Professional Documents

Culture Documents

Environmental Management System and Green Productivity (EMS - GP) Implementation in Kurdistan Cement Plant

Uploaded by

inventionjournalsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Environmental Management System and Green Productivity (EMS - GP) Implementation in Kurdistan Cement Plant

Uploaded by

inventionjournalsCopyright:

Available Formats

International Journal of Business and Management Invention

ISSN (Online): 2319 8028, ISSN (Print): 2319 801X

www.ijbmi.org || Volume 5 Issue 4 || April. 2016 || PP01-07

Environmental Management System and Green Productivity

(EMS_GP) Implementation in Kurdistan Cement Plant

Jahanbakhsh Balist1*, Ebrahim Sargazi2, Hassan Hoveidi3, Shahrzad Faryadi4

1

(Ms.C Student, Environmental Planning And Management, University Of Tehran, Iran)

(Ms.C Student, Environmental Planning And Management, University Of Tehran, Iran)

3

(Assistant Professor, Environmental Planning And Management, University Of Tehran, Iran)

4

(Associated Professor, Environmental Planning And Management, University Of Tehran, Iran)

2

Abstract: the cement plant has many environmental aspect that can lead to pollution. For managing this effects

we must use of environmental and productivity technique to minimize this effects. In this study, the Kurdistan

cement plant as a case study had studied by use of two important technique: green productivity and

environmental management systems as ISO. For there more, this plant environmental aspect had identified by

brainstorming and specialist opinion. Then those causes are specified and for each one proposed an option for

controlling it. Finally in order to applying this options, these are prioritized by ranking them. The spraying

water on dust from mining and transportation is first option to applying.

Keywordsgreen productivity, environmental management system, cement plant, environmental aspect

I.

Introduction

In the context of debate on the considerable human and material damage generated by environmental

degradation, the role of the environmental performance of companies merits attention [1]. To identify the main

factors able to influence the maturity of the environmental management practiced by each organisation [2]. The

maturity of the environmental management of companies concerns the environmental level or stage of evolution

in the environmental management of the companies [3]. This environmental maturity (EMM) may be influenced

by many factors, not only technical (e.g., cleaner technologies) but also organisational and human, related to

the motivation and training of employees to achieve the goals of environmental management, leading companies

to better environmental maturity [4, 5, 6]. Among the organisational and human factors relevant to

environmental management, environmental training (ET) stands out as one of the most relevant ones [7, 5, 8].

And paradoxically as one that has received less attention from experts [9].

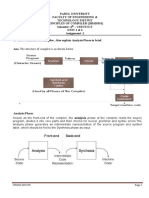

Green Productivity and Environmental Management Systems are complementary systems and both help

improve the environmental performance of an organization. GP is an analytical methodology to help identify

opportunities to prevent pollution and improve productivity, especially resource productivity. GP uses a number

of different analytical tools, but it does not require development of a specific management structure or

documentation. The process specifies how an organization can review its operations to look for waste and poor

resource productivity, but is not a comprehensive set of policies or procedures for an organization[10].

An EMS in contrast, is a management system designed to help identify environmental impacts and implement

improvements. An EMS consists of policies and procedures to help minimise a companys impacts on the

environment on a routine basis. An EMS does dictate how to improve performance, but provides an internal

system to manage environmental performance and to ensure continual improvement.

Successful

implementation of an EMS will require the use of analytical methodologies such as GP, but EMS itself is not an

analytical tool. Rather it is a process for ensuring a company takes action to continually improve its

environmental performance.

The GP assessment methodology works within the framework of an EMS to help a company concentrate on

opportunities to prevent pollution and improve material productivity. The process of developing and running a

GP program for several cycles is an excellent foundation for developing a broader EMS. To move from GP to

EMS appropriate documentation needs to be developed and the GP assessment practices needs to be integrated

into the companys daily operations (eg. add audit procedures to operation manuals, adjust job descriptions). In

addition, the scope of environmental assessment activities may need to be broadened. Although the GP

methodology can be used in any part of a company, many organizations use it primarily for manufacturing

areas. A complete EMS however requires a company to address all the potential environmental impacts in all

departments. This would include office areas, transportation, storage and even product distribution.

www.ijbmi.org

1 | Page

Environmental Management System And Green Productivity (EMS_GP) Implementation In Kurdistan

II.

