Professional Documents

Culture Documents

Condenser Without Subcooling

Uploaded by

tatvaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Condenser Without Subcooling

Uploaded by

tatvaCopyright:

Available Formats

www.thechemicalengineering.blogspot.

in

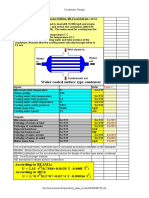

CONDENSER WITHOUT SUBCOOLING

Flow rate 0.1kmol/s of essentially pure acetone vapour

from the overhead of a distillation column is to be considered

without any condensate sub-cooling. The condensation is to

be taken place on the shell side of a horizontal shell and tube

heat exchanger against cooling water flowing in a 2 pass in

the tube side. The operating pressure of the condenser is 1.52

bar. At this pressure Acetone condenses at 67 0C. The cooling

water can be assumed to be at 25 0C and to be returned to the

cooling tower at 350C. Assume the fouling coefficient to be

1100 W/m2K and 5000 W/m2K for the shell side and tube side

respectively. Design the condenser for the above duty:

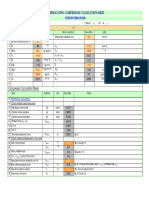

Given data,

Physical properties

Density, (Kg/m3)

Specific heat, Cp (J/Kg.K)

Viscosity, (Ns/m2)

Thermal Conductivity, K

(W/mK)

Latent heat, (J/Kg)

Molecular weight

Acetone (67 0C)

736

2320

0.213 x 10-3

0.137

Water (35 0C)

996

4180

0.797 x 10-3

0.618

494000

58.079

18

Step 1: Heat Balance

For Hot fluid,

Q = mh

mh = 0.1kmol/s = 0.1 x 58.079 kg/s

1

www.thechemicalengineering.blogspot.in

mh = 5.8 kg/s

Q = 5.8 x 494000

Q = 2865200 J/s

For cold fluid, Q = mcCpctc

tc = 35 25 = 10 0C

Now for finding mc ;

mc = Q / (Cpctc)

mc = 2865200 / (4180 x 10)

mc = 68.54 kg/s

Step 2: LMTD

www.thechemicalengineering.blogspot.in

LMTD (Logarithmic Mean Temperature Difference)

LMTD=

( T h 1T c2 )(T h 2T c1 )

ln

So,

(T h 1T c 2)

(T h 2T c 1)

LMTD=

( 6735 )(6725)

(6735)

ln

(6725)

LMTD = 36.77

LMTD correction factor: FT = 1 (since the process is

Isothermal)

Step 3: Routing

Hot fluid (Acetone) Shell side

Cold fluid (Cooling water) - Tube side

Step 4: Assuming the value of overall heat transfer

coefficient (U0)

The value of U0 can be taken from Perrys hand book (Page:

11-25)

For condensing vapour-liquid media

We take U0 = 100-200 Btu/0F.Ft2.h

Taking U0 = 150 Btu/0F.Ft2.h =150 x 5.678 W/m2.K

ie, U0 = 851.7 W/m2.K

Step 5: Overall Heat transfer area (A0)

3

www.thechemicalengineering.blogspot.in

A 0=

Q

U 0 . LMTD. FT

A 0=

2865200

851.7 x 36.77 x 1

A0 = 91.49 m2

Step 6: Tube size, Pitch and Head

2-tube pass heat exchanger

Reference: Perrys hand book (Page: 11-42, Table: 11-12)

Assuming tube size, 14 BWG:

Outside diameter (d0)

=0.01905m

Inside diameter (di) = 0.584 = 0.0148m

Thickness (t)

= 0.083 = 0.0021m

Assuming Tube Length (L) = 16 ft = 4.876m

Assuming Tube pitch, Triangular Tube pitch (Pt)

