Professional Documents

Culture Documents

Blade Drift Eliminators

Uploaded by

Avicena AlbiruniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blade Drift Eliminators

Uploaded by

Avicena AlbiruniCopyright:

Available Formats

BLADE DRIFT ELIMINATORS

The blades are held together with one-piece end caps,

forming an assembled module that is lightweight

but strong enough to span up to 6 ft. (1.8 m)

between supports ... saving material and

labor costs and reducing

air blockage.

DE-120

DE-080

DE-097

DIRECTIONAL

DISCHARGE

DEFLECTORS

DE-080 and DE-120

DE-097

Brentwood AccuPac DE-080 and DE-120 Blade

Drift Eliminator modules use a tightly-spaced

series of sinusoidal-shaped PVC (or HPVC)

blades that force the leaving air to make distinct

changes of direction at three impact zones

(right), resulting in maximum drift droplet

removal. And this performance does not come at

the expense of fan energy, as the engineered flow

through these high-performance drift eliminators

achieves very low pressure drop (see back).

DE-097 Blade Drift Eliminators are specifically

designed for use in forced-draft cooling towers.

Like the DE-080 and DE-120, this drift eliminator

use a series of sinusoidal-shaped blades, but

where this product differs is the additional

deflector designed into the discharge edge of each

blade. These deflectors increase the velocity of the

airstream and direct it (at a 45 angle) away from

the intake fans to prevent recirculation of warm,

moist air through the fans.

BLADE

DRIFT

ELIMINATORS

D

W

SPECIFICATIONS

DE-080

DE-120

DE-097

Standard Materials

PVC

PVC or HPVC

PVC

Module Depth (D)

5.75 in. (146 mm)

5.75 in. (146 mm)

4.75 in. (121 mm)

Max. Module Width (W)

24 in. (610 mm)

24 in. (610 mm)

23.25 in. (590 mm)

Module Length (L)

1 to 12 ft. in 1 ft. increments

(305 to 3660 mm in 305 mm incr.)

1 to 12 ft. in 2 ft. increments

(305 to 3660 mm in 610 mm incr.)

1.5 to 12 ft. in 1.5 ft. increments

(457 to 3660 mm in 457 mm incr.)

Blade Spacing

.800 in. (20 mm)

1.200 in. (30.5 mm)

.968 in. (24.6 mm)

Blade Thickness

.025 in. (.64 mm)

.025 in. (.64 mm)

.025 in. (.64 mm)

Dry Weight

1.40 lbs/ft2 (6.8 kg/m2)

.90 lbs/ft2 (4.4 kg/m2)

.90 lbs/ft2 (4.4 kg/m2)

Maximum Span

6 ft. (1.8 m)

6 ft. (1.8 m)

6 ft. (1.8 m)

Drift Loss*

.002 % recirculation

.005 % recirculation

.004 % recirculation

Flame Spread**

15

15

15

* Test Method CTI-HBIK Standard 140

** Per ASTM Method E84

APPLICATIONS

MATERIALS

Brentwood Blade Drift Eliminators are designed for use

in counterflow or crossflow Cooling Towers.

All Brentwood Blade Drift Eliminators are made from PVC (or HPVC for high

temperatures) that meets CTI (Cooling Technology Institute) Standard 136

and are UV-protected. These PVC compounds have outstanding resistance to

weather exposure and are nearly impervious to chemical degradation by

alkalis, acids, grease, fats, oils, and biological attack. These materials have

excellent fire rating due to their self-extinguishing characteristics.

The DE-097 features engineered directional discharge

deflectors on the trailing edge of each blade that increase

the velocity of the leaving airstream and direct it at a 45

angle away from the intake fans to prevent recirculation of

warm, moist air through the fans.

The DE-080 and DE-120 feature an open drainage design

for crossflow induced draft applications.

Brentwood Blade Drift Eliminator modules "nest" with the

adjoining modules to provide "seamless" panel installations.

PRESSURE DROP

.120

(3)

INCHES WG (MILLIMETERS WG)

Easy to assemble on-site, our Blade Drift Eliminators

are a popular choice for international projects. (Shipping

unassembled components vs. assembled modules can

save significantly on freight costs.)