Material and methods:

2.1 Case study

Kurdistan Cement Company, the largest industrial unit roof of Iranian Kurdistan province in the northwest city

of Bijar. The production capacity of 3,200 tons of clinker per day to continue its activities.

Geographical location and general specifications of factory

the factories km northwest 5 Bijar

Plant capacity: 3,200 tons of clinker per day

Altitude: 2017 meters

The average minimum and maximum temperature maximum and minimum -24 C +37 C

Wind speed and direction dominant: 32 meters per second

The annual rainfall: 619 mm

potential severity of the earthquake: 98 Mercalli

2.2 Methods

The methodology of the project broadly followed the GP methodology introduced by the Asian Productivity

Organization (APO) and the ISO 14001 standard requirements to establish an Environmental Management

System. The GP methodology was used as a foundation for implementing ISO 14001 in KurdistanCement

Company. In this way the methodology diverges from the traditional GP methodology. Each step of

methodology has been further divided in to a number of tasks as follow:

Step 1: Getting Started

Task 1: GP EMS team formation

GP methodology is based on a participatory approach, where by environmental management and solutions are

carried out by a team of employees. It is necessary, when initiating a GP process that management sponsors

and facilitates team formation in the relevant departments, and that roles within these teams are assigned and

resources are provided to undertake their responsibilities.

These roles should focus on the skills and

experiences of the employees, in relation to their role within the enterprise. A broad range of members that are

involved in the widest verity of processes and tasks is optimum. The teams should encourage all levels of

employees to input into the process. A steering committee is also necessary to oversee the program, which

should have representation from both internal and external personnel. External personal may include members

of organisations who are providing technical advice as well as from other effected parties, for instance the local

community.

Task 2: Walk through survey of the production process

A preliminary audit of the business should be undertaken, that compiles basic information about the resources

available and the processes involved. It will include such information as personnel, machinery, equipment and

processes. It will also briefly detail possible sources of environmental problem or areas of inefficient use of

resources. It should include a flow diagram of the processes involved as well as all inputs and outputs,

including waste and products.

Step 2: Planning

Task 3: Training on GP methodology and ISO 14000 standard.

The objective of the training workshop was to train the senior management of the cement factory on GP

methodology and Environmental Management System. The following topics were covered in the training:

GP methodology tools and techniques

Environmental Management System according to ISO 14001 standard (awareness and documentation).

Identification of problems and causes/environmental legal and other requirements, Aspect and impacts.

Generation, evaluation and prioritisation of GP options;

Task 4: Identification of Problems and Causes

Building on the preliminary audit an in depth discussion of the areas that require improvement is undertaken.

Identifying and recording specific problems is carried out using analysis techniques including brainstorming to

locate and then pinpoint the cause of problems existing in the system.

Task 5: Setting Objectives and Targets

After identifying the problems and their causes, it is necessary to set objectives and targets to ameliorate them.

Objectives should be based on problems and causes identified.

One objective can have multiple targets.

Targets should be based on needs.

Indicators should be established to track the progress of each objective.

It is necessary to prioritise the problems, with relation to their feasibility, costs and the resources and

technologies that are available.

Step 3: Generation, Evaluation and Prioritisation of GP Options

www.ijbmi.org

2 | Page

Environmental Management System And Green Productivity (EMS_GP) Implementation In Kurdistan

Task 6: Generation of GP Options

The most significant task in GP methodology relates to the development of GP options. These options emerge

directly from the cause analysis. The use of techniques such as brainstorming and group discussions improve the

quality of ideas. A logical approach to generating options is as follows:

Establishing a brainstorming exercise for generating options, based on the identification of causative

factors,

Determine the nature of the solution required.

Task 7: Screening, Evaluation and Prioritisation of GP options

Not all GP options generated need a detailed evaluation. Some of the GP options can be eliminated on the basis

of certain criteria, or by the process of screening. GP implementation at community level has many different

features in comparison with other sectors, especially in technical skill and funding fields. That is why these

options need to be carefully evaluated; otherwise the success of GP options may be negligible. The option

evaluation needs to directly relate to feasibility. This includes technology, economic viability (rate of turnover

from investment, payback period), environmental aspects and social aspects.

After assessing the option based on this criteria the options may be divided into 3 categories:

Options to be applied. These options are usually inexpensive, efficient and easy to implement and maintain.

