Professional Documents

Culture Documents

1-1 Checking The Installation Space

Uploaded by

Manuel VidalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1-1 Checking The Installation Space

Uploaded by

Manuel VidalCopyright:

Available Formats

Chapter 1 Press Installation

1-1

Checking the installation space

A. Installation space

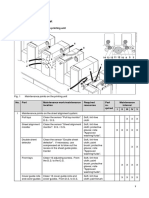

The press dimensions are shown below.

There should be enough space between the wall and press to allow operation and maintenance.

Check the entrance of the room that the press will be installed in.

RYOBI 522GE Press dimensions

320mm

(12.6")

270mm

(10.6")

470mm

(18.5")

2,598mm (8' 6")

130mm (5.1")

Power cord wiring place

RYOBI 524GE Press dimensions

1,260mm (4' 2") [RYOBI PCS-JX]

974mm (3' 3") [RYOBI PCS-J]

Cord length 5m (16' 5")

130mm (5.1")

270mm 470mm

(10.6") (18.5")

Power cord wiring place

4,096mm (13' 5")

This illustration shows the RYOBI PCS-J.

Chapter 1 Press Installation

B. Press installation place

The foundation construction should be done by a specialist.

100 - 150mm

(4" - 6")

Concrete

200 - 300mm

(8" - 12")

Gravel

(Note)

bolt. So please consult a contractor who has this specialized knowledge.

(Reference : Load capacity per 1m2 is over 1,200kg. / Load capacity per square feet is over 246 lbs.)

3. The ceiling height should be over 2,500mm (8' 2").

C. Necessary tools when carrying the press

10

Allen wrench

14mm

Wrench

19mm, 24mm

Pipe (Round pole)

50mm (Outer diameter) x 1,700mm (Length)

Jack

More than 2, each with a capacity of 2 tons

Others

Delivery tools (Hydraulic pallet truck)

Level (0.02mm/m)

Chapter 1 Press Installation

1-2

Carrying procedures

A. Lifting procedures

RYOBI 522GE

Lifting gauge set No. 5522 J 010

(Reference)

Mounting the lifting gauge

1)

Remove the grip.

2)

Remove the 2nd unit safety

cover dampers.

4)

Mount the 2 stays between the

hooks at the 1st unit and 2nd

unit.

5)

Mount the 2 stays between the

hooks at the operation side and

non operation side.

3)

Mount the 4 hooks at the 1st unit

and 2nd unit.

A t t h i s t i me , p l a ce p ac k i n g

(cardboard or rubber) between

the frame and hook.

11

Chapter 1 Press Installation

RYOBI 524GE

Lifting gauge set No. 6524 J 010

Mount the 4 gauges on the press using the bolts and lift it using

the wires.

Gauge

B. Jacking up

RYOBI 522GE

(Notice)

illustration.

2. Be careful that the whole press is kept in balance.

12

RYOBI 524GE

Chapter 1 Press Installation

(Reference)

Jack up bolt position and point weight (

RYOBI 522GE

[Unit : mm (inch)]

470 (18.5")

a1

b1

c1

a2

b2

c2

411.5

(16.2")

893

(35.2")

d1

d2

430 561.5 302

(16.9") (22.1") (11.9")

Point weight

a1

a2

b1

b2

c1

c2

d1

d2

Total

525

525

525

525

525

525

100

100

3,350

a1

a2

b1

b2

c1

c2

(Unit : kg)

d1

d2

Total

220

220

7,382

(Unit : lbs.)

RYOBI 524GE

[Unit : mm (inch)]

b1

a1

a2

374

(14.7")

b2

1,275.5

(50.2")

c1

d1

c2

d2

1,211

(47.7")

408.5

(16.1")

e1

e2

525

302

(20.7") (11.9")

Point weight

a1

a2

b1

b2

c1

c2

d1

d2

828.8 828.8 828.8 828.8 828.8 828.8 828.8 828.8

a1

a2

b1

b2

c1

c2

d1

d2

1,827 1,827 1,827 1,827 1,827 1,827 1,827 1,827

e1

e2

Total

100

100

6,830

e1

e2

Total

220

220

15,056

(Unit : kg)

(Unit : lbs.)

