Professional Documents

Culture Documents

Us1998499 PDF

Uploaded by

Azri LunduOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us1998499 PDF

Uploaded by

Azri LunduCopyright:

Available Formats

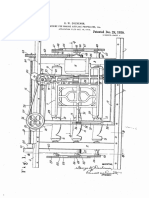

April 23, 1935.

F. L. FOSTER ET AL

1,998,499 -

PATTERN COPYING MACHINE

Filed Oct. 2, 1931

2 Sheets-Sheet 1

58

W4;

April 23, 1935.

F. |_. FOSTER ET AL

1,998,499

PATTERN COPYING MACHINE

Filed Oct. 2, 1931

2 Sheets-Sheet 2

WVE/V 717/?5

@221 bf M

7 Maag

1,998,499

Patented Apr. 23, 1935

1- UNITED STATES. PATENTOFFICE >

7

1,998,499

PATTERN COPYING MACHINE

Fred L. Foster and Herbert A.,Colby, Lynn, Mass.,

assignors to, United Shoe Machinery Corpora

tion, Paterson, N. J., a corporation oi New

Jersey '

Application October 2, 1931, Serial No. 566,504

7 Claims. (01. 33-23)

This invention relates to pattern reproducing vide in a pattern grading machine improved

machines, that is, machines for reproducing a means which are capable of dealing with diffi

model in a work piece, and is illustrated herein culties of the kind aboveindicated.

as embodied in a pattern grading machine of the > Accordingly, the invention provides novel

5 two-dimensional kind for producing shoe upper means whereby, at any time during a grading op

patterns from a model.

.

. eration, the pantograph mechanism of the ma

Machines of the type shown comprise four chine maybe quickly and easily rendered inop

primary instrumentalities, namely, a model hold erative so far as grading effect is concerned with

er, a work holder, amodel guide or follower, and out causing relative movement to take place be

10

10 a cutting tool, interconnected by two panto tween any of the primary, instrumentalities due

graphic mechanisms operating to magnify or re to the said adjustment of the pantograph mecha

duce the length and width of the model relatively nism. The machine will then grade at a 1:1

to length and width grading axes independently, ratio irrespective of the actual settings of the

grading mechanism. A change back to the nor;

in the work piece.

.

Pattern grading machines are used in the boot mal grade'is effected with similar case and ad

and shoe industry for reproducing from a flat vantage.

model or template of apart of a boot or shoe

upper, one or more patterns which are used sub

These and other features of the invention com

prising certain combinations and ~- arrangements

sequently in cutting out the part from leather of parts will be apparent from the following de

scription of a preferred embodiment of the inven- 20

20 or other suitable material. A pattern generated

by such a machine will, in general, if it is not tion shown in the drawings, in which

Fig. 1 is a plan view; and

'

of the same size as the model, be a general panto

Figs. 2, 3 and 4 are details of the center grading

graphic enlargement or diminution of the model

relatively to the grading axes, the magni?cation

mechanism.

The illustrated machine is, in its main struc 25

ture, a Hartford pattern grader of ordinary, con

pendent.

'

It is sometimes desiredto grade a pattern from struction. The main frame or bed I0 is provided

a model having an ornamental cut-out portion with smooth tracks or ways-upon which the car

in such manner as to cause a chosen part of the riage 12 slides freely toward and from the op

corresponding cut-out portion on the work to erator (or north and south) on wheels 14. The 30

grade into position, along acertain direction, rel carriage l 2. is provided with tracks I6, I ,1 on which

atively to an edge of the work but yet to grade the model wheel carriage I8, and a similar car

the cut-out portion itself in such manner as to riage 20, slide freely east and. west on wheels '22,

cause its dimension in the work along the said 24 respectively. 'The carriage 20 is provided with

a. track on which the tool carriage 26 slides north

35 direction to be equal to that of the cut-out portion

in the model along the corresponding direction. and south on wheels one of which is shown at 28.

Such a method of grading part of the model at The modelwheel is indicated at 30, and the tool

.

