Professional Documents

Culture Documents

Chapter-1: Introduction To Visakhapatnam Port

Uploaded by

Sai Kishore TamminaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter-1: Introduction To Visakhapatnam Port

Uploaded by

Sai Kishore TamminaCopyright:

Available Formats

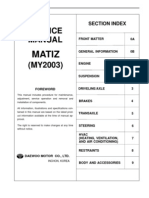

CONTENTS

CHAPTER-1: INTRODUCTION TO VISAKHAPATNAM PORT

1.1 HISTORY

1.2 VISION & MISSION

1.3 ACHIEVEMENTS OF THE PORT

CHAPTER-2: INTRODUCTION TO ORE HANDLING COMPLEX

2.1 ORGANISATION STRUCTURE OF OHC

CHAPTER-3 : RECEIVING SYSTEM

3.1 SEQUENCE OF ACTIVITIES AT OHC RECEIVING SYSTEMS

3.2 BEETEL CHARGER

CHAPTER-4 : TIPPLERS

4.1 WAGON TIPPLING SYSTEM

4.2 WAGON TIPPLER

4.3 WAGON POSITIONING EQUIPMENT

4.4 UNLOADING HOPPER

4.5 RAIL TRACKS

4.6 FEEDER BELOW THE HOPPER

4.7 DUST CONTROL SYSTEM

4.8 CONTROL ROOM

4.9 UNLOADING SYSTEM TRACK HOPPER

4.10 TRACK HOPPER

4.11 DISCHARGE GATE OPENING MECHANISM

4.12 FEEDER BELOW THE TRACK HOPPER

4.13 APRON PAN FEEDERS

4.14 OPERATION OF TIPPLER

4.14.1 ELECTICAL SUPPLY

4.14.2 TIPPLER

4.14.3 PLATFORM

4.14.4 FRAMES AND PEDESTRAL BEARINGS

4.14.5 END FRAMES DRIVES

4.14.6 TOP STOP AND SIDE BEAM

4.14.7 TIPPLER RAIL TABLE

4.14.8 WAGON CLAMPING BEAM

4.15 TWIN TIPPLER

4.15.1 DETAILS OF TWIN WAGON TIPPLER

4.16 THIRD TIPLER

4.16.1 DETAILS OF THIRD TIPPLER

4.17 WAGON DETAILS

CHAPTER-5 : CONVEYOR SYTEM

5.1 NEED FOR CONVEYOR SYSTEM

5.2 STEEL CHORD CONVEYORT BELT

5.2.1 GENERAL STEEL CHORD CONVEYOR BELT

5.2.2 TEAR RESISTANT STEEL CHORD CONVEYOR SYSTEM

5.2.3 CHARACTER

5.2.4 TEAR RESIST BELT WITH DETECHOR STRUCTURE

5.2.5 CHARACTERESTICS

5.2.6 MAIN TECHNICAL PARAMETERS OF THE STEEL CORD

5.2.7 THE RECOMMENDED MINIMUM CONVEYOR

5.3 NYLON CONVEYOR BELT AND EP CONVEYOR BELT

5.3.1 APPLICATION

5.3.2 FEATURES

5.3.3 THE PHYSICAL AND MECHANICAL PROPERTIES OF NYLON

CONVEYOR BELT AND EP CONVEYOR BELT

5.4 CORE RUBBER

5.5 EQUIPMENT OF BELT CONVEYOR SYSTEM

5.5.1 THE BELT

5.5.2 DRIVING GEAR

5.5.3 FEEDERS

5.5.4 PAN FEEDER

5.5.5 HOPPERS

5.5.6 CHUTES

5.5.7 ROCK BOXES

5.5.8 SKIRT BOARDS

5.5.9 IDLERS

5.5.10 CARRYING IDLERS

5.5.11 RETURN IDLERS

5.5.12 IDLER SPACING

5.5.13 MAGNETIC SEPERATION

5.5.14 CLEANING DEVICES

5.5.15 BRAKING AND RESTRAINING DEVICE

5.5.16 COVERING THE CONVEYOR

CHAPTER-6 : DESIGN PROCEDURE OF CONVEYOR SYSTEM

6.1 DESIGN CONCLUSIONS

CHAPTER-7 : STACKERS

7.1 DESCRIPTION

7.2 SET OF TRAVEL BOGIES

7.2.1 Travelling gear

7.2.2 Drive wheel bogie

7.2.3 Rail clamp

7.3 SLEW PLATFORM

7.4 DISCHARGE BOOM

7.5 HYDRAULIC SYSTEMS FOR LUFFING

7.5.1 Boom conveyor

7.5.2 Drive for discharge boom conveyor

7.5.3 Structure and belt loop for tripper

7.6 PULLEYS AND IDLERS

7.6.1 Pulleys