WET (OPERATING) PRESSURE DROP

FEATURES & BENEFITS

.100

(2.5)

DE-097

.080

(2)

.060

(1.5)

DE-120

.040

(1)

DE-080

.020

(.5)

.000

200 (1)

Nested Seam

300 (1.5)

400 (2)

500 (2.5)

600 (3)

700 (3.5)

800 (4)

VELOCITY

Flat Seam

FEET/MINUTE (METERS/SECOND)

Copyright 2008 Brentwood Industries, Inc.

Brentwood Industries, Inc., P.O. Box 605, 610 Morgantown Road, Reading, PA 19603, USA, Phone 1-610-236-1100, Fax 1-610-236-1199, Email ctsales@brentw.com

Brentwood Asia, Ltd., A3 Floor, Le Concorde Tower, 202 Rajchadapisek Road, Huaykwang, Bangkok 10310, Thailand, Phone 662-694-1060-2, Fax 662-694-1063, Email asiasales@brentw.com

Brentwood Europe s.r.o., Plzenska 610, 338 05 Myto, Czech Republic, Phone +420 371 595 795, Fax +420 371 580 795, Email europesales@brentw.com

www.brentwood-ind.com/cool

You might also like

- Cooling Tower 434Document15 pagesCooling Tower 434arslan MaqboolNo ratings yet

- Tender Document of Irregation Pipe and FittingDocument103 pagesTender Document of Irregation Pipe and Fittingደስታ ጌታውNo ratings yet

- Industrial BoilersDocument22 pagesIndustrial BoilersAbdul Razzaq MughalNo ratings yet

- Ekoplastik PPR Catalogue of Products PDFDocument36 pagesEkoplastik PPR Catalogue of Products PDFnamNo ratings yet

- PPR Products Technical InformationDocument26 pagesPPR Products Technical InformationJoe VergheseNo ratings yet

- Cross FluteDocument6 pagesCross FluteAvicena AlbiruniNo ratings yet

- Water SprayDocument1 pageWater SpraySubharajkNo ratings yet

- Piping Info - Carbon Steel & Stainless Steel Guide SpacingDocument2 pagesPiping Info - Carbon Steel & Stainless Steel Guide SpacingpalluraviNo ratings yet

- Monthly Blood Pressure Log Excel TemplateDocument8 pagesMonthly Blood Pressure Log Excel TemplateZeeshan Hyder Bhatti100% (1)

- Transfer of Liquefied Natural Gas On Long Insulated Lines PDFDocument6 pagesTransfer of Liquefied Natural Gas On Long Insulated Lines PDFIgnacio ChaparroNo ratings yet

- Green PPR Pipe FittingDocument12 pagesGreen PPR Pipe FittinggeorgeNo ratings yet

- 12-Design Fundamentals of BoilerDocument12 pages12-Design Fundamentals of BoilerVishalVaishNo ratings yet

- Tender Document T.N.11 2019 ECD P PDFDocument815 pagesTender Document T.N.11 2019 ECD P PDFWaheed AhmadNo ratings yet

- 367 Steam Tracing GuidelinesDocument1 page367 Steam Tracing Guidelineslink2u_007No ratings yet

- Appendices For BoilerDocument4 pagesAppendices For BoilersarahNo ratings yet

- Process Data Sheet For Tank / Vessel: XXX XXX XXX XXX XXX XXXDocument2 pagesProcess Data Sheet For Tank / Vessel: XXX XXX XXX XXX XXX XXXsafaldNo ratings yet

- HRSGDocument24 pagesHRSGsathishsggsNo ratings yet

- Mutual Funds SIP Dynamic CalculationsDocument21 pagesMutual Funds SIP Dynamic CalculationsSurendra KhatriNo ratings yet

- Flanged Immersion Heaters Design GuideDocument7 pagesFlanged Immersion Heaters Design GuidecamspsNo ratings yet

- Ref Pipe Sizing Ver 02 21 11Document12 pagesRef Pipe Sizing Ver 02 21 11Ahmef100% (1)

- Smart MaterialsDocument26 pagesSmart MaterialsManoj JaiswalNo ratings yet

- Technical Specification For Auxiliary Cooling Tower 2 PDFDocument1 pageTechnical Specification For Auxiliary Cooling Tower 2 PDFAnonymous vwbLPTpjNo ratings yet