Options needing further analysis. These options usually require a significant financial investment and/or the

expected outcomes are not clear.

Options which are not suitable. These options are usually very expensive and complicated. Often technical

expertise that is not present within the organisation would be required, even after project implementation for

maintenance.

Step 4: Implementation of GP Options

Task 8: Formulation of GP plan

The development of a document that considers important logistical aspects of GP implementation is required.

Some topics in the GP plan will include finances, resources, technology and timeframe. The implementation

plan should also contain a detailed activity plan, input, required time frame and the persons responsible for

implementation. It may combine the work of various GP teams in different sections.

A plan will be most effectively implemented if all members involved in the implementation are interested and

aware of all the factors involved. The GP team needs to answer the following questions when designing the

plan.

What needs to be done?

What is the timetable for implementation?

Who will be responsible for each task?

How will each option be implemented?

How/Where will equipment and expertise be sourced?

What support is available (are there others have implemented in a similar industry, or is other external

technical advice available)?

Task 9: Implementation of selected Options

The GP team together with experts and the support of the management strata implement all steps detailed in the

implementation plan. Training needs should be identified and provided where required.

Task 10: Training, awareness building and developing competence

The provision of training may cover a broad range of topics. It will be required for the GP EMS teams in the

methodology and environmental management strategies EMS internal audit, but also for those on site using

equipment and procedures that may be altered in the GP process. The degree of training required will vary

between GP options and may also take a variety of forms from formal seminars to informal on the spot

instruction. Some options will require no training, implementation can be immediately and others may require a

significant training period. Options will therefore be implemented at various stages. Some options may be

interdependent.

Step 5: Monitoring and Review

Task 11: Monitoring and Evaluation of Results

The monitoring and evaluation of GP options is an important task in the project cycle. It enables a comparison

to be made between the objectives and the outcomes of the project. Project coordinators from the VPC have a

responsibility to review the project, and external experts are also invited to evaluate these results. Any problems

identified within the project need to be assessed and possible solutions identified. Monitoring should be an

ongoing task of a GP program, it should occur at all stages of implementation, ensuring that problems are

identified and solved as soon as possible. The aim of GP projects is to achieve sustainability, which is only

possible if problems are identified and if possible solved quickly.

www.ijbmi.org

3 | Page

Environmental Management System And Green Productivity (EMS_GP) Implementation In Kurdistan

Task 12: Management review

Management reviews are necessary to evaluate the progress of the GP project. All activities must be recorded

during the implementation of project for future reference. After implementation, management together with the

steering committee must examine the GP program to determine how effective the project has been at meeting

the specified objectives. When reviewing, management will look at the final report and other ongoing

documentation from the project.

Step 6: Sustaining GP

Task 13: Incorporating changes into the organizations system of management

GP cannot exist in isolation. It needs to be integrated with regular activities of the management and day-to-day

functioning of the enterprise. Therefore, all employees need to be familiar with the activities and objectives of

the GP program. Participation of the workforce as well as consultation with other interested parties, including

the community in which the industry is based is an important factor contributing to the long-term sustainability

of GP. One way to ensure that GP becomes a regular activity is to document and enforce procedures within each

work area.

Task 14: Identifying new/ additional problem areas for continualimprovement

Once the first cycle of GP is complete within the organisation, the procedures and knowledge should be in place

so that the cycle may be repeated. Green Productivity system specifically designed to facilitate continuous

improvement.

Tools

2.4.1

Management Tools

GP tools provide information on the equipment and devices utilized in implementing GP plans. One of the most

essential elements in GP tools is brainstorming, a process in which ideas are generated from answering critical

questions such as: What are solutions to reduce dust generation? What is the best choice? The more people

involved in the brainstorming process, the greater the amount of quality ideas will be available. The best choice

will be selected from a number of solutions. The process flow was a useful tool to see in the detail of each

activity to find out where the waste generated and understand whole the production process. This tool can

identified exactly where have problem.

Equally important to brainstorming is the fish bone diagram, also known as a cause-and-effect diagram. It

displays all the possible reasons and causes that contribute to a specific result. This diagram is used in the

solving most problems, particularly in large-scale problems that have resulted from a number of causes and are

related to a number of activities. Therefore, the fish bone diagram plays a crucial role in pinpointing problems in

order to solve them.

