Professional Documents

Culture Documents

Air Bag Explorer

Uploaded by

Enrique Felipe Reveco BahamondesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Bag Explorer

Uploaded by

Enrique Felipe Reveco BahamondesCopyright:

Available Formats

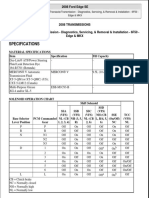

AIR BAG RESTRAINT SYSTEM

Article Text

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

ARTICLE BEGINNING

1997 ACCESSORIES/SAFETY EQUIPMENT

Ford Motor Co. - Air Bag Restraint System

Ford; Explorer

Mercury; Mountaineer

* PLEASE READ THIS FIRST *

WARNING: To avoid injury from accidental air bag deployment, read and

carefully follow all WARNINGS and SERVICE PRECAUTIONS.

IDENTIFICATION

Vehicle is equipped with driver-side and passenger-side air

bags and are identified by a letter "L" in fourth position of Vehicle

Identification Number (VIN). VIN is located on top of instrument

panel, near lower left corner of windshield. VIN is also stamped on

Vehicle Certification (VC) label, mounted on left front door pillar.

The words Supplemental Restraint System (SRS) are embossed on

steering wheel center hub and/or on instrument panel above glove box.

A label denoting that vehicle is equipped with air bags is affixed to

driver-side sun visor.

DESCRIPTION & OPERATION

The Supplemental Restraint System (SRS) is designed to

provide increased accident protection for driver and passenger by

deploying air bags in a front-end collision. The air bags, stored in

center of steering wheel and in instrument panel above glove box,

deploy in about 40 milliseconds after impact sensors close. SRS is

designed to be used with 3-point safety belts.

During a front-end collision, front impact sensor internal

balls are thrown forward. The balls complete an electrical circuit and

ignite inflator to deploy air bag. At least 2 sensors, one safing

sensor and one front impact sensor, must activate simultaneously to

inflate air bag.

SRS includes following components: diagnostic monitor,

driver-side air bag module, passenger-side air bag module, SRS

readiness light (AIR BAG warning light), front impact sensor and

safing sensor, ignitor assemblies (in air bag modules), clockspring)

and associated wiring harnesses.

BACK-UP POWER SUPPLY

A back-up power supply is used on all models and is located

inside diagnostic monitor. If battery or battery cables are damaged in

a collision before front impact sensors close circuit, back-up power

supply will deploy air bags. Back-up power supply will hold a

deployment charge for approximately one minute after positive battery

AIR BAG RESTRAINT SYSTEM

Article Text (p. 2)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

cable is disconnected.

CLOCKSPRING

The steering column contains a clockspring contact assembly

to transfer electrical signals from steering column wiring harness to

driver-side air bag module. Clockspring is mounted to steering column

behind steering wheel.

DIAGNOSTIC MONITOR

The diagnostic monitor is located at center of instrument

panel. The diagnostic monitor contains a microcomputer, which monitors

electrical system components and connections. Diagnostic monitor

performs a system self-check of SRS internal circuits every time

ignition switch is turned to RUN position. Monitor also energizes SRS

readiness indicator light (AIR BAG warning light) during initial

system self-check and whenever a fault is detected. Faults are

translated into flash codes and are displayed through AIR BAG warning

light.

If a system fault exists and/or AIR BAG warning light is

malfunctioning, an audible tone will sound, indicating need for

service. See TONE GENERATOR. Diagnostic monitor can also disarm SRS if

certain faults occur.

DRIVER-SIDE AIR BAG MODULE

The driver-side air bag module is mounted on front face of

steering wheel, covered by steering wheel trim cover. When front

impact sensors and safing sensor close, signaling an impact, ignitor

triggers inflator. During ignition, sodium azide reacts with copper

oxide, producing nitrogen gas, which inflates air bag.

When air bag deploys, tear-seams molded into steering wheel

trim cover separate, allowing inflation of air bag assembly. Driverside air bag module is not serviceable and must be replaced as a

complete assembly.

PASSENGER-SIDE AIR BAG MODULE

The passenger-side air bag module is mounted in right side of

instrument panel, above glove box. When a front impact sensor and

safing sensor close, signaling an impact, air bag igniters trigger

inflator.

Since passenger-side air bag is larger than driver-side air

bag, inflator contains more gas generant in a different configuration

to produce more gas. When air bag is activated, instrument panel trim

cover tears at seams and hinges, allowing inflation. Passenger-side

air bag module is only serviced as a complete assembly.

ELECTRICAL SYSTEM

SRS is powered directly from battery and can function with

AIR BAG RESTRAINT SYSTEM

Article Text (p. 3)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

ignition switch in any position, including OFF and LOCK. System can

also function when driver-side and passenger-side seats are

unoccupied. The 3 main functions performed by electrical subsystem

are: detecting an impact, switching electric power to igniters for air

bags, and monitoring readiness of SRS.

IMPACT SENSORS

Each impact sensor reacts to impacts according to direction

and force. It discriminates between impacts that require air bag

inflation and impacts that do not.

When an impact occurs requiring air bag inflation, impact

sensor contacts close, completing electrical circuit necessary for

system operation. At least 2 sensors, one safing and one front impact,

must be activated simultaneously to inflate air bags. Front impact

sensors are located at left and right sides of radiator support.

Safing sensor is integral with air bag diagnostic monitor.

Fig. 1: Locating SRS Components

Courtesy of Ford Motor Co.

AIR BAG RESTRAINT SYSTEM

Article Text (p. 4)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

TONE GENERATOR

AIR BAG warning light is prime means of determining SRS

condition; however, a series of 5 audible tones, indicating that

system requires servicing, will sound if AIR BAG warning light is out,

and a fault occurs in system. Unless serviced, SRS may not function

properly in an accident.

SYSTEM OPERATION CHECK

1) When checking SRS operation, and upon completion of each

diagnostic test, check for faults in SRS. To check system, turn

ignition switch to RUN position. If AIR BAG warning light glows for 48 seconds and then goes out, SRS is functioning properly and no fault

codes exist.

2) If a fault code is detected in SRS during initial system

check, AIR BAG warning light will either fail to light, stay on

continuously, or flash a code sequence. If AIR BAG warning light

flashes, indicating a fault in system, count number of flashes after

fault code has cycled twice. Number of flashes represents a code

number used to diagnose SRS. See DIAGNOSIS & TESTING.

3) If a system fault exists and AIR BAG warning light fails

to light, an audible tone will be heard, indicating AIR BAG warning

light is out and service is required. See TONE GENERATOR

under DESCRIPTION & OPERATION.

SERVICE PRECAUTIONS

These precautions should be observed when working with SRS:

*

*

*

*

Disable SRS before servicing any SRS or steering column

components. Failure to do so may result in accidental air

bag deployment and personal injury. See procedures under

DISABLING & ACTIVATING AIR BAG SYSTEM.

Wait one minute after disabling SRS before working on

vehicle. Back-up power supply holds a deployment charge for

approximately one minute after positive battery cable is

disconnected. Servicing SRS before one minute may cause

accidental air bag deployment and possible personal injury.

Because of critical system operating requirements, DO NOT

service impact sensors, clockspring, diagnostic monitor or

air bag modules. Repairs are made by replacement only.

Always wear safety glasses whenever servicing an air bag

equipped vehicle or handling an air bag.

When carrying a live air bag module, ensure air bag module

and trim cover are pointed away from your body. This

minimizes chance of injury in event of an accidental

deployment.

When placing a live air bag module on a bench or other

surface, always face air bag module and trim cover facing up

and away from surface. This will reduce motion of module if

it is accidentally deployed.

AIR BAG RESTRAINT SYSTEM

Article Text (p. 5)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

*

*

*

*

*

*

After deployment, air bag surface may contain deposits of

sodium hydroxide, which may irritate skin. Sodium hydroxide

is a product of gas generant combustion. Always wear gloves

and safety glasses when handling a deployed air bag. Wash

your hands using mild soap and water. Follow correct

disposal procedures. See DISPOSAL PROCEDURES.

If scrapping a vehicle with an undeployed air bag module,

air bag must be deployed. See DISPOSAL PROCEDURES.

If a part is replaced and new part does not correct

condition, reinstall original part and perform diagnostic

procedure again.

Never probe connectors on air bag module. Doing so may cause

air bag deployment and/or personal injury.

Instruction to disconnect always refers to connector. DO NOT

remove component from vehicle if instructed to disconnect.