Pt = 1.25 d0

Pt = 1.25 x 0.01905 = 0.0238 m

Head: Assuming Floating Head

Step 7: Number of Tubes

n=

A0

d0 L

n=

91.49

x 0.01905 x 4.876

= 313.46

www.thechemicalengineering.blogspot.in

n 320

So corrected actual A0 value is,

A0,actual = nd0L

A0,actual = 320 x x 0.01905 x 4.876m= 93.38 m2

Similarly changed Actual U0,

U 0,actual =

Q

A 0,actual . L MTD . FT

U 0,actual =

2865200

93.38 x 36.77 x 1

= 834.46 W/m2.K

Step 8: Inside Heat transfer coefficient (hi)

Inside Tube, it is Cooling water. In order to calculate hi

physical properties of Cooling water have to be considered.

G=

mc

68.54 2 4

=

n 2 320 0.01482

d

24 i

= 2490.06 kg/m2.s

Reynolds number, Re = Gdi /

Re = 2490.06 x 0.0148 / 0.797 x 10-3

Re = 46239.50

Prandtl Number, Pr = Cp / K = 4180 x 0.797 x 10-3 / 0.618

Pr = 5.39

Friction factor, f = 0.25 (0.79 ln(Re) 1.64)-2

f = 0.25 (0.79 ln46239.50 1.64)-2

f = 5.33 x 10-3

5

www.thechemicalengineering.blogspot.in

f/2 = 2.66 x 10-3

Nu=

(f /2)( 1000) Pr

1

2

2

3

1+12.7 (f /2) ( Pr 1)

Taking K = 1

Nu=

( 2.66 x 103 ) ( 46239.501000 ) 5.39

1

3 2

2

3

1+12.7 (2.66 x 10 ) (5.39 1)

Nu = 275.07

hi = Nu.K / di

hi = 275.07 x 0.618 /0.0148

hi = 11486.03 W/m2 K

Step 9: Outside heat transfer coefficient (h0)

1

1 1 d 0 xw d 0

= +

+

+ Rd i+ Rd0

U 0 h 0 hi d i K d m

Where, xw = (do - di) / 2 = 0.0021

dw = (do + di) / 2 = 0.0169

Km = 16.262 W/mK

1

1

1

0.01905

0.0021

0.01905

1

=

h0 834.46 11486.03 0.0148 16.262 K 1905.:Outside heat transfer coefficient () 0.0169 11000

Solving,

h0 = 1537.32 W/m2 K

Step 10: Wall temperature and Film temperature

6

www.thechemicalengineering.blogspot.in

Tmean = 67 0C

tmean = (t1 +t2) / 2 = 30 0C

t meant w t w T mean

=

1

1 d0

h

hi d i

o

30t w

t 67

= w

1

0.01905

1

11486.03 0.0148

1537.32

Equating the above equation,

The wall temperature, tw = 35.47 0C

The film temperature,

tf=

t w+ tb

2

www.thechemicalengineering.blogspot.in

t f =

35.47+67) / 2

tf = 51.23 0C = 324.23 K

Properties of Acetone at tf = 324.23 K,

From Perrys Hand book,

Cf = 226.58J/kg K

= 0.23 x 10-3 Pa s

Kf = 146 x 10-3 W/m K

= 756.314 kg / m3

Step 11: Finding film heat transfer coefficient:

Re = 4 / f

For Horizontal Heat exchanger, = mh / 2L

For Vertical Heat exchanger, = mc / d0

So, = 5.8 / (2 x 4.876) = 0.5947

=

4 0.5947

0.26 103

Re = 9149.23

3

1.51 D g

Nu= 1 ( 0 2f ) 3

f

3

Nu=

1.51

0.019053 756.314 2 9.8 13

(

)

9149.232/ 3

(0.26 103 )2

Nu = 59.975

8

www.thechemicalengineering.blogspot.in

Now, hf = Nu.Kf / d0

hf = 59.575 x 0.146 / 0.01905

hf = 459.65 W/m2.K

Correspondingly changed Overall heat transfer coefficient U o1

is,

1

1 1 d0 xw d0

= +

+

+ Rdi + Rd 0

U o 1 h f h i di K d m

Substituting the values and solving the above equation,

Uo1 = 367.17 W/m2.K

Compare Uo1 and U0,actual

Here, U0,actual = 834.46 W/m2.K and Uo1 = 367.17 W/m2.K

Hence Uo1 U0,actual; the design needs recalculation

The recalculation is done by the following methods,

1) Changing the Length of the tube.

