Professional Documents

Culture Documents

1987 RAM 50 2.6L Carburetor Adjustments

Uploaded by

MetalAnonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1987 RAM 50 2.6L Carburetor Adjustments

Uploaded by

MetalAnonCopyright:

Available Formats

1987 Dodge RAM 50

Submodel: SPORT | Engine Type: L4 | Liters: 2.6

Fuel Delivery: CARB | Fuel: GAS

Accelerator Cable

1.

Warm the engine up completely and make certain the high idle cam is not engaged.

2.

Check the action of the accelerator pedal. There should be little to no free-play between the normal "at rest" position and the point that engine speed begins to increase. Correct

free-play measurement is 00.8 in. (020mm).

3.

If there is excessive free-play, loosen the cable adjusting nuts located on the cable mount on the carburetor. With both nuts loosened, the cable may be adjusted to remove slack.

Do not adjust the cable beyond the point of no free-play; the engine idle speed will be changed.

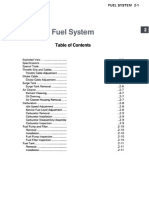

Float Level

1.

Remove the top of the carburetor and remove the gasket. The carburetor does not need to be removed for this procedure. Follow the directions within the carburetor overhaul

procedure later in this section.

Fig. 1: Exploded view of the accelerator pedal, cable and

associated components

Fig. 2: The bracket retaining the accelerator cable is

equipped with an adjustment slot

Fig. 3: Use a universal float level gauge to inspect the

distance from the bottom of the float to the surface of the float

chamber cover

Fig. 4: Sets of shims are available for adjusting float height

Fig. 5: The shims fit under the seat of the needle valve

2.

Hold the carburetor top and float upside down. Use a float gauge or depth gauge to measure the distance from the bottom of the float (now the top, since it's upside down) to the

inside of the carburetor top. The correct distance is 0.760.84 in. (1921mm).

3.

If the dimension is not correct, the shim below the needle seat must be changed. Use a thicker shim to increase the measurement (or lower the float level) or a thinner shim to

decrease the measurement (raise the float level).

4.

The shim kit contains 3 shims: 0.3mm, 0.4mm and 0.5mm. The float measurement will change by 3 times the measurement of the shim installed or removed. Shims may be

combined as necessary. Some arithmetic after measuring should provide the correct shim thickness on the first try.

5.

To replace the shim, remove the float pin and the float. Remove the needle valve.

6.

Use a pair of pliers to gently unscrew the seat at its widest point. Take great care not to damage the seat or the surrounding metal.

7.

Slip the shim(s) over the narrow portion of the seat and then reinstall the seat. Gently tighten it without damage.

8.

Reassemble the needle valve and float.

9.

Re-measure the float height and replace the shim(s) if necessary to get the correct height.

10.

Reinstall the carburetor top.

Throttle Opener

The 197982 models do not have any adjustments possible.

198387 MODELS

1.

Disconnect the vacuum hose running to the throttle opener port.

2.

Connect a hand vacuum pump to the nipple of the throttle opener. Install a tachometer to read engine speed. Make certain the idle speed for the engine is set correctly.

3.

Run the engine at curb idle (fully warm). Apply 11.8 in. Hg (39.8 kPa) with the hand pump; idle speed should increase to 900950 rpm. If the idle does not increase, replace the

dashpot/throttle opener assembly.

A.

Remove the throttle return spring from the throttle lever.

4.

B.

Disconnect the throttle opener rod from the free lever.

C.

Remove the two attaching screws and remove the throttle opener/dashpot assembly.

D.

Install the new unit, connect the rod and install the spring.

Reconnect the vacuum hose to the nipple. Start the engine, run it at curb idle and turn the air conditioning on. Idle speed should increase to 900950 rpm.

Fig. 6: The location of the throttle opener adjusting screw. Do

not adjust SAS 1 or 3

Fig. 7: Adjusting the throttle opener

Fig. 8: The location of the throttle opener setting screw

5.

If the throttle opener needs adjustment, do so by turning the screw on the throttle opener/dashpot assembly. Don't turn any other screws to adjust the throttle opener; the curb idle

or other important settings may be affected.

198889 MODELS

1.

