Professional Documents

Culture Documents

Syme Elbasc Enel Speq 0006 b03

Uploaded by

mCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Syme Elbasc Enel Speq 0006 b03

Uploaded by

mCopyright:

Available Formats

PROJECT:

SOUTH YARAN OIL FIELD

DEVELOPMENT PROJECT

DOCUMENT TITLE

DOCUMENT NO

:

:

Specification for Emergency Generator

SYME-ELBASC-ENEL-SPEQ-0006-B03

SHEET NO. : REV. :

B03

1 of 10

Specification

for

Emergency Generator

B03

2-Feb-2014

Issued for Design

T.Rostami

S.Garjani

A.Bodaghi

B02

15-Dec-2013

Issued for Design

S.Garjani

S.Garjani

A.Bodaghi

B01

19-Sep-2013

Issued for Comment

S.Garjani

S.Garjani

A.Bodaghi

Rev.

Date

Description

Prepared

Checked

Approved

SAZ. POI :

This document is the property of OWNER. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

IFC1

PROJECT:

SOUTH YARAN OIL FIELD

DEVELOPMENT PROJECT

DOCUMENT TITLE

DOCUMENT NO

Specification for Emergency Generator

SYME-ELBASC-ENEL-SPEQ-0006-B03

:

:

SHEET NO. : REV. :

B03

2 of 10

TABULATION OF REVISED PAGES

SHEET

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

REVISIONS

01 02 03 04 05 06 07

X

X

X

X

X

X

X

X

X

X

SHEET

REVISIONS

01 02 03 04 05 06 07

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

This document is the property of OWNER. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

PROJECT:

SOUTH YARAN OIL FIELD

DEVELOPMENT PROJECT

DOCUMENT TITLE

DOCUMENT NO

:

:

Specification for Emergency Generator

SYME-ELBASC-ENEL-SPEQ-0006-B03

SHEET NO. : REV. :

B03

3 of 10

Table of Contents

1. Purpose..................................................................................................................... 4

2. Applicable Documents .............................................................................................. 4

3. Definitions ................................................................................................................. 4

4. Overview ................................................................................................................... 4

4.1

Introduction .................................................................................................................... 4

5. General Requirements .............................................................................................. 4

5.1 Language ....................................................................................................................... 4

5.2 Climate data ................................................................................................................... 5

6. IPS Clarification (IPS-M-EL-138(1)) .......................................................................... 5

6.1 Clause 2: References (Addition) .................................................................................... 5

6.2 Clause 5.2: Stator Winding and Cable Termination (Addition) ...................................... 5

6.3 Clause 5.5: Exciter (Addition) ........................................................................................ 6

6.4 Clause 5.6: Automatic Voltage Regulation (Addition) .................................................... 6

6.5 Clause 5.8: Bearing and Lubrication (Addition) ............................................................. 6

6.6 Clause 5.9: Anti Condensation Heater (Addition) .......................................................... 7

6.7 Clause 5.15: rating plate ................................................................................................ 7

6.8 Clause 5.16: Generator Control Panel (Addition) .......................................................... 7

6.9 Clause 6.9: Over speed (Addition) ................................................................................. 9

6.10 Clause 9: Painting (Addition) ......................................................................................... 9

6.11 Clause 10: documentation (Addition) ............................................................................. 9

6.12 Clause 14: Spare parts (Addition) ................................................................................ 10

7. Attachments ............................................................................................................ 10

7.1

Attachment #1: IPS-E-EL-138(1) (36 Sheets) .............................................................. 10

This document is the property of OWNER. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

PROJECT:

SOUTH YARAN OIL FIELD

DEVELOPMENT PROJECT

DOCUMENT TITLE

DOCUMENT NO

Specification for Emergency Generator

SYME-ELBASC-ENEL-SPEQ-0006-B03

:

:

SHEET NO. : REV. :

B03

4 of 10

1. Purpose

B03

This job specification shall be used to support the engineering, manufacturing and

supplying of synchronous generator for the south YARAN Project.

