Professional Documents

Culture Documents

Study On Tappet and Dobby Shessing Mechanism .

Uploaded by

tusharOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Study On Tappet and Dobby Shessing Mechanism .

Uploaded by

tusharCopyright:

Available Formats

SOUTHEAST

UNIVERSITY

Experiment No:

Experiment Name: Study on tappet and

dobby shedding mechanism.

SUBMITTED TO:

Emdad Sarkar

Lecturer of FMT-ll Lab

Department of Textile

Southeast University

SUBMITTED BY:

Name:Thushar kumar Bhowmik.

ID: 2007200400062

Batch: 6th

Group: B

Date of experiment: /

/2009

Date of Submission: / /2009

Introduction:

Shedding is the first primary motion of weaving .It is done by means of

treadles, dobby or jacquard ,both in hand and power looms .In handlooms

the thread treadles are operated by the weavers feet ,where as in power

looms they are mechanically operated by shedding tappets ,Healds are also

used in dobbies for shedding ,where as jacquard s control warp threads

separately by means of hooks, harness cords and knives .

Tapped are generally used for heald shedding .Tapped, cams and wipers

are names given indiscriminately to those irregular pieces of mechanism to

which a rotary motion is given for the purpose of producing by sliding

contact, reciprocating motion is rods and levers .The pricile of the tapped

shedding motion in using a tappet impinges upon an anti-friction roller or

bowl, supported in treadle .This shedding motion has the widest range of

application.

Objectives:

To know the tappet mechanism.

To know about the shedding tappet.

By knowing it , turning into higher production

To know about the shedding & types of shedding.

To know the general knowledge of dobby.

To know about the dobby capacity.

To know about the necessary parts shedding by dobby mechanism.

Finally gain the actual things help in our practical field.

Tappet Shedding:

From figure, A and A are two plates and both are fixed on the tapped shaft

benearth the centre the of the heald C and C .Two treadle D and D move

on a fulcrum pin E and each Carrie an anti-friction roller or needle bowl F;

F upon which the tappet plates act, a they rotates G and G are straps and

cords which connects the treadle D and D to the bottom heald shaft .Cords

and straps H and H ,connected to the upper heald shaft ,are secured respect

to the peripheries of two roller K and K ,Which may be either fast or loose

upon a shaft B .

When bottom shaft get motion then it starts revolving .At a time one

shedding cam starts to presses the one adjacent treadle bowl .So treadle

lever goes down word .AS a results it pulls the connected heald shaft with

treadle lever down word .

For reciprocating motion to the other heald shaft goes upward .So one shed

is produced .After that another shedding can presses the another upper

mechanism .

So we can see that two shed is produced for one revolution of bottom shaft

because there are two shedding cms are attached at 180 angles.

Dobby Shedding Mechanism:

The dobby is a shedding device placed on the top of a loom in order to

produce figure patterns by using a large number of heads than the capacity

of a tappet .

The number of shaft which can be actuated by a dobby varies between 6

and 40 .Theoretically the capacity is 2-56 ..Dobby offers greater facilities

for producing a variety of patterns with more number of healds.

Remarks:

Dobby shedding mechanism:

The dobby is a shedding device pleased on the top of a loom in order to

produce figure patterns by using a large number of healds than the capacity

Of a tappet

The number of shaft which can be actuated y a dobby varies between 6 &

40 a .Theoriticall the capacity is 2-56.Dobbied offer grater facilities for

producing a surely of pattern with more numvreof heals .

