLEEVES BY MEANS APPROVED

BY THE ENGINEER.

REINFORCING STEEL SHALL BE DEFORMED ROUND BARS OF

INTERMEDIATE GRADE (GRADE 40 & GRADE 60) CONFORMING TO AASHTO OR

M-31 (ASTM A-615) WITH MINIMUM YIELD STRENGTH OF 2812 Kg/Sq.Cm.

(60,000Psi)

4.4

12.

8.3 GIRDERS SHALL BE INSTALLED IN THEIR CORRECT POSITION ON

BEARINGS BY LIFTING OR LAUNCHING AND SHALL BE TEMPORARILY

BRACED UNTIL CASTING OF DIAPHRAGMS.

UNLESS OTHERWISE NOTED, CONCRETE SHALL BE CLASSIFIED AS FOLLOWS:

4.3

CONSTRUCTION & ERECTION

8.2 CONCRETE FOR THE BARRIERS AND SIDEWALKS SHALL BE PLACED NO

SOONER THAN 20 DAYS AFTER PLACING OF CONCRETE IN THE DECK

SLAB.

CONCRETE

CONCRETE

EXPANSION JOINT SYSTEM SHALL BE APPROVED BY THE ENGINEER.

ALLOWABLE MOVEMENT BETWEEN MAXIMUM AND MINIMUM GAP ARE

25mm IN THE DIRECTION OF TRAFFIC. EXCEPT AS INDICATED E.Jt.

SYSTEM SHALL BE INSTALLED ATLEAST ONE MONTH AFTER

COMPLETING THE DECK, BY SAW CUTTING IN THE CONTINUOUS

WEARING COURSE. CONTRACTOR SHALL SUBMIT NECESSARY

INSTALATION DETAILS FOR ENGINEER'S APPROVAL BEFORE STARTING

THIS WORK.

8.1 CONCRETE IN DECK SLAB SHALL BE PLACED IN FULL WIDTH. NO

CONSTRUCTION JOINT SHALL BE PERMITTED. DIAPHRAGMS AND DECK

SLAB SHALL BE CAST MONOLITHICALLY.

4.1 ALL THE MATERIALS AND WORKMANSHIP SHALL BE ACCORDING TO THE

AASHTO SPECIFICATIONS AND ASTM STANDARDS EXCEPT WHERE

MODIFIED BELOW, OR IN "PARTICULAR SPECIFICATIONS AND

SPECIAL PROVISIONS" OF TENDER DOCUMENTS.

4.2

EXPANSION JOINTS.

LAPPED SPLICES

THE LAP LENGTH AND DEVELOPMENT LENGTH OF BARS SHALL BE IN

ACCORDANCE WITH SECTION 8 OF AASHTO-1996.

3.4 GIRDER TOP SHALL BE ROUGHENED TO FULL AMPLITUDE OF 6 mm.

4.

FOUNDATIONS

10.1 THE LENGTH AND DIAMETER OF THE PILE UNDER ABUTMENT PILECAP

OF THE BRIDGE IS TENTATIVE AND SHALL BE FINALIZED AFTER

THE SUB-SOIL INVESTIGATIONS.

Bending diameter :

135

2.2 A SINGLE LOAD OF 95 KN (21 Kip) ON 600x300 mm AREA, FOR THE

DESIGN OF DECK SLAB ONLY.

3.

10.

2.1 SINGLE LANE OF CLASS 'AA' (MILITARY 70 TON TANK) LOADING OR

TWO LANES OF CLASS 'A' LOADING WHICH EVER GOVERNS, OF

PAKISTAN CODE OF PRACTICE FOR HIGHWAY BRIDGES- 1967.

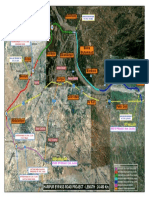

DESIGN OF WIDENING / DUALIZATION OF

MURREE CHOWK - THANDIANI CHOWK AND

NAWANSHIR LINK ROAD

DRAWN

M.S

JOB NO.

JB102 -T-RB

DESIGN

TJ

SCALE

AS SHOWN

CHECKED

KR

DATE

JAN, 2016

PAVRON, ISLAMABAD

H NO. 364 STREET NO. 33 F- 11/2 ISLAMABAD

DISTRICT: ABBOTTABAD

DRAWING NO.