- Is 14164 2008Document45 pagesIs 14164 2008Pukhraj DagaNo ratings yet

- E401 1000 Air Cooled CondensersDocument4 pagesE401 1000 Air Cooled CondensersNguyen Anh TuanNo ratings yet

- Expansion Tank Capacity Calculation SheetDocument5 pagesExpansion Tank Capacity Calculation SheetDEX TERRNo ratings yet

- Delivering Excellence in Combustion and Process HeatingDocument11 pagesDelivering Excellence in Combustion and Process HeatingsajjadyasinNo ratings yet

- Refrigeration: Refrigerant CompressorDocument88 pagesRefrigeration: Refrigerant CompressorKhalidNo ratings yet

- SMST-Tubes Product Range en 2010 WebDocument16 pagesSMST-Tubes Product Range en 2010 Webalbejo_r9No ratings yet

- TEWI AnalysisDocument63 pagesTEWI Analysismirali74No ratings yet

- P&ID Process Cooling Symbols and Their Usage PDFDocument4 pagesP&ID Process Cooling Symbols and Their Usage PDFHV UioNo ratings yet

- Liquid Valve CV CalcDocument4 pagesLiquid Valve CV Calcamit_kt1973No ratings yet

- Pressure Gauge DatasheetDocument2 pagesPressure Gauge DatasheetazlanNo ratings yet

- Specific Size Agitator Selection Process & Specification PDFDocument310 pagesSpecific Size Agitator Selection Process & Specification PDFParth ThakarNo ratings yet

- IR HL Heatless DryerDocument1 pageIR HL Heatless DryerYing Kei ChanNo ratings yet

- A Demister Pad Is Similar To An Air Filter Except Instead of Removing Dust ParticlesDocument1 pageA Demister Pad Is Similar To An Air Filter Except Instead of Removing Dust ParticlesyogacruiseNo ratings yet

- Design Note For Air Reciever TankDocument6 pagesDesign Note For Air Reciever TankJoshua Balaram RaoNo ratings yet

- RTWD Series R (TM) 70-250 Ton Water-Cooled Chiller Dimension DrawingsDocument2 pagesRTWD Series R (TM) 70-250 Ton Water-Cooled Chiller Dimension DrawingsJhon LewisNo ratings yet

- DemisterDocument4 pagesDemistermariniabrahanNo ratings yet

- Moore Fan 02Document7 pagesMoore Fan 02vikramNo ratings yet

- Condenser & EvaporatorDocument21 pagesCondenser & EvaporatorfitratulqadriNo ratings yet

- Compressed Air Dryer: Industrial Ammonia SystemsDocument8 pagesCompressed Air Dryer: Industrial Ammonia Systemsfernando_tkm_65065No ratings yet

- Design of Air IDocument5 pagesDesign of Air IInvedeNo ratings yet

- Boiler Commissioning & Functional Testing - Quality AssuranceDocument1 pageBoiler Commissioning & Functional Testing - Quality Assurancebandithaguru6338No ratings yet

- Selección de CompresoresDocument23 pagesSelección de CompresoresjowarNo ratings yet

- 6206 Guide For Selection Installation andDocument32 pages6206 Guide For Selection Installation andakbavra80% (5)

- Boiler Combustion & EmissionDocument15 pagesBoiler Combustion & EmissionMustafa HusainNo ratings yet

- PumpLab Book 1 PreviewDocument11 pagesPumpLab Book 1 Previewcorey6No ratings yet

- 4 - Pipe Insulation With PU BASF 2012 05 08Document24 pages4 - Pipe Insulation With PU BASF 2012 05 08dzungNo ratings yet

- Spirax Sarco Product HandbookDocument1 pageSpirax Sarco Product Handbooklmt76No ratings yet

- Air PropertiesDocument19 pagesAir PropertiesVanbiervlietNo ratings yet

- VAD Variable Area Desuperheaters: Desuperheater OverviewDocument6 pagesVAD Variable Area Desuperheaters: Desuperheater OverviewLucasZanaNo ratings yet