A matrix is often set up to rate the feasibility of a number of options. Not all options are selected for

implementation, due to the difference in priorities. Those options, which are significant and applicable, will

have the first and foremost priorities. Similarly, the less difficult and low-cost options also have advantages over

the more difficult and high-cost ones. In fact, it is not so easy to classify the priorities of options because the

most urgent ones often requires high costs for implementation while the inexpensive ones are not so applicable.

2.4.2 Environment Tools

As one of the two components making up GP tools, environmental tools, often called technical tools require a

number of specific skills such as good housekeeping, solid waste management, wastewater treatment, air

pollution treatment, mass balance and process flow.

Good housekeeping aims to minimize wastes, prevent the loss of material water pollution and money for a

company. This tool requires the involvement of all individuals together, forming a cohesive company. If each

member of the company takes responsibility for using the right way of oil, material transportation as well as rag

oil, the pollution by company contributed to environment will consequently be reduced.

GP tools also focus on oil contamination in wastewater, dust generation and solid waste management. Solid

waste are often collected and separated to hazard waste, recyclable and non-recyclable waste before delivery for

treatment.

III.

Result and discussion

3.1 GP implementation

GP implementation in Kurdistan Cement Company was based on the GP methodology that introduced by APO

and integrated with ISO 14001 development process.

Getting started

GP-EMS Team formation

Establishing a GP team is an effective method for considering all possible aspects the existing problems in a

company. A team should effectively utilise the skills and experiences of many people and incorporates their

various ideas, views and opinions. GP-EMS team was established in Kurdistan Cement Company. These teams

www.ijbmi.org

4 | Page

Environmental Management System And Green Productivity (EMS_GP) Implementation In Kurdistan

consisted of top-level management and managers from all involved departments such as the technical, quality

control and environmental management department, as well as the labour union.

Problem identification

Based on the data collected from survey the GP-EMS team conducted a group discussion to list all problems in

each process related to environment and productivity. See Table 1.

Table.1. Problems of Kurdistancement company

Depart

Problems

Environmental

ment/

Process

Mining

and

transportation

of

raw material

Limestone crusher

process

Clay

crusher

process

Conveyer

belt

transportation from

crusher to storage

Kilns

Compressor room

Productivity

-Dust from mining explosions, transportation

and loading and unloading of raw materials

-

Noise pollution

Dust generation

Noise pollution

Dust generation

Dust generation at direction change

points (from this conveyer to other

conveyer)

Waste heat

Air emissions

Wastewater

Waste oil

Oil leakage

Solid waste

Noise

Oil leakage

-Short lifetime of hammer

-Low capacity

Cement mill

Loading clinker and

cement

Packaging area

Maintenance

workshop

All company

Dust generation

Dust generation

Solid waste

Wastewater

Solid waste

Air emissions

Solid waste

Low inefficiency of kiln

Energy consumption

Production lower than design capability

Energy consumption

Cause identification

This task very important so that the GP-EMS team used GP tools such as brainstorming to find out the root

causes of each problem.

Table.2. Problems of Kurdistan cement company

Depart

Problems

Causes

Options

ment/

Process

Mining

and

transportation

of

raw material

Material too dry

A lot of dust on the road

Spray water on the limestone before

upload and unload

Dust

from

mining

explosions,

transportation

and

loading and unloading

raw materials

Noise pollution

Old crushers

Wearing ear Protection

equipment

Dust emissions

Limestone crushing

process.

Clay

crushing

process

Conveyer

belt

transportation from

crusher to storage

of line I

Short lifetime of the limestone

crushers hammer

Low capacity

Dust

generation

at

direction change points

(from this conveyer to

other conveyer)

Bag

filter

operate

inefficiency

and

bag

damaged

See fish bone diagram

The bag filter efficient and

has low capacity

Not cover all conveyor

belt at that point

www.ijbmi.org

Periodical maintenance of bag

filter and should be change

damaged bags filter diligently.

Reduce SiO2 in limestone by

change mixer formula

Install a pre-crusher and

screen.

Replace by new bag filter

Cover the point lack off.

5 | Page

Environmental Management System And Green Productivity (EMS_GP) Implementation In Kurdistan

Raw material mill

Kilns

Capacity lower than

design capacity

Low inefficiency of kiln

Waste heat

Noise

Compressor room

Oil leakage

Cement mill

Lower capacity

Clinker Loading

Dust generated when

loading the clinker onto

the ship.

