Professional Documents

Culture Documents

Fuel Tank Mounting Kit 704282 - 55879-2-IM

Uploaded by

Nishanth0 ratings0% found this document useful (0 votes)

134 views4 pagesOriginal Title

Fuel Tank Mounting Kit 704282_55879-2-IM

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

134 views4 pagesFuel Tank Mounting Kit 704282 - 55879-2-IM

Uploaded by

NishanthCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

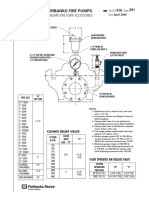

FUEL TANK MOUNTING INSTRUCTIONS

NOTE: These installation instructions are only for fuel tank bracket kits built after January 2014

FACTORY KIT 704282

For 30 and 50 Gallon - 18'' Diameter Tanks

Installed onto Trailers with Standard Cross Member Spacing

Fuel tank mounting kit 704282 contains components to install either a 30 or 50 gallon, 18'' diameter

fuel tank onto a typical trailer with standard cross member spacing of 6'', 8'', 10'' or 12''.

This kit is specifically designed to install a 30 or 50 gallon 18'' diameter fuel tank in a hanging position

under a trailer attached to the floor cross members. Substitutions are not acceptable!

KIT COMPONENTS

Item

Part Number

Description

Qty.

1.

99-7832

Bracket, hanger mounting

2.

98-9143

Hanger, assembly

3.

98-9144

Strap, assy.

4.

33-4479

Pad, rubber self-adhesive

5.

55-2252

Screw-HH, -13 x 1.5

6.

55-5270

Washer-flat,

20

7.

55-3686

Nut-hexstop,

12

8.

55-1469

Screw, 3/8-16

9.

55-402

Flat washer, 3/8

16

10.

55-5078

Nut-hexstop, 3/8-16

11.

TK 55879-2-IM

Installation Instructions

TK 55879-2-IM (Rev. 3, 03/15) Copyright 2014 Thermo King Corp. Minneapolis, MN, USA

IMPORTANT FUEL TANK INSTALLATION INFORMATION

DANGER: An improperly installed fuel tank could lead to serious injury or death! Consult your trailer

manufacturer for specific details on proper fuel tank installation and recommendations.

CAUTION: The trailers cross members must be strong enough to safely support the combined weight

of the mounting hardware, fuel tank and fuel.

Fuel Tank Capacity

Combined Total Weight

30 Gallon Diesel

126 KG (278 lbs.)

50 Gallon Diesel

188 KG (415 lbs.)

A. Fuel Tank Position

Thermo King recommends the fuel tank be mounted 203.2 mm (8.00 in.) when possible under

the trailer as shown. Otherwise, the OEM or installer is responsible to ensure the fuel tank

position meets or exceeds DOT or Federal Highway regulations, when applicable.

B. Tank Strap Position

30 Gallon Tanks - Fuel tank straps must be positioned 597 mm (23.50 in.) apart.

50 Gallon Tanks - Fuel tank straps must be positioned 673 mm (26.5 in.) apart as shown.

C. Rubber Strips and Pads

Rubber strips must be properly installed on both the mounting bands and the rubber pads must

be installed onto the underside of the hanger assemblies to prevent metal to aluminum contact.

D. Mounting Hardware

Grade 5 mounting hardware is supplied. Substitutions are not acceptable!

All mounting hardware must be properly installed and torqued to the specifications listed.

E. Fuel Pump Mounting Hole Location (Precedent Units Only)

The fuel pump mounting holes should be located directly above the fuel tank and in an area

that protects it from road debris and allows for routine filter removal.

Tank shown for illustration purposes only.

Your tank may vary.

FUEL TANK INSTALLATION

NOTE: Location of mounting holes may change if other trailer options are added.

1. Locate the existing sets of 10.3 mm (.406'' dia.) pre-punched holes in the cross members

(if applicable). New holes may need to be drilled to accommodate tank location. See note above.

2. Align the two holes of each hanger bracket with the holes in the cross member and secure with

two, 3/8-16 screws, washers and locking nuts. Torque the hardware to 42 Nm (31 ft-lb).

