Professional Documents

Culture Documents

Shearing Resistance of Steel Fiber Reinforced Self Consolidating Concrete Beams Without Stirrups

Uploaded by

Sheik MohamedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shearing Resistance of Steel Fiber Reinforced Self Consolidating Concrete Beams Without Stirrups

Uploaded by

Sheik MohamedCopyright:

Available Formats

Shearing Resistance of Steel Fiber Reinforced Self

Consolidating Concrete Beams Without Stirrups

M.Sheik Mohamed1,C.Makendran2

1

Assistant Professor, Civil Engineering,AalimMuhammedSalegh College of

Engineering,Muthapudupet, Avadi-IAF, Chennai -600055,TamilNadu,India

Assistant Professor& Head, Civil Engineering,AalimMuhammedSalegh College of

Engineering, Muthapudupet,

Avadi-IAF, Chennai-600055, TamilNadu,India

--------------------------------------------------------------------***---------------------------------------------------------------------

Abstract

The objective of this paper is to present

the results of shear strength of steel fiber

reinforced self consolidating concrete

beams as well as normal concrete beams

made without stirrups. Totally three mixes

representing one for control mix and two

for self consolidating concrete with and

without steel fiber. The beams were

tested under two point loading until shear

failure occurred. The experimental test

parameters included size of coarse

aggregate, percentage of the longitudinal

reinforcement and steel fiber content.

Shear span to effective depth of beams

was

kept

constant

(a/d=1.36).The

performance

of

code

based

design

equations

in

predicting

the

shear

resistance of self consolidating concrete

and ordinary concrete is also presented

and compared with the experimental

results. The beams were tested for

ultimate shear failure and experimental

shear loads were taken for first flexural

crack/diagonal shear crack and ultimate

cracking conditions.

Key Words: Self consolidating concrete, steel

fiber, shear span to effective depth ratio, shear

strength, crack width etc

1.INTRODUCTION

SCC means Self-Consolidating Concrete, or Self

Compacting Concrete has the property of high

flow ability, passing ability and filling ability.

Self-compacting concrete is used to cast

structural elements very rapidly and promotes

faster construction. This type of concrete can be

placed in crowded reinforcement zones without

any difficulty and reduces the mechanical

efforts used for concrete compaction. Self

consolidating

concrete

allows

structural

designers to provide thin concrete sections and

congested reinforcement detailing. It has the

better structural performance in terms of bond

strength, crushing strength etc.SCC now widely

used in all the types of structures all around the

world.SCC uses the industrial wastes as a part

of making concrete, tends to reduce wastage of

industrial wastes and acts as an ecofriendly.

Concrete has low tensile strength and has a

brittle failure in nature. Steel fibers in the

concrete

can

enhance

the

mechanical

properties such as ductility and energy

absorbing capacity underseismic, impact and

blast loading. Steel fibers are also used to

increase the compressive strength, shear

strength and tensile strength of concrete.

Residual shear strength of a beam after shear

cracking remained constant as a/d was

decreased up to 2.5, then it increased rapidly as

a/d was further decreased below 2.5 showing

minimum capacity at a/d = 2.5. Both ACI code

and Zsuttys equations gave conservative value

especially for a/d less than 2.5[1].Shear

strength of rectangular fiber reinforced concrete

beams depends mostly on the shear span-todepth ratio, reinforcement ratio, concrete

strength, and fiber properties [3]. Anticipated

shear failure of light weight concrete beams

without shear reinforcement tended to be

brittle; higher the concrete compressive

strength, greater the brittleness became.

Beams with a/dof 1.5, 2.0, and 2.5, under

design loads mostly fail in concrete crushing

above the inclined cracks, while beams with

a/dof 3.0 may fail by bond failure attributed to

splitting

of

bond

along

the

tension

reinforcement

[5].

As

the

longitudinal

reinforcement decreased, there was an observe

reduction in concrete shear strength [8]. SCC

beams showed lower ultimate shear strength

than the normal concrete beams. The shear

strength reduction was higher in deeper beams

with lower reinforcement ratios [9]. Optimum

fiber content was governed by the workability

requirements of the concrete mix [10]. A

significant increase in the shear capacity is

observed

by

providing

orthogonal

web

reinforcement and a desired mode of ductile

failure can be achieved through orthogonal web

reinforcement [19].SudheerReddyet al [20]

studied shearing resistance high strength

beams without web reinforcement. An attempt

had been made to study shear strength of high

strength concrete beams (70 Mpa) with different

shear span to depth ratios (a/d = 1, 2, 3 & 4)

without web reinforcement and compared the

test results with the available shear models

namely, American Concrete Institute, Canadian

Standard, CEPFIP Model, Zsutty Equation and

Bazant Equation. The results revealed that the

most excellent fit for the test data was provided

by Zsuttys Equation. The authors believed that

the factor of safety for shear should be greater

than for flexure (when the areas of flexural and

shear reinforcement equal that required for

strength) as shear failure occurred suddenly

with little if any warning [21].

Design shear strength of concrete,

c=

0.85 ( 0.8 f ck ) ( 1+ 5 )1

6

(N/mm2)

[1]

=0.8fck/6.89pt or 1 whichever is greater.

Where, fck = characteristic compressive strength

of concrete (N/mm2), = empirical factor, pt =

longitudinal tension steel (%).

According to British Standard (BS) [4] shear

strength of concrete members is given by

Design shear stress,

vc=

( )(

0.79

m

100 A s

bv d

( 13 )

1

( )

4

f cu

25

1

( )

3

)( )( )

400

d

(N/mm2)

[2]

2. SHEAR CONCEPT

From the theory of mechanics, shear force is

nothing but unbalance vertical force acting

either to the left or right of the section.