,

I

a 1:1 ratio, called center grading, often presents at 32.

difficulties particularly when the model has a ' The carriages I8 and'20 are; connected by the

length grading mechanism comprising an arcuate 40

40 number of cut-out portions distributed over its

length grading lever 34 having a straight exten

. Heretofore this problem has been dealthwith by sion 35 withone end pivoted at 36 to a link 38

locatingapoint of the patternatwhich it is desired which is pivoted to the carriage I2. This lever is

to begin the center grading at the grading center pivoted atv 42. on the carriage l8, and a link 44,

of the machine, The grading center is a point adjustable along the are 34 and pivoted thereto at 45

such that when the model follower is located upon its point of adjustment 46, is pivoted to the car

it, the grading mechanism settings. can be al riage 20 at 48. With the parts as shown in Fig. 1

tered without causing'any relative movement of an east or west movement of the carriage l 8 and

the tool and work. This procedure has not been model wheel 30 will cause a smaller but propor

successful since there are often several points at. tional movement of the carriages 20 and 26 and 50

whichsuch a change, either to begin or to end tool 32. The effect of the link 38 is substantially

the center grading, is desirable, and the change that of a north and south slide to permit the lever

will cause a jog in the work if made anywhere else 34,35,to swing. Such a slide is found on some

25 factors relatively to the two axes being inde

area.

than at the grading center.

The object of the present invention is to pro

machines of this type.

' .

'

The "width "grading mechanism connects the 55

2.

1,998,499

carriages 20 and 26 and effects proportional north

and south movements of the tool 32 and model

wheel 30. It comprises the arcuate width grading

lever 50 having a straight extention 5| with its

end pivoted at 52 in an overhanging east and west

Suppose now that a point has been reached on

the model periphery at which it is desired to

change the length grade from that shown in

Fig. 1 to a 1:1 ratio. The operator will loosen the

nut 14, tighten the stud 90 (thereby clamping the

slideway 54 mounted on an arm 56 on the frame link 96 rigidly to the ?ange 13 on the pivot 10, and

ill. It is pivoted at 60 on the carriage 20, is joined hence to the lever 34) , pull down the pin 84, and

to the lever by a link 62 at an adjustable pivot 54, shove in a little slide I03 (Fig. 3) which passes

and is connected to the carriage 26, at the pivot over the top of the pin 84 and prevents its rising.

10 65. With the parts as shown in Fig. 1, a north Then the carriage 20, link 96, are 34, and link 44

movement of the model wheel 30 will cause a form a rigid quadrilateral, and the two carriages

greater, but proportional, north movement of the . l8 and, 20 must move at a 1:1 velocity ratio, thus

15

30

35

40

accomplishing the 1:1 length grading, or center

cutter 32.

The model table is indicated at 61, and the work grading in length, as desired. This causes no

table at E8.

'

disturbance of the machine, or jog in the work,

Each of the grading levers is'provided with a and a reversal of the setting procedure described

mechanism known as a shift. This consists above will set the machine back into the length

essentially of a pivot between the straight and grade for which it was set without disturbance.

arcuate parts of the levers, at 10, 12, respectively, During the center grading the parts 34 and 35

with clamps to render the levers normally rigid. will swing relatively to each other about the pivot

These constructions are alike on both levers, and 10, which thus provides a. lost motion device pre

'

are shown in detail in Figs. 2, 3 and 4. The pivot venting locking or cramping.

70 is formed as a stud having a ?ange I3 under

A similar construction, including a link I04,

lying the member 35, the stud extending up pivoted to the carriage 20 at I06, is provided in

through the members 34 and 35. A screw thread connection with the width grading lever 5?}, 51.

at its top is engaged by a handled nut 14 to clamp The clamping of the link IM to the lever 50 looks

the parts 34 and 35~?rmly together. The are 34 the lever 50 to the carriage 20, thus holding the

is provided with an arm 16. with a pointer 18 co tool carriage 26 relatively motionless thereon.

operating with a segment 80 mounted on the

Thus center grading in both length and width,

member 35. The segment 80. has a series of holes independently, at any: desired pointv in the pro

82 engageable by a sliding pin 84 in the arm 16. duction of a work piece, is secured, without dis

This pin is pressed up into a hole 82 by a spring turbance of the machine at the points of transi~

85 and is pulled down out of the hole by a lever 88. tion from one grade to the other.

>

Thus, when the nut T4 is loosened, the pin 84 can

A handle I98 is provided at the end of the lever

be used to set the members 3 and 35 at. a 34 nearest the operator, and is used to control

different angle to each other and then the. nut H the movement of the model wheel around the

is tightened again. The purpose of this mecha model in the heavier machines oi the type shown.

nism, which is well known, is. to avoid, for ex The connection of the link'96 at the point 10 of

ample, grading the top of a high shoe. When the lever 34 renders it possibleito use this handle

such a shoe is regularly width graded, the top ef?ciently without any lost motion, or cramping,

line of the leg portion comes too high to look well, which might result if, for example, the link 95

and the shift at 12 is used to throw the tool north were connected straight across between the car

or south, discontinuously, to lower the top line riages i8, 20, or straight across between the car

and cut off the unwanted portion by the east or riage 20 and the pivot 42, in case the pivotl?

west movement along the top.

happened to be near the pivot 42.