Material output coarse

-decrease size of material out put

-high energy consumption of

pre heater

Lack of waste heat

recovery system

Old compressor

Lack of noise prevention

facility

Old compressors

Existing dust collectors

capacity (80 m3/min) is

too small.

Dust suction pipe too

small

The cover of suction head

is not inadequate

Packaging area and

cement loading

All company

Dust generation during

packaging, transporting

on

conveyor

belt,

loading cement on ship

truck on train

Solid waste generation

from all departments

Lack of solid waste

management regulation.

Solid waste collection

system inadequate.

Lack of awareness on

environment protection.

Lack of environmental

management system.

Install auxiliary furnace for

preheater

Install a waste heat recovery

generation system in both

kilns.

Install noise protection box to

cover individual compressors

Build a separate operation

room

Increase maintenance activities

Replace to new compressors

Install a pre-griding system

upstream of the existing ball

mill.

Replace

filter

with

Electrostatic precipitator (EP)

Change the cover with one that

has improved material and

design

Modify the dust collection

system at packaging machine

Education class for employees

Appling Hard Regulation

Install a new waste collector

system

Training for employees related

to waste oil generation

In order to prioritization the option for decreasing and management of environmental and productivity, with the

remaining 16 options, GP EMS team screened, evaluated to set priorities for each options. Some criteria that

were chosen to evaluate them are:

1. Cost of investment: the higher cost of investment, the lower the priority of option

2. The complexity of technique: the more complicated, the lower priority of option

3. The efficiency of option both in terms of environmental performance and productivity: the more efficiency,

the higher priority of option

4. The ability of workers to control and operate system: the easier for worker to operate, the higher priority of

option

5. Suggested options were ranged from 1-5 marks for each criteria, in which 1 represents for the low and 5

presents for higher priority. All options are listed and evaluated by criteria as the table below:

Table.3. priority of option

Spray water on the limestone before upload

and unload

Periodically spray water on the surface road

Replace by new bag filter.

Cover the point lack off.

Replace bigger suction pipe.

Modify the dust collector system in bag car

Wearing ear protection

Install sound choker on compressor

Build up the separate operation room

Rising maintenance operating

Change compressor

Install pre heater

Install recovering residue temperate in heater

Install pre crasher and filters

Appling Hard Regulation

Criteria 1

4.1

Criteria 2

4.52

Criteria 2

3.42

Criteria 4

3.89

multiple

246.5

priority

1

2.52

3.57

2.94

2.47

4.21

2.84

2.57

3.1

2.16

2.42

2.21

2.73

3.57

2.94

4

3.1

2.31

4.21

3.37

3.1

2.84

3.1

2.63

2.05

3

3.57

3.94

3.21

3.26

3.79

2.89

3.42

3.1

3.21

3.52

3.47

3.52

3.31

3.82

2.73

3.47

2.73

2.52

3.73

3.05

2.89

2.94

3.21

2.79

2.68

3

2.63

79.69

159.06

81.11

54.49

191.06

99.83

71.37

83.08

75.65

61.61

42.73

81.32

128.04

10

4

9

15

3

6

13

7

11

14

16

8

5

www.ijbmi.org

6 | Page

Environmental Management System And Green Productivity (EMS_GP) Implementation In Kurdistan

Install a new waste collector system

Training for employees related to waste oil

generation

2.63

3.84

2.68

4

3.84

3.78

2.73

3.36

73.88

195.08

12

2

Monitoring and review:

Internal audit reports and assess compliance with legal requirements and other requirements that the

organization is committed applied.

1. Internal audit report:

Internal audit was conducted on 17 and 18 may 2014, as the non-compliance of environmental management

system follow:

- Non-compliance at this stage should be identified and appropriate corrective action taken on them.

2. Report meetings to assess compliance with legal requirements and specified non-compliance in this respect to

assess compliance with the requirements of environmental law based on the identification and registration

procedure legal requirements, assess the compliance with legal requirements and procedures and aspects of

identified risks, as discussed below have.

2.1.1. Performance monitoring and self-reported in accordance with rules and requirements administered by the

Department of Environment every six months, based on the results in all cases the expected environmental

organization, the company has been consistent.