You might also like

- The Fastest Weaving Machine in the World: M8300 multi-phaseDocument4 pagesThe Fastest Weaving Machine in the World: M8300 multi-phaseKathirrveluSubramainan100% (1)

- Revised List of Mechanics of Fibrous Structures (TET) 2k19Document35 pagesRevised List of Mechanics of Fibrous Structures (TET) 2k19RAZA Khn100% (1)

- Shade Analysis by Spectrophotometer.Document5 pagesShade Analysis by Spectrophotometer.bub0% (1)

- Study parts and functions of two needle four thread overlock machineDocument6 pagesStudy parts and functions of two needle four thread overlock machinetahaNo ratings yet

- Textile Wet ProcessingDocument24 pagesTextile Wet ProcessingAli Imran100% (1)

- Visual Assessment of Color (Between Standard and Trial Sample) by Light Box.Document5 pagesVisual Assessment of Color (Between Standard and Trial Sample) by Light Box.bubNo ratings yet

- Stuy On Overlock Sewing MachineDocument3 pagesStuy On Overlock Sewing MachineRifatNo ratings yet

- By: Hemant Ghanghor & Patanjal KumarDocument15 pagesBy: Hemant Ghanghor & Patanjal KumarpatanjaliictNo ratings yet

- JBF Industries Ltd. Dalal Mott Mac DonaldDocument76 pagesJBF Industries Ltd. Dalal Mott Mac DonaldJimish PanchalNo ratings yet

- Study Ring Frame Machine Parts & Yarn Path DiagramDocument2 pagesStudy Ring Frame Machine Parts & Yarn Path DiagramSaif Anwar100% (1)

- Study On Desizing Cotton Fabric by Using Acid-1Document2 pagesStudy On Desizing Cotton Fabric by Using Acid-1Mr RiyadNo ratings yet

- Development of Jute / Cotton Blended Garment For Winter Wear By: B. Sathish BabuDocument31 pagesDevelopment of Jute / Cotton Blended Garment For Winter Wear By: B. Sathish BabuAjaz Banna100% (1)

- WPT 2Document141 pagesWPT 2SalimNo ratings yet

- Scouring & Bleaching of Cotton at Double StageDocument3 pagesScouring & Bleaching of Cotton at Double StageMd Abdullah Al NomanNo ratings yet

- Alimur Sir TTQC 2 HWDocument3 pagesAlimur Sir TTQC 2 HWAfsana Afrin RummonNo ratings yet

- Assignment: A U S & TDocument6 pagesAssignment: A U S & TArif Mahmud100% (1)

- Lap Former Machine - Features of Lap Former Machine - Textile LearnerDocument1 pageLap Former Machine - Features of Lap Former Machine - Textile LearnerTanmay JagetiaNo ratings yet

- Sulphur DyesDocument11 pagesSulphur DyesSiddharth Manu100% (1)

- Yarn Manufacture - Set of 2 VolsDocument2 pagesYarn Manufacture - Set of 2 VolsAnonymous Pt7NHkat9No ratings yet

- Studying Effects of Fabric Thickness, Loop Shape Factor, Fabric Tightness Factor and Aerial Weight On Thermal Conductivity of Plain Single Jersey Cotton Knitted Fabric Using Box Behnken DesignDocument8 pagesStudying Effects of Fabric Thickness, Loop Shape Factor, Fabric Tightness Factor and Aerial Weight On Thermal Conductivity of Plain Single Jersey Cotton Knitted Fabric Using Box Behnken DesignIJEACS UKNo ratings yet

- Fabric Manufacturing Technology Lab-1 Final Exam SolutionDocument16 pagesFabric Manufacturing Technology Lab-1 Final Exam SolutionAlif SheikhNo ratings yet

- JUTE Fibre To Yarn PDFDocument217 pagesJUTE Fibre To Yarn PDFMoshiur RahmanNo ratings yet

- Gel Spun PE FiberDocument35 pagesGel Spun PE FiberNimra GhafoorNo ratings yet

- Testing of Comfort Properties of Textiles and ApparelsDocument5 pagesTesting of Comfort Properties of Textiles and ApparelsJana Muthu100% (1)

- DesizingDocument4 pagesDesizingsyed asim najam100% (2)

- Dying of Cotton Fabric With Azoic Dye.Document6 pagesDying of Cotton Fabric With Azoic Dye.Redwan Ibn MahbubNo ratings yet