This specification is an addendum to IPS specifications:

IPS-M-EL-138(1) Material and equipment standard for synchronous generators,

Clauses not mentioned in this specification remain unaltered.

2. Applicable Documents

Document references which shall be used in conjunction with this general specification are

listed below, but shall not be limited to the below documents;

SYME-ELBASC-ENEL-CIDE-0001

Electrical Design Criteria

In the event of any conflict between this specification and engineering documents, this

specification shall take precedence.

3. Definitions

OWNER

CLIENT

CONSULTING ENGINEER

PROJECT

LOCATION

APPROVED

: NIOC

:Petroleum Engineering and development Co.(PEDEC)

:Sazeh Consultants

:South Yaran oil Field Development (Basic Engineering)

:Khuzestan Province-120Km west of AHWAZ

:Approved by Client

4. Overview

4.1

Introduction

South Yaran oil field is located in Khuzestan province 120KM west of Ahwaz

with 20Km length and 2.5Km width at south part of Yaran oil field.

24 No wells considered at this area consisting of 14 No Sarvak wells, 8 No

Fahlian & Gadvan wells and 2 No appraisal wells for sarvak and fahlian&

Gadvan layers with total estimated output between 50,000 to 60,000 STB/Day.

Flow of wells is transferred to the 2 phase separation unit (Cluster) for

separation of gas from liquids and dehydrating of gas.

The dehydrated gas is transferred to NGL 3200 and the liquids are transferred

to Karoon production plant for further processing.

5. General Requirements

5.1

Language

All documents, drawings and submittals shall be in English.

This document is the property of OWNER. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

PROJECT:

SOUTH YARAN OIL FIELD

DEVELOPMENT PROJECT

DOCUMENT TITLE

DOCUMENT NO

5.2

:

:

Specification for Emergency Generator

SYME-ELBASC-ENEL-SPEQ-0006-B03

Climate data

Max absolute temperature

Min temperature

Max & Min Wind speed

Storm wind speed

Soil temperature

Maximum sun temperature

Rain fall volume

Barometric pressure

Maximum & Minimum Humidity

B03

SHEET NO. : REV. :

B03

5 of 10

50 oC

0 oC

9.6 & 6.2 m/s

68 m/s

40 oC (1m under finish grade)

85 oC

170-250mm/y

736 mmHg

74% & 41%

6. IPS Clarification (IPS-M-EL-138(1))

6.1

Clause 2: References (Addition)

The following standards shall be added to the standard list of clause 2.1

Dimensions and Output Ratings for Rotating

IEC 60072-1991

Electrical Machines

IEC 60079-2001

Electrical Apparatus for Explosive Gas Atmospheres

IEC 60085-2004

Thermal Classification of Electrical Insulation

IEC 60255-1990

Electrical Relay

IEC 61000-2002

Electromagnetic Compatibility (EMC) (All Parts)

IEC60034-9

Noise limit

IEC60364

Electrical installation in building

Degree of protection provided by enclosures (IP

IEC60529

code).

Recommended practices for testing of synchronous

IEEE STD 115

machines

Recommended practices for emergency and

IEEE STD 446

standby power systems for industrial and

commercial applications

6.2

Clause 5.2: Stator Winding and Cable Termination (Addition)

All six stator winding ends shall be brought out to a separate terminal box (main

terminal box 0.4kV) for cable termination.

The arrangement of the terminals shall have adequate space to accommodate

the size and type of cable as specified. Means shall be provided by the vendor

to prevent accidental reduction of the clearance at terminal due to lose strand of

movement of insinuated cable lugs.

Both ends of each stator winding shall be brought out to terminal positions on

the stator casing, the phase end terminal box being arranged for 3-phase and

neutral connection. The terminal box shall be designed to accept flexible 4-core

XPLE insulated PVC sheathed cables and shall include a bolted dust-tight cover

which can be removed without disturbing the cables.

The generator shall withstand the specified overload continuously and direct

short circuit on the output terminals for 3 seconds.

