Professional Documents

Culture Documents

BC Elkton Cs

Uploaded by

Mohammed A. HelalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BC Elkton Cs

Uploaded by

Mohammed A. HelalCopyright:

Available Formats

Orbal Biological Nutrient Removal (BNR) system

Town of Elkton, MD WWTP

Envirex energy efficient activated sludge process meets stringent regulations while minimizing costs

Orbal BNR system enhanced biological

nutrient removal for an environmentally

conscious community.

Industry

Municipal Wastewater

Adapting to change

Business Challenges

The Town of Elkton, Maryland, located in Cecil County near the

head of the Chesapeake Bay, has a population of approximately

15,000 and an average elevation of 9.1 m (30 ft). Elkton

is an economically strong, stable community that is very

conscientious about environmental issues. In an effort to protect

the Chesapeake Bay aquatic life, new stringent wastewater

effluent regulations were implemented requiring very low

nutrient levels in wastewater treatment plant discharge.

Meet new stringent effluent requirements

Maximizing efficiency and gaining control with the Orbal BNR

system and SmartBNR process controls

In 2005, Elkton found itself out of compliance with the new,

lower nutrient level removal requirements for wastewater

treatment effluent. The existing system at the Elkton WWTP

consisted of fine bubble air diffusers, which failed to provide

consistent nitrification and sufficient denitrification to meet the

new stringent effluent requirements. The variability of treatment

conditions caused by diurnal flow and load changes was solved

by incorporating the SmartBNR electrical control system in the

design.

Satisfy the demands of a conscientious community

Keys to Success

Identify a BNR solution that provides constant

nitrification and sufficient denitrification

Minimize implementation and operating costs

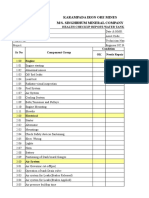

Results

Exceptional effluent quality

Flow 1.80 MGD

Power 1,930 kWh/MG, 0.97 kWh/lb BOD

BOD5 4.06 mg/L

TSS 3.41 mg/L

TP 0.07 mg/L with chemical addition

TN 1.95 mg/L

Energy consumption reduced by 40%

To ensure compliance, the town selected the proven Orbal BNR

system from Evoqua. The Orbal system is a suspended growth

activated sludge process that consists of a series of concentric

oxidation ditch channels operating in series. The design of this

system provides a higher overall kinetic reaction rate allowing

for treatment at higher organic loadings, the reduction in the

size of the basins, and lower construction costs.

The Orbal BNR system was the ideal solution for stringent nutrient

requirements at the Elkton, MD WWTP.

www.evoqua.com

Analyzing the process

The suspended growth activated sludge process begins when screened and

de-gritted wastewater is directed to the outer channel of the basin and mixed

with RAS from the clarifiers to form the systems mixed liquor. The combined

mixed liquor passes progressively through the Orbal BNR systems channels

before passing on to the final clarifiers. The outer channel is operated as an

aerated anoxic reactor with dissolved oxygen levels near 0 mg/L. Simultaneous

nitrification/denitrification and phosphorus release occurs in this zone.

Oxidation/reduction potential (ORP) is used to monitor the condition of the

outer channel. The middle channel is a transition zone between the outer

anoxic channel and the inner aerobic channel. Its condition may vary depending

on the load coming into the plant. The inner channel is maintained in an aerobic

state with dissolved oxygen levels at or above 2.0 mg/L. This supports the

final nitrification required to complete treatment. Each channel is physically

separated so the environment within each channel can be controlled precisely

to produce consistent treatment results.

The SmartBNR PLC based control system measures the ORP and dissolved

oxygen (DO) conditions within each treatment zone in the system.

Elktons Orbal BNR system basin was designed with a 16-day solids retention

time (SRT) to assure nitrification during cold weather operation. Other design

parameters were a MLSS of 4,000 mg/L and an organic loading rate of 16 lb

BOD/day /1000 ft3.