Shearing force acts in beams when there is

change in bending moment along the span.i.e,

this force is equal to the rate of change of

bending moment. Normally shear forces are

classified into two types i.e. vertical shear force

and horizontal shear force. The horizontal shear

force occurs in beams when they are subjected

to bending stresses. The vertical shear force

present in beams when they are subjected to

zero bending stresses. From the principle of

complementary shear, vertical shear forces are

always accompanied with the horizontal shear

forces. These forces are very much predominant

in beams as they cause severe deformation and

lead to cause failure of structures. The main

obstacle behind in shear transfer mechanism is

the number of parameters involved and these

parameters are yet to be known. In the

contribution of shear strength of concrete,

especially in beam mechanism aggregate

interlock mechanism is the for most one

resisting shear force. Even in arch action

compression strut promotes most of the shear

resistance depends on the size of coarse

aggregate. Normally, SCC is the type of

concrete in which the amount of coarse

aggregate content and maximum nominalsize

of coarse aggregate is less when compared to

normal concrete. The above factor has to be

studied in SCC in order to predict the shear

strength of concrete.

3.

DESIGN

EQUATIONS

FOR

SHEAR STRENGTH OF CONCRETE

According to Indian standard (IS) [15] shear

strength of concrete members is given by

K=

400

d

1

( )

4

( )

= size effect factors and should

not be less than 0.67 and pt% should not be

greater than 3.0. This formula gives values of v c

for concrete grade 25. For higher grades of

concrete, values should be multiplied by (f cu/25)

(1/3)

. The value of fcu should not be greater than

40.where, m = safety factor for concrete =1.25,

As = area of main tension reinforcement (mm 2),

bv = width of beam (mm), d = effective depth of

beam (mm), fcu =concrete cube compressive

strength (N/mm2)

According to Japanese Society of Civil

Engineering (JSCE)[17] shear strength of

concrete members is given by

Design shear capacity,

Vcd=

0.2 d p n f

b

1

( )

3

cy

bd

(kN)

(3)

d=((1000/d)(1/4))1.5, p=(100pt)(1/3)1.5, n=1,

Where, fcy = compressive strength of cylinder at

28 days (N/mm2), n = coefficient to consider

effect of axial force on shear capacity, d =

coefficient to consider effect of effective depth

on shear capacity, n = coefficient to consider

effect of longitudinal reinforcement on shear

capacity, d= effective depth of beam (mm), b

= member factor = 1.3.b=width of beam(mm)

According to Authors equation, Shear strength

of concrete members is given by

VC =

(V cs +V ts )

(kN)when 1<(a/d)<2.5

b

[4]

Where, Vcs=0.125bdcz

Vts= 12.5Ast (

f ck

(kN),

L

(0.01)

(kN)

D ) fck

VC = shear strength of concrete (kN), Vcs =

shear resistance of compression strut (kN), V ts =

shear resistance of tension tie (kN), d cz =depth

of compression zone of beam (mm), L = span of

beam (mm), D = overall depth of beam (mm),

Ast= area of main tension reinforcement (mm2),

b = safety factor for beam = 1.20.

3.1 Flexural cracking moment

According to American concrete constitute (ACI)

[2] flexural cracking moment is given by

Cracking

moment,

(Nmm)

Mcr=

(0.62( f cy )0.5 I g )

yt

[5]

Where, Ig= moment of inertia of gross section

(mm4), yt = distance of centroidal axis of gross

section (mm).fcy= compressive strength of

cylinder at 28 days (N/mm2)

According to Canadian Standards Association

(CSA) [6] flexural cracking moment is given by,

Mcr=

(0.6(f cy )0.5 I g )

(Nmm)

yt

[6]

According Indian standard[15] flexural cracking

moment is given by

Mcr=

(0.7(f ck )0.5 I g)

yt

(Nmm)

[7]

4. EXPERIMENTAL PROGRAM

In this work, totally three mixes were adopted in

which NC represents Normal Concrete, SCC

means Self Consolidating Concrete and SCCF

means Steel Fiber Reinforced Self Consolidating

Concrete. In the normal concrete, coarse

aggregate size of 20mm was used. In the first

mix of self consolidating concrete, coarse

aggregate size of 12.5mm was used and the

steel fiber added self consolidating concrete

coarse aggregate size of 20mm was used. For

every mix, both rheological properties and

mechanical properties were found out. For

finding of compressive strength,

totally

eighteen cubes of side 150mm were cast and

test carried out at 7th and 28th day. Similarly, for

finding of indirect tensile strength of concrete,

totally nine cylinders of size 150mm diameter

and 300mm height were cast and test carried

out at 28thday.For computing shear strength of

concrete,

totally

nine

beams

of

size

1000mmx150mmx250mm were cast and test

carried out at 28thday. For every mix, three

beams were cast and with three different

reinforcement ratios ranging from 0.25, 0.5 and

one %. All the specimens were cast in steel

moulds and in a single batch. The inside faces

of the moulds were applied with grease to

prevent water absorption and for providing

better

surface

finishability.

The

control

specimens were compacted using needle

vibrator and the SCC specimens compacted

without

any

mechanical

devices.

The

reinforcement was carefully placed inside the

mould and concrete was filled from one side.

The specimens were cured for a period 28 days

after stripping of specimens from moulds.

4.1 Materials

The cement used in all mixes was Ordinary

Portland Cement (OPC) had the compressive

strength of 43N/mm2.The specific gravity of the

cement was found out be as 3. The initial and

final setting times were found as 80minutes and

620 minutes respectively. The fine and coarse

aggregates conform to IS 383 [13] standards

used in this work. The sand passed through

4.75mm Indian Standard (IS) sieve was used.