2) Changing the number of the tubes.

Step 12: Recalculating by changing length of tube:

Change L = 24 ft = 7.315 cm

When L changes hf also changes as follows,

1

3

3

h f ,old Lnew

=h f ,new Lold

So,

h f ,new =459.65

7.315

4.876

1

3

hf,new = 526.19 W/m2 K

9

www.thechemicalengineering.blogspot.in

When hf,new changes Overall heat transfer coefficient also

changes subsequently.(Uo,2)

1

1

1 d 0 xw d0

=

+

+

+ Rd i+ Rd 0

U o 2 h f , new hi d i K d m

Substituting values and solving the above equation,

Uo2 = 407.02 W/m2 K

Compare Uo2 and U0,actual

Hence UO2 U0,actual; the design needs recalculation

Step 13: Recalculating by changing number of tubes:

Changing n = 450 (assuming)

When n changes hi also changes.

To find new hi ,

G=

mc

68.54 2 4

=

n 2 450 0.01482

d

24 i

= 1770.713 kg/m2.s

Reynolds number, Re = Gdi /

Re = 1770.713 x 0.0148 / 0.797 x 10-3

Re = 33172.85

Prandtl Number, Pr = Cp / K = 4180 x 0.797 x 10-3 / 0.618

Pr = 5.39

Friction factor, f = 0.25 (0.79 ln(Re) 1.64)-2

f = 0.25 (0.79 ln(33172.85) 1.64)-2

10

www.thechemicalengineering.blogspot.in

f = 5.76 x 10-3

f/2 = 2.88 x 10-3

Nu=

(f /2)( 1000) Pr

1

2

2

3

1+12.7 (f /2) ( Pr 1)

Taking K = 1

Nu=

( 2.88 x 103 ) ( 33172.851000 ) 5.39

1

3 2

2

3

1+12.7 (2.88 x 10 ) (5.39 1)

Nu = 206.97

hi,new = Nu.K / di

hi,new = 206.97x 0.618 /0.0148

hi,new = 88642.51 W/m2 K

When hi changes, Film temperature have to be recalculated,

t meant w , new t w ,new T mean

=

1

1 d0

h o ,new

hi ,new d i

So,

30t w ,new

t

67

= w , new

1

0.01905

1

8642.51 0.0148

526.19

Equating the above equation,

The wall temperature, tw,new = 28.76 0C

The film temperature,

11

www.thechemicalengineering.blogspot.in

t f , new =

t w , new +t b

2

t f , new=

28.76+67) / 2

tf,new = 47.8 0C = 320.8K

Properties of Acetone at tf = 324.23 K,

From Perrys Hand book,

= 0.27 x 10-3 Pa s

Kf = 145 x 10-3 W/m K

= 760 kg / m3

Now find the subsequent film heat transfer coefficient (hf1);

Re = 4 / f

For Horizontal Heat exchanger, = mh / 2L

So, = 5.8 / (2 x 7.315) = 0.396

=

4 0.396

0.27 103

Re = 5873.26

3 2

1

1.51 D0 f g 3

Nu= 1 (

)

2f

3

Re

Nu=

1.51

0.019053 7602 9.8 13

(

)

5873.262/ 3

(0.27 103 )2

Nu = 68.01

Now, hf1 = Nu.Kf / d0

12

www.thechemicalengineering.blogspot.in

hf1 = 68.01 x 0.145 / 0.01905

hf1 = 517.68 W/m2.K

Correspondingly changed Overall heat transfer coefficient U o2

is,

1

1 1 d0 xw d0

= +

+

+ Rd i + Rd0

U o 2 h f 1 hi d i K d m

Substituting the values and solving the above equation,

Uo2 = 397.36 W/m2.K

Compare Uo2 and U0,actual

Hence Uo2 U0,actual; the design is correct.