2.1.2. In relation to other legal requirements relating to the environment in accordance with the accepted

procedure of registration and monitoring of conformity assessment done.

IV.

Conclusion

Technology development altered range of human life. However, due to the lack of consistency harmful effects

of technology on the natural interaction, gradually turning the control vital imbalance actually suffered the

effects of these disorders will be affect the man as part of nature. At the global level, especially in developing

countries, issues such as population growth, economic and cultural poverty and lack of environmental programs,

they will be broader problem of environmental conservation. In our country to find a reasonable and effective

solution of all harmful agents in the environment must be identified and evaluated. Then measures and by taking

them to a comprehensive environmental management plan be developed at the country level. So, in order to

improve the quality of the environment in Kurdistan Cement Factory, two techniques, environmental

management systems and green productivity are integrated. Therefore, the first step to form a team and then

identify environmental problems techniques and environmental causes of them in the factory and then to solve

these problems strategies proposed by the executive team and the experts in the field using the options suggested

took priority. It was found that the priorities of options water splashing on the rocks before loading and

unloading of the highest priority and should be in the field adopt necessary measures.the proposed solutions

were prioritized.

References

[1].

[2].

[3].

[4].

[5].

[6].

[7].

[8].

[9].

[10].

Hart, S.L., Dowell, G., 2011. A natural-resource-based view of the firm fifteen years after. J. Manag. 37 (5), 1464e1479.

Gonzlez-Benito, J., Gonzlez-Benito, ., 2006. A review of determinant factors of environmental proactivity. Bus. Strat.

Environ. 15 (2), 87e102.

Jabbour, C.J.C., 2010. Non-linear pathways of corporate environmental management: a survey of ISO 14001-certified companies

in Brazil. J. Clean. Prod. 18 (12), 1222e1225.

Graves, L.M., Sarkis, J., Zhu, Q., 2013. How transformational leadership and employee motivation combine to predict employee

proenvironmental behaviors in China. J. Environ. Psychol. 35, 81e91.

Renwick, D.W., Redman, T., Maguire, S., 2013. Green human resource management: a review and research agenda. Int. J.

Manag. Rev. 15 (1), 1e14.

Wagner, M., 2013. Green human resource benefits: do they matter as determinants of environmental management system

implementation? J. Bus. Ethics 114, 443e456.

Andersson, L., Jackson, S.E., Russell, S.V., 2013. Greening organizational behavior: an introduction to the special issue. J. Org.

Behav. 34 (2), 151e155.

Ji, L., Huang, J., Liu, Z., Zhu, H., Cai, Z., 2012. The effects of employee training on the relationship between environmental

attitude and firms performance in sustainable development. Int. J. Hum. Resour. Manag. 23 (14), 2995e3008.

Jackson, S., Renwick, D., Jabbour, C.J.C., Muller-Camen, M., 2011. State-of-the-art and future directions for green human

resource management. Z. Personalforschung 25, 99e116.

Technical Report on ISO 14001 & GP Demonstration Project in Hoang Thach and Sai Son Cement Company, Vietnam

Productivity Centre Directorate for Standards and Quality, Vietnam 2002.

www.ijbmi.org

7 | Page

You might also like

- The Effect of Transformational Leadership, Organizational Commitment and Empowerment On Managerial Performance Through Organizational Citizenship Behavior at PT. Cobra Direct Sale IndonesiaDocument9 pagesThe Effect of Transformational Leadership, Organizational Commitment and Empowerment On Managerial Performance Through Organizational Citizenship Behavior at PT. Cobra Direct Sale Indonesiainventionjournals100% (1)

- Effects of Online Marketing On The Behaviour of Consumers in Selected Online Companies in Owerri, Imo State - NigeriaDocument12 pagesEffects of Online Marketing On The Behaviour of Consumers in Selected Online Companies in Owerri, Imo State - Nigeriainventionjournals100% (1)

- Islamic Insurance in The Global EconomyDocument3 pagesIslamic Insurance in The Global EconomyinventionjournalsNo ratings yet

- A Discourse On Modern Civilization: The Cinema of Hayao Miyazaki and GandhiDocument6 pagesA Discourse On Modern Civilization: The Cinema of Hayao Miyazaki and GandhiinventionjournalsNo ratings yet

- Muslims On The Margin: A Study of Muslims OBCs in West BengalDocument6 pagesMuslims On The Margin: A Study of Muslims OBCs in West BengalinventionjournalsNo ratings yet