The specific gravity and fineness modulus of

fine aggregate were found as 2.65 and 3.18.The

water absorption and moisture content of fine

aggregate were found as 0.8% and 2%.The

coarse aggregate passed through 75mm IS

sieve was used. The specific gravity and

fineness modulus of coarse aggregate were

found as 2.8 and 6.75.The water absorption and

moisture content of coarse aggregate were

found as 0.6% and 1%.Class F type Fly ash used

as a powder material conform to IS 3812[14]

and obtained from Tuticorin thermal power

plant, Tamil Nadu, India was used in this study.

Class F type fly ash had the specific gravity of

2.Enfiq Super Plast-400 was used with a specific

gravity of 1.19as a super plasticizer. Cera Hyper

Plast XR W-40 was used in this study with a

specific gravity of 1.11 as a viscosity modifying

admixture. Shaktiman MSH 10050 steel fiber of

diameter 1 mm, fiber had a tensile strength

1100 Mpa. The aspect ratio of fibers was

50.TulysanNec Fe 415 High Yield Strength

Deformed bars (HYSD) was used with a yield

and ultimate strength of 415N/mm2 and

710N/mm2.

4.2 Mix design

In this study, two types of concrete were used. The mixes

were designed for M30.The normal concrete mix design was

carried out by IS 10262:2009[16].The ratio of normal

concrete, 1:1.76:3.45:0.42.The Self compacting concrete

mix design was carried out by European guidelines as per

European Federation for Specialist Construction Chemicals

and Concrete Systems [7].The powder content (cement and

fillers) was fixed as 450kg/m3.Fly ash occupied 20% of

powder content. The super plasticizer and stabilizer dosages

were fixed at 1.5% and 1% of powder content. The initial

mix design ratio was to be 1:1.81:1.6:0.38.After that, several

trials were conducted on SCC in order to ensure both fresh

and mechanical properties. The fiber addition added in last

SCC mix, also optimized as a one percent of cement

content. The final ratio of SCC, 1:2:1.9:0.42.

4.3 Test procedure

Once the beam specimens were taken out from

the curing, the test beams were cleaned and

white washed to assist for crack detection. The

specimens were tested under two point loading

Mix

Slump Compaction Slump

Vtype

value

factor

(mm)

flow

Funnel

(mm)

Time

(s)

NC

80

0.87

SCC

730

5.8

SCCF

690

6.6

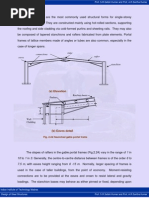

until shear failure occurred. Fig.1 shows test

setup for beams under two point loading. The

center to center distance between the bottoms

beds assemblies of rollers kept constant at

900mm.The loading configuration was arranged

keeping the shear span constant at 300 mm

yielding a shear span-to-depth ratio of 1.36.In

order to avoid the sudden shear failure the

reinforcement was provided with L-bend as

shown in Fig.1.The load was applied to the

specimens gradually with the help of hydraulic

jack. The loads were taken for fist flexural,

diagonal and ultimate cracking conditions. The

tests also gave information about development

of cracks, crack widths, crack pattern, shear

transfer mechanism and failure modes.

Fig-1: Test setup (dimensions are in mm)

Mix

NC

Average

7 days

compress

ive

strength

(N/mm2)

23.5

Average

28 days

compress

ive

strength

(N/mm2)

35

Average

28days

split

tensile

strength

(N/mm2)

2.3

SCC

16.8

31

1.9

SCC

F

19

33

1.1

5.

TEST

DISCUSSION

RESULTS

AND

The fresh properties as well as hardened

properties were found out by conducting both

workability tests and shear test.The test results

are given below with detailed explanations.

5.1 Rheological properties

Table 1 shows the workability of concrete mixes.

The fresh properties for both ordinary and self

consolidating concrete mix were taken. For

control concrete slump value and compaction

factor tests were carried out as per normal

concrete procedures. The results for controlled

concrete based on slump value and compaction

factor showed medium degree of workability.

For self consolidating concrete, the workability

tests were carried out as per European mix

design guide lines. The test results showed

better workability for SCC mixes. The SCC mix

had a very good slump flow and V-funnel values

due to addition of appropriate percentage of fly

ash and super plasticizer content. The mix of

SCC without steel fiber showed better

workability than SCC with steel fiber. The steel

fiber affects the self consolidating concrete

workability namely slump and V-funnel. The

fresh properties of steel fiber reinforced self

consolidating concrete was not affected too

much by the steel fiber due to the lesser

addition of fiber content.

Table- 1:Workability of concrete mixes

5.2 Mechanical properties

Table 2 shows the stiffened properties of

concrete. The test results showed compressive

strength and split tensile strength of concrete.

The rate of strength development of 7 days to

28 days ranged from 0.5 to 0.7 for all the mixes.

The rate of strength development in SCC mixes

was slow when compared to normal concrete.

This was due to addition of filler material of fly

ash retarded the compressive strength growth

rate. It was also observed that SCCF mix

showed compressive strength as very close to

ordinary concrete. It was due to increase in size

of aggregate in the SCCF mix from 12.5 mm to

20mm. But the SCC mixes showed considerable

amount of increase in compressive strength at

28 days. The steel fiber addition in SCC

contributed sufficient amount of split tensile

strength as closer to normal concrete. The plain

mix of SCC showed less amount of split tensile

strength.

Table- 2:Compressive and split tensile strength

of mixes

5.3 Shear strength

Table 3, 4 and Chart 1 show the experimental

and theoretical shear loads of concrete. The

analytical results obtained based on various

code provisions and also with the proposed

empirical formulae without considering safety

factors. The proposed empirical equation

suggested based on empirical analysis. The

loads obtained from experiment were converted

into shear loads. The loads obtained for first

flexural crack (Vfc) diagonal shear crack (Vsc)and

ultimate cracking conditions (Vu).The numerical

numbers indicated on the mixes i.e. 1, 2, 3

denoted the reinforcement ratios from 0.25, 0.5

and one. The results indicated shearing

resistance of concrete. Shearing resistance of

concrete is the resistance of concrete up to

formation of diagonal shear crack. From, Fig.2

the experimental results clearly showed that,

the post cracking shear resistance of concrete

beams more or less same with the diagonal

shearing resistance. This showed that concrete

did not have the ultimate shear resistance when

compared with shearing resistance of concrete.