3. Install each hanger assembly facing each other as shown onto the hanger brackets with 1/2-13

screws, washers and locking nuts. Torque the hardware to 81 to 88 Nm (60-65 ft-lb).

4. Install a self-adhesive rubber pad to the underside of each hanger assembly.

5. Loosely install the tank straps t-bolts onto the hanger assemblies with 1/2'' washers and locking

nuts. Verify the rubber strips are properly installed on the mounting bands.

6. Install the fuel tank into the straps with the tank positioned vertically within plus or minus 5 degrees

and tighten the tank straps to 48 Nm (35 ft-lb).

IMPORTANT: The fuel tank filler must be positioned vertically within plus or minus 5 degrees for the

Ultrasonic Fuel Level Sensor (UFLS) to read fuel level accurately.

Tank shown for illustration purposes only.

Your tank may vary.

Hardware Size

Torque Specifications

3/8-16 Grade 5

42 Nm (31 ft-lb.)

1/2 -13 Grade 5

81 to 88 Nm (60-65 ft-lb)

1/2'' T-bolts

48 Nm (35 ft-lb.)

FUEL PUMP & FUEL LINE INSTALLATION - PRECEDENT UNITS ONLY

Refer to the model specific Precedent Installation Manuals regarding the installation of the electric fuel

pump, fuel pump harness and fuel line connections.

FUEL LINE INSTALLATION - SB TRAILER UNITS ONLY

DANGER: Leaking fuel lines could cause a fire resulting in death or serious injury! All fuel lines

must be tight and leak free!

DANGER: Do not route fuel lines with battery cables or electrical wires, as this could cause a fire!

1. Fuel lines should be routed in a protective housing with no kinks or sharp bends.

2. Rubber grommets must be used when routing fuel lines through sheet metal.

3. Remove the protective plugs from each of the fuel pick up tubes on the fuel tank and install fuel

line fittings.

4. From the unit, route the fuel supply line to the fuel tank:

Cut the end of the nylon fuel supply line at a 45 degree angle and insert into one of the fuel line

fittings on the tank.

Feed the fuel line down into the tank until it hits bottom. then pull it back up 25 mm (1.00 in.).

Tighten the fuel line fitting securely.

5. From the unit, route the fuel return line to the fuel tank:

Insert the fuel line into the other fuel line fitting. Tighten the fuel line fitting securely.

6. Remove the plastic cap from the fuel vent and point it towards the rear of the trailer.

IMPORTANT: The factory installed fuel tank air vent must be in place and functional for the Thermo King

units fuel system to operate correctly and for the fuel tank to remain in compliance with Federal Motor

Carrier Safety Administration specifications (title 49, paragraph 393.67). A plugged or restricted fuel tank air

vent can result in premature damage to the fuel pump and could also cause severe damage to the fuel tank.

NEVER remove or install any other component in place of the fuel tank air vent.

7. Operate the unit and check all fuel line fittings for leaks.

SB fuel line connections shown.

Precedent units require an electric fuel

pump installed directly above the fuel

tank. Refer to your Precedent Installation

Manual for details.

You might also like

- Trane Twa Split CtenDocument89 pagesTrane Twa Split CtenAJ OMNo ratings yet

- Goodman ARUF Air Handler Installation InstructionsDocument14 pagesGoodman ARUF Air Handler Installation InstructionsJavier Gonzalez BarronNo ratings yet

- Ac Compressor Oil CheckingDocument3 pagesAc Compressor Oil CheckingToua YajNo ratings yet

- Service Report MR - AcangDocument5 pagesService Report MR - Acangboy qsiNo ratings yet

- Carrier PDFDocument49 pagesCarrier PDFSijo JoyNo ratings yet

- Operating Instructions PC Diagnostics V2.08Document36 pagesOperating Instructions PC Diagnostics V2.08gerlinde-meyerNo ratings yet

- Culligan Water Conditioner 1994-1998Document17 pagesCulligan Water Conditioner 1994-1998Jay SommersNo ratings yet

- Acson Digital Variable Multi Units Application ManualDocument116 pagesAcson Digital Variable Multi Units Application ManualDota NgNo ratings yet

- WSC and WMC Centrifugal Chillers Reassembly of Knockdown ShipmentsDocument50 pagesWSC and WMC Centrifugal Chillers Reassembly of Knockdown ShipmentsGiang Nguyễn HươngNo ratings yet

