Professional Documents

Culture Documents

518 1 PDF

Uploaded by

wisnuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

518 1 PDF

Uploaded by

wisnuCopyright:

Available Formats

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

PEDEEE

SYRIAN ARAB REPUBLIC

MINISTRY OF ELECTRICITY

PUBLIC ESTABLISHMENT FOR

DISTRIBUTION AND EXPLOITATION

OF ELECTRICAL ENERGY

(PEDEEE)

SPECIFICATION FOR

20/0.4 KV DISTRIBUTION TRANSFORMER

FITTED WITH

-OPEN TERMINAL BUSHINGS AND HERMETICALLY SEALED

630 K.V.A

Eng Nabeel Al-laham

Eng Ghassan omar Hussien

Eng Abd-alrahman darkazenly

Eng Haifa Doghoz

Eng Maisa maaroof

/ director of supply & warhouses /

Eng Bassam Kouider

Approved by General Director

Eng Mohammad Abdalwahab Alhasan

File : spec. Trans. (630) KVA

1 / 20

june2011

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

1.

GENERAL

1.1

Instruction to tenderers

PEDEEE

Tenderers are invited for the supply and delivery of distribution transformers to PEDEEE,

Damascus, Syrian Arab Republic. The equipment offered shall comply with the requirements

of the IEC standards applicable at the time of contract placement and with the technical

requirements of this specification.

Tenderers are required to examine carefully the tender documents in order to ascertain the

matters on which they will be deemed to have satisfied themselves and the risks and

obligations which they are to undertake.

The Schedules shall be completely filled in and shall form the contractual guarantee

schedules.

1.2

Language

The offer and its enclosed documents and references shall be submitted in English.

The correspondence if abroad shall be in English and if inland shall be in Arabic.

1.3

Tenderers qualification and experience

The tenderer is required to state in the offer the manufacturers experience in the design and

manufacture of the equipment they have proposed. In particular the tenderer shall state:

Manufacturers annual production capacity for the last two years.

Manufacturers client reference list over the last two years.

1.4

Quality assurance

The tenderer is required to describe in the offer the applied design and manufacturing quality

assurance (QA) procedures and to submit accredited independent QA verification certificate

such as ISO certificate. PEDEEE reserve the right to inspect the tenderers design and

manufacturing facility to undertake a QA audit during the period of tender evaluation.

File : spec. Trans. (630) KVA

2 / 20

june2011

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

1.5

PEDEEE

Packaging

The type of packaging should be suitable for export and shipping to the Syrian Arab

Republic, and should provide complete protection for marine, truck or rail loading and

transportation. Appropriate measures shall be taken to prevent vibration or movement.

Packaging should be acceptable to the insurance company.

Each transformer should be packed within wooden crate provided with wooden base with

suitable dimensions that secure a protection distance between each packed transformer and

another one to protect it from shocks .

Each crate must contain one transformer only and must include a protected packing list fixed

on the crate in addition to the packing list inside the crate.

Each crate must be marked clearly on two sides of the crate with the following:

Purchaser name: PEDEEE

Contract number

Delivery and shipment numbers

Manufacturing date

Name of Manufacturer

Equipment:20/0.4 KV distribution transformer

Main technical specification: voltage ratio, rating, etc.

Transformer serial number

Gross weight

Net weight

1.6

Tender technical submission

A complete tender shall include three copies of the following documents in English:

Fully completed technical specification schedules and all associated drawings

and documents required by those schedules

Catalogues (original) .

Calculation sheets for construction .

Technical information about the used materials.

File : spec. Trans. (630) KVA

3 / 20

june2011

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

PEDEEE

2.

TECHNICAL SPECIFICATION

2.1

Introduction

This section covers the technical specification for oil-filled distribution transformers having a

voltage ratio of 20/0.4 kV 3-phase. The transformers are to be used in the Syrian Electrical

Network and shall be constructed in compliance with relevant IEC standards to an accredited

quality control system and shall be suitable for use at the specified ambient conditions.

2.2

Applicable Standards

The transformer design shall comply with the requirements of the latest current edition of

relevant IEC standards and with the specific technical requirements of this specification.