Step 14: Shell side specifications:

Pt = 0.0238 m

Finding the Bundle diameter (Db)

For 2-tube pass,

Nt = 1266 + 73.58 C + 1.234 C2 0.0071 C3 0.0005 C4 ---(page 11-43, eqn:11-74b)

Neglecting the variable C4 term in above equation we get,

450 = 1266 + 73.58 C + 1.234 C2 0.0071 C3

Equation on solving gives, C = 222.68, -15.44, -33.41

But accuracy of C is -24 C 24

Hence, C = -15.44

13

www.thechemicalengineering.blogspot.in

C=0.75

Db

36

d0

So, Db = (36-15.44) 0.01905 / 0.75

Bundle diameter, Db= 0.522 m

For finding Shell inside diameter (DS)

DS = Db + 2(clearance)

Taking clearance be 0.029 m (for floating head)

DS = 0.522 + (2 x 0.029)

Shell inside diameter, DS = 0.58 m

Step 15: Pressure drop calculations:

1) Tube Side pressure drop:

P1 =

4 G2 fL

2

2 g d i

P1 =

4 1770.7132 5.76 103 7.315

2 9.8 9962 0.0148

P1 = 1.836 m/pass

Entrance and exit lose;

4 G2

P 2=

2 g 2

P2 =

4 1770.7132

2

2 9.8 996

P2 = 0.645 m/pass

14

www.thechemicalengineering.blogspot.in

P = P1 + P2 = (1.836 + 0.645) m/pass

P = 3.48 Pa/pass

Total number of pass is 2,

So, P = 3.48 x 2

P = 6.96 Pa

1) Shell side pressure drop:

Reference: Perrys hand book

1)

DS

[ 12 ( lc /D S ) ]

Pp

N C=

------- (eqn:11-7)

Taking lc = 0.25 (0r) (25%)

N C=

0.58

[12 ( 0.25 / 0.58 ) ]

0.0206

NC = 3.883

2)

S m=l s D sDotl +

Here

ls

D otlD o

P

'

= BS and

S m=0.59 0.580.522+

( P' Do )

------------(eqn: 11-10b)

P' =Pt

0.5220.01905

( 0.02380.01905 )

0.0238

Sm = 0.079 m2

From figure: 11-15(a); fK = 0.19

Pbk =

b f k W 2 N c w

b

S2m

0.14

( )

-------------(eqn:11-25)

Where, b = 2 x 10-3

Pbk =

2.0 103 0.18 5.8 2 3.883 0.27 104

736 0.079 2

0.213 103

Pbk = 0.010

15

0.14

www.thechemicalengineering.blogspot.in

N cw=

Then

0.8 l c 0.8 0.025

=

=9.7

Pp

0.00206

2 lc

Ds

1

()(1

2l c

2l

) 1 1 c

Ds

Ds

---------(eqn: 11-15)

cos

D2

Swg = s

4

1

()(1

0.5

0.58

0.5

0.5 2

) 1(1

)

0.58

0.58

cos1

0.582

S wg=

Swg = 0.109 m2

FC =

[ (

D 2 l c

D 2 l c

D 2l c

1

+2 s

sin s

2 cos1 s

Dotl

D otl

D otl

) (

)]

--------(eqn: 11-

8)

Here Dotl = Db

FC =

[ (

1

0.580.5

0.580.5

0.580.5

+2

sin

2 cos1

0.522

0.522

0.522

) (

FC = 0.195

S wt =

Nt

(1F c ) D20

8

S wt =

450

( 10.195 ) x 0.019052

8

-------------(eqn: 11-16)

Swt = 0.0519 m2

Sw = Swg - Swt

---------------(eqn: 11-14)