- Pioneer Series Digital Scroll Variable Refrigerant Flow (VRF) System Spare Parts & Exploded ViewsDocument55 pagesPioneer Series Digital Scroll Variable Refrigerant Flow (VRF) System Spare Parts & Exploded ViewsArshad Mahmood100% (1)

- 38CKC Product DataDocument26 pages38CKC Product DataCarlos Enrique Godoy Sifontes0% (1)

- 17 - 12 - 7) Alarm Code Ver VDocument8 pages17 - 12 - 7) Alarm Code Ver VAstin R. MartinezNo ratings yet

- Compressor ClutchDocument6 pagesCompressor Clutchbobbynicky007100% (1)

- VCV WesperDocument12 pagesVCV Wesperciperu55No ratings yet

- Ice Qube ManualDocument16 pagesIce Qube ManualGiorgio FerNo ratings yet

- 19XR, XRV Product Data PDFDocument56 pages19XR, XRV Product Data PDFCristian Ramos PNo ratings yet

- INNOVAIR VM Blutec Condenser Service Manual 2nd GenDocument46 pagesINNOVAIR VM Blutec Condenser Service Manual 2nd GenEdgard Martin Mejia Solano100% (1)

- #0WSMZ120: Workshop ManualDocument74 pages#0WSMZ120: Workshop ManualΣτάθης ΣαλNo ratings yet

- Webasto Manual IndepthDocument36 pagesWebasto Manual IndepthbarnumlivesNo ratings yet

- 30XA Product Data PDFDocument36 pages30XA Product Data PDFanoopkumar1231150100% (2)

- Thermo TopDocument24 pagesThermo TopziroopNo ratings yet

- Install Air Top 3500Document30 pagesInstall Air Top 3500Marjan DraškovićNo ratings yet

- Engine Cooling SystemDocument68 pagesEngine Cooling SystemGreg Hanna0% (1)

- Split Type Aircon Installation ManualDocument30 pagesSplit Type Aircon Installation Manualfreddie reyesNo ratings yet

- Installation Operation Maintenance: Air-Cooled Scroll ChillersDocument276 pagesInstallation Operation Maintenance: Air-Cooled Scroll ChillersCésarVanegasNo ratings yet

- STAL Miniplant Blocks PDFDocument65 pagesSTAL Miniplant Blocks PDFzikhail93100% (2)

- Daikin Mcquay Pathfinder™ Air Cooled Chiller Screw Compressor 3 Circuit Unit Revision 00 (Code 62)Document79 pagesDaikin Mcquay Pathfinder™ Air Cooled Chiller Screw Compressor 3 Circuit Unit Revision 00 (Code 62)Rafael Escalona100% (1)

- W203 Crankshaft Position Sensor RemovalDocument2 pagesW203 Crankshaft Position Sensor RemovalCraig O'malleyNo ratings yet

- Manual AC CompressorDocument56 pagesManual AC CompressorGerman Diego Salazar RosasNo ratings yet

- Aksesoris PumpDocument10 pagesAksesoris PumpDido AlexanNo ratings yet

- Carrier Transicold TECHLINE July2012Document4 pagesCarrier Transicold TECHLINE July2012Carlitos Enrique Corpus PonceNo ratings yet

- Copeland ZR125KC-TF5-950 Scroll Compressor - Carrier HVACDocument3 pagesCopeland ZR125KC-TF5-950 Scroll Compressor - Carrier HVACjacc42No ratings yet

- Webasto Van Heaters Guide 2013Document21 pagesWebasto Van Heaters Guide 2013David ButlerNo ratings yet

- Manual Tehnic START and PLUS EnglishDocument28 pagesManual Tehnic START and PLUS EnglishiuliNo ratings yet

- Canatal M-Series IOMDocument47 pagesCanatal M-Series IOMNurmansyah Dwi CahyonoNo ratings yet

- 6+Engine+Cooling+1 25L PDFDocument28 pages6+Engine+Cooling+1 25L PDFEko SulistyoNo ratings yet