7.6.2 Idlers

7.7 PROCESS

7.7.1 Luffing

7.7.2 Travelling

7.7.3 Slewing

7.8 STACKER- I&III

7.8.1 Technical Specifications

CHAPTER-8 : RECLAIMERS

8.1 DESCRIPTION

8.1.1 BOGIES ASSEMBLE (TRAVELLING)

8.1.2 MAIN STRUCTURE

8.1.3 SLEW DECK:

8.1.3.1 Drive units

8.1.3.2 Slew ring

8.2 BOOM ASSEMBLY

8.2.1 Beam structure and pivots

8.2.2 Bucket wheel assembly

8.2.3 Bucket wheel drive

8.3 CONVEYORS

8.3.1 Boom conveyor:

8.4 BOOM SUPPORT AND LUFF SUPORT STRUCTURE

8.5 HYDRAULICS SYSTEM FOR LUFF OPERATION

8.6 PROCESS

8.7 RECLAIMER TYPES

8.8 Control systems

8.9 RECLAIMER II

8.10 RECLAIMER III:

8.10.1 Technical Specifications

8.11 RECLAIMER-IV

8.11.1 Technical Specifications

CHAPTER-8 : MAINTENANCE

8.1 NECESSITY FOR BELT CONVEYOR MAINTENANCE

8.2 APPLICATIONS OF MAINTENANCE TECHNIQUES ON BELT

CONVEYORS

8.2.1 SCHEDULED AND PLANNED MAINTENANCE

8.2.2 PREVENTIVE MAINTENANCE

8.2.3 PRODUCTIVE MAINTENACE/SELECTIVE MAINTENANCE

8.2.4 PREDICTIVE MAINTENANCE / ON LOAD MAINTENANCE

8.3 ELEMENTS OF GOOD MAINTENANCE PROGRAMME

8.3.1 ORGANISATION

8.3.2 PLANNING AND SCHEDULING

8.3.3 INSPECTION

8.3.4 LUBRICATION

8.3.5 ENGINEERING RECORDS

8.3.6 INVENTORY CONTROL OF MAINTENANCE STORES AND

SPARES

8.3.7 MACHINE REPLACEMENT POLICY

8.3.8 ENGINEERING ANALYSIS / FAILURE ANALYSIS

8.3.9 STANDARDISATION AND VARIETY REDUCTON

8.3.10 SHOPS TOOLS AND MAINTENANCE FACILITIES

8.3.11 TRAINING OF MAINTENANCE PERSONNEL

8.3.12 MAINTENANCE STANDARD

8.3.13 BUDGETING AND COST CONTROL

8.4 CONCLUSION:

8.5 MAINTENANCE OF BEETLE CHARGER

8.6 MAINTENANCE OF TWIN TIPPLERS

8.7 MAINTENANCE OF TWIN TIPPLERS APRON PAN FEEDER AND HOPPER

8.8 MAINTAINANCE OF THIRD TIPPLERS

8.9 MAINTENANCE OF THIRD TIPPLERS APRON FEEDERS AND BEETLE

CHARGERS

8.10 MAINTENANCE OF CONVEYOR SYSTEM

8.11 MAINTENANCE OF STACKER-I & III

CHAPTER-9 : SAFETY DEVICES

9.1 VARIOUS TYPES OF SAFETY DEVICES

CHAPTER-10 : BELT AND EQUIPMENT DEVICES

CHAPTER-11 : VULCANIZING

11.1 Setup of the working table

11.2 Dismantling of Press

CHAPTER-12 : STACKERS AND RECLAIMERS AVAILABLE UPGRADES FOR

EXISTING EQUIPMENT

CHAPTER-13 : SHIPPING SYSTEM

13.1 SEQUENCE OF ACTIVITIES AT THE SHIPPING SYSTEM

13.2 RECEIVING SYSTEM

13.3 DETAILS OF EQUIPMENTS OF RECEIVING SYSTEM:

13.4 SHIPPING SYSTEM

13.5 SHIP LOADER

13.6 TRAVELLING

13.7 LONG TRAVEL DRIVE UNITS

13.8 LONG TRAVEL BUFFERS

13.9 LONG TRAVEL STORM LOCKS

13.10 SLEWING

13.11 SLEW GEAR DRIVE

13.12 HYDRAULICS FOR LUFFING

13.13 CONVEYOR SYSTEM

13.14 BOOM CONVEOYR

13.15 DRIVE FOR DISCHARGE BOOM CONVEYOR

13.16 STRUCTURE & BELT LOOP FOR TIPPER

13.17 OPERATION

CHAPTER-14 : TARGETS OF MATERIAL HANDLING EQUIPMENT IN

VISAKHAPATNAM PORT TRUST

You might also like