16

)]

www.thechemicalengineering.blogspot.in

Sw = 0.109 0.0519 = 0.0571 m2

Pwk =

b W 2 (2+0.6 N cw )

Sm Sw

Here, b =

Pwk =

----------------(eqn: 11-25)

4

5 10

4

2

5 10 5.8 [2+ ( 0.6 9.7 ) ]

0.0571 0.079 736

Pwk = 0.396

N b=

L2 l e

+1

ls

N b=

-------(eqn: 11-19)

7.315(2 x 0.25)

+1

0.573

Nb = 12.41 13

To find Rb (fig11-7)

Taking Nss/Nc = 0.1

Fbp =( DsD otl )

ls

Sm

---------------(eqn:11-11)

Fbp =( 0.580.522 )

Fbp = 0.42

Rb = 0.56

0.58

0.079

(from graph)

To find Rl (fig: 11-16)

S tb=b D 0 N t (1+ F C )

-------------------(eqn: 11-12)

Where b = 6.223 x 10-4

17

www.thechemicalengineering.blogspot.in

Stb = 6.223 x 10-4 x 0.01905 x 450 (1 + 0.195)

Stb = 6.37 m2

S sb =

Ds s b

2l

cos1 (1 c )

2

Ds

S sb =

----------------(eqn: 11-13)

0.58 x 0.029

0.5

cos1 (1

)

2

0.58

Ssb = 0.014 m2

S sb+ S tb

=0.25

Sm

S sb

=0.687

S sb+ S tb

Rl = 0.34

a.

(from graph)

Ps = ( N b 1 ) Pbk R b+ N b P wk Rl +2 Pbk Rb 1+

N cw

Nc

)]

---------(eqn:11-

25)

Ps = ( 9 0.01 0.56 ) + ( 8 0.396 0.34 ) +2 0.01 0.56 1+

Ps

= 0.2361 lbf/ft2

18

9.7

3.883

)]

www.thechemicalengineering.blogspot.in

19

You might also like

- Distillation Column: Major Equipment DesignDocument45 pagesDistillation Column: Major Equipment Designrubesh_rajaNo ratings yet

- Rotary Dryer DesignDocument43 pagesRotary Dryer DesignsasitharNo ratings yet

- Basic Heat Exchanger DesignDocument10 pagesBasic Heat Exchanger DesignKvspavan KumarNo ratings yet

- Greg Heat Loss To SurroundingDocument6 pagesGreg Heat Loss To SurroundingMarta BaptistaNo ratings yet

- Design of Heat ExchangersDocument23 pagesDesign of Heat ExchangersKhalid Turki100% (2)

- Gas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetDocument5 pagesGas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetNaqqash Sajid0% (2)

- Detailed energy balance of belt dryer and sterilizerDocument31 pagesDetailed energy balance of belt dryer and sterilizerkennethmsorianoNo ratings yet

- Spreadsheet Heat Loss from a PipeDocument1 pageSpreadsheet Heat Loss from a PipeJogender DhayalNo ratings yet

- Chapter7-Assignment and SolutionDocument9 pagesChapter7-Assignment and SolutionDavidNo ratings yet

- Line Sizing GuidelinesDocument2 pagesLine Sizing GuidelinesHarryBouterNo ratings yet

- Wet Air Properties Calculation Sheet: at Low PressureDocument2 pagesWet Air Properties Calculation Sheet: at Low Pressurezsmith0% (1)

- API 2000 guidance for inert gas blanketing of tanksDocument2 pagesAPI 2000 guidance for inert gas blanketing of tankssandeshNo ratings yet

- Control Valve Sizing - EnggcyclopediaDocument4 pagesControl Valve Sizing - EnggcyclopediaazitaggNo ratings yet

- Mixer (So3 Jadi H2so4)Document6 pagesMixer (So3 Jadi H2so4)Evi SiswantoNo ratings yet

- Pressuredrop Calculations by Kern Method SRRDocument18 pagesPressuredrop Calculations by Kern Method SRRrajeev50588No ratings yet