After any servicing, ensure AIR BAG warning light does not

indicate any fault codes. See SYSTEM OPERATION CHECK.

Replace air bag module if trim cover (deployment doors) is

marred or damaged. DO NOT repaint trim cover. Paint may

degrade cover material. Replace air bag module as necessary.

See SCRAPPED VEHICLE under DISPOSAL PROCEDURES.

DISABLING & ACTIVATING AIR BAG SYSTEM

* PLEASE READ THIS FIRST *

WARNING: Wait one minute after disabling SRS before working on

vehicle. Back-up power supply holds a deployment charge for

approximately one minute after positive battery cable is

disconnected. Servicing SRS before one minute may cause

accidental air bag deployment and possible personal injury.

CAUTION: When battery is disconnected, vehicle computer and memory

systems may lose memory data. Driveability problems may

exist until computer systems have completed a relearn cycle.

See COMPUTER RELEARN PROCEDURES in GENERAL INFORMATION

before DISCONNECTING BATTERY.

DISABLING SYSTEM

NOTE:

Following procedure should be used for component replacement

purposes only. If vehicle was involved in a collision and air

bag did not deploy or if SRS is not functioning properly, and

vehicle needs to be driven, complete system deactivation is

required. See COMPLETE SYSTEM DEACTIVATION.

Disconnect negative battery cable and then positive battery

cable. Wait at least 1 minute before servicing any air bag components.

System is now disabled.

ACTIVATING SYSTEM

AIR BAG RESTRAINT SYSTEM

Article Text (p. 6)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

Connect positive battery cable and then negative battery

cable. System is now activated. From outside of vehicle, turn ignition

switch to RUN position. Check AIR BAG warning light for system fault

codes. Perform system operation check to ensure SRS is functioning

properly. See SYSTEM OPERATION CHECK.

COMPLETE SYSTEM DEACTIVATION

WARNING: Back-up power supply will hold a deployment charge for

approximately one minute after positive battery cable is

disconnected. Servicing SRS before one minute may cause

accidental air bag deployment and possible personal injury.

Always deactivate driver-side and passenger-side air bag

modules before attempting any service procedures.

NOTE:

Complete system deactivation sequence is required

for following situations:

*

*

*

Vehicle was involved in a collision, air bags did not

deploy, and vehicle needs to be driven.

SRS is not functioning properly, and vehicle needs to

be driven.

Diagnosis and testing purposes.

1) Disconnect negative and positive battery cable Wait at

least one minute to deplete charge in back-up power supply. Remove

driver-side air bag module. See DRIVER-SIDE AIR BAG MODULE under

REMOVAL & INSTALLATION.

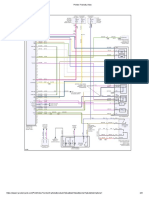

2) Connect Air Bag Simulator (105-00011) to vehicle harness

at top of steering wheel. See Fig. 2. Remove passenger-side air bag

module. See PASSENGER-SIDE AIR BAG MODULE under REMOVAL &

INSTALLATION. Connect air bag simulator (105-000-10) to passenger-side

air bag vehicle harness connector. Connect negative battery cable. To

reactivate SRS, see COMPLETE SYSTEM REACTIVATION.

Fig. 2: Installing Driver-Side Air Bag Simulator

Courtesy of Ford Motor Co.

AIR BAG RESTRAINT SYSTEM

Article Text (p. 7)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

COMPLETE SYSTEM REACTIVATION

1) Disconnect negative and positive battery cables. Remove

air bag simulator from clockspring connector. Remove air bag simulator

from passenger-side air bag vehicle harness connector. Install driverside air bag module. See DRIVER-SIDE AIR BAG MODULE under REMOVAL &

INSTALLATION.

2) Install passenger-side air bag module. See

PASSENGER-SIDE AIR BAG MODULE under REMOVAL & INSTALLATION. Reconnect

positive and negative battery cables. System is now reactivated.

Perform system operation check to ensure SRS is functioning properly.

See SYSTEM OPERATION CHECK.

DISPOSAL PROCEDURES

* PLEASE READ THIS FIRST *

WARNING: Refer to SERVICE PRECAUTIONS before proceeding.

Air bag disposal may be necessary in following situations:

*

*

*

*

Scrapping vehicle with

Scrapping vehicle with

Disposal of a live but

Disposal of a deployed

deployed air bag.

live air bag.

electrically faulty air bag module.

air bag module.

AIR BAG DISPOSAL PROCEDURES TABLE

---------------------------------------------------------------------Condition

Instructions

Module Replacement

Deployed Air Bag .................. (1) Dispose Of In Usual Manner

Faulty But Live Air Bag Module ........... (2) Return For Disposal

Vehicle To Be Scrapped

Deployed Air Bag .................. (1) Dispose Of In Usual Manner

Live Air Bag .................................. (2) Deploy Air Bag

(1) - Contact vehicle manufacturer for proper disposal instructions.

(2) - See SCRAPPED VEHICLE.

---------------------------------------------------------------------DEPLOYED AIR BAG

Dispose of deployed air bag module as any other part. Air bag

module components are not reusable.

UNDEPLOYED AIR BAG - FAULTY UNIT

If an undeployed air bag module is diagnosed as faulty,

contact vehicle manufacturer for proper disposal instructions.

SCRAPPED VEHICLE

AIR BAG RESTRAINT SYSTEM

Article Text (p. 8)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

CAUTION: DO NOT dispose of undeployed air bag modules without first

deploying air bag. If this is not possible through

procedure outlined, contact vehicle manufacturer for

further instructions.

If vehicle is to be scrapped, undeployed air bag module must

first be deployed. Use the following procedure for deployment of air

bag.

Remote Deployment Of Air Bag

This procedure is to be used when a vehicle with a live

driver-side or passenger-side air bag is to be scrapped, but a problem

in air bag electrical system prevents deployment with air bag still

installed in vehicle.

WARNING: Perform remote deployment outdoors. Keep all personnel at

least 20 feet away to ensure physical and hearing safety

from projected objects and loud noise of air bag deployment.

1) Before proceeding, see SERVICE PRECAUTIONS. Deactivate

system. See DISABLING & ACTIVATING AIR BAG SYSTEM.

2) Remove air bag modules. See DRIVER-SIDE AIR BAG MODULE and

PASSENGER-SIDE AIR BAG MODULE under REMOVAL & INSTALLATION. With air

bag modules removed, cut air bag connector from wiring harness near

air bag module. Strip 1" of insulation from wire ends. Obtain 2 wires

at least 20 feet long. Connect one end of each 20-foot wire to one end

of each air bag module wire.

WARNING: When placing a live air bag on a bench or other surface,

always face air bag and trim cover up and away from surface.

This will reduce motion of air bag module if it is

accidentally deployed.

3) Place air bag module with trim cover facing upward on a

flat surface, in remote area such as parking lot or field. Remain at

least 20 feet away from air bag module. Deploy air bag by touching

loose ends of both wires to 12-volt battery terminals.

4) If successful, a loud noise will be heard and bag material

will be visible. Allow at least 10 minutes for cooling and dissipation

of air bag effluents before approaching air bag. Air bag is now

inoperative. If air bag does not deploy, air bag module is faulty.

Contact vehicle manufacturer for further instructions on disposal

procedures.

POST-COLLISION INSPECTION

When a vehicle has been involved in a collision, certain

components of the passive restraint system must be inspected or

replaced. See PASSIVE RESTRAINT SYSTEM INSPECTION article in the

GENERAL INFORMATION section for post-collision inspection information.

AIR BAG RESTRAINT SYSTEM

Article Text (p. 9)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

REMOVAL & INSTALLATION

* PLEASE READ THIS FIRST *

WARNING: Failure to follow service precautions may result in air bag

deployment and personal injury. See SERVICE PRECAUTIONS.

After component replacement, ensure proper system operation.

See SYSTEM OPERATION CHECK.

CAUTION: When battery is disconnected, vehicle computer and memory

systems may lose memory data. Driveability problems may

exist until computer systems have completed a relearn cycle.

See COMPUTER RELEARN PROCEDURES in GENERAL INFORMATION

before DISCONNECTING BATTERY.

CLOCKSPRING

1) Before proceeding, see SERVICE PRECAUTIONS. Disable SRS.

See DISABLING & ACTIVATING AIR BAG SYSTEM.

CAUTION: When removing steering wheel, DO NOT use a knock-off type

steering wheel puller, or strike steering wheel or shaft

with a hammer. A sudden impact could damage bearing or

collapse steering column.