For enhanced denitrification, an internal recycle wall pump with a maximum

capacity of 12.8 MGD was included in the design to recycle nitrates in the

nitrified MLSS from the inner channel to the anoxic outer channel. A second

anoxic zone followed by a re-aeration zone downstream of the Orbal BNR

system basin was also included in the design to achieve greater than 95%

total nitrogen removal. The second anoxic zone was designed to have carbon

provided by endogenous respiration. This environment allows for maximum

denitrification without the need for supplemental carbon addition, which

results in additional daily operational cost savings.

Solutions/Services

Orbal BNR system, part of the

Envirex product line from Evoqua.

The solution includes a SmartBNR

Process Control system that makes

automatic process adjustments

Customers Primary Business

The public works department for

the Town of Elkton is charged with

protecting the quality of surface

waters, ponds, creeks and the Elk River,

while meeting regulatory requirements

for water and wastewater that ensure

the health of its approximately 15,000

residents.www.elkton.org/dept_works

Customer Location

Elkton, Maryland, USA

Effluent Characteristics

Flow

1.80 MGD

Power

1,930 kWh/MG

0.97 kWh/lb BOD

BOD5

4.06 mg/L

TSS

3.41 mg/L

TP

0.07 mg/L*

TN

1.95 mg/L

Exceeding expectations while conserving energy

The new Elkton Orbal BNR system was commissioned in December 2008 and

quasi steady-state operation was achieved by April 2009. The plant has been

producing outstanding effluent quality (performance data summarized on the

front). Additionally, the operational staff was able to optimize energy usage

to reduce power consumption by approximately 40% compared to their prior

system.

4800 North Point Parkway, Suite 250, Alpharetta, GA 30022

+1 (866) 926-8420 (toll-free)

+1 (978) 614-7233 (toll)

www.evoqua.com

Envirex, Orbal and SmartBNR are trademarks of Evoqua, its subsidiaries or affiliates in some countries.

All information presented herein is believed reliable and in accordance with accepted engineering practices. Evoqua

makes no warranties as to the completeness of this information. Users are responsible for evaluating individual product

suitability for specific applications. Evoqua assumes no liability whatsoever for any special, indirect or consequential

damages arising from the sale, resale or misuse of its products.

2014 Evoqua Water Technologies LLC

Subject to change without notice

BC-ELKTON-CS-0814

You might also like

- Flux Enhancement of RO Desalination ProcessesDocument5 pagesFlux Enhancement of RO Desalination ProcessesMohammed A. HelalNo ratings yet

- WOODAP - Solutions - METAWATERDocument2 pagesWOODAP - Solutions - METAWATERMohammed A. HelalNo ratings yet

- 06 Membrane Desalination CostsDocument2 pages06 Membrane Desalination CostsMohammed A. HelalNo ratings yet

- Integrity Journey enDocument7 pagesIntegrity Journey enMohammed A. HelalNo ratings yet

- Pathways To Resilience CCCPDocument68 pagesPathways To Resilience CCCPMohammed A. HelalNo ratings yet

- TMFD Web CV 8-14Document38 pagesTMFD Web CV 8-14Mohammed A. HelalNo ratings yet

- Activated Carbon or Charcoal FiltersDocument2 pagesActivated Carbon or Charcoal FiltersMohammed A. HelalNo ratings yet

- Tangential Flow Separation A New Way To Treat WasteDocument3 pagesTangential Flow Separation A New Way To Treat WasteMohammed A. HelalNo ratings yet

- Activated Carbon For Waste Water Treatment v2 NDocument8 pagesActivated Carbon For Waste Water Treatment v2 NMohammed A. Helal100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Christena Nippert-Eng - Watching Closely - A Guide To Ethnographic Observation-Oxford University Press (2015)Document293 pagesChristena Nippert-Eng - Watching Closely - A Guide To Ethnographic Observation-Oxford University Press (2015)Emiliano CalabazaNo ratings yet