- Specification Sheet For Separator: Operating Conditions SketchDocument12 pagesSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- (Kern Metode) Design Data: Shell and Tube Heat Exchanger SizingDocument32 pages(Kern Metode) Design Data: Shell and Tube Heat Exchanger SizingLisa SeptidianaNo ratings yet

- Expt. 7 Finned TubeDocument6 pagesExpt. 7 Finned TubePradeep DiwakarNo ratings yet

- Desuperheater Boiler Feed Water RequirementDocument2 pagesDesuperheater Boiler Feed Water Requirementmehul10941No ratings yet

- L.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o oDocument9 pagesL.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o omedias indah monica sariNo ratings yet

- Calculating Gas Properties with Mixing Rule SpreadsheetDocument2 pagesCalculating Gas Properties with Mixing Rule Spreadsheetvictor javier nuñezNo ratings yet

- Gas Line Pressure LossesDocument4 pagesGas Line Pressure Lossesyash saragiyaNo ratings yet

- Muhammad Nauman Abbas: Equipment: Heat ExchangerDocument8 pagesMuhammad Nauman Abbas: Equipment: Heat ExchangerNauman KhanNo ratings yet

- SP SP VP V PR) : Velocity Pressure Method Calculation SheetDocument6 pagesSP SP VP V PR) : Velocity Pressure Method Calculation SheetAnkit LonareNo ratings yet

- Design: of Shell & Tube Heat ExchangerDocument27 pagesDesign: of Shell & Tube Heat ExchangerBalamurugan SakthivelNo ratings yet

- Evaporator Design CalculationDocument58 pagesEvaporator Design CalculationManoj BNo ratings yet

- Air Receiver Sizing CalculationDocument1 pageAir Receiver Sizing CalculationAziz HaqueNo ratings yet

- Shell Tube Heat Exchanger DesignDocument7 pagesShell Tube Heat Exchanger DesignAbhijeet JhaNo ratings yet

- Condenser DesignDocument2 pagesCondenser DesignRahul ChandrawarNo ratings yet

- BoilerCalcSteamPropDocument4 pagesBoilerCalcSteamPropMarc EdwardsNo ratings yet

- 4.1.3 Step-by-Step CalculationDocument11 pages4.1.3 Step-by-Step Calculationmohamed nizal100% (1)

- Shell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsDocument6 pagesShell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsrajachemNo ratings yet

- Vapor Line Sizing-Mpp6Document10 pagesVapor Line Sizing-Mpp6Nitin KurupNo ratings yet

- Stacks: Ammonia Injection: A Route To CleanDocument8 pagesStacks: Ammonia Injection: A Route To CleanZEN MA100% (1)

- Desuperheater Flow CalculationDocument1 pageDesuperheater Flow CalculationMechanicalVee18No ratings yet

- Condensate Line SizingDocument23 pagesCondensate Line SizingNirnay Patil100% (2)

- Perhitungan Dan Disain HeaterDocument19 pagesPerhitungan Dan Disain HeatersehonoNo ratings yet

- 4.4 Heat Ex ChangersDocument7 pages4.4 Heat Ex Changersmukesh kaushikNo ratings yet

- Mean Metal Temperature CalculationDocument28 pagesMean Metal Temperature CalculationAvijit DasguptaNo ratings yet

- Pipe Heat Transfer CalculationsDocument12 pagesPipe Heat Transfer CalculationsmansourotaibiNo ratings yet

- Heat Exchanger DesignDocument22 pagesHeat Exchanger DesignRupack HalderNo ratings yet

- Double Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterDocument3 pagesDouble Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterBagusRekaNo ratings yet

- Kalyani Steels Ltd. Media Consumption ListDocument14 pagesKalyani Steels Ltd. Media Consumption Listmadhusri002No ratings yet

- Design of Flash DrumDocument7 pagesDesign of Flash DrumJonathan OrNo ratings yet