2) Remove driver-side air bag module. See

DRIVER-SIDE AIR BAG MODULE. Ensure vehicle front wheels are in

straight-ahead position and steering column shaft alignment mark is at

12 o'clock position. Remove steering wheel. See STEERING WHEEL.

3) If equipped, twist tilt wheel handle and shank and remove.

Remove 3 screws and upper and lower steering column shroud. Insert

ignition key into ignition switch and turn to RUN position. Push lock

cylinder release tab with punch while pulling out ignition lock

cylinder. Use service lock to fix sliding contact in position. If

service lock is missing, apply 2 strips of making tape across

clockspring to prevent accidental rotation. Remove key-in warning

indicator switch.

4) Disconnect clockspring connector and separate air bag

electrical connector from bracket. Pry retaining clips loose. Separate

wire from 2 retaining clips holding wire to column. Feed wire harness

through steering column. Remove clockspring.

NOTE:

Service replacement clockspring will contain a Red plastic

locking insert to prevent rotation. DO NOT remove insert

until clockspring is securely installed on column.

AIR BAG RESTRAINT SYSTEM

Article Text (p. 10)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

Fig. 3: Removing Clockspring From Steering Column

Courtesy of Ford Motor Co.

Installation

1) Install and align clockspring with air bag electrical

pigtail pointing at 3 o'clock position and dot on steering shaft

should be at 9 o'clock position. Press at 6, 12 and 3 o'clock

positions to seat clockspring. Rotate wiring, secure into wire clips,

connect 2 electrical connectors and snap into bracket. Install key-in

ignition warning indicator switch. If new clockspring is used, remove

yellow anti-rotation tab.

3) If clockspring was rotated accidentally during removal

from vehicle, adjust clockspring. See CLOCKSPRING.

4) To complete installation, reverse removal procedure.

Activate air bag system. Check AIR BAG warning light to assure system

is functioning properly. See SYSTEM OPERATION CHECK.

DIAGNOSTIC MONITOR

CAUTION: When replacing air bag diagnostic monitor, with blown

internal thermal fuse, be sure that all short circuits and

damaged wiring have been repaired. Diagnostic portion of

diagnostic monitor are still intact, and must be used to

diagnose and verify repairs before diagnostic monitor

replacement.

AIR BAG RESTRAINT SYSTEM

Article Text (p. 11)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

Removal

1) Before proceeding, see SERVICE PRECAUTIONS. Disable SRS.

See DISABLING & ACTIVATING AIR BAG SYSTEM.

2) Diagnostic monitor is located behind right side kick

panel. See Fig. 4. Remove front door scuff plate. Remove right kick

panel. Diagnostic monitor is the Blue box. Disconnect diagnostic

monitor connectors. Remove diagnostic monitor bracket retaining bolts.

Remove diagnostic monitor and bracket as an assembly.

Fig. 4: Removing Air Bag Diagnostic Monitor

Courtesy of Ford Motor Co.

Installation

To install diagnostic monitor, reverse removal procedure.

Tighten retaining screws to specification. See TORQUE SPECIFICATIONS.

Activate air bag system. Check AIR BAG warning light to ensure system

is functioning properly. See SYSTEM OPERATION CHECK.

DRIVER-SIDE AIR BAG MODULE

1) Before proceeding, see SERVICE PRECAUTIONS. Disable SRS.

See DISABLING & ACTIVATING AIR BAG SYSTEM.

AIR BAG RESTRAINT SYSTEM

Article Text (p. 12)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

2) Remove 2 cover plugs from rear of steering wheel. Remove

screws and washers which retain air bag module to steering wheel. See

Fig. 5. Disconnect air bag electrical connector from clockspring

(clockspring assembly). Remove air bag module from vehicle.

Fig. 5: Removing Driver-Side Air Bag Module

Courtesy of Ford Motor Co.

Installation

Connect air bag module to clockspring connector. Position air

bag module onto steering wheel. Install air bag module retaining

screws and washers and tighten to specification. See

TORQUE SPECIFICATIONS. Activate air bag system. Check AIR BAG warning

light to ensure system is functioning properly. See

SYSTEM OPERATION CHECK.

PASSENGER-SIDE AIR BAG MODULE

1) Before proceeding, see SERVICE PRECAUTIONS. Disable SRS.

See DISABLING & ACTIVATING AIR BAG SYSTEM.

2) Open glove box. Remove 2 screws and pull out passengerside air bag. Disconnect electrical connector. See Fig. 6.

Installation

To install passenger-side air bag, reverse removal

procedures. Check AIR BAG warning light to ensure system is

functioning properly. See SYSTEM OPERATION CHECK.

AIR BAG RESTRAINT SYSTEM

Article Text (p. 13)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

Fig. 6: Removing/Installing Passenger-Side Air Bag

Courtesy of Ford Motor Co.

Installation

To install, reverse removal procedure. Tighten bracket bolts

to specifications. See TORQUE SPECIFICATIONS. Activate air bag system.

Check AIR BAG warning light to ensure system is functioning properly.

See SYSTEM OPERATION CHECK.

FRONT IMPACT SENSORS

Removal

1) Front impact sensors are attached to left and right sides

of radiator support. Before proceeding, see SERVICE PRECAUTIONS.

Disable SRS. See DISABLING & ACTIVATING AIR BAG SYSTEM.

2) Remove radiator grille and opening cover. Remove screws,

disconnect connectors and remove sensor and bracket. See Fig. 7.

AIR BAG RESTRAINT SYSTEM

Article Text (p. 14)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

Fig. 7: Removing Front Impact Sensor

Courtesy of Ford Motor Co.

Installation

To install, reverse removal procedure. Tighten retaining

screws to specification. See TORQUE SPECIFICATIONS. If proper torque

cannot be achieved, replace stripped mounting bracket and screw with

Bracket (14B191), Screw (N806327-S190), and Screw (W620397-S36). Check

AIR BAG warning light to ensure system is functioning properly. See

SYSTEM OPERATION CHECK.

NOTE:

Vehicle sensor orientation is critical for proper system

operation. If a vehicle equipped with SRS is involved in a

crash, and fenders or grille area have been damaged, inspect

AIR BAG RESTRAINT SYSTEM

Article Text (p. 15)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

sensor mounting brackets for deformation. If damaged, system

should be deactivated to ensure air bag does not deploy. See

COMPLETE SYSTEM DEACTIVATION under DISABLING &

ACTIVATING AIR BAG SYSTEM. Damaged sensor(s) should be

replaced, whether or not air bag has been deployed. In

addition, ensure body structure in area of sensor mounting is

restored to its original construction.

STEERING WHEEL

Removal

1) Before proceeding, see SERVICE PRECAUTIONS. Disable SRS.

See DISABLING & ACTIVATING AIR BAG SYSTEM.

2) Disconnect speed control wiring harness (if equipped) from

steering wheel. Loosen steering wheel retaining bolt 2-3 turns.

Install Differential Side Bearing Puller (T77F-4220-B1), at position

marked PULL. Unseat steering wheel and remove puller.

3) Remove and discard steering wheel retaining bolt. Remove

steering wheel. Route clockspring wiring harness through steering

wheel as wheel is lifted from steering shaft.

Installation

1) Ensure front wheels are in straight-ahead position. Route

clockspring wiring harness through steering wheel opening at 3 o'clock

position. Position steering wheel on steering shaft and align

installation marks.

2) Ensure air bag clockspring wire is not pinched when

positioning steering wheel. Install new steering wheel retaining

bolt, and tighten to specification. See TORQUE SPECIFICATIONS. Connect

speed control wiring harness (if equipped) to steering wheel, and snap

connector assembly into steering wheel clip.

3) Install driver-side air bag module. See

DRIVER-SIDE AIR BAG MODULE. Activate SRS. Check AIR BAG warning light

to ensure system is functioning properly. See SYSTEM OPERATION CHECK.

ADJUSTMENTS

Information is not available from manufacturer. Wiring from

clockspring to air bag module must align with hole in steering wheel.

If wiring is not aligned properly, wiring may accidentally be cut when

steering wheel is installed and rotated.

WIRE REPAIR

To repair damage to sensor wiring and wiring harnesses, note

following conditions and proceed to REPAIR PROCEDURE.

*

*

*

All wire splice connections must be staggered at least

2" (50 mm) apart.

Use proper size butt connectors and shrink tubing for size

of wire being spliced.

All repaired connections must be waterproofed using heat

AIR BAG RESTRAINT SYSTEM

Article Text (p. 16)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

shrink tubing.