REV.

DESCRIPTION

DATE

APPROVED

MNR

ACE-AB-GN-BR-001

DRAWING TITLE:

BRIDGE AT STA. 1+410

GENERAL NOTES

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 2020 Commencement ProgramDocument113 pages2020 Commencement ProgramÉrika DLNo ratings yet

- 3 M H Stone Masonry Retaining Wall Design Sheet - ModifiedDocument9 pages3 M H Stone Masonry Retaining Wall Design Sheet - ModifiedEngr Amir Jamal QureshiNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Welder and Wps Qualification Control ProcedureDocument24 pagesWelder and Wps Qualification Control ProcedurejhuliocessarsNo ratings yet

- M183Document2 pagesM183Franz Richard Sardinas Mallco100% (1)

- Masonry DesignDocument21 pagesMasonry DesignkevinblacheNo ratings yet

- Design of Wall For Water Tank Both Side WaterDocument19 pagesDesign of Wall For Water Tank Both Side Waterrushicivil1No ratings yet

- Iso 15504 - Maturity Model For SoftwareDocument11 pagesIso 15504 - Maturity Model For SoftwarethaistalynNo ratings yet

- Falar 2 and 3Document41 pagesFalar 2 and 3jbonvier71% (7)

- Letter To Consultants For Mobilization at SiteDocument2 pagesLetter To Consultants For Mobilization at SiteEngr Amir Jamal Qureshi57% (7)

- Plan and Profile STA. 04+200 TO STA. 04+550Document1 pagePlan and Profile STA. 04+200 TO STA. 04+550Engr Amir Jamal QureshiNo ratings yet

- Plan and Profile STA. 03+850 TO STA. 04+200Document1 pagePlan and Profile STA. 03+850 TO STA. 04+200Engr Amir Jamal QureshiNo ratings yet

- Plan and Profile STA. 04+550 TO STA. 04+900Document1 pagePlan and Profile STA. 04+550 TO STA. 04+900Engr Amir Jamal QureshiNo ratings yet

- Summary of The Chief Minister KPK DraftDocument2 pagesSummary of The Chief Minister KPK DraftEngr Amir Jamal Qureshi100% (1)

- Plan and Profile STA. 03+150 TO STA. 03+500Document1 pagePlan and Profile STA. 03+150 TO STA. 03+500Engr Amir Jamal QureshiNo ratings yet

- Typical Cross Section For Cut and Fill Area: Annex 2 - 2Document3 pagesTypical Cross Section For Cut and Fill Area: Annex 2 - 2Engr Amir Jamal QureshiNo ratings yet

- Plan and Profile STA. 04+450 TO STA. 04+800Document1 pagePlan and Profile STA. 04+450 TO STA. 04+800Engr Amir Jamal QureshiNo ratings yet

- Bridges Progress-May 2016Document3 pagesBridges Progress-May 2016Engr Amir Jamal QureshiNo ratings yet

- HARI PUR BYPASS Alignment With DetailsDocument1 pageHARI PUR BYPASS Alignment With DetailsEngr Amir Jamal QureshiNo ratings yet

- Location Map Thanidani Nathiagali 3Document1 pageLocation Map Thanidani Nathiagali 3Engr Amir Jamal QureshiNo ratings yet

- NWFP Public Propert (Removal of Encroachment) Act 1977Document6 pagesNWFP Public Propert (Removal of Encroachment) Act 1977Engr Amir Jamal QureshiNo ratings yet

- Detail Estimate For 2mRWall & Analtsis For 3m 4m&5mDocument48 pagesDetail Estimate For 2mRWall & Analtsis For 3m 4m&5mEngr Amir Jamal QureshiNo ratings yet

- Ace Design Projects Invoices Detail-June 2016Document2 pagesAce Design Projects Invoices Detail-June 2016Engr Amir Jamal QureshiNo ratings yet

- Government of Khyber Pakhtunkhwa11Document1 pageGovernment of Khyber Pakhtunkhwa11Engr Amir Jamal QureshiNo ratings yet

- NOC Fuel Station PannianDocument1 pageNOC Fuel Station PannianEngr Amir Jamal QureshiNo ratings yet

