Professional Documents

Culture Documents

Roles and Responsibilitiess

Uploaded by

Muthuraj740 ratings0% found this document useful (0 votes)

28 views2 pagesRoles and responsibilities

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRoles and responsibilities

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

28 views2 pagesRoles and Responsibilitiess

Uploaded by

Muthuraj74Roles and responsibilities

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

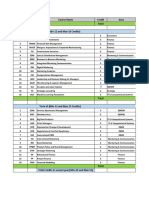

Roles and Responsibilities of Design Engineer

1. Understanding customer requirement, tendering documents, development of

primary engineering models based on order.

2. GIS, Substation design, Microsoft Office, CAD

3. Usage of 2D and 3D CAD tools. AUTODESK, ProE, Solid works.

4. Creation, control, and maintenance of release packages and design history files.

5. Data management and release process activities

6. Develops manufacturing drawings in accordance with applicable standards

7. BOM release

8. Handle technical issues on the product as much as possible independently and

in close co-ordination with the suppliers and factory.

9. Independently conduct endurance/ validation tests on the product as per defined

procedure, analyze results and report findings

10. Keep all related documents up to date with latest revision

11.Assist engineering staff in the design and development of components. Interface

with engineering staff effectively to ensure the form, fit and function of designs

while also working with fabrication to ensure cost effectiveness and

manufacturability of designs.

12. Collaborate with the engineering staff to produce design sketches and drawings

in accordance with applicable standards. Mentioning of welding symbols and

tolerances into design drawings accurately

13. Originate and/or review structural analyses, prototype test processes,

operations procedures, and reports using computer aided engineering (CAE)

and appropriate computer software.

14. Review and verify design drawings and other technical documentation prepared

by others to ensure correctness and accuracy in form, fit and function.

15. Design and optimization of mechanical components

16. Interfaces with outside vendors for component selection, manufacturing, and

assembly.

17. Read and interpret blueprints, technical drawings, schematics, and computer

generated reports.

18. Confer with system engineers and other personnel to implement operating

procedures, resolve system malfunctions, and provide technical information.

19. Research and analyze customer design proposals, specifications, manuals, and

other data to evaluate the feasibility, cost, and maintenance requirements of

designs or applications.

20. Specify system components or direct modification of products to ensure

conformance with engineering design and performance specifications.

21. Support to determine root cause analysis and testing activities

Roles and Responsibilities of Quality Engineer

Job Description

1. The Quality Engineer will be the primary contact between Quality Assurance

and Manufacturing.

2. This person will provide QA support to Operations, in ensuring goals and

objectives are achieved for the company

Role & Responsibilities

1. Organizing the daily work schedule of Quality technicians to ensure agreed

metrics are achieved.

2. Manage training plans & development requirements for all QC staff.

3. Take a Hands On approach to In Process Inspection of new Medical Device

Projects ensuring inspections & manufacturing documentation is completed

appropriately.

4. Liaise with Quality Manager in relation to all aspects of internal and external

Audits.

5. Be capable of making decisions on Product Quality.

6. Drive continuous quality improvement in conjunction with engineering and

operations

7. Quality control assurance of Vendor, Manufacturing , process, dispatch, site

erection and commissioning.

8. Perform all daily inspection and test of the scope and character necessary to

achieve the quality of construction required in the drawings and specifications

for all works under the contract performed ON or OFF site.

9. Cary out inspection and checking for all quality related procedures in the site

and ensures activity at site are as per approved method statement and

inspection test plan.

10. Coordinate with the consultants representative and Site En-charge for

inspection and meeting about quality problems including closure of NonCompliance Report.