- Bachelors - Harvest Moon Animal ParadeDocument12 pagesBachelors - Harvest Moon Animal ParaderikaNo ratings yet

- Standard nfx15-211Document2 pagesStandard nfx15-211Luis Enrique Cóndor PorrasNo ratings yet

- Explore The WorldDocument164 pagesExplore The WorldEduardo C VanciNo ratings yet

- Ed Post Lab Heat of Formation of NaClDocument4 pagesEd Post Lab Heat of Formation of NaClEdimar ManlangitNo ratings yet

- Conveyor Control Using Programmable Logic ControllerDocument7 pagesConveyor Control Using Programmable Logic ControllerWann RexroNo ratings yet

- Lec. 2Document22 pagesLec. 2محمدNo ratings yet

- Distribution BoardDocument7 pagesDistribution BoardmuralichandrasekarNo ratings yet

- Public Access - The GauntletDocument1 pagePublic Access - The GauntletTesting0% (2)

- A Review of Stories Untold in Modular Distance Learning: A PhenomenologyDocument8 pagesA Review of Stories Untold in Modular Distance Learning: A PhenomenologyPsychology and Education: A Multidisciplinary JournalNo ratings yet

- Buss40004 - Balance of PowerDocument3 pagesBuss40004 - Balance of PowerVishwa NirmalaNo ratings yet

- Nuclear Power Engineering (MEE 2027) : Fall Semester (2020-2021)Document13 pagesNuclear Power Engineering (MEE 2027) : Fall Semester (2020-2021)AllNo ratings yet

- Mule 4 Error Handling DemystifiedDocument8 pagesMule 4 Error Handling DemystifiedNicolas boulangerNo ratings yet

- HU - Century Station - PAL517PDocument232 pagesHU - Century Station - PAL517PTony Monaghan100% (3)

- 2a Unani Medicine in India - An OverviewDocument123 pages2a Unani Medicine in India - An OverviewGautam NatrajanNo ratings yet

- Chap9 PDFDocument144 pagesChap9 PDFSwe Zin Zaw MyintNo ratings yet

- Taylor Et Al v. Acxiom Corporation Et Al - Document No. 91Document40 pagesTaylor Et Al v. Acxiom Corporation Et Al - Document No. 91Justia.comNo ratings yet

- Alpha Sexual Power Vol 1Document95 pagesAlpha Sexual Power Vol 1Joel Lopez100% (1)

- FAO-Assessment of Freshwater Fish Seed Resources For Sistainable AquacultureDocument669 pagesFAO-Assessment of Freshwater Fish Seed Resources For Sistainable AquacultureCIO-CIO100% (2)

- Topic Group Present (Week 8) Chapter 1:sociology and Learning ManagementDocument2 pagesTopic Group Present (Week 8) Chapter 1:sociology and Learning ManagementLEE LEE LAUNo ratings yet

- BIOBASE Vortex Mixer MX-S - MX-F User ManualDocument10 pagesBIOBASE Vortex Mixer MX-S - MX-F User Manualsoporte03No ratings yet

- Ymrtc LogDocument26 pagesYmrtc LogVinicius Silveira0% (1)

- Water Tanker Check ListDocument8 pagesWater Tanker Check ListHariyanto oknesNo ratings yet

- P. E. and Health ReportDocument20 pagesP. E. and Health ReportLESSLY ABRENCILLONo ratings yet

- Power Control 3G CDMADocument18 pagesPower Control 3G CDMAmanproxNo ratings yet

- Internship ReportDocument36 pagesInternship ReportM.IMRAN0% (1)

- Will Smith BiographyDocument11 pagesWill Smith Biographyjhonatan100% (1)

- PreviewpdfDocument83 pagesPreviewpdfJohana GavilanesNo ratings yet

- Morse Potential CurveDocument9 pagesMorse Potential Curvejagabandhu_patraNo ratings yet

- Rockwell Collins RDRDocument24 pagesRockwell Collins RDRMatty Torchia100% (5)