The radii of the arcs 34 and 50 are equal to the

Having described our invention, what We claim

lengths of the links .44 and 62 respectively. 0b as new and desire to secure by Letters Patent of

viously, when the parts are in such a position that the United States is:

the are 34 lies symmetrically-relatively to the line

V 1. In a pattern reproducing machine, four

50 42, 48, the'length grader setting can be changed primary instrumentalities, namely, a model hold

without causing any movement of other parts er, a work holder, a. model guide and a tool, grad

The north and south line on the model holder 61- ing mechanism interconnecting them for e?ect~

which registers with the model wheel 30 at such ing relative movements between the work holder

time is called the length grading axis, and an east and tool to reproduce a model in a work piece, an

50

and west line corresponding to a similar- position element operatively connected with one 01' said 55

of the width grading lever 50, 5| is. known as the primary instrumentalities. in such manner as to

width grading axis. Their intersection is the have the same movement, perpendicular to the

grading center, above mentioned.

'

width grading axis, as said primary instrumental~

All of the structure above described is well ity and movable relatively to another of the said

known.

"

The new structure cooperating with parts al

ready described to effect the objects of the inven-1

tion will now be described.

The stud .70._is tapped at its lower end to receive

65 a stud 90 having a ?at head 92. This stud passes

through a slot 94 in a link 96, pivoted at 98 to

the carriage 20. The head 92 is clamped against

the link, thus. holding it ?rmly to. the stud by a

handle I08 having an adjustable engagement

with it, as shown in Fig. 4, so thatv the requisite

primary instrumentalities in the width grading 60

direction during the action of the width grading

mechanism, means comprising a clamp i'or posi

tively holding said element and said last-named

primary instrumentality against relative move

ment in the width grading direction, at the will

of the operator at any time during the production

or a work piece, and a lost motion means in said

grading mechanism acting to prevent cramping

when said element and said primary instrumen

tality are so held.

range of movement of the handle can be secured

without interference with other parts.

70

2. In a pattern reproducing machine, four

(The primary instrumentalities, namely, a model hold

same object

accomplished in the case of- the er, a work holder, a model guide and a tool, con

nut 14 by the set screw I02 in the arc 34, which nections between them comprising a- grading

permits rotary adjustment of the ?ange 13.).

mechanism for effecting relative movements be

75

'

1,998,499

tool to reproduce a. model in a work piece, said

grading mechanism comprising a lever and a link

operatively located between two of said primary

instrumentalities to transmit movement from a.

manner as to have the same movement, perpen one to the other, a second link operatively lo

dicular to a grading axis, as said primary instru cated between said lever and one of said two pri

mentality and moves relatively to a certain other mary instrumentalities, means for clamping said

primary instrumentality during the grading ac last-named link to said lever, when center grad

tion, a holding means arranged to hold said ele ing is'desired, and a lost motion device operable

and said certain other primary instrumen to prevent cramping when said last-named link 10

1.0 ment

tality positively against relative movement, when is clamped to said lever.

6. In a pattern reproducing machine, four pri

it is desired to center grade, and a lost motion de

vice arranged to absorb the normal grading mary instrumentalities, namely, a model holder,

movement of the machine to prevent cramping, a work holder, a model guide and a tool, grading 15

mechanism interconnecting them for effecting

15 when center grading is being done.

3. In a pattern reproducing machine, four pri relative movements between the work holder and

mary instrumentalities, namely, a model holder, tool to reproduce a model in a work piece, said

a work holder, a model guide and a tool, grading grading mechanism comprising a lever and a link

mechanism interconnecting them for effecting operatively located between two of said primary

relative movements between the work holder and instrumentalities to transmit movement from one

tool to reproduce a model in a work piece, said to the other, a second link operatively located be

grading mechanism comprising a lever operative tween said lever and one of said two primary in

ly located between two of said primary instru strumentalities, means for clamping said last

mentalities to transmit movement from one to named link to saidrlever, when center grading 25

the other, means operative to hold said lever im is desired, and a normally rigid pivoted joint in

movable relatively to one of said two primary in said lever to be loosened when center grading is

tween the work holder and tool to reproduce a

model pantographically in a work piece, said con

nections including a member which is operatively

connected to one primary instrumentality in such

strumentalitiesin order to e?ect center grading, desired, said second-named link being connected

and a lost motion device operable when the lever with said lever at said joint.

'7. In a pattern reproducing machine, four pri

is so held, to prevent cramping.