11.Taking care of QA/QC documents of the entire project including certificates,

calibration, test results, inspection requests, non-compliance reports and site

instruction/observations, permanent materials delivered and other QA/QC

documents. Responsible for closure of Non-conformance, NCR and Site

Instruction

You might also like

- Lunar RoverDocument6 pagesLunar RoverMuthuraj74No ratings yet

- Arc InternalDocument17 pagesArc InternalMuthuraj74No ratings yet

- EDS 06-0013 Grid and Primary Substation Earthing DesignDocument59 pagesEDS 06-0013 Grid and Primary Substation Earthing DesignShiva Naga KumarNo ratings yet

- Michael Porter - New Global Strategies For Competitive Advantage PDFDocument11 pagesMichael Porter - New Global Strategies For Competitive Advantage PDFVikrant PareekNo ratings yet

- Transformer Site TestDocument2 pagesTransformer Site TestMuthuraj74No ratings yet

- Distribution TransformersDocument8 pagesDistribution TransformerskittieyNo ratings yet

- Modular Shielded Room: Main Advantages of Siepel TechnologyDocument2 pagesModular Shielded Room: Main Advantages of Siepel TechnologyMuthuraj74No ratings yet

- Very Fast Transients in Gas Insulated SubstationDocument45 pagesVery Fast Transients in Gas Insulated SubstationMuthuraj74No ratings yet

- Spc-004-Leak Testing of Vacuum VesselsDocument10 pagesSpc-004-Leak Testing of Vacuum VesselsMuthuraj74No ratings yet

- Double Shielded PD Lab Attenuates Noise 57dBDocument1 pageDouble Shielded PD Lab Attenuates Noise 57dBMuthuraj74No ratings yet

- Mobile TestDocument5 pagesMobile TestMuthuraj74No ratings yet

- Protection and Control Switchgear - Schneider10Document10 pagesProtection and Control Switchgear - Schneider10Muthuraj74No ratings yet

- Maintenance of Circuit-Breaker Drive Mechanism ELK SN / BBC: SF Gas-Insulated SwitchgearDocument2 pagesMaintenance of Circuit-Breaker Drive Mechanism ELK SN / BBC: SF Gas-Insulated SwitchgearMuthuraj74No ratings yet

- Aluminim WPSDocument4 pagesAluminim WPSMuthuraj74No ratings yet

- Partial Discharge TheFutureDocument5 pagesPartial Discharge TheFutureMuthuraj74No ratings yet

- A Synthetic Test Circuit For Current Switching Tests of HVDC Circuit BreakersDocument5 pagesA Synthetic Test Circuit For Current Switching Tests of HVDC Circuit BreakersMuthuraj74No ratings yet

- The Welding of Aluminium - Mig & Tig Fusion - Pocket Guide PDFDocument36 pagesThe Welding of Aluminium - Mig & Tig Fusion - Pocket Guide PDFrogersampaiocostaNo ratings yet

- Aluminim WPSDocument4 pagesAluminim WPSMuthuraj74No ratings yet

- Article - Benchmarking Understanding The BasicsDocument4 pagesArticle - Benchmarking Understanding The Basicskary290790No ratings yet

- New 550-kV Gas-Insulated Switchgear: Hirohiko Yatsuzuka Manabu Takamoto Masaharu MatsuyamaDocument5 pagesNew 550-kV Gas-Insulated Switchgear: Hirohiko Yatsuzuka Manabu Takamoto Masaharu MatsuyamaMuthuraj74No ratings yet

- Powerline BookDocument15 pagesPowerline BookMuthuraj74No ratings yet

- Interlock RequirementsDocument2 pagesInterlock RequirementsMuthuraj74No ratings yet

- Interruption Techniques2Document20 pagesInterruption Techniques2Muthuraj74No ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- MR - Shahabb Elk 3Document29 pagesMR - Shahabb Elk 3Muthuraj74No ratings yet

- A Wide Band High Accuracy Sf6Document9 pagesA Wide Band High Accuracy Sf6Muthuraj74No ratings yet

- First Below Ground Traction at Church Road Anook K GuptaDocument49 pagesFirst Below Ground Traction at Church Road Anook K GuptaMuthuraj74No ratings yet

- 34 108 1996Document6 pages34 108 1996Muthuraj74No ratings yet

- Zero Flux CTDocument8 pagesZero Flux CT김영우No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Foreign Currency Revaluation Configuration - SAP Q&ADocument12 pagesForeign Currency Revaluation Configuration - SAP Q&ATDAMU88No ratings yet

- Finance, Marketing & HR courses in MBA 2nd yearDocument28 pagesFinance, Marketing & HR courses in MBA 2nd yearGaneshRathodNo ratings yet

- Import Direct From ChinaDocument29 pagesImport Direct From Chinagrncher100% (2)