To inspect the solenoid, identify the vacuum control solenoid on the firewall. Label and carefully remove the two vacuum hoses running to the unit.

2.

Disconnect the electrical connector from the solenoid.

3.

Connect a hand vacuum pump to the solenoid port which held the vacuum hose with the white stripe.

4.

Using jumper wires, connect battery voltage to one terminal of the solenoid and connect the other terminal to a good ground.

5.

With battery voltage applied to the solenoid, draw vacuum with the hand pump. Use the chart to check the properties of the valve with proper combinations of vacuum and

electricity applied or removed.

6.

Remove the 12 volt jumpers. Use an ohmmeter to measure the resistance of the solenoid. Resistance should be 4046 ohms at 68F (20C).

Fig. 9: Attach a hand vacuum pump to the nipple of the

where stripped vacuum hose was connected

Fig. 10: Connect battery voltage to one terminal of the

solenoid and the other to ground

Fig. 11: The valve should operate as indicated

Fig. 12: Use an ohmmeter to measure the resistance of the

solenoid

Fig. 13: The throttle opener adjusting screw is located on the

side of the carburetor

7.

If the solenoid does not behave correctly under ALL test conditions, it must be replaced.

8.

Start the engine.

9.

Set a tachometer per manufactures instructions.

10.

Turn on the air conditioner switch.

11.

Check the engine speed during this operation. Speed should be 850950 rpm. If the engine speed is out of specification, adjust using the throttle opener adjusting screw.

NOTE: The solenoid valve will open and the intake manifold vacuum will act on the throttle opener to fully activate it.

You might also like

- Mazda FE y F2Document27 pagesMazda FE y F2jads30117971% (14)

- Detroit s60 Valve AdjustmentDocument12 pagesDetroit s60 Valve AdjustmentÑengo Flow Full Record50% (2)

- 4 3 Vortec Engine Manual Powerdyne Automotive Products IncDocument6 pages4 3 Vortec Engine Manual Powerdyne Automotive Products Incgarrett86No ratings yet

- Tune-Up Guide For Geo Metro 1.0 Liter CarsDocument8 pagesTune-Up Guide For Geo Metro 1.0 Liter CarsDerek JewettNo ratings yet

- E15 CarburetorDocument16 pagesE15 CarburetorPriyantha Galgepitiya100% (5)

- HSBC in A Nut ShellDocument190 pagesHSBC in A Nut Shelllanpham19842003No ratings yet

- Repair Guides - Carbureted Fuel System - Rochester 2se - E2se CarburetorDocument5 pagesRepair Guides - Carbureted Fuel System - Rochester 2se - E2se CarburetoreducsalNo ratings yet

- Carburetor Troubleshooting Repair Guide For HondaDocument9 pagesCarburetor Troubleshooting Repair Guide For HondaRoyal ENo ratings yet

- CAT 3412 Air Inlet and Exhaust SystemDocument8 pagesCAT 3412 Air Inlet and Exhaust SystemCEVegaO100% (2)

- Throttle Body Dan TPS Corolla 88-97Document4 pagesThrottle Body Dan TPS Corolla 88-97Fitri Wibowo100% (1)

- Weber ManualDocument28 pagesWeber ManualMedardo SilvaNo ratings yet

- GE 175d2750g313Document2 pagesGE 175d2750g313Emmanuel Vieira Villasana100% (1)

- Adjusting Fuel TimingDocument3 pagesAdjusting Fuel TimingSanjay MadakaNo ratings yet

- Perkins 20 Kva (404D-22G)Document2 pagesPerkins 20 Kva (404D-22G)RavaelNo ratings yet

- 5 Star Hotels in Portugal Leads 1Document9 pages5 Star Hotels in Portugal Leads 1Zahed IqbalNo ratings yet

- Expectation Vs Reality: Job Order and Contract of ServiceDocument10 pagesExpectation Vs Reality: Job Order and Contract of ServiceMikee Louise MirasolNo ratings yet

- 1987 RAM 50 2.6L Carburetor OverhaulDocument14 pages1987 RAM 50 2.6L Carburetor OverhaulMetalAnonNo ratings yet

- Ford CarbDocument27 pagesFord Carbsmcdonald2536100% (1)

