Professional Documents

Culture Documents

Basic Setup of Lean Manufacturing AX2012

Uploaded by

Nitish SridharOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basic Setup of Lean Manufacturing AX2012

Uploaded by

Nitish SridharCopyright:

Available Formats

Expert session

Basic setup of

Lean

Manufacturing

AX2012

HSO. All rights reserved. No part of this publication may be reproduced and/or

published by print, photoprint, microfilm or any other means without the prior written

permission of HSO.

Basic setup of Lean Manufacturing AX2012|

06-03-2015

Document history

Version Description

Author(s)

Date

1.0

Dennis Koning

06-03-2015

Initial version

the results company

Basic setup of Lean Manufacturing AX2012|

06-03-2015

Table of content

1

Expert team................................................................................................4

Business case............................................................................................. 5

2.1 Overview......................................................................................................................... 5

2.2

Related customers/projects...........................................................................................6

2.3

Related Microsoft KB articles.........................................................................................6

Possible solutions.......................................................................................7

3.1 Setup of a Sales Event Kanban....................................................................................7

3.1.1 Items...................................................................................................................... 7

3.2

3.1.2

Workcell............................................................................................................... 7

3.1.3

Value stream....................................................................................................... 8

3.1.4

Production group................................................................................................. 8

3.1.5

Production flow models........................................................................................ 9

3.1.6

Production flows.................................................................................................. 9

3.1.7

Kanban rules..................................................................................................... 11

3.1.8

Demonstration of the process............................................................................12

Setup of a fixed amount Kanban..............................................................................15

3.2.1

Kanban rules..................................................................................................... 15

3.2.2

Demonstration of the process............................................................................15

Conclusion................................................................................................ 17

Open issues.............................................................................................. 18

Actions..................................................................................................... 19

the results company

Basic setup of Lean Manufacturing AX2012|

06-03-2015

1 Expert team

Dennis Koning

the results company

Basic setup of Lean Manufacturing AX2012|

06-03-2015

2 Business case

2.1 Overview

Lean manufacturing is a systemic method for the elimination of waste ("Muda") within a

manufacturing process. Lean takes into account waste created through overburden ("Muri")

and waste created through unevenness in workloads ("Mura"). Lean is the set of "tools" that

assist in the identification and steady elimination of waste (muda).

A non-exhaustive list of such tools would include: SMED, value stream mapping, Five S,

Kanban (pull systems), poka-yoke (error-proofing), total productive maintenance,

elimination of time batching, mixed model processing, rank order clustering, single point

scheduling, redesigning working cells, multi-process handling and control charts (for

checking mura). 1

Although the term Lean Manufacturing in AX2012 is slightly exaggerated (in my opinion),

Ax can simplify the process without losing to much of the ERP registrations and

traceability.

The essence of Lean manufacturing in AX2012 is based on Kanban pull-systems and a

simplification of the administrative process of picking, transferring and producing items by

using Kanban jobs. Besides Kanban also Value stream mapping is recognizable in the

setup of production flows. Production flows are chains of dependent jobs. If an item

requirement is generated, this requirement is pulled through the production flow by

generating Kanban jobs for each process step.

The supported replenishment strategies are:

Event Kanban rules (pegged to the source requirements) originate from:

Sales order lines

Production BOM lines

Kanban lines

Minimum inventory settings.

Fixed quantity Kanban rules.

Calculate optimal fixed quantity Kanban quantities (based on demand)

Planned/scheduled Kanban (MRP)

The advantage of lean manufacturing:

1. One form is used for planning the Kanban manufacturing jobs

2. Two forms are used for executing the Kanban jobs (manufacturing/pick and transfer).

3. Drag and drop planning of Kanban Jobs

4. Visual overview of availability of required items

5. Only one click is needed for picking the required items from inventory

6. Only one click is needed to complete a process Job (manufactured product).

Because of the simplification there are also limitations/disadvantages:

1. No registration of hours on the process jobs

2. One click means that warehouse and production employees must know exactly what

they are doing. Its easy to make an error

http://en.wikipedia.org/wiki/Lean_manufacturing

the results company

Basic setup of Lean Manufacturing AX2012|

06-03-2015

the results company

Basic setup of Lean Manufacturing AX2012|

06-03-2015

2.2 Related customers/projects

2.3 Related Microsoft KB articles

https://hso1com.sharepoint.com/sites/kb/ax/Manufacturing/AX2012_ENUS_Lean

Manufacturing.pdf

https://technet.microsoft.com/en-us/library/hh242439.aspx

Why use and event Kanban: http://ibisinc.com/blog/why-use-an-event-kanban/

eBECS Lean Webinar, part 1:

https://www.youtube.com/watch?v=Hi68o8Ei0vg

eBECS Lean Webinar, part 2:

https://www.youtube.com/watch?v=UK8ccZ5Ka6Q

eBECS Lean Webinar, part 3:

https://www.youtube.com/watch?v=lMurK0evaP0

eBECS Lean Webinar, part 4:

https://www.youtube.com/watch?v=poEPpTj8wvI

eBECS Lean Webinar, part 5:

https://www.youtube.com/watch?v=BWEAa1Duzs4

the results company

Basic setup of Lean Manufacturing AX2012|

06-03-2015

3 Possible solutions

3.1 Setup of a Sales Event Kanban

3.1.1 Items

In my example Im going to use a BOM-item with two products attached to it:

K001 Box of pens

K002 Pen

K003 Box

BOM Quantity: 100

BOM Quantity: 1

Make sure in the default order settings of the BOM-item the order type is set to Kanban

3.1.2Workcell

Go to Organization administration > Common forms > Resources > Resource groups

Create a new resource group and make sure its defined as a work cell.