- Fuel Supply Agreement - LNG - UI 2021 (407769612.1)Document54 pagesFuel Supply Agreement - LNG - UI 2021 (407769612.1)Edmund KhoveyNo ratings yet

- Business Finance: Introduction To Financial ManagementDocument9 pagesBusiness Finance: Introduction To Financial ManagementAprhile Darlene ObagNo ratings yet

- Financial Planning & ForecastingDocument44 pagesFinancial Planning & Forecastingnageshalways503275% (4)

- Free SWOT Analysis Template MacDocument1 pageFree SWOT Analysis Template MacGirish Des ManchandaNo ratings yet

- Case 3 4Document2 pagesCase 3 4Salvie Angela Clarette UtanaNo ratings yet

- OMB Memo Re: Reducing Regulatory Burden For Federal AgenciesDocument12 pagesOMB Memo Re: Reducing Regulatory Burden For Federal AgenciesFedSmith Inc.100% (1)

- Kellogg's Case Study AnalysisDocument3 pagesKellogg's Case Study Analysissalil1235667% (3)

- Mini Project II Instructions Segmentation and RegressionDocument6 pagesMini Project II Instructions Segmentation and RegressionSyed Anns Ali0% (1)

- A Rib A Supplier EnablementDocument2 pagesA Rib A Supplier Enablementeternal_rhymes6972No ratings yet

- Application OF THE Balanced Scorecard IN Strategy Implementation by Unilever Tea Kenya LimitedDocument50 pagesApplication OF THE Balanced Scorecard IN Strategy Implementation by Unilever Tea Kenya LimitedShokry AminNo ratings yet

- Cestui Que Vie TERMINATION THE PERMANENT ESCAPE FROM SLAVERYDocument1 pageCestui Que Vie TERMINATION THE PERMANENT ESCAPE FROM SLAVERYQiydar The KingNo ratings yet

- Kavanagh4e PPT01Document24 pagesKavanagh4e PPT01colin0% (1)

- OpenText Vendor Invoice Management For SAP Solutions 7.5 SP4 - Administration Guide English (VIM070500-04-AGD-En-2)Document228 pagesOpenText Vendor Invoice Management For SAP Solutions 7.5 SP4 - Administration Guide English (VIM070500-04-AGD-En-2)Goran Đurđić Đuka100% (3)

- Dabur Sales ManagementDocument20 pagesDabur Sales Managementrohitpatil222No ratings yet

- Responsibility Centers Management AccountingDocument3 pagesResponsibility Centers Management AccountingRATHER ASIFNo ratings yet

- Caso Carvajal S.A.Document22 pagesCaso Carvajal S.A.Indrenetk Leon100% (1)

- Week 6-7 Let's Analyze Acc213Document5 pagesWeek 6-7 Let's Analyze Acc213Swetzi CzeshNo ratings yet

- SM AssignmentDocument17 pagesSM AssignmentElvinNo ratings yet

- Tsigemariam BelaynehDocument96 pagesTsigemariam BelaynehadamNo ratings yet

- Retail Management: A Strategic Approach: 11th EditionDocument9 pagesRetail Management: A Strategic Approach: 11th EditionMohamed El KadyNo ratings yet

- Brand Book AmChamDocument16 pagesBrand Book AmChamDraganescu OanaNo ratings yet

- Eatest Financial AssetDocument216 pagesEatest Financial AssetsssNo ratings yet

- Ds Netsuite Data CenterDocument4 pagesDs Netsuite Data CenterPABLONo ratings yet

- Rsik ManagementDocument221 pagesRsik ManagementNirmal ShresthaNo ratings yet

- The Law and Business Administration in Canada 14th Edition SolutionDocument32 pagesThe Law and Business Administration in Canada 14th Edition SolutiontestbanklooNo ratings yet

- Gig1003 Group 18 Team 2 Report EssayDocument3 pagesGig1003 Group 18 Team 2 Report EssayamishaNo ratings yet

- BRM Research Waseem Jaffri and Urooba GhaniDocument11 pagesBRM Research Waseem Jaffri and Urooba GhaniSyed Waseem Abbas Shah JaffriNo ratings yet