In particular the following IEC standards shall apply:

IEC 76 :

IEC 137 :

IEC 296 :

IEC 354 :

2.3

Power transformers

Insulated bushings for alternating voltages above 1000 V

Specification for unused mineral insulating oils

for transformers and switch-gear

Loading guide for oil-immersed power transformers

System Details and Service Conditions (General Data)

The performance of the transformers shall be guaranteed for the following operating,

installation and environmental conditions of Syria.

20 kV Distribution System

20 kV + 5%

Three phases, three wires

Earthed through an earthing transformer 20/0,4kV (Zn Yn11)

Vector group of distribution transformer 20 kV/0,4 kV DYn11

Maximum service voltage : 24 kV

Rated frequency : 50 Hz

Impulse withstand voltage level : 125 kV at 1.2/50 s

Short circuit apparent power of the system 500 MVA

File : spec. Trans. (630) KVA

4 / 20

june2011

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

PEDEEE

Environmental Conditions

Altitude above sea level:

Max. ambient temperature:

Min. ambient temperature:

Average annual temperature:

Maximal temperature variation in one day :

Average max . relative humidity:

(Relative humidity - in some site of Syria -of up to

100% is possible )

1000 m (max.)

50 oC

- 10 oC

35 oC

20 oC

80%at 30 deg

The offered products should be suitable for use under semi - arid

use on coastal area.

2.4

Technical Requirements

2.4.1

Rating

conditions as well as for

Ratings shall be based on permissible winding temperature rises (as measured by resistance)

and top-oil temperature rises (as measured by thermometer) with maximum ambient air

temperature, as specified in General Data.

The transformer shall have overload capabilities in accordance with IEC 354 (item 2-3) .

All associated components of the transformer, including bushing and tap switches shall have

overload capabilities not lower than that of the transformer with which they are associated.

The transformer shall be capable of providing full rated power at all tap positions.

2.4.2

Short circuit capability

Transformers together with all equipment and accessories shall be designed and constructed

to withstand , without damage, the thermal and dynamic effect of external short circuit under

the condition specified in item 2.3

2.4.3

Tank

Transformer tanks must have the necessary mechanical strength and shall be designed to

allow the complete transformer to be lifted by crane and transported without overstraining

any joints or causing distortion. The tank cover shall be fitted with an adequate number of

fixing points suitable for attaching of lifting equipment.

The tank with its sealed cover is capable to withstand over-pressure of 0.3 Bar

File : spec. Trans. (630) KVA

5 / 20

june2011

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

PEDEEE

The reinforcing of the bottom shall not prevent draining of all oil from the tank.

The transformer tank shall be designed to avoid pockets wherein gas may collect.

All the Tank sides shall be corrugated suitable for hermetically sealed type.

The transformer tanks shall have a filling valve, oil level indication, thermometer pocket and

a drain plug. The drain plug shall be so designed that the transformer can be completely

drained.

2.4.4

Painting specification

The tenderer shall submit his painting specification and must be high quality which will

demonstrate :

1-removing the grease.

2-cleaning should be by machine using sand shot blasted .

3-Painting method : should be electro static or by drying oven ( electro static is preferable ) .

The offerer should submit the method of painting in detail.

4- painting by hand and normal drying is not accepted.

5-final color cement grey or olive green .

2.4.5

Windings

The windings shall be one piece for each phase and made of electrolytic copper and shall

comply in all respects with the relevant IEC standards. They shall be effectively clamped so

as to withstand the thermal, electrical and mechanical stresses as well as all forces that may

be produced by the short circuit currents as specified in Section 2.3 .

Winding insulation and all non-metallic material used in the windings shall be so treated that

no further shrinkage shall take place after assembly.

The windings shall be designed such that they may be replaced with the minimum of

difficulty.

The connection between the secondary bushing and the ends of the low voltage winding shall

be made of flexible copper bar connected to the secondary bushing , and copper bar

connected to the ends of the low voltage winding.

The connection between the primary bushings and the ends of the primary windings shall be

directly connected without joints.

The tenderer shall submit a detailed description of the windings and the insulation proposed.

2.4.6

Neutral earthing

The neutral point of the transformer secondary winding shall be brought out to a separate

fully insulated bushing and suitable for solid connection to the earth stud.