The variation between the experimental shear

loads of first flexural crack and diagonal crack

of all beams also less but mainly varied due to

the increase in amount of main tension

reinforcement as well as increase in size of

coarse aggregate. The SCCF mix had higher

ultimate shear strength when compared with all

the mixes. All the major codes safely predicted

the shear strength of concrete even without

safety factors. The Indian code estimated shear

strength slightly higher when compared with

the JSCE and authors empirical equation. When

compared to IS code, BS code estimated shear

strength of concrete slightly higher and at the

same time BS code estimated shear strength

value closer to experimental results. Japanese

code also predicted ultimate shear strength of

concrete was at the slower rate. The proposed

equation for the arch-rib mechanism formed to

yield lower bound solutions, in which rate of

shear strength prediction was slow when

compared to code predictions and yielding safer

results for the experimental results. This

proposed equation estimated results very close

to Japanese code and also predicted test results

at slower rate.

Table- 3:Experimental shear loads(kN)

Beam

Vfc

Vsc

Vu

NC-1

NC-2

NC-3

SCC-1

SCC-2

SCC-3

SCCF-1

SCCF-2

SCCF-3

19.6

22.05

23.03

18.13

19.6

22.05

19.62

24.53

26.95

20.87

26.46

29.89

18.64

21.06

27.94

20.11

25.9

31.85

25.68

27.17

36.27

23.03

25.51

28.94

23.54

29.4

36.6

Table- 4:Theoretical shear loads (kN)

Beam

IS

BS

JSCE

NC-1

14.8

5

23.1

0

32.6

7

16.5

23.1

0

32.6

4

16.5

22.74

18.81

Author

s

17.57

30.36

23.58

23.68

34.14

29.85

28.32

21.84

29.02

18

22.65

18

24.06

32.80

28.67

28.73

22.31

18.44

18.38

23.1

0

32.6

3

29.55

23.13

24.46

33.50

29.27

29.13

NC-2

NC-3

SCC-1

SCC-2

SCC-3

SCCF1

SCCF2

SCCF3

S

h

a

e

r

l

o

a

d

(

k

N

)

40

35

30

25

Vfc

20

15

Vsc

10

IS

5

0

BS

Vu

JSCE

Author's

Beam name

Chart-1: Experimental and theoretical loads

5.4 Flexural cracking moment

Table 5 shows the experimental and theoretical

cracking moments. The cracking moment

results

obtained

from

the

experiments

compared with the code predictions. The

following table shows the cracking moment

results of various mixes. The experimental loads

converted into shear loads to predict the

experimental cracking moment. The moment is

obtained for first flexural cracking load and

ultimate cracking load. As similar to the case of

shear strength, flexural cracking moment

directly increased with increase in area of

longitudinal reinforcement, size of coarse

aggregate and characteristic compressive

strength of concrete. The test results showed

gradual increment of moment values of

cracking and ultimate moment. The normal and

self consolidating concrete beams with higher

percentage of main tension reinforcement had

the

maximum

ultimate

moment.

The

standardized codes predicted initial cracking

moment based upon the compressive strength

of concrete. The Canadian code estimated

flexural cracking moment very less. Indian code

predicted flexural cracking moment better than

other codes. At the same time American code

safely predicted flexural cracking moment.

Table-5: Experimental& theoretical cracking

moments

1

SCCF6

230

10

SC

2

SCCF6

240

8

SC

3

DT-Diagonal tension, SC-Shear compression, BFBearing failure

5.6 Failure behavior

The failure behavior beams under shear failure

are described in a detail manner as given below.

The failure modes also play an important role in

predicting shearing strength capacity of beams.

5.6.1 Diagonal tension failure

This kind of failure observed in NC-1 beam.

Initially flexural cracks are appeared and then

flexure shear cracks originate from the final

flexural crack. Due to the increase in load this

type of crack propagates gradually until it

Beam

5.5 Cracking study and mode of

failure

Table 6 shows details of cracks in beams. Cracks developed

for every beam in terms of its height, number of cracks,

maximum crack width and maximum crack height at failure

stages were noted. The beams with higher longitudinal

reinforcement generated cracks more when compared to

beams with lower reinforcement content. Self consolidating

concrete beams developed less cracks as compared to

normal concrete beams. The propagation of cracks from its

originating point towards loading point were increased with

increase in size of coarse aggregate and percentage of

longitudinal reinforcement. But in case of anchorage failure,

the height of crack at failure contrast to the other failure

mode conditions. The crack width at failure stage reduced

with increase in longitudinal reinforcement. Generated crack

width in the SCC with fiber added was less as compared to

normal concrete. It proved that steel fibers were better crack

arresters.

Table-6: Details of cracks in beams

Beam

NC-1

NC-2

NC-3

SCC-1

SCC-2

SCC-3

SCCF-

No. of

crack

s at

failur

e

4

7

10

3

4

4

5

Maxim

um

height

of

crack

at

failure

(mm)

202

208

220

223

230

238

212

Maximu

m width

of crack

at

failure

(mm)

20

10

7.5

5

3.5

2.3

14

Mode

of failure

Mcr

(kNm

)

Mu

(kNm

)

Theoretical

cracking moment

Mcr

(kNm)

ACI

CSA

IS

NC-1

5.88

7.70

5.27

5.1

5.96

1

NC-2

6.62

8.15

5.27

5.1

5.96

1

NC-3

6.91 10.88 5.27

5.1

5.96

1

SCC-1

5.44

6.91

4.96

4.8

5.61

SCC-2

5.88

7.65

4.96

4.8

5.61

SCC-3

6.62

8.68

4.96

4.8

5.61

SCCF5.88

7.06

5.12

4.9

5.78

1

6

SCCF7.36

8.82

5.12

4.9

5.78

2

6

SCCF8.08 10.98 5.12

4.9

5.78

3

6

reaches the loading point. While no web-shear

cracks were observed, the outer most flexure

crack in the shear span propagated diagonally

towards the loading point. This type of failure

crack pattern usually has greater crack width

and originates either left or right end support of

beam.