MV generator neutral shall be grounded via a high resistance ground fault

detector, supplied complete with normally open contacts for a remote alarm

device. Low voltage generator neutral point shall be solidly earthed.

This document is the property of OWNER. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

PROJECT:

SOUTH YARAN OIL FIELD

DEVELOPMENT PROJECT

DOCUMENT TITLE

DOCUMENT NO

6.3

:

:

Specification for Emergency Generator

SYME-ELBASC-ENEL-SPEQ-0006-B03

SHEET NO. : REV. :

B03

6 of 10

Clause 5.5: Exciter (Addition)

The excitation unit of the exciter shall consist of the following components:

Rectifier transformer.

Static current transformer (for distribution of the reactive load during parallel

operation).

Current transformers required.

Chokes.

Capacitors, electronic controller.

The excitation unit shall have devices for setting the following parameters:

voltage required +5%, -5%

controller gain,

reset time,

drooping,

Disturbance feed forward control

The target voltage value shall be adjusted with the aid of a remote controller

(depending on operation mode fixed value or reference value from the

synchronization unit).

In such a case the generator voltage can be set to the target value by means of

an adjustable resistor installed in parallel with the exciter winding.

The exciter circuit shall be protected by an integrated over voltage release

system.

The exciter shall be protected against diode failure by connected fuses,

provided with visual indication for operation of a diode fuse.

The exciter rotor shall be arranged on the generator shaft.

The excitation system shall satisfy the following performance requirements:

Single running with a voltage regulation of 2% at generator loads up to

continuous rating over the power factor range unity to 0.80 lag.

Parallel on load operation with the system.

For conditions above no loss of control or instability shall occur, and KVA

and KVAR load sharing shall be within the limits of generator capability.

Manual and auto control shall be provided.

Control voltage should be 5% of set voltage overall specified operating

conditions.

The minimum forcing field voltage capability shall be twice the generator

field voltage at full load.

Maximum transient voltage variation on the sudden application or removal of

rated load or on starting of the largest connected motor should be 20%

6.4

Clause 5.6: Automatic Voltage Regulation (Addition)

An automatic voltage regulator (AVR) of the silicon controlled rectifier type shall

be supplied. The AVR shall provide with adjustments for gain and stabilizing.

6.5

Clause 5.8: Bearing and Lubrication (Addition)

Bearings shall be protected against damage during transport by securing the

shaft, even when coupled to the diesel engine.

0.4kV generator shall have 2 independent bearings

This document is the property of OWNER. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

PROJECT:

SOUTH YARAN OIL FIELD

DEVELOPMENT PROJECT

DOCUMENT TITLE

DOCUMENT NO

:

:

Specification for Emergency Generator

SYME-ELBASC-ENEL-SPEQ-0006-B03

SHEET NO. : REV. :

B03

7 of 10

The non-drive-end bearing shall be insulated to prevent any shaft currents. The

drive-end bearing shall be earthed. The rotor shall be provided with a shaft

earthling brush.

A minimum of one resistance temperature detector for each bearing shall be

provided. All detector lead shall be metallic armored (temperature controller see

winding paragraph).

Bearings shall be protected against damage during transport by securing the

shaft, even when coupled to the diesel engine.

Bearings shall be either rolling elements anti-friction types or lubricated sleeve

types.

Selection shall be based on the criteria listed in API 610. Sleeve bearings shall

be equipped with an oil level indicator.

6.6

Clause 5.9: Anti Condensation Heater (Addition)

The anti condensation heater shall be switched on and of automatically

depending the temperature accessed from the EDG control system.

6.7

Clause 5.15: rating plate

Below items to be added in rating plate items:

Project title

Equipment tag no.