- Pruebas y Ajustes SISTEMA HIDRAULICO AP200BDocument12 pagesPruebas y Ajustes SISTEMA HIDRAULICO AP200BhectorNo ratings yet

- Solex Adj ProcedureDocument6 pagesSolex Adj Procedureprivate 2No ratings yet

- Dodge Ram A/C Compressor ClutchDocument7 pagesDodge Ram A/C Compressor ClutchKkbhuvan KkNo ratings yet

- Carburetor AdjustmentsDocument4 pagesCarburetor Adjustmentsconimec0% (1)

- 2: 4 Ford Single Carburetor (Manual Choke)Document8 pages2: 4 Ford Single Carburetor (Manual Choke)Tony TzuNo ratings yet

- Ajuste de Valvulas PDFDocument8 pagesAjuste de Valvulas PDFRoberto Rincon Robles100% (1)

- Operation 1Document9 pagesOperation 1Wbamlak AshebrNo ratings yet

- Holley Carb AdjustmentsDocument8 pagesHolley Carb AdjustmentsAaron SteeleNo ratings yet

- ACTUADOR PT Cummins EngineDocument29 pagesACTUADOR PT Cummins EngineMartin BiesseNo ratings yet

- 2.0l 4 Cyl Nissan b13Document52 pages2.0l 4 Cyl Nissan b1325912530No ratings yet

- Hydraulic Brake Booster Installation LC 200Document17 pagesHydraulic Brake Booster Installation LC 200Yannick de WalqueNo ratings yet

- SB388CDocument13 pagesSB388CBenjamin LeedsNo ratings yet

- Steering Control Page 225Document10 pagesSteering Control Page 225vidurav@gmail.comNo ratings yet

- Sum-Carb InstrDocument14 pagesSum-Carb InstrbobNo ratings yet

- Bottom Feed Port Fuel InjectorsDocument6 pagesBottom Feed Port Fuel InjectorsdarherreraNo ratings yet

- Ac Compressor ServicingDocument25 pagesAc Compressor ServicingAnimemanuel MuñozNo ratings yet

- Ac Compressor ServicingDocument25 pagesAc Compressor ServicingffyddNo ratings yet

- Holley Contender Intake ManifoldDocument4 pagesHolley Contender Intake Manifoldpaul_a_rodriguezNo ratings yet

- Experiment 5 Aim::-Diagnosis of Ignition System Faults Apparatus RequiredDocument5 pagesExperiment 5 Aim::-Diagnosis of Ignition System Faults Apparatus Requiredbansalmohit01No ratings yet

- Jeep Cherokee XJ 1988-1992 Transmission Servicing A - TDocument5 pagesJeep Cherokee XJ 1988-1992 Transmission Servicing A - Tjess230580No ratings yet

- Installation of The Power Take-OffDocument9 pagesInstallation of The Power Take-OffJames TrottNo ratings yet

- Dellorto Carb Install Instructions For 13bDocument7 pagesDellorto Carb Install Instructions For 13bBrent Z. BaileyNo ratings yet

- Tci-378805 378905 PDFDocument6 pagesTci-378805 378905 PDFAntonio PerezNo ratings yet

- zxr400 H 02Document11 pageszxr400 H 02hugo_bikerNo ratings yet

- Valve Lash AdjustmentsDocument13 pagesValve Lash AdjustmentsEnriqueNo ratings yet

- Series 60 - Section 6.3 Intake ManifoldDocument7 pagesSeries 60 - Section 6.3 Intake ManifoldJuan RiveraNo ratings yet

- 7 TroubleshootingDocument6 pages7 TroubleshootingvanapeerNo ratings yet

- Steering Gear PowerDocument10 pagesSteering Gear PowerToua YajNo ratings yet

- Timing Belt 1.8lDocument13 pagesTiming Belt 1.8lStuartBohmNo ratings yet

- Automatic TransmissionDocument14 pagesAutomatic TransmissionKomáromi LászlóNo ratings yet

- 1.9l 4-Cylinder Turbo DieselDocument26 pages1.9l 4-Cylinder Turbo Dieselfloresf5100% (1)

- 00M12 PDFDocument6 pages00M12 PDFurania22000No ratings yet

- Electrical System: Service ManualDocument4 pagesElectrical System: Service ManualEdin HadzicNo ratings yet