5.6.2 Bearing failure

DT

SC

SC

BF

BF

BF

SC

This kind of failure observed in three beams of

SCC without fiber. In this case, the shear crack

is carried as an inclined between load and

reaction that almost eliminates ordinary

diagonal tension concepts. Normally an inclined

crack travelled from loading point to the

supporting point.

5.6.3 Shear compression failure

This kind of failure observed in remaining

beams. This type failure takes place either by

crushing of reduced concrete section above the

tip of the crack under combined shear and

compression is known as shear compression

failure. In this failure, the beam behaved like a

tied arch. The load was carried by direct

compression between the load and the reaction

point and by tension in the longitudinal steel.

[5]

[6]

6. CONCLUSIONS

Thecompressive strength for SCC mixes

increased as the size of coarse aggregate

changed from 12.5mm to 20mm. The

workability properties for SCC mixes slightly

reduced due to increase in coarse aggregate

size and also addition of steel fiber. Shear

strength self consolidating concrete beams

were gradually increased due to the increase in

percentage of longitudinal reinforcement, size

of coarse aggregate and steel fiber content. The

British code estimated shear strength of

concrete slightly higher and yielding good

results when compared to other codes. The

shear strength results obtained from proposed

empirical equation were closed to Japanese

code equation results. The prediction of flexural

cracking moment has high accuracy in Indian

code as compared with Canadian and American

codes. Crack growths in normal concrete beams

were more as compared to self compacting

beams. The failure pattern in terms of the shear

was not same mode in all beams. It was

observed that, perfect arch-rib mechanism was

formed in five out of nine beams. Bearing failure

was observed in SCC beams without steel fiber.

Diagonal tension failure occurred in a single

beam associated with large crack width. These

types of shear failures always revealed that

shear transfer mechanisms in concrete complex

criteria, cant be predicted with high accuracy.

[2]

[3]

[4]

CSA CAN3-A23.3,Design

Structures,

Canadian

Association,

Rexdale

Canada,2004.

of

Concrete

Standards

Ontario

[7] EFNARC,Specification and guide lines for

self

compacting

concrete,European

Federation for Specialist Construction

Chemicals and Concrete Systems, United

Kongdom,2002.

[8]

Eric TomposJ,Robert frosh J,Influence of

beam size, longitudinal reinforcement and

stirrup effectiveness on concrete shear

strength,ACI

Structural

Journal,vol.99,pp.559-567,Sep-Oct.2002.

[9]

Hassan

AAA,

Hossain

KMA,LachemiM,Strength, cracking and

deflection

performance

of

self

consolidating concrete beams subjected

to shear failure.Engineering Structures,

vol.32,pp.1262- 1271,2010.

[10] Hemant B Dhonde, YL Mo, Thomas TC, Hsu

and John Vogel,Fresh and hardened

properties of self consolidating fiber

reinforced concrete,ACIMaterial Journal,

vol.104, pp.491500, Sep-Oct.2007.

[11]

IS 1199, Indian standard code of

specifications

for

workability

tests,Bureau of Indian Standards, New

Delhi, 1959.

[12]

AbdulGhaffar,

AfzalJaved,

HabiburRehman,

KafeelAhmed andIlyas.Development of shear

capacity equations for rectangular reinforced

concrete beams,PakJ.Engg& Appl.Sc.,vol.6,pp.18,Jan.2010.

IS 2386,Indian standard code of methods

of tests for aggregates for concrete part IIII,Bureau of Indian Standards, New

Delhi, 1963.

[13]

ACI 318, Building code requirements for structural

concrete, ACI committee,Farmington Hills,

Michigan, USA, 2007.

IS 383,Indian standard code of coarse

and fine aggregates from natural sources

for concrete,Bureau of Indian Standards,

New Delhi, 1970.

[14]

IS 3812,Indian standard code for specification for

fly ash for use as pozzolana

and

admixture,Bureau of Indian Standards, New Delhi,

1981.

REFERENCES

[1]

Chao-Wei Tang, Tsong Yen and HowJiChen,Shear behavior of reinforced

concrete beams made with sedimentary

lightweight aggregate without shear

reinforcement,Journal of Materials in

Civil

EngineeringASCE,vol.21,pp.730739,Dec.2009.

Altaan SA, Alfeel JR. Evaluation of shear

strength of concrete beams,Cement and

Concrete

composites,vol.12,pp.8794,1990.

BS 8110, Structural use of concrete-part

1 code of practice for design and

construction,British

Standard

Institution,Milton Keynes, London,1997.

[15] IS 456,Indian standard code of plain and

reinforced

concrete

code

of

practice,Bureau of Indian standards,

New Delhi, 2000.

[16]

IS 10262,Indian standard code of

recommended guidelines for concrete mix

design,Bureau of Indian standards, New

Delhi, 2009.

[17]

Japanese

Society

of

Civil

Engineering,Specification for design and

construction of concrete structures,JSCE

Standards, Part 1, Japan, 2007.

[18]

Jin-Keun Kim, Yon-Dong Park, Prediction

of shear strength of reinforced concrete

beams without web reinforcement,ACI

Materials Journal, vol.93, pp.213-222,

May-June.1996.