13

Chapter 1 Press Installation

C. When setting the oil pan

Delivery side

Feeder side

Bed

frame

Oil pan

C

B

14

Model

RYOBI 522GE

60mm (2.4")

60mm (2.4")

100mm (3.9")

RYOBI 524GE

50mm (2")

50mm (2")

40mm (1.6")

Chapter 1 Press Installation

1-3

Press leveling

A. Leveling accuracy measuring places

The level that is used should have an accuracy of 0.02mm per one meter.

Check the press leveling accuracy at the 3 places shown in the illustration.

RYOBI 522GE

RYOBI 524GE

(2) Operation side

(3) Non operation side

(1)

(1)

(2) Operation side

(3) Non operation side

On the 2nd unit ink fountain roller............................ (1)

On the 1st unit ink frame ...................................(2), (3)

On the 2nd unit impression cylinder ........................ (1)

On the bed frame...............................................(2), (3)

B. Adjustment procedures

RYOBI 522GE

(2) Operation side

(3) Non operation side

(1)

(A)

bolts (A), (B), and (C).

(D). At this time, be careful not to change the level of the

press section.

(B)

(C)

(D)

15

Chapter 1 Press Installation

RYOBI 524GE

bolts (A), (B), and (C).

and (E). At this time, be careful not to change the level of

the press section.

(1)

(A)

(B)

(C)

(D)

(E)

(2) Operation side

(3) Non operation side

(Note)

1. Any oil and foreign particles must be wiped off from the surface where the level is to be positioned.

vibration may result.

16

Chapter 1 Press Installation

1-4

Press wiring

A. Power source wiring

These presses require a power source shown in the table below. Prepare a power cord. Ground the press properly

using the ground wire.

RYOBI 522GE

RYOBI 524GE

Power supply

3 phase, 200V, 27A

3 phase, 200V, 47A

Power consumption

7.5kW (27,000kJ,

6,450kcal, 25,590BTU)

13.5kW (48,600kJ,

11,600kcal, 42,060BTU)

Cross sectional area of power cord

Over 5.5mm2

Over 14mm2

Power cord length

Less than 10m

Less than 10m

B. Wiring procedures

To power source

PE

PE

1)

2)

Connect the power wires to the

terminal base (R, S, T, and PE)

in the power box.

Fix the power cord to the box

using the bushing.

Connect the power wires to the

power source.

[Press with a transformer only]

Transformer

Primary side tap

To the power source

Secondary side tap

(Reference)

When using a transformer, connect the transformer so that

it is between the power source and press.

Wires to the power source : Primary side tap in the

transformer

Wires from the press :

Secondary side tap in the

transformer (200V)

(Note)

Check that the connection of the wires (primary side tap) to

the power source matches the voltage of the power source.

From the press

17

You might also like

- Ryobi 3302 Service ManualDocument568 pagesRyobi 3302 Service Manualvijayakumasar81% (21)

- CPC 1-04 PDFDocument88 pagesCPC 1-04 PDFFabian Etchenique80% (10)

- Polar 76 Schema ElectronicaDocument13 pagesPolar 76 Schema ElectronicassdfsfNo ratings yet

- KMS-CP OperationManual enDocument92 pagesKMS-CP OperationManual enHuy Nguyen QNo ratings yet

- CD 102 SpecsDocument198 pagesCD 102 SpecsAqsa Sahar100% (1)

- Diagnostic Printer 68XXDocument18 pagesDiagnostic Printer 68XXAdrian RouxNo ratings yet

- Maintenance - Repair MO PDFDocument342 pagesMaintenance - Repair MO PDFjose100% (2)

- Pqa-C: Operation ManualDocument46 pagesPqa-C: Operation ManualHuy Nguyen Q100% (3)