- Gas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsFrom EverandGas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsNo ratings yet

- Automotive Air Conditioning and Climate Control SystemsFrom EverandAutomotive Air Conditioning and Climate Control SystemsRating: 4 out of 5 stars4/5 (6)

- Cat Forklift Ndc100 Service ManualDocument27 pagesCat Forklift Ndc100 Service Manualfrankstewart270488qny100% (81)

- Cat Forklift Npp60 Service ManualDocument21 pagesCat Forklift Npp60 Service Manualpatrickheath070882eqa100% (123)

- Cat Forklift t40c t50c t55c SchematicDocument27 pagesCat Forklift t40c t50c t55c Schematicalexhughes210188sxi100% (47)

- Book - 2001 - Highway Stormwater Pump Station DesignDocument221 pagesBook - 2001 - Highway Stormwater Pump Station Designbabak60No ratings yet

- Cat Forklift Nr3500 36v Schematic Operation Maintenance ManualDocument27 pagesCat Forklift Nr3500 36v Schematic Operation Maintenance Manualmichellemacias080283gfz100% (52)

- Cat Forklift Ep5000 Ep6000 Operation Maintenance ManualDocument27 pagesCat Forklift Ep5000 Ep6000 Operation Maintenance Manualiancarrillo210188ris100% (41)

- Cat Forklift v70f v90f Vc110f Service ManualDocument27 pagesCat Forklift v70f v90f Vc110f Service Manualericbowman021099rgo100% (118)

- Cat Forklift Noh10n Service Operation Maintenance ManualDocument27 pagesCat Forklift Noh10n Service Operation Maintenance Manualpatrickheath070882eqa99% (126)

- Cat Forklift Nr4000 24v Operation Maintenance ManualDocument26 pagesCat Forklift Nr4000 24v Operation Maintenance Manualrodneycox060901aqk100% (128)

- Cat Forklift p8000 Schematic Service Operation Maintenance ManualDocument27 pagesCat Forklift p8000 Schematic Service Operation Maintenance Manualangelahorton220692gom100% (80)

- Cat Forklift v25d v30d v35d Schematic Service ManualDocument27 pagesCat Forklift v25d v30d v35d Schematic Service Manualjacquelinerodriguez060494sdt100% (134)

- Cat Forklift Nrm20k Service Operation Maintenance ManualDocument24 pagesCat Forklift Nrm20k Service Operation Maintenance Manualfrankstewart270488qny100% (82)

- Cat Forklift Nsp30 Nsp40 Service ManualDocument27 pagesCat Forklift Nsp30 Nsp40 Service Manualkristinjohnston120300qmf100% (122)

- Table of ContentDocument10 pagesTable of ContentShu Wen TeoNo ratings yet

- Cat Forklift Pd10000 Pd11000 Pd12000 Pd8000 Schematic Service Operation Maintenance ManualDocument27 pagesCat Forklift Pd10000 Pd11000 Pd12000 Pd8000 Schematic Service Operation Maintenance Manualmichellemacias080283gfz100% (49)

- Cat Forklift Et3500 Schematic Service Operation Maintenance ManualDocument27 pagesCat Forklift Et3500 Schematic Service Operation Maintenance Manualiancarrillo210188ris100% (46)