Use of transparent butt connectors allows inspection of

finished crimped connector to ensure proper connection.

Repair Procedure

Cut shrink tubing 1" longer than butt connector. Slide shrink

tubing onto one wire end first. Insert pre-stripped wire ends into

proper size butt connector, and crimp connector using appropriate

crimping pliers. See Fig. 8. Slide shrink tubing over butt connector,

leaving 1/2" of tubing on each side of connector. Using heat gun, hair

dryer or match, heat tubing until it shrinks and adhesive flows from

each end of tubing. Connection is now waterproofed.

Fig. 8: Repairing & Waterproofing Wiring Connections

Courtesy of Ford Motor Co.

DIAGNOSIS & TESTING

* PLEASE READ THIS FIRST *

WARNING: Failure to follow service precautions may result in air bag

deployment and personal injury. See SERVICE PRECAUTIONS.

After component replacement, ensure proper system operation.

AIR BAG RESTRAINT SYSTEM

Article Text (p. 17)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

See SYSTEM OPERATION CHECK.

SELF-DIAGNOSTICS

During vehicle operation, air bag diagnostic monitor detects

and stores both intermittent and hard failure codes in non-volatile

memory. The DTCs can be retrieved with the New Generation Star (NGS)

tester using the retrieve/clear continuous codes option. If no DTCs

are present, NGS Tester will display SYSTEM PASSED message. Once a

fault code is logged in air bag diagnostic monitor memory, it will

stay in memory until 80 ignition cycles have been recorded or until

NGS is used to erase the DTCs.

RETRIEVING FAULT CODES

1) To retrieve and/or clear DTCs, follow these step: Connect

NGS to Data Link Connector (DLC). Turn ignition switch to RUN

position. Select MODEL YEAR and VEHICLE. Select DIAGNOSTIC DATA LINK.

Select IABM-INTEGRATED AIR BAG MONITOR. Select DIAGNOSTIC TEST MODES.

Select RETRIEVE/CLEAR CONTINUOUS DTCs.

2) After pressing START, all continuous DTCs will be

displayed open screen. Before proceeding with clearing operation, make

note of DTCs displayed. See FAULT CODE IDENTIFICATION table. See

DIAGNOSTIC TESTS. Once cleared, DTCs cannot be retrieved.

RETRIEVING STORED FAULT CODES

To clear all DTCs, press C ALL. Clearing of individual

(C ONE) is not supported by air bag diagnostic monitor. The NGS

retrieve DTCs again after clearing DTCs, and if any remain they

be displayed. Hard DTCs will be redisplayed after clearing DTCs

they cannot be cleared from air bag diagnostic monitor.

FAULT CODE IDENTIFICATION TABLE

-----------------------------------------------------------Fault Code

Flash Code

Description

B1342

B1867

B1869

B1913

B1914

B1921

....

....

....

....

....

....

B1922

....

B1923

....

B1924

....

B1932

....

24 ............ Internal Microprocessor Fault

12/52 ................... Low Battery Voltage

-- ......... No Indicator/Inoperative Circuit

13/53 ..... Air Bag Circuit Shorted To Ground

14/54 ......... Impact Sensor Short To Ground

21 ........... Diagnostic Monitor Not Mounted

To Vehicle Properly

22 ................. Safing Sensor Shorted To

Battery Voltage

23 ...................... Memory Clear Circuit

Improperly Grounded

24 ........ System Disarm Failure Or Internal

Diagnostic Monitor Fault

32 .................. High Resistance Or Open

In Driver-Side Air Bag Circuit

DTCs

will

will

since

AIR BAG RESTRAINT SYSTEM

Article Text (p. 18)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

B1933

....

33

.................. High Resistance Or Open

In Passenger-Side Air Bag Circuit

B1934 .... 34 .................. Low Resistance Or Short

In Driver-Side Air Bag Circuit

B1935 .... 35 .................. Low Resistance Or Short

In Passenger-Side Air Bag Circuit

B1941 .... 41 ............... Center/Right Impact Sensor

Feed/Return Circuit Open

B1942 .... 42 ....................... Left Impact Sensor

Feed/Return Circuit Open

B1944 .... 44 ............... Center/Right Impact Sensor

Not Mounted To Vehicle Properly

B1945 .... 45 ....................... Left Impact Sensor

Not Mounted To Vehicle Properly

-----------------------------------------------------------DIAGNOSTIC TESTS

ON-DEMAND SELF-TEST

1) Connect NGS to data link connector. Turn ignition switch

to RUN position. Select MODEL YEAR and VEHICLE. Select DIAGNOSTIC DATA

LINK. Select IABM-INTEGRATED AIR BAG MONITOR. Select DIAGNOSTIC TEST

MODES. Select ON-DEMAND SELF TEST. Press START and then TRIGGER.

2) Air bag diagnostic monitor will run on demand self test

and display ON-DEMAND DTCs on the screen.

PINPOINT TEST A: LFC52/DTC B1867 - LOW BATTERY VOLTAGE

NOTE:

Before proceeding, see SERVICE PRECAUTIONS. After

servicing has been performed, recheck AIR BAG warning light.

If system is okay, install air bag modules and reactivate air

bag system.

1) Check For Hard Or Intermittent DTC

Connect NGS tester to DLC. Perform ON-DEMAND SELF-TEST. If

DTC B1867 is retrieved, go to step 2). If DTC B1867 is not retrieved,

go to step 7).

WARNING: Certain fault conditions may cause diagnostic monitor to

intentionally blow mini fuse 4 (10A). DO NOT use any other

fuse value except a 10-amp fuse. Substituting any other fuse

value may cause future disarming failure and may result in

danger to vehicle occupants.

2) Check B+ Power Supply

Connect NGS to DLC. Select IABM. Select Pid/Data Monitor and

Record. Select Pid VBATIAB. If voltage is less than 5 volts, go to

step 4). If voltage is more than 5 volts, go to next step.

3) Check Charging System

Measure charging system voltage. If voltage is more than 9

AIR BAG RESTRAINT SYSTEM

Article Text (p. 19)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

volts, deactivate system. See COMPLETE SYSTEM DEACTIVATION. Replace

air bag diagnostic monitor. Reconnect system. Verify system.

Reactivate system and go to step 10).

4) Check Battery Fuses

Deactivate system. See COMPLETE SYSTEM DEACTIVATION.

Disconnect air bag diagnostic monitor connectors. Check mini fuse 4

(10-amp) in power distribution box feeding diagnostic monitor terminal

No. C232-13 and C232-14. See Fig. 9. If fuse is blown, go to next

step. If fuse is not blown, repair circuit 937 (Red/White wire) for

open. Check in-line connector, crimps, etc. Connect diagnostic

monitor. Go to step 10).

Fig. 9: Identifying Air Bag Diagnostic Monitor Connectors

Courtesy of Ford Motor Co.

AIR BAG RESTRAINT SYSTEM

Article Text (p. 20)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

5) Check For Short in Harness

Replace blown fuse. Do not use any substitutions. If fuse

blows again, repair short to ground on circuit 937 (Red/White wire).

Connect air bag diagnostic monitor. Go to step 10). If fuse does not

blow, go to next step.

WARNING: Certain fault conditions may cause diagnostic monitor to

intentionally blow mini fuse 4 (10A). DO NOT use any other

fuse value except a 10-amp fuse. Substituting any other fuse

value may cause future disarming failure and may result in

danger to vehicle occupants.

6) Confirm Condition

Reconnect air bag diagnostic monitor connectors. If fuse

blows, replace diagnostic monitor. Replace fuse. Reconnect system.

Reactivate system. Go to step 10). If fuse does not blow, go to step

10).

7) Check If repaired

Deactivate system. If DTC B1867 has just been repaired, check

mini fuse 4 (10A). Go to step 10). If DTC B1867 has not just been

repaired, go to step 8).

8)

If

mini fuse 4

problem, go

Check Charging System

there is a charging system problem, repair problem. Check

(10A). Go to step 10). If there is not a charging system

to next step.

9) Check Battery Feed

Inspect all crimps, terminals, fuses, wires, etc. in circuit

937 (Red/White wire) feeding terminal No. C232-13 and C232-14 of air

bag diagnostic monitor. See Fig. 9. Look for poor connections, etc. If

problems are noted, repair problems, check mini fuse 4 (10A) and go to

step 10). If no problems are noted, recheck fault code. Look for

causes of intermittent low battery voltage at terminal No. C232-13

circuit 937 (Red/White wire). See Fig. 9. Correct intermittent fault

and go to step 10).