- Computer Control: Control Processor UC Control Processor TVDocument23 pagesComputer Control: Control Processor UC Control Processor TVmaxxiss75% (4)

- Ryobi 3200 PDFDocument139 pagesRyobi 3200 PDFKevinSuriyanNo ratings yet

- BQ270 Operator ManualDocument123 pagesBQ270 Operator Manualsudalfa0% (1)

- Heidelberg GTO Old Style PDFDocument88 pagesHeidelberg GTO Old Style PDFLuis Carlos Madera CarrollNo ratings yet

- Syn Gto 52 RollerDocument1 pageSyn Gto 52 RollerSamsung Kzoom100% (1)

- Service Instructions: PERFECTA 76 / 92 / 115 / 132 / 168 Uc / TVDocument32 pagesService Instructions: PERFECTA 76 / 92 / 115 / 132 / 168 Uc / TVmaxxissNo ratings yet

- CD 102 New Feeder PDFDocument170 pagesCD 102 New Feeder PDFنبيلNo ratings yet

- KBA Rapida 75 Basic Technical Information PDFDocument53 pagesKBA Rapida 75 Basic Technical Information PDFMedyou83% (6)

- Heidelberg SM 102 FPDocument1 pageHeidelberg SM 102 FPSegaf Sang Pengelana100% (1)

- Confidential Confidential Confidential Confidential: First Edition: November, 2007 Latest Edition: Revision: BetaDocument13 pagesConfidential Confidential Confidential Confidential: First Edition: November, 2007 Latest Edition: Revision: BetaManuel Vidal100% (4)

- Murphy Autostart 700 PDFDocument2 pagesMurphy Autostart 700 PDFBEN100% (1)

- EF-35 - Service ManualDocument53 pagesEF-35 - Service ManualsudalfaNo ratings yet

- Description of Compucut® GO Scope of SupplyDocument2 pagesDescription of Compucut® GO Scope of SupplyKanniyappan GounderNo ratings yet

- Schematic View of Rollers: WaterDocument11 pagesSchematic View of Rollers: Watersuhas k100% (1)

- POLAR Cutting Machine D 66 ProductsheetDocument2 pagesPOLAR Cutting Machine D 66 ProductsheetKanniyappan GounderNo ratings yet

- Interface AdapterDocument16 pagesInterface AdapterAnthonyNo ratings yet

- Computer Control: Control Processor UC Control Processor TVDocument23 pagesComputer Control: Control Processor UC Control Processor TVmaxxiss50% (2)

- IOControl SdokuDocument23 pagesIOControl Sdokushiva100% (1)

- Cutting - in - Practice - Blades IndicationsDocument24 pagesCutting - in - Practice - Blades IndicationsHector Elias Mercedes HazimNo ratings yet

- Gto Montaje de AlastraDocument88 pagesGto Montaje de AlastraTecnico Artes GraficasNo ratings yet

- SAK2 Memory Analog BoardDocument7 pagesSAK2 Memory Analog BoardErman GÖGENNo ratings yet

- Module 5 - SoftwareDocument16 pagesModule 5 - Softwareshiva100% (1)

- Overallcontrol SystemDocument36 pagesOverallcontrol SystemAnthony100% (3)

- Technical Data CD102 PDFDocument2 pagesTechnical Data CD102 PDFSegaf Sang Pengelana100% (2)

- Heidelberg SM 74 - 5 H: Curriculum Vitae of The Machine Reference Number: 20059Document2 pagesHeidelberg SM 74 - 5 H: Curriculum Vitae of The Machine Reference Number: 20059Magros TamNo ratings yet

- Microcut HSTD ManualDocument25 pagesMicrocut HSTD ManualPedro IsmaelNo ratings yet

- Manual - Speedmaster Motor ControlDocument88 pagesManual - Speedmaster Motor ControlTerence Wood100% (2)

- Dampening Sistem SM52-1Document29 pagesDampening Sistem SM52-1Димитър ПетровNo ratings yet

- 11493PQC Data Manager enDocument95 pages11493PQC Data Manager enHiếu TrầnNo ratings yet