- Daewoo Matiz 0 ContentsDocument10 pagesDaewoo Matiz 0 ContentsDilip BanerjeeNo ratings yet

- Cat Forklift f40d P Schematic Service ManualDocument27 pagesCat Forklift f40d P Schematic Service Manualjacksonanderson110902fne100% (115)

- 321 Owner ManualDocument127 pages321 Owner ManualSeafar Yachting100% (1)

- Cat Forklift t30b Service and Parts ManualDocument27 pagesCat Forklift t30b Service and Parts Manualangelahorton220692gom100% (81)

- Cat Forklift Ec30k Schematic Service Operation Maintenance ManualDocument27 pagesCat Forklift Ec30k Schematic Service Operation Maintenance Manualsamanthamoyer170885csp100% (76)

- Abb Acs2000Document204 pagesAbb Acs2000gadgil_vikrant57% (7)

- PDFDocument21 pagesPDFdeion29No ratings yet

- Cat Forklift Gc25 Schematic Service ManualDocument27 pagesCat Forklift Gc25 Schematic Service Manualfrankstewart270488qny99% (80)

- Cat Forklift f25 f30 f35 Schematic Service ManualDocument27 pagesCat Forklift f25 f30 f35 Schematic Service Manualpatrickheath070882eqa100% (118)

- Cat Forklift Ec20ks Service ManualDocument27 pagesCat Forklift Ec20ks Service Manualsamanthamoyer170885csp100% (75)

- Cat Forklift v225b Operation Maintenance ManualDocument27 pagesCat Forklift v225b Operation Maintenance Manualjacquelinerodriguez060494sdt100% (123)

- Cat Forklift v165b v180b Operation Maintenance ManualDocument27 pagesCat Forklift v165b v180b Operation Maintenance Manualjacquelinerodriguez060494sdt100% (132)

- Cat Forklift Ep18acn Service Operation Maintenance ManualDocument27 pagesCat Forklift Ep18acn Service Operation Maintenance Manualmelissabell100788qae100% (122)

- Cat Forklift Nrr30 Nrr30p Nrr35 Nrr35p Nrr40 Nrr45p Service ManualDocument27 pagesCat Forklift Nrr30 Nrr30p Nrr35 Nrr35p Nrr40 Nrr45p Service Manualangelahorton220692gom100% (82)

- Cat Forklift v330b Service ManualDocument26 pagesCat Forklift v330b Service Manualashleymcneil190382yko98% (125)

- Cat Forklift v300c v330c Service ManualDocument27 pagesCat Forklift v300c v330c Service Manualashleymcneil190382yko100% (117)

- Cat Forklift Et4000 Schematic Service Operation Maintenance ManualDocument27 pagesCat Forklift Et4000 Schematic Service Operation Maintenance Manualjacksonanderson110902fne100% (116)

- Cat Forklift Dp40n1 Schematic Service Operation Maintenance ManualDocument28 pagesCat Forklift Dp40n1 Schematic Service Operation Maintenance Manualzolefiw100% (33)

- Cat Forklift v200b Operation Maintenance ManualDocument27 pagesCat Forklift v200b Operation Maintenance Manualethanmann190786ikm99% (82)

- Cat Forklift Gp40n1 Schematic Service Operation Maintenance ManualDocument27 pagesCat Forklift Gp40n1 Schematic Service Operation Maintenance Manuallarryowens100695djb98% (123)

- Cat Forklift Mc60d Sa Service ManualDocument27 pagesCat Forklift Mc60d Sa Service Manualpatrickheath070882eqa100% (129)

- Koomey S S ManualDocument95 pagesKoomey S S Manualasatyamanoj100% (2)

- Cat Forklift Gc15 Service ManualDocument27 pagesCat Forklift Gc15 Service Manualfrankstewart270488qny100% (79)

- Cat Forklift Nr4000p 36v Schematic Operation Maintenance ManualDocument27 pagesCat Forklift Nr4000p 36v Schematic Operation Maintenance Manualrodneycox060901aqk100% (120)

- LS-20S - SullairDocument102 pagesLS-20S - SullairWalter CarmonaNo ratings yet

- Cat Forklift Nrdr25 Service ManualDocument27 pagesCat Forklift Nrdr25 Service Manualfrankstewart270488qny100% (81)