[19]

LondheR,Shear strength analysis and

prediction of reinforced concrete transfer

beams in high-rise buildings, Structural

Engineering & Mechanics,vol.37, pp.3959,2011.

[20]

Sudheer

Reddy

L,RamanaRao

NV,

GunneswaraRaoTD,Shear resistance of

high strength concrete beams without

shear

reinforcement,International

Journal

of

Civil

and

Structural

Engineering,vol.1,pp.101-113,2010.

[21]

Vollum RL, SagasetaJ,Influence of beam

cross section, loading arrangement and

aggregate

type

on

shear

strength,Magazine

of

Concrete

Research,vol.63,pp.139-155,2011.

BIOGRAPHIES

Mr.M.Sheik

Mohamed

is

currently working as an

Assistant

Professor,

Department

of

Civil

Engineering

in

AalimMuhammedSalegh

College

of

Engineering,

Chennai.He had totally 3.5

years

experience

in

construction, design and

teaching and his area of

interests

in

Concrete

Technology,

Analysis

of

Structures and Design of

Structures.

Mr.C.Makendran working as

an Assistant Professor and

Head, Department of Civil

Engineering

in

AalimMuhammedSalegh

College

of

Engineering,

Chennai, He had totally 7

years

experience

in

Industry and teachingand

his area of interest in

Transportation with urban

planning. He had published

paper in International paper.

You might also like

- Irjet V2i985Document8 pagesIrjet V2i985sheikNo ratings yet

- Irjet V2i985Document8 pagesIrjet V2i985sheikNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Ductility of Prefabricated Cage Reinforced Concrete Beams: Analytical StudyDocument9 pagesDuctility of Prefabricated Cage Reinforced Concrete Beams: Analytical StudymagdyamdbNo ratings yet

- Two Mark QuestionsDocument9 pagesTwo Mark QuestionsNitin SureshNo ratings yet

- Predicting The Response of Shear-Critical Reinforced Concrete Beams Using Response-2000 and SNI 2847:2013Document9 pagesPredicting The Response of Shear-Critical Reinforced Concrete Beams Using Response-2000 and SNI 2847:2013Rizky Dwi IryandiNo ratings yet

- Comparison of Punching Shear Requirements in Bs8110, Ec2 and MC2010Document42 pagesComparison of Punching Shear Requirements in Bs8110, Ec2 and MC2010Anish KumarNo ratings yet

- Strain, Reinforced Concrete, ConfinementDocument125 pagesStrain, Reinforced Concrete, ConfinementArjun Mullu100% (1)

- Punching Shear Resistance of SlabDocument8 pagesPunching Shear Resistance of SlablinkgreencoldNo ratings yet

- RCC BendableDocument30 pagesRCC BendableLak Chauhan50% (2)

- Seismic Strengthening of RC Structures PDFDocument6 pagesSeismic Strengthening of RC Structures PDFGajendra JoshiNo ratings yet

- (Dr. Mirvat Bulbul) ENCE335 Fundamentals of Reinfo PDFDocument41 pages(Dr. Mirvat Bulbul) ENCE335 Fundamentals of Reinfo PDFCY LeeNo ratings yet

- Paper 7Document9 pagesPaper 7RakeshconclaveNo ratings yet

- Encased ColumnsDocument14 pagesEncased ColumnsjimmyfontanaNo ratings yet

- Effect of Variation in The Strength of Concrete and Reinforcing Bars On The Behavior of RC BeamsDocument6 pagesEffect of Variation in The Strength of Concrete and Reinforcing Bars On The Behavior of RC BeamsEngr. Quazi SamirNo ratings yet

- Singly Reinforced BeamDocument21 pagesSingly Reinforced BeamSaurabh GodhaNo ratings yet

- Dr. Mirvat Bulbul-EnCE335 Fundamentals of Reinforced Concrete Design According ACI 318-05-Birzeit University, Palestinian جامعة بيرزيت هي جامعة فلسطينية (2011-2012)Document41 pagesDr. Mirvat Bulbul-EnCE335 Fundamentals of Reinforced Concrete Design According ACI 318-05-Birzeit University, Palestinian جامعة بيرزيت هي جامعة فلسطينية (2011-2012)Seifeldin Ali MarzoukNo ratings yet

- Design in Reinforced Concrete: Prepared By: M.N.M Azeem Iqrah B.SC - Eng (Hons), C&G (Gdip)Document66 pagesDesign in Reinforced Concrete: Prepared By: M.N.M Azeem Iqrah B.SC - Eng (Hons), C&G (Gdip)rashmiNo ratings yet

- Design in Reinforced Concrete: Prepared By: M.N.M Azeem Iqrah B.SC - Eng (Hons), C&G (Gdip)Document66 pagesDesign in Reinforced Concrete: Prepared By: M.N.M Azeem Iqrah B.SC - Eng (Hons), C&G (Gdip)Glistering DharNo ratings yet

- Composite Columns IDocument15 pagesComposite Columns IHeng Kimseng100% (1)

- E3sconf Icdmm2021 05011Document4 pagesE3sconf Icdmm2021 05011Darko NikolicNo ratings yet

- Seismic Behavior of Beam Column Joints in Reinforced Concrete Moment Resisting Frames 2Document36 pagesSeismic Behavior of Beam Column Joints in Reinforced Concrete Moment Resisting Frames 2m7j7a7No ratings yet

- Nagesh 2018Document11 pagesNagesh 2018Juan Pablo GMNo ratings yet

- ACI 232-3 Punching ShearDocument18 pagesACI 232-3 Punching ShearRandy MillerNo ratings yet

- MB Structural Design Compendium May16Document52 pagesMB Structural Design Compendium May16aldert_path100% (2)

- Size Effect On Shear Strength of RC Beams Using HSC Without Shear ReinforcementDocument16 pagesSize Effect On Shear Strength of RC Beams Using HSC Without Shear ReinforcementHuda JawadNo ratings yet