6.8

Clause 5.16: Generator Control Panel (Addition)

Generator control panel mounted in the diesel room shall be a freestanding

control panel type with access doors lockable by padlocks, complete and

including the following and depending on rating, voltage and application of

specific cases:

1 Selector switch for automatic / off/ manual

1 Set of engine control relays

1 Set of alarm equipment

1 Set of automatic shut-down

1 mechanically operated hour meter

3 ammeter

1 Voltmeter with selection switch

1 Frequency indicator

1 Unbalanced toad wattmeter for 3-phase 4-wire supply

1 Set of generator field control equipment

1 Engine speed controller

1 Set of start and "stop" push buttons.

Signal lamp

1 Emergency stop push button, shrouded type.

Complete set of alarms & trips signals including followings shall be provided &

indicated on alarm lamp on the roof of diesel generator room.

High water temperature alarm

High water temperature trip

Low lubricating oil pressure alarm

Low lubricating oil pressure trip

Cooling water pressure alarm

This document is the property of OWNER. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

PROJECT:

SOUTH YARAN OIL FIELD

DEVELOPMENT PROJECT

DOCUMENT TITLE

DOCUMENT NO

:

:

Specification for Emergency Generator

SYME-ELBASC-ENEL-SPEQ-0006-B03

SHEET NO. : REV. :

B03

8 of 10

Cooling water pressure trip

Lubricating oil temperature alarm

Lubricating oil temperature trip

Over speed protection operated trip

24 volts control or starting charger failure alarm

Loss of 24 V control or starting voltage alarm

Failure to start alarm

Auto / off / Man. switch not in auto position alarm

Daily fuel tank low-level alarm

Fire protection faulty or operated alarm

Ventilation or heating system faulty alarm

Six alarm windows for protective relays should be considered as a spare.

Following alarms shall be provided to be sent to switchgear room:

Group signaling of above-mentioned signals called "diesel generator trouble"

Main fuel tank low level

Selector switch not in auto position.

Diesel generator in service

All sensors, trips and indicators shall be powered from the generator battery.

All trip and alarm systems should be reset manually.

Before changing the position of auto/off/man selector switch to off position, trip

signal should not be reset

Protection relay:

According to single line diagram, following electrical protection relays shall be

provided for generators and mounted on the remote generator control panels in

the substation:

Winding over temperature (26 w), alarm and trip

Bearing over temperature (26 b), alarm and trip

Bearing vibration (39), alarm and trip

Stator differential overcurrent (87), trip

Stator negative sequence overcurrent (46), trip

Rotating rectifier diode failure (94d), trip

Rotor earth fault (64R), trip

Stator over voltage and under voltage (59, 27), trip

Stator over frequency and under frequency (81), trip

Field failure or loss of synchronism (40), trip

Stator reverse power (32), trip

Stator voltage restrained 3 phase overcurrent (51V), trip

Stator neutral earth fault (51N), trip

Coolant over temperature or failure(26C) alarm

Time delayed audible overload alarm and contact outputs (49)

The following will be provided by contractor in the switchboard:

All line side current transformers

Voltage transformer

Protection relays shall be microprocessor type, withdrawable, with full testing

facilities to allow secondary injection of the relays. A setting proposal document

for all relays including calculations shall be provided, however final settings shall

be mutually agreed with contractor.

Sequence of operation:

This document is the property of OWNER. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

PROJECT:

SOUTH YARAN OIL FIELD

DEVELOPMENT PROJECT

DOCUMENT TITLE

DOCUMENT NO

:

:

Specification for Emergency Generator

SYME-ELBASC-ENEL-SPEQ-0006-B03

SHEET NO. : REV. :

B03

9 of 10

Diesel generator control panel shall be equipped with an automatic change over

switch. Voltage and frequency of normal supply is sensed and if the voltage and

frequency is less than setting voltage and frequency in specified time, change

over switch automatically open the normal supply breaker and then send start

command to diesel. After diesel reach to normal speed and voltage and the

minimum 120 sec., the generator breaker shall be closed and will be supplied

the load.

If the normal supply restored to normal voltage and frequency the generator

breaker is opened and the normal supply breaker is closed. After 5-10 minutes

that diesel is cooled the stop command send to diesel.