- Repair GuidesDocument20 pagesRepair GuidesIgree Y. BleaNo ratings yet

- Cummins Engine InfoDocument13 pagesCummins Engine Infovictor villaseñor garciaNo ratings yet

- Automatic TransmissionDocument18 pagesAutomatic TransmissionWoong-Sub LeeNo ratings yet

- Procedure of Inspection or Replacement of Thrust Washer (SH Cranes)Document1 pageProcedure of Inspection or Replacement of Thrust Washer (SH Cranes)Mohamed SharaweyNo ratings yet

- CAV Pintaux Injection Nozzle RebuildDocument6 pagesCAV Pintaux Injection Nozzle RebuildDanny DanNo ratings yet

- 2005 Volkswagen PASSAT: - L4 - 1.8 FI - GASDocument4 pages2005 Volkswagen PASSAT: - L4 - 1.8 FI - GASRussell Leon LoydNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Speed Sensor - AdjustDocument6 pagesSpeed Sensor - AdjustЕвгений АбрамовNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Two Cycle Carburetor and the Back Alley MechanicFrom EverandTwo Cycle Carburetor and the Back Alley MechanicRating: 4.5 out of 5 stars4.5/5 (2)

- Datamaster DMT Breath Test Operator Training Course ManualDocument147 pagesDatamaster DMT Breath Test Operator Training Course ManualMetalAnonNo ratings yet

- Suzuki GSX-R1100 '86-88 Service ManualDocument295 pagesSuzuki GSX-R1100 '86-88 Service ManualMetalAnon100% (2)

- Dakota County, MN - DCC Annual Report - 2021Document27 pagesDakota County, MN - DCC Annual Report - 2021MetalAnonNo ratings yet

- Installroot 5.2 User Guide For Unclassified Systems: Dod Public Key Enablement (Pke) Reference GuideDocument59 pagesInstallroot 5.2 User Guide For Unclassified Systems: Dod Public Key Enablement (Pke) Reference GuideMetalAnonNo ratings yet

- Law Enforcement Guide: 2345 Crystal Drive - Suite 910 Arlington, VA 22202 - 202-637-0077Document80 pagesLaw Enforcement Guide: 2345 Crystal Drive - Suite 910 Arlington, VA 22202 - 202-637-0077MetalAnonNo ratings yet

- PaperDocument17 pagesPaperMetalAnonNo ratings yet

- A Survey On Malicious Domains Detection Through DNS Data AnalysisDocument35 pagesA Survey On Malicious Domains Detection Through DNS Data AnalysisMetalAnonNo ratings yet

- Anonymous Operations and TechniquesDocument26 pagesAnonymous Operations and TechniquesMetalAnonNo ratings yet

- LeagueDocument39 pagesLeagueMetalAnonNo ratings yet

- OFFICIAL MN State Capitol Rules of Conduct - Anonymous - Million Mask March MN 2016Document3 pagesOFFICIAL MN State Capitol Rules of Conduct - Anonymous - Million Mask March MN 2016MetalAnonNo ratings yet

- State of Minnesota Department of Public Safety: Uniform Crime ReportDocument98 pagesState of Minnesota Department of Public Safety: Uniform Crime ReportMetalAnonNo ratings yet

- MinnesotaDocument66 pagesMinnesotaMetalAnonNo ratings yet

- May 2016 Prison Rape Elimination Act (PREA) Compliance Audit For The Three Rivers Federal Correctional InstitutionDocument26 pagesMay 2016 Prison Rape Elimination Act (PREA) Compliance Audit For The Three Rivers Federal Correctional InstitutionMetalAnonNo ratings yet

- INSTRUCTION MANUAL Digipulse 450i Power SourceDocument36 pagesINSTRUCTION MANUAL Digipulse 450i Power SourceMetalAnonNo ratings yet

- Triple Five Energy Worldwide Brochure (Oil and Gas)Document55 pagesTriple Five Energy Worldwide Brochure (Oil and Gas)MetalAnonNo ratings yet

- The Anonymous Movement in The Context of Liberalism and Socialism - A Paper By:christian FuchsDocument32 pagesThe Anonymous Movement in The Context of Liberalism and Socialism - A Paper By:christian FuchsMetalAnonNo ratings yet