Attach a calendar and work cell capacity

3.1.3Value stream

the results company

Basic setup of Lean Manufacturing AX2012|

06-03-2015

Go to production control > setup > organization > Value streams

Create a new value stream:

3.1.4Production group

Go to production control > setup > production > production groups

Create a new production group and fill in the accounts:

the results company

Basic setup of Lean Manufacturing AX2012|

06-03-2015

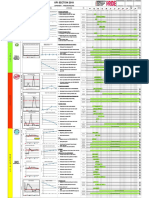

3.1.5Production flow models

Go to production control > setup > Lean manufacturing > Production flow models

Create a new production flow model:

3.1.6Production flows

Go to production control > setup > Lean manufacturing > Production flows

Create a new production flow:

10

the results company

Basic setup of Lean Manufacturing AX2012|

06-03-2015

11

the results company

Basic setup of Lean Manufacturing AX2012|

06-03-2015

3.1.7Kanban rules

Go to production control > setup > Lean manufacturing > Kanban rules

Create a new Kanban rule of type manufacturing and Replenishment strategy Event

12

the results company

Basic setup of Lean Manufacturing AX2012|

06-03-2015

3.1.8Demonstration of the process

Create a new sales order for item K001. After the line is saved, click Product and supply >

View pegging tree

From the pegging tree all Kanbans can be planned automaticaly by selecting Plan entire

pegging tree. Based on the sales order quantity and the Work cell throughput quantity

(chapter 3.1.2 Workcell) the Kanban is automaticaly planned. A production manager can

reschedule this planning later.

The planning of Kanbans doesnt necesarry need to be done from the sales order. It can also

be done manualy in the Kanban Schedule Board.

13

the results company

Basic setup of Lean Manufacturing AX2012|

06-03-2015

Go to production control > common forms > Lean manufacturing > Kanban schedule board

The Kanbans are scheduled, but the planning can be changed by dragging and dropping the

jobs to other days.

Go to production control > common forms > Lean manufacturing > Kanban board for

process jobs

I made sure there was enough inventory to pick.

14

the results company

Basic setup of Lean Manufacturing AX2012|

06-03-2015

By hitting the complete button, the required items are picked and the manufactured product

is now Onhand.

15

the results company

Basic setup of Lean Manufacturing AX2012|

06-03-2015

3.2 Setup of a fixed amount Kanban

3.2.1Kanban rules

I used almost the same setup as chapter 3.1. The difference is the Kanban rule.

The replenishment strategy is now fixed. This setup is also known as a 2 (or more) bin

system.

3.2.2Demonstration of the process

Go to production control > common forms > Lean manufacturing > Kanban schedule board

For item K001 the schedule board shows that the Kanban is below the boundary minimum

(red).

16

the results company

Basic setup of Lean Manufacturing AX2012|

06-03-2015

By clicking the button create Kanban the system suggest the Kanban that need to be

scheduled

Now 5 kanbans are scheduled:

Go to production control > common forms > Lean manufacturing > Kanban board for

process jobs

Create and complete the same way as described in chapter 3.1.8.

17

the results company

Basic setup of Lean Manufacturing AX2012|

06-03-2015

4 Conclusion

Lean manufacturing can support companies by setting up easy replenishment and

manufacturing tasks. The setup takes some time but after that Ax suggest the Kanbans to

plan in a specific period.

For companies who want to compose products, but dont feel the need for a production

setup (and posting hours), Lean manufacturing can be a great solution. Also replenishment

of floor stock can be setup by using AX2012 Lean manufacturing.

18

the results company

Basic setup of Lean Manufacturing AX2012|

06-03-2015

5 Open issues

In this document I described only the basic setup for Lean manufacturing. Based on your

business case I think youll have enough information the start setting up Process Flows and

Kanban Rules.

Important to know is that multiple dependent activities can be added to a process flow.

I also only described the manufacturing process, but its also possible to create Kanban

Rules for withdrawal (transfer goods from one place to another).

The usage of Kanban cards and performing the process using barcode scanners isnt

covered in this document.

19

the results company

Basic setup of Lean Manufacturing AX2012|

06-03-2015

6 Actions

List any actions to be set out within the HSO organization (within or outside Expert team).