6.9

Clause 6.9: Over speed (Addition)

The range of adjustment shall be not less than plus and minus 5% of rated

speed.

B03

6.10

Clause 9: Painting (Addition)

The color of final layer shall be light grey according BS 381C No. 631C unless

otherwise specified in data sheet. Painting shall be done according to IPS-TP100. If vendor use another standard for painting it shall be submitted to client for

approve.

6.11

Clause 10: documentation (Addition)

The Vendor shall provide the following drawings and data in English at no cost

to the owner:

Complete technical Vendor's products catalog.

Comprehensive catalogues, technical data, dimensional outline drawings,

proposed test procedure, service facilities, etc. of the equipment offered and

its various components.

Preliminary connection and wiring diagrams, dimensional and cross

sectional drawings, control system diagram.

Declaration of confirmation with the set standards and/or clear indication of

deviations from the standards and this specification.

Vendor's design calculation, necessary documents and/or data for the

calculation of the power output of the engine in respect to the site and

climatic condition detailed in data sheet.

Drawing curves.

Performance curve showing torque, fuel consumption, engine speed and

power output.

Recommended commissioning and 2 years running consumable and spare

parts separately listed, numbered, referenced and duly priced.

Shipping dimensions (length, width and height) and weight with shipping

schedules.

This document is the property of OWNER. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

PROJECT:

SOUTH YARAN OIL FIELD

DEVELOPMENT PROJECT

DOCUMENT TITLE

DOCUMENT NO

6.12

B03

Specification for Emergency Generator

SYME-ELBASC-ENEL-SPEQ-0006-B03

:

:

SHEET NO. : REV. :

B03

10 of 10

Clause 14: Spare parts (Addition)

6.12.1 Spare Parts for Installation and Commissioning (Start-Up Spares)

Precommissioning and commissioning spare parts are required to safeguard

the operation of equipment during the running in and start up period of the

equipment.

Vendor shall quote pre-commissioning and commissioning spare parts for a

period at least 3 months.

These spare parts will be agreed upon by the vendor and purchaser and

purchased with the main equipment.

6.12.2 Spare Parts for Two Years of Operation

These spare parts are required for commissioning and the subsequent

continuous operation on the basis of the details listed below.

Wear and corrosion during normal operation.

Damage or deficiencies during operation, maintenance or inspection of

equipment

The required components and quantities shall be suggested by the vendor for a

two-year operation period and quoted in the offer for the equipment.

7. Attachments

B03

7.1

Attachment #1: IPS-E-EL-138(1) (36 Sheets)

This document is the property of OWNER. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

You might also like

- Data Sheet For Dry Chemical Portable Pportable Extinguisher: ProjectDocument3 pagesData Sheet For Dry Chemical Portable Pportable Extinguisher: ProjectmNo ratings yet

- PCD SF 181 (Cover)Document2 pagesPCD SF 181 (Cover)mNo ratings yet

- Procedure For Preparation of Water/Foam Monitor Data Sheet: Quality Management System DocumentDocument7 pagesProcedure For Preparation of Water/Foam Monitor Data Sheet: Quality Management System DocumentmNo ratings yet

- PCD-SF-187-Attachment#1 Water Hose Reel Data SheetDocument4 pagesPCD-SF-187-Attachment#1 Water Hose Reel Data SheetmNo ratings yet

- PCD SF 195Document13 pagesPCD SF 195mNo ratings yet

- Procedure For Fire Water Max. Demand Calculation: Quality Management System DocumentDocument4 pagesProcedure For Fire Water Max. Demand Calculation: Quality Management System DocumentmNo ratings yet

- Procedure For Fire Water Max. Demand Calculation: Quality Management System DocumentDocument4 pagesProcedure For Fire Water Max. Demand Calculation: Quality Management System DocumentmNo ratings yet

- Procedure For Preparation of Dry Chemical Wheeled Extinguishers Data SheetDocument5 pagesProcedure For Preparation of Dry Chemical Wheeled Extinguishers Data SheetmNo ratings yet