- An Appraisal of The Current State of Affairs in Nigerian Party PoliticsDocument7 pagesAn Appraisal of The Current State of Affairs in Nigerian Party PoliticsinventionjournalsNo ratings yet

- The Social Composition of Megaliths in Telangana and Andhra: An Artefactual AnalysisDocument7 pagesThe Social Composition of Megaliths in Telangana and Andhra: An Artefactual AnalysisinventionjournalsNo ratings yet

- Effects of Online Marketing On The Behaviour of Consumers in Selected Online Companies in Owerri, Imo State - Nigeria.Document12 pagesEffects of Online Marketing On The Behaviour of Consumers in Selected Online Companies in Owerri, Imo State - Nigeria.inventionjournalsNo ratings yet

- The Network Governance in Kasongan Industrial ClusterDocument7 pagesThe Network Governance in Kasongan Industrial ClusterinventionjournalsNo ratings yet

- Negotiated Masculinities in Contemporary American FictionDocument5 pagesNegotiated Masculinities in Contemporary American FictioninventionjournalsNo ratings yet

- The Usage and Understanding of Information and Communication Technology On Housewife in Family Welfare Empowerment Organization in Manado CityDocument10 pagesThe Usage and Understanding of Information and Communication Technology On Housewife in Family Welfare Empowerment Organization in Manado CityinventionjournalsNo ratings yet

- Literary Conviviality and Aesthetic Appreciation of Qasa'id Ashriyyah (Decaodes)Document5 pagesLiterary Conviviality and Aesthetic Appreciation of Qasa'id Ashriyyah (Decaodes)inventionjournalsNo ratings yet

- Inter-Caste or Inter-Religious Marriages and Honour Related Violence in IndiaDocument5 pagesInter-Caste or Inter-Religious Marriages and Honour Related Violence in IndiainventionjournalsNo ratings yet

- Student Engagement: A Comparative Analysis of Traditional and Nontradional Students Attending Historically Black Colleges and UniversitiesDocument12 pagesStudent Engagement: A Comparative Analysis of Traditional and Nontradional Students Attending Historically Black Colleges and Universitiesinventionjournals100% (1)

- The Impact of Leadership On Creativity and InnovationDocument8 pagesThe Impact of Leadership On Creativity and InnovationinventionjournalsNo ratings yet

- E0606012850 PDFDocument23 pagesE0606012850 PDFinventionjournalsNo ratings yet

- Effect of P-Delta Due To Different Eccentricities in Tall StructuresDocument8 pagesEffect of P-Delta Due To Different Eccentricities in Tall StructuresinventionjournalsNo ratings yet

- A Critical Survey of The MahabhartaDocument2 pagesA Critical Survey of The MahabhartainventionjournalsNo ratings yet

- Non-Linear Analysis of Steel Frames Subjected To Seismic ForceDocument12 pagesNon-Linear Analysis of Steel Frames Subjected To Seismic ForceinventionjournalsNo ratings yet

- D0606012027 PDFDocument8 pagesD0606012027 PDFinventionjournalsNo ratings yet

- C0606011419 PDFDocument6 pagesC0606011419 PDFinventionjournalsNo ratings yet

- F0606015153 PDFDocument3 pagesF0606015153 PDFinventionjournalsNo ratings yet

- E0606012850 PDFDocument23 pagesE0606012850 PDFinventionjournalsNo ratings yet

- H0606016570 PDFDocument6 pagesH0606016570 PDFinventionjournalsNo ratings yet

- C0606011419 PDFDocument6 pagesC0606011419 PDFinventionjournalsNo ratings yet

- F0606015153 PDFDocument3 pagesF0606015153 PDFinventionjournalsNo ratings yet

- Non-Linear Analysis of Steel Frames Subjected To Seismic ForceDocument12 pagesNon-Linear Analysis of Steel Frames Subjected To Seismic ForceinventionjournalsNo ratings yet

- H0606016570 PDFDocument6 pagesH0606016570 PDFinventionjournalsNo ratings yet

- Development of Nighttime Visibility Assessment System For Road Using A Low Light CameraDocument5 pagesDevelopment of Nighttime Visibility Assessment System For Road Using A Low Light CamerainventionjournalsNo ratings yet