- Detail of Pavment-Markers Items For New MRSDocument6 pagesDetail of Pavment-Markers Items For New MRSEngr Amir Jamal QureshiNo ratings yet

- Ace Construction Projects Invoices Detail - June 2016Document2 pagesAce Construction Projects Invoices Detail - June 2016Engr Amir Jamal QureshiNo ratings yet

- Assessment of Consultants Staff For The Deployment of The ProjectsDocument3 pagesAssessment of Consultants Staff For The Deployment of The ProjectsEngr Amir Jamal QureshiNo ratings yet

- (750788224) USreflector Pavment MarkersDocument15 pages(750788224) USreflector Pavment MarkersEngr Amir Jamal QureshiNo ratings yet

- Reply Response of C&W DivisionDocument3 pagesReply Response of C&W DivisionEngr Amir Jamal QureshiNo ratings yet

- Transport Charges TorgharDocument10 pagesTransport Charges TorgharEngr Amir Jamal QureshiNo ratings yet

- Tegar Arief Pratama: Curriculum VitaeDocument3 pagesTegar Arief Pratama: Curriculum VitaeTegar Arief PratamaNo ratings yet

- 2Document31 pages2koko srihandokoNo ratings yet

- P InstrumentationDocument13 pagesP Instrumentationابزار دقیقNo ratings yet

- Week2 - Lesson 2. Basics of Work Breakdown Structure (WBS)Document11 pagesWeek2 - Lesson 2. Basics of Work Breakdown Structure (WBS)manorajcvNo ratings yet

- Reviewer InteriorDocument8 pagesReviewer InteriorLaurence Emmanuel BenedictosNo ratings yet

- B.tech - III Sem. Exam. 2013 14 ScheduleDocument19 pagesB.tech - III Sem. Exam. 2013 14 ScheduleAnurag AryaNo ratings yet

- W-Robocon Technical Report 2019Document332 pagesW-Robocon Technical Report 2019patrickNX9420No ratings yet

- Punch and Die Cutting Clearance Calculation ProcedureDocument7 pagesPunch and Die Cutting Clearance Calculation ProcedureVenkateswaran venkateswaranNo ratings yet

- Labunets PHD ThesisDocument162 pagesLabunets PHD ThesisNoman RazaNo ratings yet

- Bilal DataDocument8 pagesBilal DatadevilinpajamaNo ratings yet

- Lecture On Crane Safety On Construction Sites: Supervision and Management of Crane OperationsDocument2 pagesLecture On Crane Safety On Construction Sites: Supervision and Management of Crane OperationsAsyraf ZailudinNo ratings yet

- The Self-Healing Technologies of Smart Distribution Grid PDFDocument6 pagesThe Self-Healing Technologies of Smart Distribution Grid PDFedmuarizt7078No ratings yet

- 83 Kashif NaveedDocument2 pages83 Kashif NaveedSajid HanifNo ratings yet

- NTUST Electrical EngineeringDocument2 pagesNTUST Electrical EngineeringTri CardoNo ratings yet

- SLD of Vital Dates of The ProjectDocument33 pagesSLD of Vital Dates of The ProjectRheyJun Paguinto AnchetaNo ratings yet

- Buckling Restrained Braced FrameDocument24 pagesBuckling Restrained Braced Framedanish khanNo ratings yet

- TDS - Masterflow 928 TDocument4 pagesTDS - Masterflow 928 TVenkata RaoNo ratings yet

- Eal Qet2 001a LP Issue 1 0815Document17 pagesEal Qet2 001a LP Issue 1 0815AmmarNo ratings yet

- Cyient - Oil and Gas IndustryDocument8 pagesCyient - Oil and Gas Industrycyient_analyticsNo ratings yet

- Lesson 4.4 The NanoworldDocument38 pagesLesson 4.4 The NanoworldcadoarvinNo ratings yet

- LT299 Microcracking CTBDocument2 pagesLT299 Microcracking CTBArturo TotolhuaNo ratings yet

- PC Pump CourseDocument2 pagesPC Pump CourseGerman AlvarezNo ratings yet

- Víctor Falguera: Curriculum VitaeDocument9 pagesVíctor Falguera: Curriculum VitaevictorfalgueraNo ratings yet