- Quality Management System Procedure for Water Hose Reel Data SheetDocument6 pagesQuality Management System Procedure for Water Hose Reel Data SheetmNo ratings yet

- Procedure for Application of Foam Protection SystemDocument9 pagesProcedure for Application of Foam Protection SystemmNo ratings yet

- PCD SF 195Document13 pagesPCD SF 195mNo ratings yet

- Amozeshe Excel 2013Document32 pagesAmozeshe Excel 2013mNo ratings yet

- PCD SF 191Document7 pagesPCD SF 191mNo ratings yet

- PCD SF 194Document6 pagesPCD SF 194mNo ratings yet

- PCD SF 193Document6 pagesPCD SF 193mNo ratings yet

- Syme Mebasc Enme Speq 0211 b02 PDFDocument9 pagesSyme Mebasc Enme Speq 0211 b02 PDFmNo ratings yet

- Syme Tlbasc Ente Spde 0001 b02Document17 pagesSyme Tlbasc Ente Spde 0001 b02mNo ratings yet

- Syme Hvbasc Enhv Bsde 0001 B02Document16 pagesSyme Hvbasc Enhv Bsde 0001 B02mNo ratings yet

- Syme Mebasc Enme Speq 0210 b03 PDFDocument12 pagesSyme Mebasc Enme Speq 0210 b03 PDFmNo ratings yet

- Syme Elbasc Enel Lilc 0002 b02Document6 pagesSyme Elbasc Enel Lilc 0002 b02m100% (1)

- Syme Elbasc Enel Rqma 0001 b02Document16 pagesSyme Elbasc Enel Rqma 0001 b02m100% (1)

- Syme Elbasc Enel Spel 0003 b02Document15 pagesSyme Elbasc Enel Spel 0003 b02mNo ratings yet

- Syme Elbasc Enel Dsel 0002 b03Document28 pagesSyme Elbasc Enel Dsel 0002 b03m100% (1)

- Electrical Load List: Project: South Yaran Oil Field Development ProjectDocument8 pagesElectrical Load List: Project: South Yaran Oil Field Development ProjectmNo ratings yet

- Control Building Floor Plans and ElevationsDocument4 pagesControl Building Floor Plans and Elevationsm100% (1)

- Sycv Cvbasc Encv DCDS 0001 B02Document19 pagesSycv Cvbasc Encv DCDS 0001 B02mNo ratings yet

- Syme Elbasc Enel Cnel 0001 b02Document12 pagesSyme Elbasc Enel Cnel 0001 b02mNo ratings yet

- Syme Elbasc Enel Cide 0001 b02Document60 pagesSyme Elbasc Enel Cide 0001 b02m100% (1)

- Sycv Arbasc Enar Bsde 0001 B02Document12 pagesSycv Arbasc Enar Bsde 0001 B02m100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Switch-Mode Lithium-Ion Battery-Charger: General Description - FeaturesDocument8 pagesSwitch-Mode Lithium-Ion Battery-Charger: General Description - FeaturesJie99No ratings yet

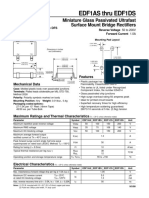

- EDF1AS Thru EDF1DS: Miniature Glass Passivated Ultrafast Surface Mount Bridge RectifiersDocument2 pagesEDF1AS Thru EDF1DS: Miniature Glass Passivated Ultrafast Surface Mount Bridge RectifiersCarlosNo ratings yet

- Basic ElectronicsDocument36 pagesBasic Electronicswhatsapp status clipsNo ratings yet

- Nema Pe5 1997Document46 pagesNema Pe5 1997Horacio EneroNo ratings yet

- SPW-CR253EHL5-E: Parts ListDocument4 pagesSPW-CR253EHL5-E: Parts ListDavid Lemos SanchezNo ratings yet

- Aegis Multifunction RelayDocument4 pagesAegis Multifunction RelaySuranjana DasNo ratings yet