10) Check For Other DTCs

Connect NGS to DLC. If other DTCs are retrieved go to proper

DTC test. If no other DTCs are retrieved, reactivate system and clear

all DTCs.

PINPOINT TEST B: LFC13, LFC53/DTC B1913 - AIR BAG CIRCUIT

SHORT TO GROUND

NOTE:

Before proceeding, see SERVICE PRECAUTIONS. After

servicing has been performed, recheck AIR BAG warning light.

If system is okay, install air bag modules and reactivate air

bag system.

1) Check For Hard Or Intermittent DTC

AIR BAG RESTRAINT SYSTEM

Article Text (p. 21)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

Connect NGS tester to DLC. Perform ON-DEMAND SELF-TEST. If

DTC B1913 is retrieved, go to step 2). If DTC B1913 is not retrieved,

go to step 11).

2) Check For Shorted Air Bag

Deactivate air bag system. See COMPLETE SYSTEM DEACTIVATION

under DISABLING & ACTIVATING AIR BAG SYSTEM. Connect NGS to DLC. Turn

ignition switch to RUN position and perform ON-DEMAND SELF-TEST. If

DTC B1913 is retrieved, go to next step. If DTC B1913 is not

retrieved, go to step 10).

3) Check Driver-Side Air Bag Circuit

Disconnect diagnostic monitor. Inspect clockspring wiring

harness connector at base of steering column for damaged, chafed or

pinched wires. Repair as necessary. If wiring is okay, measure

resistance between terminal No. C232-2 (Gray/Orange wire) and C232-18

(Black/White wire) of diagnostic monitor connector. See Fig. 9. If

resistance less than 1M ohm, go to next step. If resistance not less

than 1M ohm, go to step 5).

4) Check Circuit 614 For Short To Ground

Disconnect clockspring at base of steering column. Use

ohmmeter to check resistance between terminal No. C232-2 and ground.

See Fig. 9. If resistance is less than 1M ohm, repair circuit 614 (

Gray/Orange wire) or circuit 615 (Gray/White wire) for short to

ground. Reconnect system. Verify system. Reactivate system and go to

step 13). If resistance not less than 1M ohm, replace clockspring.

Reconnect system. Verify system. Reactivate system and go to step 13).

5) Check Passenger-Side Air Bag Module Circuits For Shorts

Inspect wiring and connector where air bag module wiring

mates to main vehicle harness. Check for pinched or chafed wires. Use

ohmmeter to measure resistance of circuit 607 (Light Blue/Orange wire)

to ground. Connect one lead to terminal No. C232-5 and one lead to

terminal No. C232-18. See Fig. 9. If resistance is less than 1M ohm,

go to next step. If resistance not less than 1M ohm, go to step 7).

6) Check Circuit 607 For Short To Ground

Disconnect passenger side air bag simulator from main

harness. Remove shorting bar from harness side connector. Use ohmmeter

connected to good ground, connect other lead to terminal No. C232-5.

See Fig. 9. If resistance is less than 1M ohm, repair circuit 607 (

Light Blue/Orange wire) for short to ground. Reconnect system. Verify

system. Reactivate system and go to step 15). If resistance not less

than 1M ohm, repair circuit 616 (Pink/Black wire) for short top

ground. Reconnect system. Verify system. Reactivate system and go to

step 15).

7) Check Impact Sensors

Use ohmmeter connected to a good ground to measure resistance

of terminal No. C232-15 and terminal No. C232-16. See Fig. 9. If

resistance is greater than 40k/ohms replace air bag diagnostic

AIR BAG RESTRAINT SYSTEM

Article Text (p. 22)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

monitor. Reconnect system. Verify system and go to step 15. If

resistance is less than 40k/ohms, go to next step.

8) Check For Open Sensor

Disconnect impact sensor that was less than 40k/ohms in step

7). Use ohmmeter to measure resistance across terminals of impact

sensor connector. If resistance greater than 40K ohm, replace sensor,

reconnect system and go to step 15. If resistance is not greater than

40K ohms, go to next step.

9) Check For Shored Sensor Circuit

Disconnect air bag diagnostic monitor and use ohmmeter

connected to good ground to check resistance of terminal No. C232-15

or terminal No. C232-16. See Fig. 9. If resistance is less than 1M

ohm, repair circuit 619 (Pink/White wire) or circuit 617 (Pink/Orange

wire) for short to ground. Reconnect system. Verify system and go to

step 11. If resistance not less than 1M ohm, repair circuit 625 (

Yellow/Light Green wire) or 624 (Yellow/White wire) for short to

ground. Reconnect system. Verify system and go to step 11.

10) Determine Which Bag is Shorted

Disconnect air bag diagnostic monitor. Inspect wiring and

connector where clockspring mates to main vehicle harness under

steering column. Make sure shorting bar is properly installed in

passenger side air bag connector.

WARNING: Use a hand held digital ohmmeter with less than 10MA

short circuit current on the lowest resistance scale

possible (200 ohm setting). Failure to use a meter of

this type may cause personal injury due to air bag

deployment.

Use ohmmeter to measure resistance between either of the

terminals in passenger-side air bag connector and metal case of air

bag module. If resistance is infinite (open), replace driver-side air

bag module. Reconnect system and go to step 11. If resistance is not

infinite (open), replace passenger-side air bag module. Reconnect

system and go to step 11).

11) Check For DTC Service

Deactivate system. See COMPLETE SYSTEM DEACTIVATION. If DTC

B1913 has just been repaired, check mini fuse 4 (10A). Do not use

substitutions. Reconnect system and go to step 15). If DTC B1913 has

not just been repaired, go to next step.

12) Check For Intermittent Shorts

Inspect circuits 614 (Gray/Orange wire), 615 (Gray/White

wire), 607 (Light Blue/Orange wire) and 616 (Pink/Black wire) for

pinched or chafed wires or other problems. If problems are noted,

repair wiring, check mini fuse 4 (10A), go to step 15). If no problems

are noted, go to next step.

AIR BAG RESTRAINT SYSTEM

Article Text (p. 23)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

13) Check Clockspring Contact

Inspect clockspring wiring at harness connector. Inspect

wiring in steering wheel hub. Inspect wiring where passenger-side air

bag module mates to harness connector. If any problems are noted,

repair problem, check mini fuse 4 (10A), reconnect system and go to

step 15). If no problems are noted, go to next step.

14) Check Impact Sensors

Inspect impact sensors and associated circuits 617 (Pink/

Orange wire), 624 (Yellow/White wire), 619 (Pink/White wire), and 625

(Yellow/Light Green wire). If problems are noted, replace impact

sensor, check mini fuse 4 (10A), reconnect system and go to step 15.

If no problems are noted, re-examine fault code and check for causes

of intermittent shorts or resistance to ground. Repair intermittent

problems and go to step 15).

15) Check For Other DTCs

Connect NGS to DLC. If other DTCs are retrieved go to proper

DTC test. If no other DTCs are retrieved, reactivate system and clear

all DTCs.

PINPOINT TEST C: LFC 14, LFC 54/DTC B1914 - IMPACT SENSOR

SHORTED TO GROUND

NOTE:

Before proceeding, see SERVICE PRECAUTIONS. After

servicing has been performed, recheck AIR BAG warning light.

If system is okay, install air bag modules and reactivate air

bag system.

1) Check For Hard Or Intermittent DTC

Connect NGS tester to DLC. Perform ON-DEMAND SELF-TEST. If

DTC B1914 is retrieved, go to step 2). If DTC B1914 is not retrieved,

go to step 5).

2) Identify Shorted Circuit

Deactivate air bag system. See COMPLETE SYSTEM DEACTIVATION

under DISABLING & ACTIVATING AIR BAG SYSTEM. Disconnect diagnostic

monitor. Using an ohmmeter set to 200k/ohm scale or Auto, measure

resistance between terminal No. C232-18 and terminal No. C232-15,

C232-16, C232-23 and C232-24 of diagnostic monitor connector. See

Fig. 9. If all resistance readings are infinite (open), replace

diagnostic monitor. If one or more resistance reading is not infinite,

go to next step).

3) Determine If Sensor Or Wire Is Shorted

Disconnect impact sensor where resistance reading was not

infinite in step 2). Measure resistance between terminals of sensor

connector. If resistance reading is infinite (open), go to next step.

If resistance reading is not infinite, replace impact sensor.

Reconnect system and go step 7).