4. In a pattern reproducing machine, four pri

mary instrumentalities, namely, a model holder,

a work holder, a model guide and a tool, grading

mechanism interconnecting them for eifecting

relative movements between the work holder and

mary instrumentalities, namely, a model holder, 30

grading mechanism comprising a lever operative

ly located between two of said primary instru

operatively located between two of said primary

a work holder, 2. model guide and a tool, grading

mechanism interconnecting them for effecting

relative movements between the work holder and

tool to reproduce a. model in a work piece, said

35

tool to reproduce a model in a work piece, said grading mechanism comprising a lever and a link

instrumentalities to transmit movement from one '

mentalities to transmit movement from one to to the other, a second link operatively located

the other, means operative to hold said lever im between said lever and one'of said two primary

movable relatively to one of said two primary in instrumentalities, means for clamping said last 40

45

strumentalities in order to effect center grading, named link to said lever, when center grading is

and a normally rigid pivoted joint in the lever desired, at a point remote from the point of at

operable to prevent cramping when the lever is tachment of said ?rst-named link to the lever,

a lost motion device operable to prevent cramp

so held.

5. In a pattern reproducing machine, four pri ing when said last-named link is clamped to said 45

mary instrumentalities, namely, a model holder, lever, and a handle on the end of the lever to

a work holder, a model guide and a tool, grading operate the machine.

FRED L. FOSTER.

mechanism interconnecting them for e?ecting

HERBERT A. COLBY.

relative movements between the work holder and

You might also like

- Details of Our IPO - 9Document13 pagesDetails of Our IPO - 9Azri LunduNo ratings yet

- 19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Document5 pages19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Azri LunduNo ratings yet

- Tuju Setia: MalaysiaDocument10 pagesTuju Setia: MalaysiaAzri Lundu100% (1)

- Daily Activity Statement: Mohammad Azam Bin MustapaDocument5 pagesDaily Activity Statement: Mohammad Azam Bin MustapaAzri LunduNo ratings yet

- Us1893957 PDFDocument12 pagesUs1893957 PDFAzri LunduNo ratings yet

- Set 5 ENGLISH Questions & Answers 180309: Answer ADocument9 pagesSet 5 ENGLISH Questions & Answers 180309: Answer AAzri LunduNo ratings yet

- IPO Performance For New Listings As at 09/11/2021: Stock CodeDocument2 pagesIPO Performance For New Listings As at 09/11/2021: Stock CodeAzri LunduNo ratings yet

- Cekd FullDocument331 pagesCekd FullAzri LunduNo ratings yet

- Coraza FullDocument292 pagesCoraza FullAzri LunduNo ratings yet

- Set 1 Questions & AnswersDocument15 pagesSet 1 Questions & AnswersJon Loh Soon WengNo ratings yet

- Set 2 ENGLISH Questions Answers 010808Document12 pagesSet 2 ENGLISH Questions Answers 010808Azri LunduNo ratings yet

- Us1798926 PDFDocument11 pagesUs1798926 PDFAzri LunduNo ratings yet

- Prestasi IPO 2019-2021 UpdatedDocument1 pagePrestasi IPO 2019-2021 UpdatedAzri LunduNo ratings yet

- Set 3 Questions & Answers 010808: Answer CDocument10 pagesSet 3 Questions & Answers 010808: Answer CAzri LunduNo ratings yet

- Regulated UTS Industry and Key PlayersDocument11 pagesRegulated UTS Industry and Key PlayersAzri LunduNo ratings yet

- Us2765819 PDFDocument8 pagesUs2765819 PDFAzri LunduNo ratings yet

- What Is ASRSDocument7 pagesWhat Is ASRSAzri Lundu0% (1)

- Us1363238 PDFDocument10 pagesUs1363238 PDFAzri LunduNo ratings yet

- Geneva Cam MechanismDocument58 pagesGeneva Cam MechanismAzri Lundu0% (1)

- Labwork 7b (Student)Document4 pagesLabwork 7b (Student)Azri LunduNo ratings yet

- Us2425543 PDFDocument10 pagesUs2425543 PDFAzri LunduNo ratings yet

- CombinedDocument85 pagesCombinedAzri LunduNo ratings yet

- Labwork 3 (Student)Document5 pagesLabwork 3 (Student)Azri LunduNo ratings yet

- Energy Management Centre Kerala - Energy Audit Manual - UnlockedDocument147 pagesEnergy Management Centre Kerala - Energy Audit Manual - UnlockedAzri LunduNo ratings yet

- List of ModulesDocument7 pagesList of ModulesAzri LunduNo ratings yet

- Energy Loss in PipesDocument8 pagesEnergy Loss in Pipeskelechi2475% (8)