File : spec. Trans. (630) KVA

6 / 20

june2011

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

2.4.7

PEDEEE

Core

The core shall be of the beltless type equipped with upper and lower yoke, manufactured of

high grade, grain oriented, non-aging steel laminations, having smooth surfaces. The core

construction shall be such as to minimize losses, local heating, vibration and noise.

The formation of steel cores plates must be automatic.

The core steel and all insulation associated with the core shall be designed so that no

detrimental changes in physical or electrical properties will occur during the life of the

transformer windings.

The core, framework, clamping arrangements and general structure of the transformer shall

be capable of withstanding any shocks to which it may be subjected during transport,

installation and service. Adequate provision shall be made to prevent movement of internal

parts of the transformer relative to the tank, to support the core structure within the tank and

to carry the weight of the core and windings when suspended.

The transformer core shall be free from over fluxing liable to cause damage or when

operating under the conditions of continuous over-voltage specified.

The core shall be designed to facilitate removal and replacement of the windings.

The core stack shall be internally earthed.

2.4.8

Insulating Oil

The transformer shall be complete filled with unused and not renewed mineral insulating oil

Insulating oil shall be in conformity with IEC296.

The use of PCBs as the dielectric medium is strictly prohibited.

2.4.9

Cooling

The transformer cooling system shall be ONAN.

2.4.10 Bushings

The bushings shall be designed in such a way as to allow easy dismantling.

3 HV porcelain bushings and 4 LV porcelain bushings will be fitted on the cover.

The bushings shall be designed to withstand the different thermal, electrical and mechanical

stresses as well as all forces that may be produced by the short circuit currents.

2.4.11 Tap Changer

The transformer shall be equipped with an externally operated off-load tap changer on the

high voltage side. The tapping range shall be 5 % in five equal steps. The tap changer shall

be manually operated and lockable and shall be mounted such that operation is in a horizontal

plane. The tap position number shall be durable and clearly visible.

File : spec. Trans. (630) KVA

7 / 20

june2011

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

PEDEEE

2.4.12 Transformer Accessories

The transformer shall be equipped with at least the following:

1. Oil level indicator

2. Rating plate

3. pressure relief device for oil level reduction

4. Thermostat with two contacts and with maximum indicator.

Multifunctions device for above mentioned items ( 3-4-5) is accepted and its preferable.

It indicates the temperature and oil level, its also equipped with electrical contacts for:*

Gas formation

Pressure excess

temperrature levels:alarm and trip.

5. Oil drain plug at bottom

6. Two earthing terminal

7. Filling plug

8. Four bi-directional flat rollers

9. Lifting eyes suitable for lifting by crane hook and ropes

10. Arcing horns on H.V. bushing (protection gap)

11. Any other necessary accessories

2.4.13 Rating Plate

The transformer shall be provided with a rating plate of weatherproof and corrosion resistant

material which shall be fitted in a position clearly visible to the operator.

The plate shall be indelibly marked in English. It shall include all information required by

IEC 76-1.

File : spec. Trans. (630) KVA

8 / 20

june2011

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

3.

PEDEEE

TESTING

There are many tests are required.

3.1

Prototype Manufacture testing (in the factory) .

3.2

Testing of Production (in the factory)

3.2.1

Routine Test for all Production .

3.2.2

Participation Testing for production in presence of PEDEEEs representatives

3-3

Acceptance/rejection in Syrian warehouses

3.1

Prototype manufacture testing

The contractor shall manufacture a single prototype for routine and type testing during one

month from the date of signing the contract. The prototype will be inspected and a full set of

type and routine tests performed.

The following tests are required to be carried on the prototype:

3.1.1

Routine Tests

Voltage ratio. Polarity and phase relationship test on each tapping

Resistance of all windings

No-load current and no-load losses measurement

Load losses measurement at rated current and frequency

Impedance voltage measurement

Induced over-voltage and separate source voltage withstand tests

Insulating oil tests in accordance with IEC 296

3.1.2

Type Tests

Temperature rise test

Impulse voltage withstand test .

File : spec. Trans. (630) KVA

9 / 20

june2011

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

PEDEEE

Overload test at 150% rated current for one hour after temperature rise test and

hot resistance measurement of (HV LV)

Noise level test

Oil leakage test

3.1.3

Prototype Visual Inspection

The active part (winding and core) will be removed from the tank for inspection.

3.1.4

Special Test

Short Circuit Dynamicstability Test

(test report from independent and accredited laboratory for similar transformer will be

accepted).