- Ultrox EPN Conc Liquid Lit Revision 2Document2 pagesUltrox EPN Conc Liquid Lit Revision 2AliMuhammadNo ratings yet

- Evenness: Methods of Measuring Yarn EvennessDocument14 pagesEvenness: Methods of Measuring Yarn EvennessJuan CubasNo ratings yet

- MS Access Database and Feed Off The Arm MachineDocument19 pagesMS Access Database and Feed Off The Arm Machinevikash kumarNo ratings yet

- Azoic ColorDocument4 pagesAzoic ColorMD saifu lislamNo ratings yet

- Mass Transfer Lab ManualDocument29 pagesMass Transfer Lab ManualPrajwal ChavanNo ratings yet

- Final HairdryerDocument22 pagesFinal HairdryerRodrigo Soria0% (1)

- 2 Maintenance Schdule Blow Room, Carding DecDocument15 pages2 Maintenance Schdule Blow Room, Carding DecBHASKAR MITRANo ratings yet

- Evenness: - Types of Irregularity - 1) Weight Per Unit LengthDocument69 pagesEvenness: - Types of Irregularity - 1) Weight Per Unit LengthArushi MishraNo ratings yet

- Dustbin - LiteratureDocument25 pagesDustbin - LiteratureChandini ChandiniraoNo ratings yet

- TCP - IDocument35 pagesTCP - IPrashant GauravNo ratings yet

- Loom TimingDocument7 pagesLoom TimingMardiyya SuleimanNo ratings yet

- Knitting Technology II: Lecture Note 12, 13 &14 Etsehiwot Yisma 2019Document16 pagesKnitting Technology II: Lecture Note 12, 13 &14 Etsehiwot Yisma 2019fekadeNo ratings yet

- Blowroom (Autosaved)Document61 pagesBlowroom (Autosaved)drskathirrveluNo ratings yet

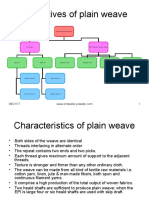

- Plain WeaveDocument8 pagesPlain Weaveghosh7171No ratings yet

- Airdye Technology Eliminates Water from Dyeing ProcessDocument7 pagesAirdye Technology Eliminates Water from Dyeing ProcessAnkita RajNo ratings yet

- Compact SpiningDocument55 pagesCompact Spiningapi-3774947100% (3)

- Dyes For CelluloseDocument18 pagesDyes For CelluloseAhmad ButtNo ratings yet

- Numerical Problems PDFDocument5 pagesNumerical Problems PDFGizachew ZelekeNo ratings yet

- Yarn Lea Strength Tester:: Prepared By-S. M. Masum AlamDocument3 pagesYarn Lea Strength Tester:: Prepared By-S. M. Masum AlamTouhidul HassanNo ratings yet

- Ring Spinning Machine LR 6/S Specification and Question AnswerDocument15 pagesRing Spinning Machine LR 6/S Specification and Question AnswerPramod SonbarseNo ratings yet

- Ring Frame Inverter DriveDocument11 pagesRing Frame Inverter Driveakshay Singh100% (2)

- Beating 1Document13 pagesBeating 1Joyonto HimoNo ratings yet

- Fabric Stiffness Tester ProfileDocument20 pagesFabric Stiffness Tester ProfileSanthosh KumarNo ratings yet

- Weaving RecordDocument11 pagesWeaving RecordPraveen RajNo ratings yet

- Nanocomposite Coating:a ReviewDocument19 pagesNanocomposite Coating:a ReviewA. SNo ratings yet

- Dry Laid NonwovensDocument10 pagesDry Laid NonwovensbledmikifrNo ratings yet

- Cellulose AcetateDocument27 pagesCellulose AcetateFitrya ChiequzaNo ratings yet