- Cat Forklift Dp35 Service Operation Maintenance ManualDocument27 pagesCat Forklift Dp35 Service Operation Maintenance Manualsamanthamoyer170885csp99% (79)

- Cat Forklift m40d Service ManualDocument27 pagesCat Forklift m40d Service Manualpatrickheath070882eqa100% (121)

- Air Compressor Industrial: Preliminary Copy 2006Document80 pagesAir Compressor Industrial: Preliminary Copy 2006taufik100% (1)

- Cat Forklift p33000 p36000 Schematic Service Operation Maintenance ManualDocument27 pagesCat Forklift p33000 p36000 Schematic Service Operation Maintenance Manualangelahorton220692gom99% (83)

- Pneumatic ProjectDocument42 pagesPneumatic ProjectJeevaNo ratings yet

- Cat Forklift Nrdr30 Nrdr30p Service ManualDocument27 pagesCat Forklift Nrdr30 Nrdr30p Service Manualfrankstewart270488qny100% (84)

- Cat Forklift Ex5000 Operation Maintenance ManualDocument27 pagesCat Forklift Ex5000 Operation Maintenance Manualshannonnichols110597biy100% (21)

- Cat Forklift Ex5000 Operation Maintenance ManualDocument27 pagesCat Forklift Ex5000 Operation Maintenance Manualnancymendoza080295pjoNo ratings yet

- Cat Forklift Dp25 Schematic Service Operation Maintenance ManualDocument27 pagesCat Forklift Dp25 Schematic Service Operation Maintenance Manualiancarrillo210188ris100% (45)

- Rig Inspection OutlineDocument4 pagesRig Inspection OutlineAdolfo Angulo100% (1)

- LS20S 02250115-257Document102 pagesLS20S 02250115-257sledhead47No ratings yet

- Cat Forklift E8000 Schematic Service Operation Maintenance ManualDocument27 pagesCat Forklift E8000 Schematic Service Operation Maintenance Manualsamanthamoyer170885csp100% (77)

- Cat Forklift t25d Service ManualDocument27 pagesCat Forklift t25d Service Manualalexhughes210188sxi100% (49)

- Cat Forklift Dp70 Service ManualDocument27 pagesCat Forklift Dp70 Service Manualsamanthamoyer170885csp100% (78)

- Cat Forklift Nsv16n Nsv16ni Service Operation Maintenance ManualDocument27 pagesCat Forklift Nsv16n Nsv16ni Service Operation Maintenance Manualnancymendoza080295pjoNo ratings yet

- Cat Forklift Nsv16n Nsv16ni Service Operation Maintenance ManualDocument27 pagesCat Forklift Nsv16n Nsv16ni Service Operation Maintenance Manualshannonnichols110597biy95% (22)

- Jain MMS International Business Brochure-21x21cm-NewDocument4 pagesJain MMS International Business Brochure-21x21cm-NewSai Kishore TamminaNo ratings yet

- StarbucksDocument9 pagesStarbucksSai Kishore TamminaNo ratings yet

- Report WritingDocument19 pagesReport WritingSai Kishore TamminaNo ratings yet

- OB Report 2Document8 pagesOB Report 2Sai Kishore TamminaNo ratings yet

- Most Important Interview Questions & AnswersDocument2 pagesMost Important Interview Questions & AnswersSai Kishore TamminaNo ratings yet

- Tata Steel PPT FinalDocument12 pagesTata Steel PPT FinalSai Kishore TamminaNo ratings yet

- A 3 LogDocument1 pageA 3 LogSai Kishore TamminaNo ratings yet

- Hosts UmbrellaDocument1 pageHosts UmbrellaFabsor SoralNo ratings yet

- Hosts UmbrellaDocument1 pageHosts UmbrellaFabsor SoralNo ratings yet

- IECM User Manual PDFDocument583 pagesIECM User Manual PDFVishnu UppalakkalNo ratings yet

- Tim Sweeney - Google SearchDocument1 pageTim Sweeney - Google SearchPatton DerionNo ratings yet

- Time: 20 Minutes Date: 16-7-2022 FN Max Marks:10 Name: H.T. No: Sign. of An InvigilatorDocument4 pagesTime: 20 Minutes Date: 16-7-2022 FN Max Marks:10 Name: H.T. No: Sign. of An InvigilatorHOD CIVILNo ratings yet