4)

Check For Shorted Sensor Circuit

AIR BAG RESTRAINT SYSTEM

Article Text (p. 24)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

Disconnect air bag diagnostic monitor. Using an ohmmeter

connected to good ground, measure resistance at terminal No. C232-15,

C232-16, C232-23 and C232-24 of diagnostic monitor connector. See

Fig. 9. If resistance is less than 1M ohm, repair circuit 619 (Pink/

White wire), circuit 617 (Pink/Orange wire), 624 (Yellow/White wire),

or 625 (Yellow/Light Green wire). Reconnect system. Verify system.

Reactivate system, go to step 7). If resistance not less than 1M ohm,

repair short between circuit 619 (Pink/White wire), 625 (Yellow/Light

Green wire), 620 (Pink/Light Blue wire), 617 (Pink/Orange wire), or

618 (Pink/Light Green wire). Reconnect system. Verify system.

Reactivate system and go to step 7).

5) Check For DTC Service

Deactivate system. See the COMPLETE SYSTEM DEACTIVATION

procedures. Run ON-DEMAND SELF-TEST. If DTC B1914 is been retrieved,

go to step 6). If DTC 1914 is not retrieved, check mini fuse 4 (10A).

Do not use substitutions. Reconnect system and go to step 7). If DTC

B1914 has not just been repaired, go to next step.

6) Check For Intermittent Shorts

Inspect circuits 617 (Pink/Orange wire), 624 (Yellow/White

wire), 619 (Pink/White wire) and 625 (Yellow/Light Green wire) for

pinched or chafed wires or other problems. If problems are noted,

replace impact sensor. Check mini fuse 4 (10A), go to step 7). If no

problems are noted, reexamine fault code and look for causes of

intermittent shorts or resistance to ground. Repair intermittent

problems and go to next step.

7) Check For Other DTCs

Connect NGS to DLC. If other DTCs are retrieved go to proper

DTC test. If no other DTCs are retrieved, reactivate system and clear

all DTCs.

PINPOINT TEST D: LFC21/DTC B1921 - DIAGNOSTIC MONITOR NOT

MOUNTED TO VEHICLE PROPERLY

NOTE:

Before proceeding, see SERVICE PRECAUTIONS. After

servicing has been performed, recheck AIR BAG warning light.

If system is okay, install air bag modules and reactivate air

bag system.

1) Check For Hard Or Intermittent DTC

Connect NGS tester to DLC. Perform ON-DEMAND SELF-TEST. If

DTC B1921 is retrieved, go to step 2). If DTC B1921 is not retrieved,

go to step 5).

2) Measure Resistance

Connect NGS to DLC. Select IABM. Select PID/Data Monitor and

Record. Select PID BRACKET. If resistance is more than 3 ohms,

deactivate system, Remove air bag diagnostic monitor and bracket. See

COMPLETE SYSTEM DEACTIVATION. Thoroughly clean mounting surfaces.

Reinstall air bag diagnostic monitor and go to next step. If

AIR BAG RESTRAINT SYSTEM

Article Text (p. 25)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

resistance is less than 3 ohms, go to step 4).

3) Recheck Resistance

Again, measure resistance between ground and diagnostic

monitor bracket. If resistance is less than 3 ohms, cleaning

diagnostic monitor mounting surfaces in step 2) has corrected problem.

Go to step 8). If resistance is more than 3 ohms, go next step

4) Check Reference Ground

Check attachment of ground connections and splices in circuit

570 (Black/White wire) feeding diagnostic monitor harness terminal No.

C232-10 and C232-18. See Fig. 9. If poor connections are noted repair

circuit as necessary. Add a ground strap from circuit 570 (Black/White

wire) to one of the air bag diagnostic monitor mounting fasteners.

Connect air bag diagnostic monitor and go to step 8). If no poor

connections are noted, replace air bag diagnostic monitor. Reconnect

system. Verify system. Reactivate system and go to step 8)

5) Check For DTC Service

Deactivate system. See COMPLETE SYSTEM DEACTIVATION

procedures. Run ON-DEMAND SELF-TEST. If DTC B1921 IS retrieved, go to

step 6). If DTC B1921 is not retrieved, go to step 8).

6) Check For Corrosion

Inspect diagnostic monitor bracket and mounting surfaces.

Look for signs of corrosion or poor contact. If significant corrosion

is found, replace air bag diagnostic monitor. Verify system.

Reactivate system and go to step 8).

7) Check Circuit 570 (Black/White wire)

Check attachment of ground connections and splices in circuit

570 (Black/White wire) feeding diagnostic monitor harness connector

terminal No. C232-10 and C232-18. See Fig. 9. If poor connections are

noted, repair as necessary. See step 4). Add ground strap from circuit

570 (Black/White wire) to one of diagnostic monitor mounting

fasteners. Connect diagnostic monitor and go to step 8). If no poor

connections are noted, remove air bag diagnostic monitor and bracket

from vehicle and thoroughly clean mounting surfaces. Replace air bag

diagnostic monitor. Re-examine fault code and look for causes of high

resistance in diagnostic monitor bracket ground. Repair any

intermittent faults and go to step 8).

8) Check For Other DTCs

Connect NGS to DLC. If other DTCs are retrieved go to proper

DTC test. If no other DTCs are retrieved, reactivate system and clear

all DTCs.

PINPOINT TEST E: LFC22/DTC B1922 - SAFING SENSOR SHORTED TO

BATTERY VOLTAGE

NOTE:

Before proceeding, see SERVICE PRECAUTIONS. After

servicing has been performed, recheck AIR BAG warning light.

AIR BAG RESTRAINT SYSTEM

Article Text (p. 26)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

If system is okay, install air bag modules and reactivate air

bag system.

1) Check For Hard Or Intermittent DTC

Connect NGS tester to DLC. Perform ON-DEMAND SELF-TEST. If

DTC B1922 is retrieved, go to step 2). If DTC B1922 is not retrieved,

go to step 6).

2) Check Driver-Side Circuit Voltage

Deactivate air bag system. See COMPLETE SYSTEM DEACTIVATION

under DISABLING & ACTIVATING AIR BAG SYSTEM. Inspect driver-side air

bag wiring for potential short to speed control and/or horn wiring.

Repair wiring as necessary. If wiring is okay, disconnect diagnostic

monitor. Measure voltage between terminal No. C232-2 and C232-18 of

diagnostic monitor connector. See Fig. 9. If voltage is more than zero

volts, go to next step. If voltage is zero volts, go to step 4).

3) Check Circuit 614 For Wire-To-Wire Short

Remove locking wedge and shorting bar from terminal No. C2322 of harness side of air bag diagnostic monitor connector. Remove

driver-side air bag simulator. Use voltmeter connected to good ground

to measure voltage at terminal No. C232-2. See Fig. 9. If voltage is

more than zero volts, repair circuit 614 (Gray/Orange wire) for short

to B+. Reconnect system. Verify system and go to step 9. If voltage is

zero volts, repair circuit 615 (Gray/White wire) for short to B+.

Reconnect system. Verify system. Go to step 9).

4) Measure Passenger-Side Voltage

Measure voltage between diagnostic monitor harness connector

terminal No. C232-5 and C232-18. See Fig. 9. If voltage is more than

zero volts, go to next step. If voltage is zero volts, replace air bag

diagnostic monitor. Reconnect system. Verify system and go to step 9).

5) Check Circuit 607 For Wire-To-Wire Short

Remove locking wedge and shorting bar from terminal No. C2325 of harness side of air bag diagnostic monitor connector. See Fig. 9.

Remove passenger-side air bag simulator. Use voltmeter to measure

voltage at between terminal No. C232-5 and C232-18. If voltage is more

than zero volts, repair circuit 607 (Light Blue/Orange wire) for short

and go to step 9). If voltage is zero volts, repair circuit 616 (Pink/

Black wire) for short to B+. Reconnect system. Verify system. Go to

step 9).

6) Check For DTC Service

Deactivate system. See COMPLETE SYSTEM DEACTIVATION

procedures. Run ON-DEMAND SELF-TEST. If DTC B1922 is retrieved, go to

step 9). If DTC B1922 is not retrieved, go to next step.

7) Check For Steering Column Shorts

Inspect driver-side air bag wiring harness for shorts to

speed control or horn wiring. If problems are noted, repair as

necessary and go to step 9). If no problems are noted, go to next

AIR BAG RESTRAINT SYSTEM

Article Text (p. 27)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

step.