- National Textile University: B.Sc. Textile Engineering Practical Lab Report / Fall-2018Document5 pagesNational Textile University: B.Sc. Textile Engineering Practical Lab Report / Fall-2018Faisal Saeed100% (1)

- 3rd Revise Introduction To YM (TE-2111 Fall 2019)Document17 pages3rd Revise Introduction To YM (TE-2111 Fall 2019)Aftab Amin0% (1)

- Keighley DobbyDocument10 pagesKeighley DobbySuraj Raghv100% (1)

- Introduction To CombingDocument12 pagesIntroduction To CombingMujahid MehdiNo ratings yet

- Renewable Energy Resources: Textile ProcessingDocument17 pagesRenewable Energy Resources: Textile ProcessingrohithNo ratings yet

- History of Polyester Fiber - 2Document18 pagesHistory of Polyester Fiber - 2tusharNo ratings yet

- Introduction To ManagementDocument36 pagesIntroduction To ManagementtusharNo ratings yet

- ARJYASASTRA BARSHA Chapter 1Document80 pagesARJYASASTRA BARSHA Chapter 1tusharNo ratings yet

- AwakPsy Ebook MaggieAndersonDocument64 pagesAwakPsy Ebook MaggieAndersonizzybjNo ratings yet

- Astro Book Western AstrogyDocument134 pagesAstro Book Western AstrogytusharNo ratings yet

- Manosik Rog o PsychotherapyDocument125 pagesManosik Rog o PsychotherapyKhan Mohammad Mahmud HasanNo ratings yet

- Bisnu Sahashra NamDocument21 pagesBisnu Sahashra NamtusharNo ratings yet

- 500 YogasDocument38 pages500 YogasBinny SharmaNo ratings yet

- R Ô GV Mi G JVW' Mön I Ivk VW' MâvqDocument20 pagesR Ô GV Mi G JVW' Mön I Ivk VW' MâvqtusharNo ratings yet

- Face Reading Lesson1Document10 pagesFace Reading Lesson1tushar100% (2)

- Automation in Garments Manufacturing 2Document22 pagesAutomation in Garments Manufacturing 2tusharNo ratings yet

- Garments Cutting Machines 1Document12 pagesGarments Cutting Machines 1tusharNo ratings yet

- Gem BookDocument31 pagesGem BookWaqar ChaudhryNo ratings yet

- Vedicmaths EbookDocument212 pagesVedicmaths Ebooksaurab83100% (9)

- ANALEMMAS On The Gnomon and On The Dial PlateDocument10 pagesANALEMMAS On The Gnomon and On The Dial PlatetusharNo ratings yet

- Islamic ZodiacDocument11 pagesIslamic ZodiacLexLaptevaNo ratings yet

- SAGE-III Sunset and Sunrise Geometry: Space MathDocument2 pagesSAGE-III Sunset and Sunrise Geometry: Space MathpianomagicianNo ratings yet

- Chinese CalendarDocument37 pagesChinese CalendarMiha MihaiNo ratings yet

- Determination of Sliver & Roving Hank by Wrap Block & Balance.Document4 pagesDetermination of Sliver & Roving Hank by Wrap Block & Balance.tushar100% (3)

- Study On Color Fastness To Rubbing by Crock MeterDocument4 pagesStudy On Color Fastness To Rubbing by Crock Metertushar100% (5)

- Sources of Water PollutionDocument6 pagesSources of Water PollutiontusharNo ratings yet

- Electrical PropertiesDocument4 pagesElectrical PropertiestusharNo ratings yet

- Yoga (Kundalini)Document168 pagesYoga (Kundalini)Alesha Rose100% (25)

- Static ElectricityDocument2 pagesStatic ElectricitytusharNo ratings yet

- Keeping The Breath in Mind - DHAMMADHARODocument104 pagesKeeping The Breath in Mind - DHAMMADHAROspeedsky100% (1)