- Air ConditioningDocument41 pagesAir Conditioningjulio73cesarNo ratings yet

- Uaast 3 MDocument84 pagesUaast 3 Mamon hoNo ratings yet

- Split System Air Conditioners: Inverter SeriesDocument428 pagesSplit System Air Conditioners: Inverter SeriesstevenloNo ratings yet

- Cars Refrigerant Oil Filling QuantitiesDocument92 pagesCars Refrigerant Oil Filling QuantitiesMahmoud MohamedNo ratings yet

- Marine Galley PDFDocument218 pagesMarine Galley PDFclodNo ratings yet

- Fire Safety Maintenance Checklist: Daily Checks (Not Normally Recorded) Yes No N/A CommentsDocument3 pagesFire Safety Maintenance Checklist: Daily Checks (Not Normally Recorded) Yes No N/A CommentshNo ratings yet

- Bw111a Engineroom and Pumproom Fixed SystemDocument6 pagesBw111a Engineroom and Pumproom Fixed SystemMihaela CimpeanuNo ratings yet

- Flotronic II 30gn040420 PDFDocument72 pagesFlotronic II 30gn040420 PDFleung ka kitNo ratings yet

- SKM and OKM User ManualDocument36 pagesSKM and OKM User ManualOutlawRNo ratings yet

- Ac DaikinDocument240 pagesAc DaikinSyifa Anggraeni100% (1)

- 16tj 1pdDocument32 pages16tj 1pd1940LaSalleNo ratings yet

- INSPECT AND SERVICE COOLING SYSTEMS - QuizDocument8 pagesINSPECT AND SERVICE COOLING SYSTEMS - QuizbalalaNo ratings yet

- Sanyo MDF-U4186S Service ManualDocument30 pagesSanyo MDF-U4186S Service ManualEmRe OflazNo ratings yet

- Constant Air Volume - CAV: Mode Enable Sensor OptionsDocument4 pagesConstant Air Volume - CAV: Mode Enable Sensor Optionssiva anandNo ratings yet

- Peec II - Peec III Brake Engine 10 P OkDocument10 pagesPeec II - Peec III Brake Engine 10 P OkEduardo AlvarezNo ratings yet

- 4756 Civic 96-2000 D16y8 Performer XDocument3 pages4756 Civic 96-2000 D16y8 Performer XRafael Isaac Lòpez Vargas100% (1)

- B13. Compressor Oil System - Kenco Klce Oil Level ControllersDocument7 pagesB13. Compressor Oil System - Kenco Klce Oil Level ControllersKleiber OrtegaNo ratings yet

- S2000 SOS Supercharger Install ManualDocument43 pagesS2000 SOS Supercharger Install ManualMatthew Chtchavlinski100% (4)

- 5vz-Fe Engine Conversion Instructions For Manual OnDocument15 pages5vz-Fe Engine Conversion Instructions For Manual Onsploople100% (2)

- Fuel TankDocument6 pagesFuel TankdonNo ratings yet

- 199R7948 5rev5 PDFDocument16 pages199R7948 5rev5 PDFbatman2054No ratings yet

- Sistema de Combustible Cat 3306Document22 pagesSistema de Combustible Cat 3306Victor Montesdeoca100% (1)

- EFI Installation Manual Rotax 4-1 Rev5Document26 pagesEFI Installation Manual Rotax 4-1 Rev5Esteban POPO ECHEVERRYNo ratings yet

- Holley Carb AdjustmentsDocument8 pagesHolley Carb AdjustmentsAaron SteeleNo ratings yet

- Injection GroutDocument8 pagesInjection GroutNishanthNo ratings yet

- Sika Rapid 1Document2 pagesSika Rapid 1NishanthNo ratings yet

- Latex Power PDFDocument3 pagesLatex Power PDFকিশলয়No ratings yet

- Cat 330clre Boom ReachDocument16 pagesCat 330clre Boom ReachNishanthNo ratings yet

- ISO 20ft Container Structural DetailsDocument5 pagesISO 20ft Container Structural DetailsNishanthNo ratings yet

- Barrier Design GuidelinesDocument22 pagesBarrier Design GuidelineskonnariNo ratings yet

- Scheda Carmix 2 5TT EN 01Document1 pageScheda Carmix 2 5TT EN 01NishanthNo ratings yet