- Prof Ir Dr. Ab Saman B. Abd Kader, Peng, Miem, Mcit Faculty of Mechanical Engineering, UtmDocument21 pagesProf Ir Dr. Ab Saman B. Abd Kader, Peng, Miem, Mcit Faculty of Mechanical Engineering, UtmakusuperNo ratings yet

- Float Board Level GaugeDocument6 pagesFloat Board Level GaugeanaismariaNo ratings yet

- Heat Loss From A Pipe Calculator - Engineers Edge - WWW - EngineersedgeDocument2 pagesHeat Loss From A Pipe Calculator - Engineers Edge - WWW - EngineersedgetiarrubuhNo ratings yet

- Plant Engineering and Design The Ultimate Step-By-Step GuideFrom EverandPlant Engineering and Design The Ultimate Step-By-Step GuideNo ratings yet

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86From EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86No ratings yet

- Multiphase Flow 1995From EverandMultiphase Flow 1995A. SerizawaNo ratings yet

- Blade Drift EliminatorsDocument2 pagesBlade Drift EliminatorsNefoussiNo ratings yet

- Converting Excavator Buckets From J-Series Base Assemblies To The K-SeriesDocument28 pagesConverting Excavator Buckets From J-Series Base Assemblies To The K-Seriespacman2803No ratings yet

- 19 TsurumiDocument11 pages19 TsurumiAvicena AlbiruniNo ratings yet

- Muslim Heritage in Religionswissenschaft: A Preliminary Study On The Purposiveness & The Non-Purposiveness of Muslim ScholarshipDocument18 pagesMuslim Heritage in Religionswissenschaft: A Preliminary Study On The Purposiveness & The Non-Purposiveness of Muslim ScholarshipAvicena AlbiruniNo ratings yet

- What Is StandingDocument1 pageWhat Is StandingAvicena AlbiruniNo ratings yet

- Understanding The Hadith PDFDocument230 pagesUnderstanding The Hadith PDFAvicena AlbiruniNo ratings yet

- The Other Islam Stephen S PDFDocument5 pagesThe Other Islam Stephen S PDFAvicena AlbiruniNo ratings yet

- Systems Science CATEGORYDocument2 pagesSystems Science CATEGORYAvicena AlbiruniNo ratings yet

- Plutocracy Is Rule by The: Modern PoliticsDocument3 pagesPlutocracy Is Rule by The: Modern PoliticsAvicena AlbiruniNo ratings yet

- Political CultureDocument7 pagesPolitical CultureAvicena Albiruni100% (1)

- Rigour or Rigor (See: o o o o oDocument6 pagesRigour or Rigor (See: o o o o oAvicena AlbiruniNo ratings yet

- P 69 + 12log: Citation NeededDocument4 pagesP 69 + 12log: Citation NeededAvicena AlbiruniNo ratings yet

- Social Rule System TheoryDocument11 pagesSocial Rule System TheoryAvicena AlbiruniNo ratings yet

- Aleph NumbersDocument4 pagesAleph NumbersAvicena AlbiruniNo ratings yet

- Punctus Contra Punctum Meaning "Point Against Point".: o o o o o o oDocument9 pagesPunctus Contra Punctum Meaning "Point Against Point".: o o o o o o oAvicena AlbiruniNo ratings yet

- P 69 + 12log: Citation NeededDocument4 pagesP 69 + 12log: Citation NeededAvicena AlbiruniNo ratings yet

- Post-Tonal Music TheoryDocument5 pagesPost-Tonal Music TheoryAvicena AlbiruniNo ratings yet

- TransformationDocument1 pageTransformationAvicena AlbiruniNo ratings yet

- Prime Form (Original Order)Document7 pagesPrime Form (Original Order)Avicena AlbiruniNo ratings yet

- Musical Set TheoryDocument5 pagesMusical Set TheoryAvicena AlbiruniNo ratings yet

- Prime Form: Music Set Transformation Transposition InversionDocument3 pagesPrime Form: Music Set Transformation Transposition InversionAvicena Albiruni100% (1)

- FOUNDATION Fieldbus Cable: Data SheetDocument4 pagesFOUNDATION Fieldbus Cable: Data SheetMiller Alexander Mora VargasNo ratings yet

- Pitppt (Final)Document33 pagesPitppt (Final)Ian GaleonNo ratings yet

- Design Windows CatalogueDocument15 pagesDesign Windows Cataloguenaresh kumarNo ratings yet