- CBM Motor Test ReportDocument4 pagesCBM Motor Test ReportRaj Kiran76% (21)

- Insulator Types and Uses for 33kV SystemsDocument2 pagesInsulator Types and Uses for 33kV SystemsShahriar AhmedNo ratings yet

- Steam Turbine Rotor Vibration Failures - Causes and Solutions - POWER Magazine 1Document11 pagesSteam Turbine Rotor Vibration Failures - Causes and Solutions - POWER Magazine 1aserf251No ratings yet

- Relays: Vacuum Gas-FilledDocument21 pagesRelays: Vacuum Gas-FilledMelike Subaşı - Elektrik Elektronik Mühendis adayıNo ratings yet

- 10, 37, 38. Hot Sale 220 KV Capacitive Voltage Transformer 230 KV - Buy 220 KV Capacitive Voltage Transformer, 220 KV Voltage Transformer, Voltage Transformer 230 KV Product OnDocument11 pages10, 37, 38. Hot Sale 220 KV Capacitive Voltage Transformer 230 KV - Buy 220 KV Capacitive Voltage Transformer, 220 KV Voltage Transformer, Voltage Transformer 230 KV Product OnSaifudin ZuhriNo ratings yet

- DS LEADER-Volt Catalog USAR ZCL08.264.US .4Document2 pagesDS LEADER-Volt Catalog USAR ZCL08.264.US .4Zouhir kéniNo ratings yet

- Agc 4 MK II Data Sheet 4921240614 UkDocument39 pagesAgc 4 MK II Data Sheet 4921240614 UkFanni Smidéliusz-OláhNo ratings yet

- ABB HV Shunt ReactorDocument30 pagesABB HV Shunt Reactortkdrt2166100% (1)

- Aircraft Presentation 26july18Document41 pagesAircraft Presentation 26july18M.Mohamed SarfrazNo ratings yet

- Generator Rotor ProtectionDocument11 pagesGenerator Rotor ProtectionjasmindpatelNo ratings yet

- Mitsubhishi S500 ManualDocument200 pagesMitsubhishi S500 ManualDeepak GuptaNo ratings yet

- Model AnswerDocument18 pagesModel AnswerKshitij SalaveNo ratings yet

- Bhim Singh SirDocument16 pagesBhim Singh SirRana Abhishek Singh KadgiNo ratings yet

- LSA 50.2 M64P - 1000kVADocument7 pagesLSA 50.2 M64P - 1000kVAArfian Edy TamaNo ratings yet

- Selection of Neutral Grounding Reactor For Line To Ground FaultDocument4 pagesSelection of Neutral Grounding Reactor For Line To Ground FaultjlcegarraNo ratings yet

- 5 Electricity - With GRESADocument15 pages5 Electricity - With GRESADianne CalladaNo ratings yet

- Variable ResistorsDocument4 pagesVariable Resistorsdev achandyNo ratings yet

- Block Diagram: X541UV Repair GuideDocument7 pagesBlock Diagram: X541UV Repair GuideIlham PanjiNo ratings yet

- Battery Voltage Sensor BVS 1930Document3 pagesBattery Voltage Sensor BVS 1930AjitKumarPandeyNo ratings yet

- Leading Manufacturer Automatic Control PanelsDocument12 pagesLeading Manufacturer Automatic Control PanelsKanul RiyazNo ratings yet

- High-End Portable Fault Location System: DescriptionDocument5 pagesHigh-End Portable Fault Location System: DescriptionTri Ari WibowoNo ratings yet

- 3G3PV (E7) en ManualDocument258 pages3G3PV (E7) en ManualBojan BosiljcicNo ratings yet

- Presentation On Substation 220 KVDocument37 pagesPresentation On Substation 220 KVPiyush Bansal75% (12)

- DC-AC Converter: PWM Inverter Operation and DesignDocument13 pagesDC-AC Converter: PWM Inverter Operation and Designnataphon kabkaewNo ratings yet