8) Check For Steering Column Shorts

Inspect circuit 614 (Gray/Orange wire) and 615 (Gray/White

wire) to driver-side air bag module and circuits 607 (Light Blue/

Orange wire) and 616 (Pink/Black wire) for wire-to-wire shorts. Repair

as necessary and go to step 9). If wiring is okay, re-examine fault

code and look for causes of intermittent shorts to battery voltage.

Repair intermittent problems and go to next step.

9) Check For Other DTCs

Connect NGS to DLC. If other DTCs are retrieved go to proper

DTC test. If no other DTCs are retrieved, reactivate system and clear

all DTCs.

PINPOINT TEST F: LFC23/DTC 1923 - MEMORY CLEAR CIRCUIT

IMPROPERLY GROUNDED

NOTE:

Before proceeding, see SERVICE PRECAUTIONS. After

servicing has been performed, recheck AIR BAG warning light.

If system is okay, install air bag modules and reactivate air

bag system.

1) Check For Hard Or Intermittent DTC

Connect NGS tester to DLC. Perform ON-DEMAND SELF-TEST. If

DTC B1923 is retrieved, go to step 2). If DTC B1923 is not retrieved,

go to step 5).

2) Check If Circuit 631 Is Connected

If terminal No. C232-17 of air bag diagnostic monitor has

wire connected, go to next step. See Fig. 9. If it does not, go to

step 7).

3) Check If Circuit Is Correct Color

Deactivate air bag system. See COMPLETE SYSTEM DEACTIVATION

under DISABLING & ACTIVATING AIR BAG SYSTEM. Disconnect diagnostic

monitor. See Fig. 9. Verify terminal No. C232-17 is a Tan/Red wire. If

it is, go to next step. If it is not, verify and correct harness pin

out. Reconnect system. Verify system and go to step 7).

4) Measure Resistance

Use ohmmeter set to 200K ohms scale or AUTO. Measure

resistance between diagnostic monitor harness connector terminal No.

C232-17 and terminal No. C232-18. See Fig. 9. If resistance is

infinite, replace air bag diagnostic monitor. Reconnect system. Verify

system. Reactivate system and go to step 7). If resistance is not

infinite, repair short to ground on circuit 631 (Tan/Red wire).

Reconnect air bag diagnostic monitor. Go to step 7).

5) Check For DTC Service

Deactivate system. See COMPLETE SYSTEM DEACTIVATION. If DTC

B1923 has just been repaired, go to step 7). If DTC B1923 has not just

AIR BAG RESTRAINT SYSTEM

Article Text (p. 28)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

been repaired, go to next step.

6) Check For Steering Column Shorts

Inspect circuit 631 (Tan/Red wire) for pinched or chafed

wires leading to intermittent short to ground. If problems are noted,

repair as necessary and go to step 7). If no problems are noted, go to

next step.

7) Check For Other DTCs

Connect NGS to DLC. If other DTCs are retrieved go to proper

DTC test. If no other DTCs are retrieved, reactivate system and clear

all DTCs.

PINPOINT TEST G: LFC 32/DTC B1932 - HIGH RESISTANCE OR OPEN

IN DRIVER-SIDE AIR BAG CIRCUIT

NOTE:

Before proceeding, see SERVICE PRECAUTIONS. After

servicing has been performed, recheck AIR BAG warning light.

If system is okay, install air bag modules and reactivate air

bag system.

1) Check For Hard Or Intermittent DTC

Connect NGS tester to DLC. Perform ON-DEMAND SELF-TEST. If

DTC B1932 is retrieved, go to step 2). If DTC B1932 is not retrieved,

go to step 6).

2) Check Circuit Resistance

Deactivate air bag system. See COMPLETE SYSTEM DEACTIVATION

under DISABLING & ACTIVATING AIR BAG SYSTEM. Connect NGS tester to

DLC. Perform ON-DEMAND SELF-TEST. If DTC B1932 is retrieved, go to

next step. If DTC B1932 is not retrieved, go to step 9).

3) Check For Hard Or Intermittent DTC

Turn ignition off and disconnect diagnostic monitor

connector. Record resistance reading. Remove plastic locking wedge

from Gray harness connector at air bag diagnostic monitor. Measure

resistance between diagnostic monitor connector terminal No. C232-2

and C232-3. See Fig. 9. If resistance is less than 3 ohms, replace air

bag diagnostic monitor. Reconnect system. Verify system. Go to step

9). If resistance is more than 3 ohms, go to next step.

4) Isolate Resistance

Disconnect clockspring connector at base of steering column.

Connect air bag simulator to harness connector at base of steering

column. Zero ohmmeter by touching leads together and record reading.

Measure resistance between diagnostic monitor harness connector

terminal No. C232-2 and C232-3. See Fig. 9. If resistance is less than

2.2 ohms, replace clockspring. Reconnect system. Verify system.

Reactivate system and go to step 9). If resistance is more than 2.2

ohms, go to next step.

5) Check Circuit 614 For Open

AIR BAG RESTRAINT SYSTEM

Article Text (p. 29)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

Use ohmmeter to connect one lead to circuit 614 (Gray/Orange

wire) at air bag clockspring harness connector. Connect second lead to

terminal No. C232-2. If resistance is less than 3 ohms, repair circuit

615 (Gray/White wire) for open. Reconnect system. Verify system.

Reactivate system. Go to step 9). If resistance is more than 3 ohms,

repair circuit 614 (Gray/Yellow wire) for open. Reconnect system.

Verify system. Reactivate system. Go to step 9).

6) Check For DTC Service

Deactivate system. See COMPLETE SYSTEM DEACTIVATION

procedures. Run ON-DEMAND SELF-TEST. If DTC B1932 is retrieved, go to

step 7). If DTC B1932 is not retrieved, go to next step 9)

7) Check Air Bag Connections

Disconnect air bag diagnostic monitor. Zero ohmmeter by

touching leads together and record reading. Remove plastic locking

wedge from Gray harness side connector at base of steering column. See

Fig. 9. Measure resistance between diagnostic monitor harness

connector terminal No. C232-2 and C232-3 while wiggling wires at

driver-side air bag module connector where it mates to clockspring.

If resistance is more than 3 ohms or other problems are noted, replace

clockspring. Go to step 9). If resistance is less than 3 ohms, Go to

next step.

8) Check Circuits 614 and 615

Inspect circuit 614 (Gray/Yellow wire)and 615 (Gray/White

wire) for pinched or chafed wires leading to high resistance. If

problems are noted, repair as necessary and go to next step). If no

problems are noted, reexamine DTC description. Check for causes of

intermittent high resistance or open circuits. Attempt to recreate

fault by driving vehicle, flexing wire harnesses or cycling ignition

key frequently. Repair any concerns found and go step 9).

9) Check For Other DTCs

Connect NGS to DLC. If other DTCs are retrieved go to proper

DTC test. If no other DTCs are retrieved, reactivate system and clear

all DTCs.

PINPOINT TEST H: LFC 33/DTC B1933 - HIGH RESISTANCE OR OPEN

IN PASSENGER-SIDE AIR BAG CIRCUIT

NOTE:

Before proceeding, see SERVICE PRECAUTIONS. After

servicing has been performed, recheck AIR BAG warning light.

If system is okay, install air bag modules and reactivate air

bag system.

1) Check For Hard Or Intermittent DTC

Connect NGS tester to DLC. Perform ON-DEMAND SELF-TEST. If

DTC B1933 is retrieved, go to step 2). If DTC B1933 is not retrieved,

go to step 5).

2) Check Circuit Resistance

AIR BAG RESTRAINT SYSTEM

Article Text (p. 30)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

Deactivate air bag system. See COMPLETE SYSTEM DEACTIVATION

under DISABLING & ACTIVATING AIR BAG SYSTEM. Connect NGS tester to

DLC. Perform ON-DEMAND SELF-TEST. If DTC B1933 is retrieved, go to

next step. If DTC 1933 is not retrieved, go to step 8).

3) Check Circuit 607-To-616

Disconnect diagnostic monitor. Remove plastic locking wedge

from Gray harness side connector at diagnostic monitor harness

connector. Measure resistance between diagnostic harness connector

terminal No. C232-5 and C232-4. See Fig. 9. If resistance is less than

3 ohms, replace passenger-side air bag.Reconnect system. Verify

system. Reactivate system and go to step 8). If resistance is more

than 3 ohms, go to next step.

4) Check Air Bag Connections

Disconnect passenger-side air bag simulator from main

harness. Connect ohmmeter lead to circuit 607 (Light Blue/Orange wire)

at passenger-side air bag module harness connector. Connect other lead

to terminal No. C232-5. See Fig. 9. If resistance is less than 3 ohms,

repair circuit 616 (Pink/Black wire) for open. Reconnect system.