- PVC 210 Gutter System ManualDocument38 pagesPVC 210 Gutter System ManualUci DutzuNo ratings yet

- Chemical Business FocusDocument34 pagesChemical Business FocusAtikah Abu BakarNo ratings yet

- Es X56901Document5 pagesEs X56901PongsanNo ratings yet

- Polyvinyl Acetate PhthalateDocument4 pagesPolyvinyl Acetate PhthalateHani AlhelwaniNo ratings yet

- Synthetic PolymersDocument45 pagesSynthetic PolymersIboniks Beponpiks DabondatskiNo ratings yet

- Effect of Stabilizers On Properties of PVC (Polymer) 1Document52 pagesEffect of Stabilizers On Properties of PVC (Polymer) 1DIPAK VINAYAK SHIRBHATE100% (5)

- Data Sheet-Cable-24.12.21Document22 pagesData Sheet-Cable-24.12.21YASHASHWYNo ratings yet

- Synthetic Polymers NotesDocument3 pagesSynthetic Polymers NotesajspspNo ratings yet

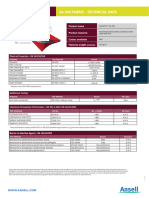

- TDS AlphaTec 66300 Fabric 2204Document1 pageTDS AlphaTec 66300 Fabric 2204rahmawanianNo ratings yet

- Abstract 2008Document54 pagesAbstract 2008Wheng Narag100% (1)

- Caracteristicas General de Polimeros PDFDocument4 pagesCaracteristicas General de Polimeros PDFmarylorena01No ratings yet

- 蓝色PVC手套EU食品检测EN1186Document5 pages蓝色PVC手套EU食品检测EN1186GIANNINo ratings yet

- NEPRO Conduit Pvc1Document16 pagesNEPRO Conduit Pvc1chaouch.najehNo ratings yet

- Interline MSDSDocument4 pagesInterline MSDSUtomoNo ratings yet

- E Program Files An ConnectManager SSIS TDS PDF Intergard 263 Eng A4 20170512Document4 pagesE Program Files An ConnectManager SSIS TDS PDF Intergard 263 Eng A4 20170512Erwin MalmsteinNo ratings yet

- Healthcare Facilities Management: Lecture 1-Dr - Mohamad Nassereddine HMTM512Document52 pagesHealthcare Facilities Management: Lecture 1-Dr - Mohamad Nassereddine HMTM512ali abdel hadiNo ratings yet

- Standar JIS K 6743 2016 - Kelas AW-compressedDocument60 pagesStandar JIS K 6743 2016 - Kelas AW-compressedadib abiyyu100% (1)

- F439Document7 pagesF439cenkunal100% (1)

- C46 - Polymer - Ishwor Thapaliya EditedDocument8 pagesC46 - Polymer - Ishwor Thapaliya EditedPrince ThakurNo ratings yet

- PET Market in Europe - State of Play 2022Document48 pagesPET Market in Europe - State of Play 2022hanssayler6No ratings yet

- Overview of Biomaterials and Their Use in Medical Devices: Uses For Biomaterials (Ref 3)Document6 pagesOverview of Biomaterials and Their Use in Medical Devices: Uses For Biomaterials (Ref 3)anwarr4040No ratings yet

- Acoustic Characterization of Natural Fibers For Sound Absorption ApplicationsDocument5 pagesAcoustic Characterization of Natural Fibers For Sound Absorption ApplicationsErika ValderamaNo ratings yet

- Synthesis of Fuel From Waste PlasticDocument63 pagesSynthesis of Fuel From Waste Plasticamirah1999No ratings yet

- M&SDocument27 pagesM&SSohel NomanNo ratings yet

- BPPL-DLOA EI Works SCH - 1 - Sopan-Annexures 1-3Document346 pagesBPPL-DLOA EI Works SCH - 1 - Sopan-Annexures 1-3dinesh meena100% (1)

- Ipj 2005 12 547Document9 pagesIpj 2005 12 547Shahin AkhlaghiNo ratings yet

- Technical Information: Pipe Jointing ProceduresDocument17 pagesTechnical Information: Pipe Jointing ProceduresJerusalemsNo ratings yet