- 03 HRR Flame Height Burning Duration Calculations Sup1Document5 pages03 HRR Flame Height Burning Duration Calculations Sup1Haris AbdulahNo ratings yet

- Pressure Drop CalculationDocument6 pagesPressure Drop CalculationNaveen Pete100% (1)

- Reciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsDocument9 pagesReciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsSlim Toumi0% (1)

- Sop For Fan SizingDocument3 pagesSop For Fan SizingHsein WangNo ratings yet

- EIND 3184 15 Liquid Flash Vessel SizingDocument20 pagesEIND 3184 15 Liquid Flash Vessel SizingzamijakaNo ratings yet

- Material Balance Ammonium SulphateDocument3 pagesMaterial Balance Ammonium SulphateAnkush singhNo ratings yet

- Evaporator (D-1) Design ExcelDocument7 pagesEvaporator (D-1) Design ExceldiRkdARyLNo ratings yet

- Test Gas CalculationDocument4 pagesTest Gas CalculationgrabettyNo ratings yet

- Achieveing Zero Liquid Discharge Through Mechanical Vapour Recompression-2015Document25 pagesAchieveing Zero Liquid Discharge Through Mechanical Vapour Recompression-2015ansarNo ratings yet

- LMTD Correction Factor ChartsDocument3 pagesLMTD Correction Factor ChartsjnmanivannanNo ratings yet

- Rotary Drier DesignDocument29 pagesRotary Drier DesignDharamvir Singh80% (5)

- Chlorine_Design-2520of-2520EquipmentsDocument23 pagesChlorine_Design-2520of-2520EquipmentsAditya KumarNo ratings yet

- 2 Design CalculationDocument22 pages2 Design CalculationLynn HuiNo ratings yet

- Capitulo 12 StoeckerDocument11 pagesCapitulo 12 StoeckerPaulo Azañero75% (4)

- MATERIAL Mechanical DesignDocument11 pagesMATERIAL Mechanical DesignanisNo ratings yet

- Laws of MotionDocument35 pagesLaws of MotiontatvaNo ratings yet

- Motion in A PlaneDocument15 pagesMotion in A PlanetatvaNo ratings yet

- Structure of AtomsDocument35 pagesStructure of AtomstatvaNo ratings yet

- Shell and Tube Heat ExchangerDocument18 pagesShell and Tube Heat ExchangertatvaNo ratings yet

- Motion in A Straight Line.Document53 pagesMotion in A Straight Line.tatvaNo ratings yet

- Some Basic Concepts of Chemistry.Document55 pagesSome Basic Concepts of Chemistry.tatvaNo ratings yet

- Condenser Without SubcoolingDocument19 pagesCondenser Without SubcoolingtatvaNo ratings yet

- Shell and Tube Heat ExchangerDocument18 pagesShell and Tube Heat ExchangertatvaNo ratings yet

- Units and Measurements.Document30 pagesUnits and Measurements.tatvaNo ratings yet

- Units & MeasurementsDocument30 pagesUnits & Measurementstatva0% (1)

- Allowable Stress & Factor of SafetyDocument2 pagesAllowable Stress & Factor of SafetySusan Mcknight100% (1)

- Structural AnalysisDocument3 pagesStructural Analysisashok PradhanNo ratings yet

- Module1 IntroductionDocument13 pagesModule1 Introductionmarlo ignacioNo ratings yet

- Noyan - Residual Stress - Measurement by Diffraction and InterpretationDocument286 pagesNoyan - Residual Stress - Measurement by Diffraction and InterpretationFrancesca SiracusaNo ratings yet

- Heat Requirement CalculationsDocument5 pagesHeat Requirement CalculationsTrishul Nath PallayNo ratings yet

- Assignment Unsteady StateDocument2 pagesAssignment Unsteady StateChirag JainNo ratings yet

- Energies: Coupled Fluid-Thermal Analysis For Induction Motors With Broken Bars Operating Under The Rated LoadDocument17 pagesEnergies: Coupled Fluid-Thermal Analysis For Induction Motors With Broken Bars Operating Under The Rated LoadPiyush AgrawalNo ratings yet