PEDEEE reserves the right to attend the prototype tests and the contractor will bear the costs

of attendance of two PEDEEE representatives at such tests. The costs borne by the contractor

will include all the costs of return air fares from Damascus to the manufacturers country,

accommodation and subsistence expenses for five work days in the country of the

manufacturers test premises. In the case of rejection of the prototype the contractor will bear

the same costs for inspection and test of the new prototype.

The prototype can be accepted only in case that the tests results are in compliance with or

better than the contractual specifications and IEC requirements without tolerance for

No-load losses

Load losses

Top oil temperature rise

Winding temperature rise

Hot spot temperature

Impedance voltage %

Current density

Dielectric tests

If during inspection and testing it is demonstrated that the prototype does not comply fully

with the requirements of the specification, the prototype will be rejected. In the event that the

prototype is rejected the contractor will prepare a new prototype ,as a second and a last

chance ,during one month only, at his own expense. The new prototype will be fully tested to

the approved test schedule. In case of rejection of the new prototype. The contractual

conditions will be applied.

File : spec. Trans. (630) KVA

10 / 20

june2011

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

PEDEEE

3.2 Testing of production

3.2.1 production testing

All transformers shall be tested Routine tests in according to IEC76 by the manufacturer

himself.As for the production testing

3.2.2 Participation Testing

5% of the transformers from each delivery shall be tested in accordance with IEC 76 in

presence of PEDEEEs representatives. The following tests shall be carried out:

3.2.2.1 Routine Tests

Resistance of all windings

No-load current and no-load losses measurement

Induced over-voltage and separate source voltage withstand tests

Voltage ratio. Polarity and phase relationship test on each tapping

Load losses measurement at rated current and frequency

Impedance voltage measurement

Insulating oil tests in accordance with IEC 296

3.2.2.2 Type Tests (for one transformer from each delivery)

Temperature rise test

Overload test in accordance with IEC 354

Noise level test

Oil leakage test

The contractor will bear the costs of attendance of tow PEDEEE representatives for each

delivery at such tests.

The costs borne by the contractor will include return air fares from Damascus to the

manufactures test premises and all accommodation and subsistence expenses for one week in

the country of the manufacturers test premises.

3.3

Acceptance, rejection and replacement

The acceptance will be in the Syrian warehouses subject to the following:

Verifying that the delivered equipment complies with the requirements of the

contractual documents and standards.

If during inspection tests carried out or supervised by PEDEEE any material or

equipment provided is proved defective or not manufactured according to the

Contractual specifications, PEDEEE shall have the right to reject such material or

equipment.

File : spec. Trans. (630) KVA

11 / 20

june2011

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

4.

PEDEEE

Penalties and Rejection

If the transformer has passed the tests described in section. 3.4 except that the losses exceed

the guaranteed limits PEDEEE may accept these transformers in accordance with the

following penalties:

If the no-load losses or load losses are higher than the guaranteed value by 15 %

PEDEEE will reject the transformers.

If the total losses exceed the guarantee value by 10 %

PEDEEE will reject the transformers.

If the no-load losses or load losses exceed the guaranteed value but are within

the limits specified above the contractor will pay the following penalties:

Iron losses: US$ 7.575 per Watt in excess

Load losses: US$ 1.137 per Watt in excess

File : spec. Trans. (630) KVA

12 / 20

june2011

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

PEDEEE

SCHEDULE A

QUALIFICATION

(Information to be provided with the Tender)

-The offerer must submit with his offer the following certificates and reports, offerer who

doesnt submit one or more of these certificates or reports shall be rejected definitely..

These certificates and reports should be for oil immersed distribution transformers not

exceeding 2500 KVA with high voltage not more than 36 KV similar to the offered

transformers as possible and produced by the same factory:

1- Routine test report by qualified laboratory acc. to clause 3.3.1 for transformers.

2- Full type test report by an independent testing qualified laboratory during the last five

years.

3- Short-circuit dynamic test report (special test ) shall be during the last ten years and

supplied with address and fax. No of the laboratory that issued this report.

4- A certificate indicating the annual turnover in USD during the last two years .

5- Reference list: outside country sellings during the last two years with a list of customer's

address's including fax number .