- POLAR Productsheet 137Document6 pagesPOLAR Productsheet 137Syed Hassan TariqNo ratings yet

- Grados de Heidelberg SM 102 4 PDF FreeDocument16 pagesGrados de Heidelberg SM 102 4 PDF FreeMinhduclabels Sales100% (1)

- Ryobi-512 Crestlain - ESPAÑOLDocument68 pagesRyobi-512 Crestlain - ESPAÑOLvergamás1100% (1)

- ZSK2 ErrorsDocument36 pagesZSK2 ErrorsHABUMUGISHA Dieudonne100% (1)

- Technical Data For Speedmaster SM 74: Printing Stock Blanket CylinderDocument1 pageTechnical Data For Speedmaster SM 74: Printing Stock Blanket CylinderMatt DWorkNo ratings yet

- Fault Displays in The ZIDDocument20 pagesFault Displays in The ZIDAnthony50% (2)

- 4995A ICS BrochureDocument8 pages4995A ICS BrochureGerardo BernardoNo ratings yet

- Inputoutput List EAKSEKDocument20 pagesInputoutput List EAKSEKAnthony100% (2)

- Technical Information For PERFECTA PREMIUM LineDocument9 pagesTechnical Information For PERFECTA PREMIUM LineDevraj KulasekarNo ratings yet

- 1 Preface: 1.1 Notes For The ReaderDocument14 pages1 Preface: 1.1 Notes For The Readerahmed samierNo ratings yet

- 16 - Chapter 8 PDFDocument60 pages16 - Chapter 8 PDFJavier Martinez CañalNo ratings yet

- Accucut-Tc ManualDocument23 pagesAccucut-Tc ManualNaresh KumarNo ratings yet

- KBA Grafitrec Performa 74 enDocument20 pagesKBA Grafitrec Performa 74 enCovek Bez FejsbukaNo ratings yet

- Baumcut 26.4 ProgrammableDocument98 pagesBaumcut 26.4 ProgrammableraduroNo ratings yet

- Aggregates: Service Training MechanikDocument24 pagesAggregates: Service Training Mechanikfroilan ochoaNo ratings yet

- Sheet Alignment ControlDocument13 pagesSheet Alignment Controlمحمد محمودNo ratings yet

- Cityline ExpressDocument4 pagesCityline Expresssunil kambleNo ratings yet

- SM 102 SpecsDocument119 pagesSM 102 SpecsAlexandre DomingosNo ratings yet

- 1 Printing Unit ChecklistDocument5 pages1 Printing Unit ChecklistMagnus BergmanNo ratings yet

- Guide Speedmaster CD 102 en PDFDocument6 pagesGuide Speedmaster CD 102 en PDFNguyen Nhan50% (4)

- 'Docslide - Us - Prinect Signa Station Users Guide en PDFDocument359 pages'Docslide - Us - Prinect Signa Station Users Guide en PDFResimasc González100% (1)

- Pages From Operation 78ed 176eedv400 - eDocument8 pagesPages From Operation 78ed 176eedv400 - eNaresh KumarNo ratings yet

- M7E01 TechData 01Document10 pagesM7E01 TechData 01lexeberu100% (1)

- Swing Rack - InstallDocument7 pagesSwing Rack - InstallGilney FreitasNo ratings yet

- 12M Montagem Freio de ServiçoDocument10 pages12M Montagem Freio de ServiçoPaulo_GleriaNo ratings yet

- 336D Cat Mando Final EnsambleDocument16 pages336D Cat Mando Final EnsambleAlicia Serje100% (1)

- SMD CodesDocument13 pagesSMD CodesManuel Vidal100% (1)

- Error Codes 6800-50Document4 pagesError Codes 6800-50ManuelVidalNo ratings yet

- Snvs 741 FDocument23 pagesSnvs 741 FManuel VidalNo ratings yet

- Cis 229Document12 pagesCis 229Manuel VidalNo ratings yet

- CDM 2 08 14 Release InfoDocument10 pagesCDM 2 08 14 Release InfoManuel VidalNo ratings yet