20

the results company

You might also like

- Transportation Management System Implementation GuideDocument67 pagesTransportation Management System Implementation GuideJenaiusNo ratings yet

- AX2012 - ENUS - Lean Manufacturing PDFDocument450 pagesAX2012 - ENUS - Lean Manufacturing PDFNitish SridharNo ratings yet

- Chapter 1: Overview: ObjectivesDocument22 pagesChapter 1: Overview: Objectiveskashan2012No ratings yet

- Slide 24 Warehouse ManagementDocument1 pageSlide 24 Warehouse ManagementNitish SridharNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 1 s2.0 S266691292200006X MainDocument12 pages1 s2.0 S266691292200006X MainDiego YauriNo ratings yet

- Exploring The Association Among Just in Time, Total Quality and Supply Chain Management Influence On Firm Performance: Evidence From IndonesiaDocument9 pagesExploring The Association Among Just in Time, Total Quality and Supply Chain Management Influence On Firm Performance: Evidence From IndonesiaIdrus RPGNo ratings yet

- Value Stream Mapping Machine ShopDocument19 pagesValue Stream Mapping Machine ShopVinoth VinoNo ratings yet

- A Brief Introduction To Lean, Six Sigma and Lean Six SigmaDocument8 pagesA Brief Introduction To Lean, Six Sigma and Lean Six SigmaDebashishDolonNo ratings yet

- Kpi Endang A 2018. Rev Agn 02Document24 pagesKpi Endang A 2018. Rev Agn 02Rahmad RiansyahNo ratings yet

- Management Information System Tata-Motors CIADocument13 pagesManagement Information System Tata-Motors CIASOLANKI DHRUVRAJ RAJU 20215048No ratings yet

- Dr.N.G.P. Institute of Technology: Department of Mechanical EngineeringDocument33 pagesDr.N.G.P. Institute of Technology: Department of Mechanical Engineeringvasanthmech092664No ratings yet

- Slidesmscsupplychainmanagementapril72016 160408070231Document34 pagesSlidesmscsupplychainmanagementapril72016 160408070231Jose SantosNo ratings yet

- A Lean Look at ErgonomicsDocument6 pagesA Lean Look at ErgonomicsJazmín GarcíaNo ratings yet

- RushiDocument34 pagesRushivijay choudhariNo ratings yet

- 5S, The Foundation For Lean System: Characteristics of World ClassDocument46 pages5S, The Foundation For Lean System: Characteristics of World ClassKaito100% (1)

- Toyota Kaizen MethodsDocument42 pagesToyota Kaizen MethodsMuhammad Biyan100% (1)

- Demand Driven MRPDocument16 pagesDemand Driven MRPManel VazquezNo ratings yet

- Gemba KaizenDocument64 pagesGemba KaizenJohnson Gitonga Nderi100% (3)

- Using Simulation To Teach Lean Methodologies and The Benefits For MillennialsDocument16 pagesUsing Simulation To Teach Lean Methodologies and The Benefits For MillennialsIvica KorenNo ratings yet

- Simulation-Based Analysis Lean and GreenDocument12 pagesSimulation-Based Analysis Lean and GreenOswald CastroNo ratings yet

- Lean System and The EnvironmentDocument4 pagesLean System and The EnvironmentArjay GuillandezNo ratings yet

- OM OutlineDocument4 pagesOM OutlineMuhammadUsmanNo ratings yet

- Unit 4 OMDocument16 pagesUnit 4 OMKRANTINo ratings yet

- Healthcare Supply Chain Mangement (SCM4191: Supply Chain Capstone Online)Document23 pagesHealthcare Supply Chain Mangement (SCM4191: Supply Chain Capstone Online)WaqasNo ratings yet

- Milliken White PaperDocument12 pagesMilliken White PaperAhmed Redwan100% (1)

- Case StudiesDocument8 pagesCase StudiesGowtham RasamsettyNo ratings yet

- An Appropriate Change StrategyDocument21 pagesAn Appropriate Change StrategyAlexanderHFFNo ratings yet

- The Lean Concept in The Food IndustryDocument11 pagesThe Lean Concept in The Food Industryfelipe_aaNo ratings yet

- McKinsey Telecoms. RECALL No. 09, 2009 - Operational TransformationDocument48 pagesMcKinsey Telecoms. RECALL No. 09, 2009 - Operational TransformationkentselveNo ratings yet

- Case Study On Lean Implementation in Nike and Inferences Drawn From ItDocument6 pagesCase Study On Lean Implementation in Nike and Inferences Drawn From ItAlexandra FoxNo ratings yet

- KP I Framework QADDocument180 pagesKP I Framework QADpelletongoNo ratings yet

- Acceptance Criteria: The Agile ManifestoDocument19 pagesAcceptance Criteria: The Agile ManifestoAmigos CrecimientoNo ratings yet

- Implementation Barriers For Six Sigma in ConstructionDocument4 pagesImplementation Barriers For Six Sigma in ConstructionseventhsensegroupNo ratings yet

- TPS and Lean ProductionDocument18 pagesTPS and Lean ProductionMikey ChuaNo ratings yet