6- Certificate indicating the total capacity of distribution transformers produced by the

manufacturers for the last two years.

7- Production capacity shall be not less 3000 units yearly.

8- - Quality assurance certificate issued by an independent authority ( ISO 9001-2000)

The tenderer shall submit all the revelant details in his tender ( address and fax Noetc. )

9- The offerer must submit detailed drawings of transformer and its parts and accessories

( windings the core-insulators. ) showing the dimensions and weights .

-All above reports and certificates should be signed and approved by the offerer and the

manufacturer and subjected to a technical evaluation by (PEDEEE) .

File : spec. Trans. (630) KVA

13 / 20

june2011

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

PEDEEE

SCHEDULE B

MANUFACTURER AND PLACE OF MANUFACTURE

(Information to be provided with the Tender)

Signed and approved by the manufacturer and the offerer )

Item

Transformer

Tank

Core origin

Windings

Bushings origin

Insulation origin

Transformer oil origin

Tank steel origin

Core steel origin

Winding copper origin

Tap changer origin

- Pressure relief device with contact.

- Protection device for oil level

reduction.

- Thermometer with two contacts

and with maximum indicator.

Or multifunction device for above .

File : spec. Trans. (630) KVA

Manufacturer

14 / 20

Place of Manufacture

june2011

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

PEDEEE

SCHEDULE C

TECHNICAL GUARANTEES AND PARTICULARS

(Information to be provided with the Tender)

Signed and approved by the manufacturer and the offerer )

Item

Description

Units

No

1

2

3

4

5

6

7

7.1

7.2

8

8.1

8.2

9

10

10.1

10.2

11

11.1

12

12.1

12.2

PEDEEE

Offered Data

Requirements

Name of manufacturer

Country of origin

transformation ratio

Vector Group

Method of cooling

Rated power when operated at

the specified site conditions

Maximum temperature rise

above50 C ambient at rated

power:

Winding temperature rise

Top oil temperature rise

Losses :

No load losses at rated voltage

Load losses at rated power

At u.p.f. and 75 oC

Impedance voltage (at 75oC,

rated power and principle

tapping )

Power frequency withstand

voltage:

20 kv winding and bushing

LV winding and bushing

Impulse withstand voltage

1.2/50 s :

20 KV winding and bushing

Winding resistance at 75oC :

20 kv winding

LV winding

File : spec. Trans. (630) KVA

kV

kVA

20/0.4

Dyn11

ONAN

630

C

C

55

50

W

W

940

5600

kV

kV

50

3

kVpeak

125

/phase

/phase

15 / 20

june2011

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

Item

PEDEEE

Description

Units

PEDEEE Requirements

A/mm2

A/mm2

kA

2.5

2.5

Tesla

1.7

Offered Data

No

13

14

14.1

14.2

15

16

17

17.1

17.2

18

19

20

20.1

20.2

20.3

20.4

20.5

Magnetising current in % of

rated current at rated voltage

Maximum current density at

rated power :

20 kv winding

LV. winding

2 sec short circuit withstand

current :

-HV winding

-LV winding

Maximum flux density at

normal voltage and frequency.

Conductor cross-section :

20 kv winding

LV .winding

Type and class of insulation:

Transformer oil :

Transformer oil :

- Viscosity at 40 C

-Viscosity at -30 C

-Falsh point

- Pour Point

-Appearance

mm2

mm2

Class A

-Acidity

-Density, at 20 C

-Water Content

-Sludge

-DDF at 90 C

- Breakdown voltage

- min.

-after laboratory treatment

Physical parameters :

Total weight

Weight of core

Weight of single 20 kv winding

Weight of single LV. winding

Oil volume

File : spec. Trans. (630) KVA

Acc to IEC 60296-2003

mm S

max 12

2/

mm S

max 1800

C

min 140

C

max-40

Clear , free from sediment

and suspended matter

mg/KOH/g

max 0.01

g/ml

max 0.895

mg/kg

Acc to IEC

Max 0.8%

O 0.005

2/

16 / 20

KV

KV

Min 30

Min 70

kg

kg

kg

kg

litre

june2011

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

Item

Description

PEDEEE

Units

No

24

24.1

24.2

25

25.1

25.2

25.3

25.4

Offered Data

Requirements

20.6 Tank cover thickness

20.7 Tank bottom thickness

20.8 Side Thickness ( all tank side

must be corregeted )