- BURNSVILLE MINNESOTA POLICE DEPARTMENT 2013 Annual ReportDocument40 pagesBURNSVILLE MINNESOTA POLICE DEPARTMENT 2013 Annual ReportMetalAnonNo ratings yet

- Wiley Chapter 11 Depreciation Impairments and DepletionDocument43 pagesWiley Chapter 11 Depreciation Impairments and Depletion靳雪娇No ratings yet

- Microwave Drying of Gelatin Membranes and Dried Product Properties CharacterizationDocument28 pagesMicrowave Drying of Gelatin Membranes and Dried Product Properties CharacterizationDominico Delven YapinskiNo ratings yet

- Reference Template For Feasibility Study of PLTS (English)Document4 pagesReference Template For Feasibility Study of PLTS (English)Herikson TambunanNo ratings yet

- Agricultural Economics 1916Document932 pagesAgricultural Economics 1916OceanNo ratings yet

- Portrait of An INTJDocument2 pagesPortrait of An INTJDelia VlasceanuNo ratings yet

- Powerpoint Presentation: Calcium Sulphate in Cement ManufactureDocument7 pagesPowerpoint Presentation: Calcium Sulphate in Cement ManufactureDhruv PrajapatiNo ratings yet

- Lab Session 7: Load Flow Analysis Ofa Power System Using Gauss Seidel Method in MatlabDocument7 pagesLab Session 7: Load Flow Analysis Ofa Power System Using Gauss Seidel Method in MatlabHayat AnsariNo ratings yet

- Efs151 Parts ManualDocument78 pagesEfs151 Parts ManualRafael VanegasNo ratings yet

- Rating SheetDocument3 pagesRating SheetShirwin OliverioNo ratings yet

- Loading N Unloading of Tanker PDFDocument36 pagesLoading N Unloading of Tanker PDFKirtishbose ChowdhuryNo ratings yet

- Enerparc - India - Company Profile - September 23Document15 pagesEnerparc - India - Company Profile - September 23AlokNo ratings yet

- Fernando Salgado-Hernandez, A206 263 000 (BIA June 7, 2016)Document7 pagesFernando Salgado-Hernandez, A206 263 000 (BIA June 7, 2016)Immigrant & Refugee Appellate Center, LLCNo ratings yet

- Sustainable Urban Mobility Final ReportDocument141 pagesSustainable Urban Mobility Final ReportMaria ClapaNo ratings yet

- Getting StartedDocument45 pagesGetting StartedMuhammad Owais Bilal AwanNo ratings yet

- Recommended Practices For Developing An Industrial Control Systems Cybersecurity Incident Response CapabilityDocument49 pagesRecommended Practices For Developing An Industrial Control Systems Cybersecurity Incident Response CapabilityJohn DavisonNo ratings yet

- Sourcing Decisions in A Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanyDocument58 pagesSourcing Decisions in A Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanyAlaa Al HarbiNo ratings yet

- Gabby Resume1Document3 pagesGabby Resume1Kidradj GeronNo ratings yet

- BluetoothDocument28 pagesBluetoothMilind GoratelaNo ratings yet

- Ces Presentation 08 23 23Document13 pagesCes Presentation 08 23 23api-317062486No ratings yet

- Accomplishment ReportDocument1 pageAccomplishment ReportMaria MiguelNo ratings yet

- Bajaj Allianz InsuranceDocument93 pagesBajaj Allianz InsuranceswatiNo ratings yet

- Amare Yalew: Work Authorization: Green Card HolderDocument3 pagesAmare Yalew: Work Authorization: Green Card HolderrecruiterkkNo ratings yet

- Lending OperationsDocument54 pagesLending OperationsFaraz Ahmed FarooqiNo ratings yet

- Cdi 2 Traffic Management and Accident InvestigationDocument22 pagesCdi 2 Traffic Management and Accident InvestigationCasanaan Romer BryleNo ratings yet

- Process States in Operating SystemDocument4 pagesProcess States in Operating SystemKushal Roy ChowdhuryNo ratings yet

- 2016 066 RC - LuelcoDocument11 pages2016 066 RC - LuelcoJoshua GatumbatoNo ratings yet