- Structural Steel Design UGNA3032Document74 pagesStructural Steel Design UGNA3032木辛耳总No ratings yet

- Restrengthening of R.C.C Beam by Beam Jacketing: January 2013Document10 pagesRestrengthening of R.C.C Beam by Beam Jacketing: January 2013passion777No ratings yet

- Bond and Ductility A Theoretical Study o PDFDocument13 pagesBond and Ductility A Theoretical Study o PDFVirendra Kumar PareekNo ratings yet

- Composite StructuresDocument25 pagesComposite StructuresVivek Premji100% (1)

- Reinforced High-Strength Concrete Beams in FlexureDocument11 pagesReinforced High-Strength Concrete Beams in FlexureAndrei IancuNo ratings yet

- 6 Portal FramesDocument7 pages6 Portal FramesGeoffrey ArmstrongNo ratings yet

- Monitoring of A Tall Building To Develop Axial Shortening Models Incorporating High Strength ConcreteDocument7 pagesMonitoring of A Tall Building To Develop Axial Shortening Models Incorporating High Strength ConcreteRico PadillaNo ratings yet

- Al-Kamyani Et Al. - 2019 - Impact of Shrinkage On Crack Width and DeflectionsDocument10 pagesAl-Kamyani Et Al. - 2019 - Impact of Shrinkage On Crack Width and DeflectionsviolettaNo ratings yet

- Study On Shear Embossments in Steel-Concrete CompoDocument11 pagesStudy On Shear Embossments in Steel-Concrete Compog401992No ratings yet

- IREA - VOL - 10 - N - 3 DCDocument7 pagesIREA - VOL - 10 - N - 3 DCTAVIONo ratings yet

- Forests 11 01313Document27 pagesForests 11 01313muhtar umjNo ratings yet

- Concrete Design Guide No5 - How To Calculate Anchorage and Lap Lengths To Eurocode 2Document8 pagesConcrete Design Guide No5 - How To Calculate Anchorage and Lap Lengths To Eurocode 2Gurvir BahraNo ratings yet

- Strengthening of Reinforced Concrete Beam-Column Joints Using ChamfersDocument16 pagesStrengthening of Reinforced Concrete Beam-Column Joints Using ChamferssuraachNo ratings yet

- Bilin18 9 2bDocument42 pagesBilin18 9 2bMd Minaz HossainNo ratings yet

- Ce1302 Design of RC ElementsDocument22 pagesCe1302 Design of RC Elementsjs kalyana rama100% (1)

- Diseño de Anclajes en HormigonDocument32 pagesDiseño de Anclajes en HormigonnagenolNo ratings yet

- Effect of Shear Reinforcement On Punching Shear CaDocument11 pagesEffect of Shear Reinforcement On Punching Shear CaFelipeMatiasCardosoNo ratings yet

- CE2404 QB PDFDocument20 pagesCE2404 QB PDFresha bhatiaNo ratings yet

- Important Questions PDFDocument20 pagesImportant Questions PDFresha bhatiaNo ratings yet

- Reinforced Concrete NoteDocument9 pagesReinforced Concrete NotemodarthNo ratings yet

- Chapter 1 - Introduction To RCDocument34 pagesChapter 1 - Introduction To RCFarhana JaniNo ratings yet

- Corrosion and its Consequences for Reinforced Concrete StructuresFrom EverandCorrosion and its Consequences for Reinforced Concrete StructuresNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Design of Steel Structures: Materials, Connections, and ComponentsFrom EverandDesign of Steel Structures: Materials, Connections, and ComponentsNo ratings yet

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- Introduction to Design of Building StructuresFrom EverandIntroduction to Design of Building StructuresRating: 4 out of 5 stars4/5 (22)

- 1) Soil Mechanics-71-109Document39 pages1) Soil Mechanics-71-109Sheik MohamedNo ratings yet

- 3) Engineering Survey-23-38Document16 pages3) Engineering Survey-23-38Sheik MohamedNo ratings yet

- IRRigationDocument10 pagesIRRigationSheik MohamedNo ratings yet

- Design of Steel Structures-161-174Document14 pagesDesign of Steel Structures-161-174Sheik MohamedNo ratings yet

- Hydrology and Ground Water-247-254Document8 pagesHydrology and Ground Water-247-254Sheik MohamedNo ratings yet

- Railway Engg.-Rotated-217-227Document11 pagesRailway Engg.-Rotated-217-227Sheik MohamedNo ratings yet

- Estimating and CostingDocument8 pagesEstimating and CostingSheik MohamedNo ratings yet

- 7) Construction Practice - 13-22Document10 pages7) Construction Practice - 13-22Sheik MohamedNo ratings yet

- 5) R.C.C Structures-143-154Document12 pages5) R.C.C Structures-143-154Sheik MohamedNo ratings yet

- Theory of Structures-63-70Document8 pagesTheory of Structures-63-70Sheik MohamedNo ratings yet

- Concrete Technology-137-142Document6 pagesConcrete Technology-137-142Sheik MohamedNo ratings yet

- Design of RCC Drains PDFDocument7 pagesDesign of RCC Drains PDFSatyanarayana Balaraman75% (4)

- 2) Strength of Material-47-62Document16 pages2) Strength of Material-47-62Sheik MohamedNo ratings yet

- 6) Construction MaterialDocument10 pages6) Construction MaterialSheik MohamedNo ratings yet

- Seive Analysis Test of Aggregate Grade-III MetalDocument5 pagesSeive Analysis Test of Aggregate Grade-III MetalSheik MohamedNo ratings yet

- Project Management-233-238Document6 pagesProject Management-233-238Sheik MohamedNo ratings yet

- Water Suppy and Treatment-111-124Document14 pagesWater Suppy and Treatment-111-124Sheik MohamedNo ratings yet