Dimension :

21

21.1 Overall length

21.2 Overall width

21.3 Overall height

22

22.1

22.2

22.3

23

PEDEEE

Bushings:

Material

Rated current (MV/LV)

Creepage distance (MV/LV)

Maximum noise level

Tappings :

Tapping range

Number of taps

Clearances :

Between the windings and the

tank

-with pressboard thickness

6 mm

-or without pressboard

Between phases

Between primary and

secondary:

with one barrier

or with two barrier

Insulation method used for

Items 27.1-27.2 27.3

File : spec. Trans. (630) KVA

mm

mm

mm

6

6

1.2

mm

mm

mm

A

mm

dB

porcelain

250/1500

500/75

2 X 2.5 %

5

mm

25

mm

mm

mm

30

15

mm

mm

14

12

paper

17 / 20

june2011

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

Item

PEDEEE

Description

Units

PEDEEE Requirements

No

Data

26

Bidiection wheels

27

Equipment aviliable at the factory

of the manufacturer

Automatic cutting (formation ) of

steel laminations core plates:

-The type

- The quantities

Automatic machine for corrugated

tank side

-The type

- The quantities

Tank cleaning machine :

- By sand shot blasted

-The type

- The quantities

M.V winding machine

-The type

- The quantities

27.1

27.2

27.3

27.4

27.5

28

Offered

Wheels should be

bidirectional (in length &

width and it is preferable to

be in all directions

Must be one at least

Must be one at least

Must be one at least

L.V winding machine:

- full automatic controlled by

computer

-universal winding machine

- The quantities for each type

Painting and drying

-the offerer must clarify the method

of cleaning the tank and the cover

and the method of painting and its

type.

-Painting by the hand is not

accepted.

-normal drying(without oven) is

not accepted.

File : spec. Trans. (630) KVA

18 / 20

june2011

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

Item

PEDEEE

Description

Units

No

29

29.1

29.2

29.3

29.4

29.5

PEDEEE

Offered Data

Requirements

Equipment available to the

manufacture laboratory which

needed to make the routine test

Measuring devices :

- the offerer must clarify the

kind of measuring device

( normal ,watt hour meter , volt

, Amp, ..meters )

or measuring center or

power analyzer

Double voltage generator

-rated power

- frequency

No load and load measurement

It is done by:

- special generator or auto

transformer, the special

generator is preferable

Oil sample laboratory

Impulse generator for testing :

- impulse test done by the

manufacturer: inside the factory

or outside the factory .

File : spec. Trans. (630) KVA

19 / 20

must be inside the

factory

one at least

KVA

Hz

one at least

outside the factory or

inside the factory

june2011

TECHNICAL SPECIFICATIONS

Trans. 630 KVA

PEDEEE

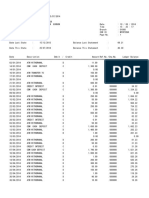

List of Quantities

(information to be provided with the tender

Item

Description

Units

QTY

No

PRICE

FOB

unite

1

2

2.1

2.2

2.3

2.4

2.5

2.6

3

630 KVA transformer

Spare Parts

Set of three primary and

secondary windings and must be

supplied in sealed oil tank

complete LV bushing

- Pressure relief device with

contact.

- Protection device for oil level

reduction.

- Thermometer with two

contacts and with maximum

indicator.

Or Multifunctions device for

above (2.3,2.4.2.5)

Off Load Tap Charger

Living expenses of two

representatives (engineers) to

the contractor country to

participate in the testing for five

work days for each delivery

Living expenses of two

representatives to study the

company's adequacy for one

week in the company's factories

Living expenses of two

representatives to attend

prototype test in the munufactur

country for(10) deys

total

CFR or CPT

unite

total

500

set

piece

Piece

20

2

Piece

Piece

2

piece

20

N.B- PEDEEE has the right to execute the item NO/4/ &/5/or delete it acc .to the necessity.