- Marthon Jotun Marine PaintDocument5 pagesMarthon Jotun Marine PaintNishanthNo ratings yet

- Design of Slip WayDocument11 pagesDesign of Slip WayNishanthNo ratings yet

- Avre 400Document196 pagesAvre 400tamere100% (1)

- Acs800 PDFDocument266 pagesAcs800 PDFRichard SianiparNo ratings yet

- Cisco UBR7200 Series Software Configuration GuideDocument324 pagesCisco UBR7200 Series Software Configuration GuideMiki RubirozaNo ratings yet

- Parallel Smith-Waterman Algorithm For Gene SequencingDocument4 pagesParallel Smith-Waterman Algorithm For Gene SequencingEditor IJRITCCNo ratings yet

- Huawei UA5000 Series Access Network, View Huawei UA5000, Huawei Product Details From Shanghai Chu Cheng Information Technology Co., Ltd. On AlibabaDocument4 pagesHuawei UA5000 Series Access Network, View Huawei UA5000, Huawei Product Details From Shanghai Chu Cheng Information Technology Co., Ltd. On AlibabaR.s. Félix100% (1)

- IkegamiDocument4 pagesIkegamialelendoNo ratings yet

- 0178 405 enDocument24 pages0178 405 enabuzer1981No ratings yet

- Physical and Data Link Layer: Kameswari Chebrolu Dept. of Electrical Engineering, IIT KanpurDocument11 pagesPhysical and Data Link Layer: Kameswari Chebrolu Dept. of Electrical Engineering, IIT Kanpur23wingsNo ratings yet

- Suvt PM ReportDocument3 pagesSuvt PM ReportRohit SaxenaNo ratings yet

- Foxboro 870ITPH Electrochemical Transmitter For PH, ORPDocument60 pagesFoxboro 870ITPH Electrochemical Transmitter For PH, ORPGabriel SilvaNo ratings yet

- MCRNC Architecture and ConfigurationsDocument65 pagesMCRNC Architecture and Configurationskone mounaNo ratings yet

- Isp Flash Microcontroller Programme:8051 ProgrammerrDocument4 pagesIsp Flash Microcontroller Programme:8051 ProgrammerrTol Man ShresthaNo ratings yet

- BCP-8000 User's ManualDocument36 pagesBCP-8000 User's ManualAsad PatelNo ratings yet

- Idoc - Pub - Pokemon Liquid Crystal PokedexDocument19 pagesIdoc - Pub - Pokemon Liquid Crystal PokedexPerfect SlaNaaCNo ratings yet

- Vol 1Document215 pagesVol 1kellyslater36No ratings yet

- Leica HDS8800Document6 pagesLeica HDS8800bbutros_317684077No ratings yet

- Fault Code TransmisiDocument7 pagesFault Code Transmisigiapy00000% (1)

- Ls CommandDocument6 pagesLs CommandDarkoNo ratings yet

- Telemetry Encoder PDFDocument5 pagesTelemetry Encoder PDFAleem AzharNo ratings yet

- Name Date Drawn Checked Eng Appr MGR ApprDocument1 pageName Date Drawn Checked Eng Appr MGR ApprLamHotNo ratings yet

- 1st Monthly - Computer 2Document7 pages1st Monthly - Computer 2Mye BeltranNo ratings yet

- Jfs and Jfs2Document4 pagesJfs and Jfs2Raj AhireNo ratings yet

- Trendnet: 8-Port Stackable Rack Mount KVM Switch With OsdDocument2 pagesTrendnet: 8-Port Stackable Rack Mount KVM Switch With OsdAlmir HoraNo ratings yet

- 10 Virtual Appliances That Can Simplify Your Job - TechRepublicDocument6 pages10 Virtual Appliances That Can Simplify Your Job - TechRepublicᗩᑿᘢ ᙜᘢᖺᗩᙜᗰᗅᖱNo ratings yet

- Cloud Hoppers Weather Station Using Arduino Uno Board and Ethernet ShieldDocument7 pagesCloud Hoppers Weather Station Using Arduino Uno Board and Ethernet ShieldPaul GomezNo ratings yet