Verify system. Reactive system and go to step 8). If resistance is

more than 3 ohms, repair circuit 607 (Light Blue/Orange wire) for

open. Reconnect system. Verify system. Reactivate system and go to

step 8).

5) Check For DTC Service

Deactivate system. See COMPLETE SYSTEM DEACTIVATION under

DISABLING & ACTIVATING AIR BAG SYSTEM. Run ON-DEMAND SELF-TEST. If DTC

B1933 is retrieved, go to step 6). If DTC B1933 is not retrieved, go

to step 6).

6) Check Air Bag Connections

Disconnect air bag diagnostic monitor. Zero ohmmeter by

touching leads together and record reading. Remove plastic locking

wedge from Gray harness side connector at base of steering column.

Measure resistance between diagnostic monitor harness connector

terminal No. C232-4 and C232-5 while wiggling wires at driver-side air

bag module connector where it mates to harness. See Fig. 9. If

resistance is more than 3 ohms or other problems are noted, replace

passenger-side air bag module. Go to step 8). If resistance is less

than 3 ohms, Go to next step.

7) Check Circuits 607 and 616

Inspect wiring and connections in circuits 607 (Light Blue/

Orange wire) and 616 (Pink/Black wire) for poor crimps, corrosion,

etc. that could cause high resistance. If problems are noted, repair

problems and go to step 8). If no problems are noted, re-examine fault

code and look for causes for intermittent faults. Correct any

intermittent faults and go to step 8).

8) Check For Other DTCs

Connect NGS to DLC. If other DTCs are retrieved go to proper

AIR BAG RESTRAINT SYSTEM

Article Text (p. 31)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

DTC test. If no other DTCs are retrieved, reactivate system and clear

all DTCs.

PINPOINT TEST J: LFC 34/DTC B1934 - LOW RESISTANCE OR SHORT

IN DRIVER-SIDE AIR BAG CIRCUIT

NOTE:

Before proceeding, see SERVICE PRECAUTIONS. After

servicing has been performed, recheck AIR BAG warning light.

If system is okay, install air bag modules and reactivate air

bag system.

1) Check For Hard Or Intermittent DTC

Connect NGS tester to DLC. Perform ON-DEMAND SELF-TEST. If

DTC B1934 is retrieved, go to step 2). If DTC B1934 is not retrieved,

go to step 5).

NOTE:

In the following step, it may be helpful to inspect

clockspring-to-main wiring harness connector for an example

of a normal shorting bar.

2) Check Circuit Resistance

Deactivate air bag system. See COMPLETE SYSTEM DEACTIVATION

under DISABLING & ACTIVATING AIR BAG SYSTEM. Connect NGS tester to

DLC. Perform ON-DEMAND SELF-TEST. If DTC B1934 is retrieved, go to

next step. If DTC B1934 is not retrieved, examine shorting bars on

driver-side air bag connector. Replace driver-side air bag module if

shorting bars are normal. Go to step 9).

NOTE:

In the following step, it may be helpful to inspect

clockspring-to-main wiring harness connector for an example

of a normal shorting bar.

3) Check For DTC B1934

Disconnect Air Bag Simulator from driver-side air bag

connector. Disconnect diagnostic monitor. Set ohmmeter for highest

scale (200K ohms or AUTO). Remove plastic locking wedge from Gray

harness connector at air bag diagnostic monitor. Measure resistance

between diagnostic monitor harness connector terminal No. C232-2 and

C232-3 while turning steering wheel. If resistance is 1M ohm or more,

examine shorting bar and if shorting bar is OK, replace air bag

diagnostic monitor if resistance is not 1M or more. Go to step 9).

4) Check For Harness Short

Disconnect clockspring from main wiring harness at base of

steering column. Measure resistance between terminal No. C232-2 and

C232-3 of diagnostic monitor connector. See Fig. 9. If resistance is 1

MEG ohm or more, check shorting bar on clockspring connector for

proper operation. If shorting bar is OK, replace clockspring. If

resistance is not 1 MEG ohm or more, locate and repair short between

circuits 614 (Gray/Orange wire) and 615 (Gray/White wire). Reconnect

system. Verify system. Reactivate system. Go to step 9).

AIR BAG RESTRAINT SYSTEM

Article Text (p. 32)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

5) Check For DTC Service

Deactivate system. See COMPLETE SYSTEM DEACTIVATION under

DISABLING & ACTIVATING AIR BAG SYSTEM. Run ON-DEMAND SELF-TEST. If DTC

B1934 is retrieved, go to step 6). If DTC is not retrieved , go to

step 9).

6) Check Shorting Bars

Disconnect air bag diagnostic monitor. Set ohmmeter to lowest

scale (200 ohms or AUTO). Zero ohmmeter by touching leads together.

Remove plastic locking wedge from Gray harness side connector. See

Fig. 9. Measure resistance between diagnostic monitor harness

connector terminal No. C232-2 and C232-3 while wiggling wires at

driver-side air bag connector where it mates to clockspring. Subtract

reading found when zeroing ohmmeter. Inspect shorting bars in driverside air bag module, clockspring connector at main wiring harness and

air bag diagnostic monitor. Look for signs of poor operation of these

shorting bars. If problems are noted or resistance reading is less

than 3 ohms, repair problems and go to step 9). If resistance is more

than 3 ohms, go to next step.

7) Check Clockspring

Remove air bag simulator from steering wheel. Measure

resistance between diagnostic monitor harness connector terminal No.

C232-2 and C232-3 while turning steering wheel. See Fig. 9. If

resistance is infinite, replace clockspring if resistance reading

jumps while turning wheel. Go to step 9). If resistance reading is not

infinite, go to next step.

8) Check Circuits 614 and 615

Inspect wiring and connections in circuits 614 (Gray/Orange

wire) and 615 (Gray/White wire). Look for potential intermittent

shorts between these circuits. Examine clockspring wires where

clockspring mates to main harness. Examine clockspring contacts and

driver-side air bag module wires where clockspring mates to driverside air bag module. If problems are noted, repair problems. Replace

clockspring or driver-side air bag module if clockspring or driverside air bag module wires are damaged. Go to step 9). Re-examine fault

code and look for causes of intermittent faults. Service any

intermittent problems and go to step 9).

9) Check For Other DTCs

Connect NGS to DLC. If other DTCs are retrieved go to proper

DTC test. If no other DTCs are retrieved, reactivate system and clear

all DTCs.

PINPOINT TEST K: LFC 35/DTC B1935 - LOW RESISTANCE OR SHORT

IN PASSENGER-SIDE AIR BAG CIRCUIT

NOTE:

Before proceeding, see SERVICE PRECAUTIONS. After

servicing has been performed, recheck AIR BAG warning light.

If system is okay, install air bag modules and reactivate air

bag system.

AIR BAG RESTRAINT SYSTEM

Article Text (p. 33)

1997 Ford Explorer

For Cise Electronica Gral. Jose M. Bustillo 3243 Capital Federal Buenos Aires 1406

Copyright 1998 Mitchell Repair Information Company, LLC

Tuesday, August 13, 2002 07:45PM

1) Check For Hard Or Intermittent DTC

Connect NGS tester to DLC. Perform ON-DEMAND SELF-TEST. If

DTC B1935 is retrieved, go to step 2). If DTC B1935 is not retrieved,

go to step 4).

NOTE:

In the following step, it may be helpful to inspect

clockspring-to-main wiring harness connector for an example

of a normal shorting bar.

2) Measure Resistance

Deactivate air bag system. See COMPLETE SYSTEM DEACTIVATION

under DISABLING & ACTIVATING AIR BAG SYSTEM. Connect NGS to DLC.

Perform ON-DEMAND SELF-TEST. If DTC B1935 is retrieved, go to next

step. If DTC B1935 is not retrieved, examine shorting bars on

passenger-side air bag connector. Replace passenger-side air bag

module if shorting bars are normal. Go to step 7).

NOTE:

In the following step, it may be helpful to inspect

clockspring-to-main wiring harness connector as an example of

a normal shorting bar.

3) Check For Open Circuit

Disconnect air bag simulator from main harness. Disconnect

air bag diagnostic monitor. Set ohmmeter to highest scale (200 ohms or

AUTO). Remove plastic locking wedge from Gray harness connector (C232)

at air bag diagnostic monitor. See Fig. 9. Measure resistance between

diagnostic monitor harness connector terminal No. C232-4 and C232-5.