- Design of R.C.C Tee Beam Bridge 5.1 Design of Deck Slab 5.1.1 DATADocument24 pagesDesign of R.C.C Tee Beam Bridge 5.1 Design of Deck Slab 5.1.1 DATANithin M.TNo ratings yet

- Fe 1 Lecture 4Document10 pagesFe 1 Lecture 4Upul Janaka PereraNo ratings yet

- Airport Engg.-228-232Document5 pagesAirport Engg.-228-232Sheik MohamedNo ratings yet

- Internal Forces in A Reinforced Concrete Box CulvertDocument194 pagesInternal Forces in A Reinforced Concrete Box CulvertSamer ElabdNo ratings yet

- Seive Analysis Test of Aggregate Grade-II MetalDocument9 pagesSeive Analysis Test of Aggregate Grade-II MetalSheik MohamedNo ratings yet

- G.O.26, HBA - Amendments (Kalviseithi)Document4 pagesG.O.26, HBA - Amendments (Kalviseithi)Sheik MohamedNo ratings yet

- 2 X 7.6 Skew 31Document48 pages2 X 7.6 Skew 31Sheik MohamedNo ratings yet

- 1-B-Earthquake Forces in BuildingsDocument4 pages1-B-Earthquake Forces in BuildingsqsultanNo ratings yet

- 5 BeamsDocument22 pages5 BeamsSheik MohamedNo ratings yet

- Building Safety and Earthquakes: Part D: The Seismic Load PathDocument4 pagesBuilding Safety and Earthquakes: Part D: The Seismic Load Pathrmm99rmm99No ratings yet

- Civil Design-Anchor BlockDocument14 pagesCivil Design-Anchor BlockSheik MohamedNo ratings yet

- 1-B-Earthquake Forces in BuildingsDocument4 pages1-B-Earthquake Forces in BuildingsqsultanNo ratings yet

- 3 - Shear Force Bending Moment - SMDocument28 pages3 - Shear Force Bending Moment - SMMinh VienNo ratings yet

- STARDOM Overview WebinarDocument47 pagesSTARDOM Overview WebinarJavierNo ratings yet

- 2012 Volvo v60 80571 PDFDocument400 pages2012 Volvo v60 80571 PDFcosmin1987No ratings yet

- Current Internet Limitations v9Document16 pagesCurrent Internet Limitations v9MadagunduNo ratings yet

- 001A Bizgram Asia Motherboard CPU Bundle AloneDocument3 pages001A Bizgram Asia Motherboard CPU Bundle AloneBizgram AsiaNo ratings yet

- AS9102 FormsDocument4 pagesAS9102 Formstongai100% (1)

- Smartform Using Select-OptionDocument23 pagesSmartform Using Select-OptionDipesh100% (2)

- C# Event ProcessingDocument25 pagesC# Event ProcessingHPK12No ratings yet

- CSCI262 Dos DdosDocument86 pagesCSCI262 Dos Ddosami_haroonNo ratings yet

- MC Design 2Document71 pagesMC Design 2Upayan Ghatak100% (1)

- User Guide PDFDocument152 pagesUser Guide PDFtxescientistNo ratings yet

- Iso 18436Document2 pagesIso 18436knsvel20000% (3)

- FN1168 Multiple PLMN and Inter-PLMN Handover SupportDocument25 pagesFN1168 Multiple PLMN and Inter-PLMN Handover SupportRazvan Corban50% (2)

- CD 4071 e CD 4081Document9 pagesCD 4071 e CD 4081Loganh NiassiNo ratings yet

- 144 BOE 31 WebI TuningDocument31 pages144 BOE 31 WebI Tuningadabral67No ratings yet

- BCB 201Document22 pagesBCB 201Rajesh Kumar100% (2)

- UIWeb ViewDocument4 pagesUIWeb Viewjackmailsjohn9456No ratings yet

- Swot DoleDocument5 pagesSwot DoleAndie BibaresNo ratings yet

- Piping Eng TestDocument2 pagesPiping Eng TestaasattiNo ratings yet

- GRT-HM05-P0UGD-125452 - Rev.0 - HVAC Calculation For Water Treatment BuildingDocument44 pagesGRT-HM05-P0UGD-125452 - Rev.0 - HVAC Calculation For Water Treatment Buildingarief bahtiarNo ratings yet

- 3100 3150 MCM User ManualDocument130 pages3100 3150 MCM User ManualJorge MuñozNo ratings yet

- 7Q 1 (1) .C ToolsDocument74 pages7Q 1 (1) .C ToolssrinivasancptNo ratings yet

- Ug Awus036achDocument19 pagesUg Awus036achEd PMNo ratings yet

- 9e921b Rotary Drive System Inst InstrDocument29 pages9e921b Rotary Drive System Inst InstrElias GarciaNo ratings yet

- UC500 CCA First Look v1.3 Lab8BDocument12 pagesUC500 CCA First Look v1.3 Lab8BPaulo Alexandre Pinto PereiraNo ratings yet

- Netscaler Data SheetDocument11 pagesNetscaler Data SheetBalvinder Singh RawatNo ratings yet

- Normal Consistency ASTM C 187Document3 pagesNormal Consistency ASTM C 187Guido GarateNo ratings yet

- Procedure: : SOP On Change ControlDocument11 pagesProcedure: : SOP On Change ControljaimurugeshNo ratings yet

- Chapter 19 - Decision-Making Under RiskDocument29 pagesChapter 19 - Decision-Making Under RiskBich Lien PhamNo ratings yet

- Phoenix Contact 0311126 enDocument46 pagesPhoenix Contact 0311126 enGiorgi AbashidzeNo ratings yet

- Module 1: Teaching and Learning With Technology: AnDocument4 pagesModule 1: Teaching and Learning With Technology: AnJasper Diñoso JacosalemNo ratings yet