- 1-Sheet 1 Measure AnswerDocument25 pages1-Sheet 1 Measure AnswerBahaa EmadNo ratings yet

- Testing StrategiesDocument8 pagesTesting StrategiesJohnny Pancito Rodriguez100% (1)

- 10 Atomic StructureDocument9 pages10 Atomic StructurearcNo ratings yet

- AppC PDFDocument10 pagesAppC PDFGuilherme PohlNo ratings yet

- Porosity Logs: Neutron LogDocument16 pagesPorosity Logs: Neutron LogayanNo ratings yet

- Residential Commercial and Industrial Electrical Systems JGWDJDocument4 pagesResidential Commercial and Industrial Electrical Systems JGWDJaa0% (2)

- Starting SystemDocument34 pagesStarting SystemGetachew Tikue100% (2)

- Flash MemoryDocument15 pagesFlash MemoryCRT07No ratings yet

- Tapco Mix120 Service Manual Plastic Power JackDocument15 pagesTapco Mix120 Service Manual Plastic Power JackMontserrat AlvarezNo ratings yet

- Power Cable High Freq ModelDocument7 pagesPower Cable High Freq ModelkrcdewanewNo ratings yet

- CP 343-1Document23 pagesCP 343-1Yahya AdamNo ratings yet

- Mir Junaid-1 PDFDocument5 pagesMir Junaid-1 PDFMir Junaid Ul HaqNo ratings yet

- MetricDocument5 pagesMetricmosesNo ratings yet

- Ec 501: Advanced Microprocessor and MicrocontrollerDocument2 pagesEc 501: Advanced Microprocessor and Microcontrollersunil kumarNo ratings yet

- R999000216 09 2015 Automation Media PDFDocument124 pagesR999000216 09 2015 Automation Media PDFJose Manuel Barroso PantojaNo ratings yet

- Eaton 216380 M22 KC10 en - GBDocument3 pagesEaton 216380 M22 KC10 en - GB3DLAB CAD/CAMNo ratings yet

- Code ClavierDocument5 pagesCode ClavierEgillNo ratings yet

- Syllabus EC5001 Embedded SystemsDocument3 pagesSyllabus EC5001 Embedded Systemskavish malakaNo ratings yet

- Amx Leclerc Main Battle Tank For The Year 2000Document6 pagesAmx Leclerc Main Battle Tank For The Year 2000Timia TalashekNo ratings yet

- Testo 175 H1 INDocument2 pagesTesto 175 H1 INsundarNo ratings yet

- Screenshot 2022-10-03 at 3.45.41 PMDocument15 pagesScreenshot 2022-10-03 at 3.45.41 PMNMP Kumar UNo ratings yet

- Instrumentation EarthingDocument13 pagesInstrumentation EarthingTrung TrầnNo ratings yet

- VLSIDocument9 pagesVLSIArunitha ArulnathanNo ratings yet

- Animesh Karandikar Meghna Mahak Jaspreet Gaurang ShubhamDocument9 pagesAnimesh Karandikar Meghna Mahak Jaspreet Gaurang ShubhamShaun NevilleNo ratings yet

- Mediana YM5500 - Service ManualDocument99 pagesMediana YM5500 - Service Manualmax51sNo ratings yet

- HW 316953Document3 pagesHW 316953carlosconstructor1No ratings yet

- Sens Battery ChargerDocument17 pagesSens Battery ChargervjNo ratings yet

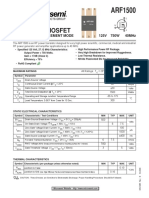

- Arf1500 PDFDocument4 pagesArf1500 PDFbookreader1968No ratings yet

- 300ma, Low Dropout, Low Noise Ultra-Fast Without Bypass Capacitor CMOS LDO RegulatorDocument11 pages300ma, Low Dropout, Low Noise Ultra-Fast Without Bypass Capacitor CMOS LDO RegulatordinhdtdNo ratings yet