- NotesDocument7 pagesNotesAzri LunduNo ratings yet

- Axial Fan ReportDocument4 pagesAxial Fan ReportAzri LunduNo ratings yet

- Assignment 1 (Hardness Test)Document14 pagesAssignment 1 (Hardness Test)Azri LunduNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Objective QuestionsDocument19 pagesObjective QuestionsDeepak SharmaNo ratings yet

- Superficial ConclusionDocument49 pagesSuperficial ConclusionIngrid ParissNo ratings yet

- CHEE319 Tutorial 4 SolnDocument13 pagesCHEE319 Tutorial 4 SolnyeshiduNo ratings yet

- Proejcr ManduaDocument552 pagesProejcr ManduaDanny NguyenNo ratings yet

- CLOZE TEST Fully Revised For SSC, Bank Exams & Other CompetitiveDocument57 pagesCLOZE TEST Fully Revised For SSC, Bank Exams & Other CompetitiveSreenu Raju100% (2)

- Radiograph Evaluation ChecklistDocument2 pagesRadiograph Evaluation ChecklistZulfadli Haron100% (1)

- MST 2 ReviewerDocument4 pagesMST 2 ReviewerAizha NarioNo ratings yet

- Subject and Content NotesDocument52 pagesSubject and Content NotesJoe Carl CastilloNo ratings yet

- Rules For Assigning Activity Points: Apj Abdul Kalam Technological UniversityDocument6 pagesRules For Assigning Activity Points: Apj Abdul Kalam Technological UniversityAnonymous KyLhn6No ratings yet

- Understanding Power Dynamics and Developing Political ExpertiseDocument29 pagesUnderstanding Power Dynamics and Developing Political Expertisealessiacon100% (1)

- HWXX 6516DS1 VTM PDFDocument1 pageHWXX 6516DS1 VTM PDFDmitriiSpiridonovNo ratings yet

- A Hirshfeld Surface Analysis and Crystal StructureDocument8 pagesA Hirshfeld Surface Analysis and Crystal StructureLidiane MicheliniNo ratings yet

- Th255, Th255c Axle Cat ServiceDocument280 pagesTh255, Th255c Axle Cat ServiceKevine KhaledNo ratings yet

- 4.3 Structural Analysis 4.3.1 ModellingDocument8 pages4.3 Structural Analysis 4.3.1 Modellingdavid ROBALINONo ratings yet

- Action Plan On GadDocument1 pageAction Plan On GadCherish Devora ArtatesNo ratings yet

- Advanced Scan I21no2Document29 pagesAdvanced Scan I21no2Jaiber SosaNo ratings yet

- Dewatering Well PointsDocument4 pagesDewatering Well Pointssalloum3No ratings yet

- Electromagnetic Braking SystemDocument14 pagesElectromagnetic Braking SystemTanvi50% (2)

- Amber ToolsDocument309 pagesAmber ToolshkmydreamsNo ratings yet

- Sea Cities British English Teacher Ver2Document6 pagesSea Cities British English Teacher Ver2Kati T.No ratings yet

- Scedule Maintenance KBN Mill 2020Document9 pagesScedule Maintenance KBN Mill 2020slamet supriyadiNo ratings yet

- Understanding Logistics and Supply Chain Management ConceptsDocument12 pagesUnderstanding Logistics and Supply Chain Management Conceptsarfat kabraNo ratings yet

- Saes H 201Document9 pagesSaes H 201heartbreakkid132No ratings yet

- Holacracy FinalDocument24 pagesHolacracy FinalShakil Reddy BhimavarapuNo ratings yet

- The Effects of Self-Esteem On Makeup InvolvementDocument9 pagesThe Effects of Self-Esteem On Makeup InvolvementMichelle Nicole Tagupa SerranoNo ratings yet

- Sulzer MC EquipmentDocument12 pagesSulzer MC EquipmentsnthmlgtNo ratings yet

- Packing, Transportation and Marketing of Ornamental FishesDocument16 pagesPacking, Transportation and Marketing of Ornamental Fishesraj kiranNo ratings yet

- The Ethological Study of Glossifungites Ichnofacies in The Modern & Miocene Mahakam Delta, IndonesiaDocument4 pagesThe Ethological Study of Glossifungites Ichnofacies in The Modern & Miocene Mahakam Delta, IndonesiaEry Arifullah100% (1)

- ST326 - Irdap2021Document5 pagesST326 - Irdap2021NgaNovaNo ratings yet

- Exp-1. Evacuative Tube ConcentratorDocument8 pagesExp-1. Evacuative Tube ConcentratorWaseem Nawaz MohammedNo ratings yet