- D0606012027 PDFDocument8 pagesD0606012027 PDFinventionjournalsNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- China's Enterprise Knowledge Management Model Case StudyDocument7 pagesChina's Enterprise Knowledge Management Model Case StudyCamilo ZuletaNo ratings yet

- Compiler Design Unit 1Document48 pagesCompiler Design Unit 1Shubham DixitNo ratings yet

- Shwetha CVDocument4 pagesShwetha CVKannan SrinivasanNo ratings yet

- Place of Assignment: Position Title: Plantilla Item No.: Salary/Job/Pay Grade: Monthly Salary: Eligibility: EducationDocument2 pagesPlace of Assignment: Position Title: Plantilla Item No.: Salary/Job/Pay Grade: Monthly Salary: Eligibility: EducationHRDBARMM CSCNo ratings yet

- Compiler Construction MCQDocument16 pagesCompiler Construction MCQSaadNo ratings yet

- Introduction to LALR ParsingDocument14 pagesIntroduction to LALR ParsingSmart BoyNo ratings yet

- Review of City's SAP Competency CentreDocument15 pagesReview of City's SAP Competency CentreLionelkeneth12No ratings yet

- Principles of Compiler Design: Million G/herDocument40 pagesPrinciples of Compiler Design: Million G/herBlack PandaNo ratings yet

- SHARMISTHA ROY CHOWDHURY'S RESUMEDocument6 pagesSHARMISTHA ROY CHOWDHURY'S RESUMEDeepak SimhadriNo ratings yet

- Getting Started With Your Financials ImplementationDocument158 pagesGetting Started With Your Financials Implementationsrikar valluNo ratings yet

- Jobster recruitment platformDocument12 pagesJobster recruitment platformAvanish PorwalNo ratings yet

- COE SetupDocument28 pagesCOE SetuphkodaliNo ratings yet

- TR2012 06 PDFDocument12 pagesTR2012 06 PDFmcmajedNo ratings yet

- E2E Project CharterDocument27 pagesE2E Project CharterMuhammad JaveedNo ratings yet

- PDF 11 Problems On Vat With Answers and Solutions - CompressDocument29 pagesPDF 11 Problems On Vat With Answers and Solutions - CompressAnna CharlotteNo ratings yet

- Project Management AssignmentDocument14 pagesProject Management AssignmentKIRUB100% (1)

- Criteria For SQF Certification Bodies: 7th EditionDocument22 pagesCriteria For SQF Certification Bodies: 7th EditionAlejandro Herrnsdorf-SakellaridisNo ratings yet

- SP QuestionDocument28 pagesSP QuestionPratik0% (1)

- CS 346: Code Generation: ResourceDocument52 pagesCS 346: Code Generation: ResourceAbhijit KaranNo ratings yet

- Ss Mod4 PDFDocument37 pagesSs Mod4 PDFLokeshwari TharaniNo ratings yet

- (Heni Vyas)Document5 pages(Heni Vyas)41- Vaibhav VyasNo ratings yet

- SAP IS Blue Print DocumentDocument4 pagesSAP IS Blue Print DocumentSupriyo DuttaNo ratings yet

- Vision, Mission, and Action DocumentDocument9 pagesVision, Mission, and Action DocumentSrivalli KondaNo ratings yet

- Technical Requirements HR System PayrollDocument115 pagesTechnical Requirements HR System PayrollbhujabaliNo ratings yet

- Pavement Management Implementation: Standard Guide ForDocument4 pagesPavement Management Implementation: Standard Guide ForEric GozzerNo ratings yet

- Greyhound Fleet Manager: Mca Project ReportDocument4 pagesGreyhound Fleet Manager: Mca Project ReportShalu OjhaNo ratings yet

- SS Gtu Question PapersDocument4 pagesSS Gtu Question PapersCS-18 Harshil JaganiNo ratings yet

- Oracle Global Human Resources Cloud: Getting Started With Your HR ImplementationDocument54 pagesOracle Global Human Resources Cloud: Getting Started With Your HR Implementationsamba0240No ratings yet

- Developing GIS Management Strategies For An OrganizationDocument22 pagesDeveloping GIS Management Strategies For An OrganizationPurushotham ReddyNo ratings yet

- Topic 3 - Memory ModelsDocument34 pagesTopic 3 - Memory ModelsThe AwsomistNo ratings yet