- CSE-Lab Report 3 (Working With Data Color)Document8 pagesCSE-Lab Report 3 (Working With Data Color)suvrodev812No ratings yet

- Rushan HoroscopeDocument37 pagesRushan HoroscopetusharNo ratings yet

- Mindfulness With Breathing & Four Elements MeditationDocument98 pagesMindfulness With Breathing & Four Elements Meditationeressendil100% (1)

- Hindu Philosophy Life After DeathDocument144 pagesHindu Philosophy Life After Death4titude100% (1)

- Presentation On Human Resource Development.Document16 pagesPresentation On Human Resource Development.tusharNo ratings yet

- Woven FabricDocument64 pagesWoven FabricSanghamitra Kalita100% (1)

- Project CadDocument30 pagesProject CadSandeep MohapatraNo ratings yet

- 2014 HOME DESIGN Booklet - Small VersionDocument96 pages2014 HOME DESIGN Booklet - Small VersionmichaelNo ratings yet

- New Microsoft Word DocumentDocument25 pagesNew Microsoft Word DocumentRahul DebsinghaNo ratings yet

- Avl PricelistDocument29 pagesAvl PricelistVictor David GomezNo ratings yet

- GATE Textile Fibres Study Material Book 2 FabricDocument15 pagesGATE Textile Fibres Study Material Book 2 FabricSantosh100% (1)

- Dobby ComparisonDocument7 pagesDobby ComparisonUshaniNo ratings yet

- Pixel Loom TutorialsDocument61 pagesPixel Loom TutorialsTurismo Asturias El Vineru Abajo100% (1)

- Woven Textile DesignsDocument35 pagesWoven Textile DesignsShresha DasNo ratings yet

- MIDDocument85 pagesMIDMD. Sharifuzzaman JoyNo ratings yet

- PDF DocumentDocument44 pagesPDF DocumentRatul HasanNo ratings yet

- Textile Internship at OCM India LTDDocument73 pagesTextile Internship at OCM India LTDHaqiqat Ali100% (4)

- کد فنی R9500Document361 pagesکد فنی R9500Hosein Asgari0% (1)

- PixelDobby ENUDocument204 pagesPixelDobby ENUCarla SantiniNo ratings yet

- Shedding DobbiesDocument63 pagesShedding Dobbiesarunmythreyee100% (4)

- Fabric Formation SystemsDocument348 pagesFabric Formation SystemsISHITANo ratings yet

- Terry TowelDocument31 pagesTerry TowelmaxheightsNo ratings yet

- Promatech Spare Parts CatalogDocument445 pagesPromatech Spare Parts CatalogSarbu Cristi100% (1)

- Complete Textile Mechanics LabDocument47 pagesComplete Textile Mechanics LabEngr Mujahid MehdiNo ratings yet

- Dobby Shedding Mechanism ExplainedDocument3 pagesDobby Shedding Mechanism ExplainedEhsaan Raahi RihaanNo ratings yet

- Dobby SheddingDocument43 pagesDobby Sheddingzameershah100% (4)

- SilkDocument65 pagesSilkManoj ReddyNo ratings yet

- Primary MotionsDocument59 pagesPrimary Motionsafroja hossainNo ratings yet

- Group 4Document30 pagesGroup 4Abdul AzizNo ratings yet

- 1st PDFDocument14 pages1st PDFzubairNo ratings yet

- Textile Internship Report AlokDocument39 pagesTextile Internship Report AlokRahul TelangNo ratings yet

- Dhaka University presentation on jacquard shedding mechanismsDocument36 pagesDhaka University presentation on jacquard shedding mechanismsAbdul AzizNo ratings yet

- Australia Machines .XLSX - EuroDocument3 pagesAustralia Machines .XLSX - Eurodipak kambleNo ratings yet

- LoomDocument11 pagesLoomYousha KhanNo ratings yet

- Dobby Shedding Mechanism TypesDocument4 pagesDobby Shedding Mechanism TypesLiz Aby100% (2)