- ZXSDR BS8900B Outdoor Cabinet Macro Base Station Product Description PDFDocument48 pagesZXSDR BS8900B Outdoor Cabinet Macro Base Station Product Description PDFK OuertaniNo ratings yet

- Risen Energy - Reference Projects - CODocument20 pagesRisen Energy - Reference Projects - COCesar Arturo SolerNo ratings yet

- Futronic MKll vs GMDSS comparisonDocument2 pagesFutronic MKll vs GMDSS comparisonViceNo ratings yet

- HCIA Routing&Switching: Huawei H12-211 Dumps Available Here atDocument4 pagesHCIA Routing&Switching: Huawei H12-211 Dumps Available Here atlandry kouadioNo ratings yet

- Siemens Gamesa Wind Turbine 4 X Platform Brochure enDocument4 pagesSiemens Gamesa Wind Turbine 4 X Platform Brochure enMendes NetoNo ratings yet

- Spartan - 6 Project Card: User ManualDocument81 pagesSpartan - 6 Project Card: User ManualunchalliNo ratings yet

- 0152 - Interational Confrence On 1200kV National Test StationDocument346 pages0152 - Interational Confrence On 1200kV National Test StationsreejitvpNo ratings yet

- Inspiron 15 3552 Laptop Service Manual en UsDocument68 pagesInspiron 15 3552 Laptop Service Manual en UsVladimir DelgadoNo ratings yet

- SEM Workshop Presentation 3Document28 pagesSEM Workshop Presentation 3felixkern1991No ratings yet

- MPH KPH Detailed InstructionsDocument10 pagesMPH KPH Detailed InstructionsRyan Emmanuel MangulabnanNo ratings yet

- 9 PMP - ProcurementDocument14 pages9 PMP - Procurementdrsuresh26No ratings yet

- Total Quality Management ManualDocument55 pagesTotal Quality Management ManualjaminkwadNo ratings yet

- SURVEYING WITH A TOTAL STATIONDocument65 pagesSURVEYING WITH A TOTAL STATIONBindeshwar YadavNo ratings yet

- DELTA Vector Control Drive C2000 Series - 20161025Document44 pagesDELTA Vector Control Drive C2000 Series - 20161025AnassErraouiNo ratings yet

- Erp KPL Jul16Document192 pagesErp KPL Jul16sriiyer85No ratings yet

- 1.4 NN MP Neuron ModelDocument20 pages1.4 NN MP Neuron ModelSatyam RanaNo ratings yet

- Ma. Sheryl Mangundayao: Career ObjectiveDocument2 pagesMa. Sheryl Mangundayao: Career ObjectiveMatheo MangundayaoNo ratings yet

- Software Engineering Unit 3Document103 pagesSoftware Engineering Unit 3navaneethNo ratings yet

- Gill - Stealth Racer - W017 - Instruction Manual - enDocument27 pagesGill - Stealth Racer - W017 - Instruction Manual - enalmoghaddamNo ratings yet

- Resume Amit BhagwatDocument5 pagesResume Amit Bhagwatabh93071046100% (3)

- Laura Cooper - ResumeDocument3 pagesLaura Cooper - ResumelaurahubbNo ratings yet

- Extended Reality XR Over 5G and 5G-Advanced New RaDocument7 pagesExtended Reality XR Over 5G and 5G-Advanced New Ra1RN20IS411No ratings yet

- Chopper Basics, Types, Applications - Power Electronics A To ZDocument7 pagesChopper Basics, Types, Applications - Power Electronics A To ZAtul KumbharNo ratings yet

- CS615 FINAL TERM SOLVED MCQs BY FAISALDocument65 pagesCS615 FINAL TERM SOLVED MCQs BY FAISALmirza adeelNo ratings yet

- Sample Test Cases For Testing Web and Desktop ApplicationsDocument7 pagesSample Test Cases For Testing Web and Desktop ApplicationsRohit Khurana100% (1)

- Vspace Pro 11 For Windows: (Version 11.1.1)Document20 pagesVspace Pro 11 For Windows: (Version 11.1.1)Bryan LimaNo ratings yet

- cpp5gs PDFDocument2 pagescpp5gs PDFmohammadNo ratings yet