- Investigation On Bolt Tension of Flanged Pipe Joint Subjected To BendingDocument8 pagesInvestigation On Bolt Tension of Flanged Pipe Joint Subjected To BendingjpkedahNo ratings yet

- Projectile Motion Senior High School Physics: Lech Jedral 2006Document32 pagesProjectile Motion Senior High School Physics: Lech Jedral 2006Ciara Adrianne Tiongzon - ReyesNo ratings yet

- Introduction to Quiz: Aerodynamics: = 8m/s V ρ = 1.225kg/mDocument4 pagesIntroduction to Quiz: Aerodynamics: = 8m/s V ρ = 1.225kg/mDaniel Alejandro Hernandez ToldoNo ratings yet

- Tuned Mass Damper On Reinforced Concrete Slab WithDocument10 pagesTuned Mass Damper On Reinforced Concrete Slab WithMuhammad Wazim AkramNo ratings yet

- Geneva MachanismDocument6 pagesGeneva MachanismjimshNo ratings yet

- (IISc Lecture Notes Series, V. 3) M L Munjal - Noise and Vibration ControlDocument294 pages(IISc Lecture Notes Series, V. 3) M L Munjal - Noise and Vibration ControlAvinash ReddyNo ratings yet

- Tasses,: Equivalent SprlngsDocument27 pagesTasses,: Equivalent SprlngsAlex SilvaNo ratings yet

- Physics TermsDocument7 pagesPhysics TermsMariaEzzaSyUyNo ratings yet

- Introduction To Using ANSYS FLUENTDocument16 pagesIntroduction To Using ANSYS FLUENTkelvin felix garciaNo ratings yet

- Introduction To Cam Design: Source: Norton, Design of MachineryDocument34 pagesIntroduction To Cam Design: Source: Norton, Design of MachinerySankar SubbiahNo ratings yet

- (195 Marks) : (1 Mark)Document44 pages(195 Marks) : (1 Mark)Manav NairNo ratings yet

- Mechanics of Materials: Symmetric Bending of Beams ExplainedDocument71 pagesMechanics of Materials: Symmetric Bending of Beams ExplainedGuillermo TubillaNo ratings yet

- M2-CV-RC-D-005 (R1)Document22 pagesM2-CV-RC-D-005 (R1)ksshashidharNo ratings yet

- Cho and Seban - 1969Document6 pagesCho and Seban - 1969Sachin ZanjeNo ratings yet

- Heat Transfer Fundamentals and ApplicationsDocument72 pagesHeat Transfer Fundamentals and ApplicationsDEEPMALA KUMARINo ratings yet

- Modeling of Post-Tensioned Rocking Bridge ColumnsDocument101 pagesModeling of Post-Tensioned Rocking Bridge ColumnsChangmushiNo ratings yet

- Chapter 10 ModifiedDocument5 pagesChapter 10 Modifiedapi-248642018No ratings yet

- BUSHP HM WorksDocument6 pagesBUSHP HM WorksPrashant GautamNo ratings yet

- Force SystemDocument15 pagesForce SystemSajjad LordNo ratings yet

- Force ExerciseDocument2 pagesForce ExerciseLiuJiewChuanNo ratings yet

- RTD 1016-1 (2017) Version 2.1 Guidelines For Nonlinear Finite Element Analysis of Concrete StructuresDocument69 pagesRTD 1016-1 (2017) Version 2.1 Guidelines For Nonlinear Finite Element Analysis of Concrete StructuresGeorgia SkroumpelouNo ratings yet

- Thus, The Velocity of The Exhaust Gas Is: MethaneDocument19 pagesThus, The Velocity of The Exhaust Gas Is: Methaneyogeshkumar3089_8250No ratings yet

- Car Following ModelsDocument15 pagesCar Following ModelsswarupmandalNo ratings yet