- TP & R3trans: Roland Hamm Sap AgDocument26 pagesTP & R3trans: Roland Hamm Sap Agprathyusha2392No ratings yet

- RTN XMC-5D ODU Quick Installation Guide 01Document43 pagesRTN XMC-5D ODU Quick Installation Guide 01Ariel Pavez Cifuentes100% (3)

- BÜCHI Sepacore C-600 Prelim. SM 96080, Chapter 1 General InformationDocument5 pagesBÜCHI Sepacore C-600 Prelim. SM 96080, Chapter 1 General InformationSebastián Saldarriaga RingwelskiNo ratings yet

- ASTM Protocol SataliteDocument46 pagesASTM Protocol SataliteChandrakumaran Sinnappah100% (1)

- B107.2 StandardDocument28 pagesB107.2 StandardMichael SkrableNo ratings yet

- Survive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveFrom EverandSurvive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveNo ratings yet

- Merle's Door: Lessons from a Freethinking DogFrom EverandMerle's Door: Lessons from a Freethinking DogRating: 4 out of 5 stars4/5 (326)

- Crazy for the Storm: A Memoir of SurvivalFrom EverandCrazy for the Storm: A Memoir of SurvivalRating: 3.5 out of 5 stars3.5/5 (217)

- The Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsFrom EverandThe Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsNo ratings yet

- Welcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthFrom EverandWelcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthRating: 4 out of 5 stars4/5 (59)

- How to Survive Anything: From Animal Attacks to the End of the World (and Everything in Between)From EverandHow to Survive Anything: From Animal Attacks to the End of the World (and Everything in Between)Rating: 4.5 out of 5 stars4.5/5 (3)

- The Optimist: A Case for the Fly Fishing LifeFrom EverandThe Optimist: A Case for the Fly Fishing LifeRating: 4.5 out of 5 stars4.5/5 (18)

- The Last of His Kind: The Life and Adventures of Bradford Washburn, America's Boldest MountaineerFrom EverandThe Last of His Kind: The Life and Adventures of Bradford Washburn, America's Boldest MountaineerRating: 4 out of 5 stars4/5 (23)

- Grandma Gatewood's Walk: The Inspiring Story of the Woman Who Saved the Appalachian TrailFrom EverandGrandma Gatewood's Walk: The Inspiring Story of the Woman Who Saved the Appalachian TrailRating: 4.5 out of 5 stars4.5/5 (308)

- 438 Days: An Extraordinary True Story of Survival at SeaFrom Everand438 Days: An Extraordinary True Story of Survival at SeaRating: 4.5 out of 5 stars4.5/5 (188)

- The Art of Resilience: Strategies for an Unbreakable Mind and BodyFrom EverandThe Art of Resilience: Strategies for an Unbreakable Mind and BodyRating: 4.5 out of 5 stars4.5/5 (117)

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderFrom EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderRating: 4 out of 5 stars4/5 (283)

- Mind Gym: An Athlete's Guide to Inner ExcellenceFrom EverandMind Gym: An Athlete's Guide to Inner ExcellenceRating: 3.5 out of 5 stars3.5/5 (18)

- Upside Down in the Yukon River: Adventure, Survival, and the World's Longest Kayak RaceFrom EverandUpside Down in the Yukon River: Adventure, Survival, and the World's Longest Kayak RaceRating: 4.5 out of 5 stars4.5/5 (2)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Freediving Manual: Learn How to Freedive 100 Feet on a Single BreathFrom EverandFreediving Manual: Learn How to Freedive 100 Feet on a Single BreathRating: 5 out of 5 stars5/5 (4)

- Divided: A Walk on the Continental Divide TrailFrom EverandDivided: A Walk on the Continental Divide TrailRating: 4 out of 5 stars4/5 (17)

- Above the Clouds: How I Carved My Own Path to the Top of the WorldFrom EverandAbove the Clouds: How I Carved My Own Path to the Top of the WorldRating: 4.5 out of 5 stars4.5/5 (25)

- How To Think Like A Spy: Spy Secrets and Survival Techniques That Can Save You and Your FamilyFrom EverandHow To Think Like A Spy: Spy Secrets and Survival Techniques That Can Save You and Your FamilyRating: 4 out of 5 stars4/5 (4)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)