File : spec. Trans. (630) KVA

20 / 20

june2011

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Bisleri 2.0Document59 pagesBisleri 2.0Dr Amit Rangnekar100% (4)

- Rehabilitation and Retrofitting of Structurs Question PapersDocument4 pagesRehabilitation and Retrofitting of Structurs Question PapersYaswanthGorantlaNo ratings yet

- An Over View of Andhra Pradesh Water Sector Improvement Project (APWSIP)Document18 pagesAn Over View of Andhra Pradesh Water Sector Improvement Project (APWSIP)gurumurthy38No ratings yet

- Payment of GratuityDocument5 pagesPayment of Gratuitypawan2225No ratings yet

- Pro Tools ShortcutsDocument5 pagesPro Tools ShortcutsSteveJones100% (1)

- Dr. Li Li Prof. Feng Wu Beijing Institute of TechnologyDocument20 pagesDr. Li Li Prof. Feng Wu Beijing Institute of TechnologyNarasimman NarayananNo ratings yet

- TP1743 - Kertas 1 Dan 2 Peperiksaan Percubaan SPM Sains 2023-20243Document12 pagesTP1743 - Kertas 1 Dan 2 Peperiksaan Percubaan SPM Sains 2023-20243Felix ChewNo ratings yet

- Bank Statement SampleDocument6 pagesBank Statement SampleRovern Keith Oro CuencaNo ratings yet

- A Winning Formula: Debrief For The Asda Case (Chapter 14, Shaping Implementation Strategies) The Asda CaseDocument6 pagesA Winning Formula: Debrief For The Asda Case (Chapter 14, Shaping Implementation Strategies) The Asda CaseSpend ThriftNo ratings yet

- Your Electronic Ticket ReceiptDocument2 pagesYour Electronic Ticket Receiptjoana12No ratings yet

- Digital Documentation Class 10 NotesDocument8 pagesDigital Documentation Class 10 NotesRuby Khatoon86% (7)

- Palm Manual EngDocument151 pagesPalm Manual EngwaterloveNo ratings yet

- CEA 4.0 2022 - Current Draft AgendaDocument10 pagesCEA 4.0 2022 - Current Draft AgendaThi TranNo ratings yet

- The Role of OrganisationDocument9 pagesThe Role of OrganisationMadhury MosharrofNo ratings yet

- A Religious LeadershipDocument232 pagesA Religious LeadershipBonganiNo ratings yet

- QuizDocument11 pagesQuizDanica RamosNo ratings yet

- 1grade 9 Daily Lesson Log For Demo 1 4Document5 pages1grade 9 Daily Lesson Log For Demo 1 4cristy olivaNo ratings yet

- Guidelines Use of The Word AnzacDocument28 pagesGuidelines Use of The Word AnzacMichael SmithNo ratings yet

- Kompetensi Sumber Daya Manusia SDM Dalam Meningkatkan Kinerja Tenaga Kependidika PDFDocument13 pagesKompetensi Sumber Daya Manusia SDM Dalam Meningkatkan Kinerja Tenaga Kependidika PDFEka IdrisNo ratings yet

- Liga NG Mga Barangay: Resolution No. 30Document2 pagesLiga NG Mga Barangay: Resolution No. 30Rey PerezNo ratings yet

- Is.14785.2000 - Coast Down Test PDFDocument12 pagesIs.14785.2000 - Coast Down Test PDFVenkata NarayanaNo ratings yet

- BSBOPS601 Develop Implement Business Plans - SDocument91 pagesBSBOPS601 Develop Implement Business Plans - SSudha BarahiNo ratings yet

- Health, Safety & Environment: Refer NumberDocument2 pagesHealth, Safety & Environment: Refer NumbergilNo ratings yet

- Study of Risk Perception and Potfolio Management of Equity InvestorsDocument58 pagesStudy of Risk Perception and Potfolio Management of Equity InvestorsAqshay Bachhav100% (1)

- Napoleon RXT425SIBPK Owner's ManualDocument48 pagesNapoleon RXT425SIBPK Owner's ManualFaraaz DamjiNo ratings yet

- 1980WB58Document167 pages1980WB58AKSNo ratings yet

- Bill Swad's Wealth Building Strategies - SwadDocument87 pagesBill Swad's Wealth Building Strategies - Swadjovetzky50% (2)

- Milestone 9 For WebsiteDocument17 pagesMilestone 9 For Websiteapi-238992918No ratings yet

- Terms and Conditions 27 06 PDFDocument4 pagesTerms and Conditions 27 06 PDFShreyash NaikwadiNo ratings yet