Professional Documents

Culture Documents

Port State Control Inspection Findings 2015

Uploaded by

Mohammad Joynal AbedinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Port State Control Inspection Findings 2015

Uploaded by

Mohammad Joynal AbedinCopyright:

Available Formats

Port State Control Inspection Findings 2015

Summary

The objective of this document is to share the results of the port state and flag state control inspections

conducted on board our fleet vessels.

Total number of inspections 66 (PSC 42, TVEL- 21, FSC - 3),

Zero observations were noted in 48 inspections (72.7%),

In 2015, Average observation rate was 0.67 per inspection,

Total number of observations 44 (Code 15 2, Code 16 10, Code 17 22, Others 10)

Improvement during the year is attributed to enhanced and focused preparatory efforts

Performance in PSC inspections has declined since 2012,

This is likely to lead to even closer scrutiny in future PSC inspections,

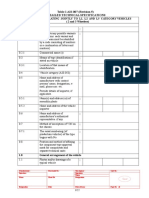

Attachment No. 1 to Circ. OT/PSC/2016/001

Port State Control Inspection Findings 2015

Observations MoU Region

Observation rate is high for Latin American (1.25) and Asia Pacific Region (1.2) per

inspection,

High observation rate for Code 17 from Black Sea and Paris MoU

Key Findings:

PSC observations were categorized as per the following SIRE Vessel inspection

Questionnaire (VIQ) chapters.

Safety Management (VIQ Ch. 5) 12 Nos,

Self-closing door not operating properly.

Lifeboat not maneuvered in water (over 3 months).

Defective firemen outfit.

Embarkation ladders - shackles are seized.

Certification and Documentation (VIQ Ch. 2) 9 Nos,

Fire fighting equipment certificate expired

Original Certificates not available on board, only copies available

Cargo and Ballast Systems (VIQ Ch. 8) 8 Nos,

Cargo tank overfill alarm not rotating,

Tank radar system not working

General Appearance and Condition (VIQ Ch. 12) 7 Nos

Cargo hatch was missing a dog cleat.

Watertight doors not properly closing.

Hatch cover for bosun store cannot fully close.

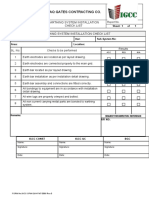

Attachment No. 1 to Circ. OT/PSC/2016/001

Port State Control Inspection Findings 2015

Preventive Actions:

Awareness and training material shared with all Fleet and management personnel,

Focused region specific pre-arrival checklist based verification conducted on board,

Deficiencies noted in PSC inspections highlighted to fleet to avoid repetition,

Senior Officers to carry out daily rounds and inspection with heightened attention on the

common deficiencies,

Maintain all equipment in a state of readiness at all times

Ensure proper housekeeping, particularly after use,

Check the condition of wiring, fittings and connections during routine testing of alarms,

Verify proper closing of Fire doors each time the fire alarms are tested,

All ship staff made aware of the fire door must be shut at all times,

Inability to lower life boats due to adverse conditions, shall be recorded in the log book and

inform office,

Any deficiencies identified by the ship staff to be rectified promptly.

The overall rising trend is indicated for observations per inspection in PSC inspections. It is noted that

older vessels (more than 15yrs old), vessels departing to or calling dry dock are more likely to face

close scrutiny from PSC inspectors.

Glossary

PSC

FSC

TVEL

SIRE

: Port State Control

: Flag State Control

: Tank Vessel Examination Letter

: Ship Inspection Report Programme (OCIMF)

Attachment No. 1 to Circ. OT/PSC/2016/001

Port State Control Inspection Findings 2015

Summary of Observations raised by PSC Region:

a) PSC Asia Pacific Region

1. Self-closing door in galley kept open by a wood block. (VIQ Ch. 5)

2. Hatch cover for Bosun store at forward mooring station cannot fully close. (VIQ Ch. 12)

3. One steam valve found leakage next to fresh water generator. (VIQ Ch. 11)

4. Fire door self-closing device at officer dining room to pantry is not arranged as per fire

control plan. (VIQ Ch. 5)

5. Lifeboat drill for maneuvering on water not conducted since 10.07.2015 (more than 3

months). (VIQ Ch. 5)

6. Enclosed space, preparation to enter and rescue operation not planned and conducted

properly. (VIQ Ch. 5)

b) PSC Black Sea MoU

1. Embarkation ladders - shackles are seized. (VIQ Ch. 5)

2. Plastic hoses are using for temporally discharging of the sewage water to the aft peak tank,

two fire doors (between ER and steering gear room) are fixed open, not safety, the additional

risk. The risk assessment form was not prepares for this situation. (VIQ Ch. 5)

c) PSC Caribbean Region

1. In the computer programme (loadicator) the damage stability is not calculated for all the

cases since 19-10-2014. Only case 1 is still inside. (VIQ Ch. 8)

d) PSC Colombia

1. Corrosion on deck at void space forepeak store. (VIQ Ch. 7)

2. Excess of garbage on board. (VIQ Ch. 6)

3. Accommodation ladder port side required change shackle. (VIQ Ch. 5)

4. Pump room door is not watertight. (VIQ Ch. 12)

e) PSC Latin American

1. SMC, ISSC and CSR original not available onboard. (VIQ Ch. 2)

2. Crew competency and endorsement certificates - original is not available onboard. (VIQ

Ch. 3)

3. Firefighting equipment certificate expire on 18 Jan 2015. (VIQ Ch. 2)

f) PSC Paris MoU

1. SMC, ISSC and CLC only copy onboard. (VIQ Ch. 2)

2. Air pressure control indicator leaking water. (VIQ Ch. 11)

Attachment No. 1 to Circ. OT/PSC/2016/001

Port State Control Inspection Findings 2015

3. 220V isolation not as required. (VIQ Ch. 11)

4. Cargo Tank 4P, high overfill alarm in-operative. (VIQ Ch. 8)

5. Tank radar system for tanks 2P & 5S inoperative. (VIQ Ch. 8)

6. Internal safety Audit and corrective action is required within 3 months. Deficiencies marked

as open are objective evidence of a failure or lack of effectiveness of the implementation of

the ISM code. (VIQ Ch. 2)

7. Found the cold rooms on -13C. It is noted in the ER logbook for a long time. Temperature

should be atleast -18C. Quality of food should be checked. Also found some food out of

date. More cleaning of the galley is required. (VIQ Ch. 12)

8. Found a penetration through the decks from the bridge down from the newly installed

computer cables. (VIQ Ch. 12)

9. Found several watertight doors not properly closing. For example Forecastle door and

workshop deck SB main deck aft. (VIQ Ch. 12)

10. Ground wires missing / damaged at cargo line joints to be repaired. (VIQ Ch. 8)

11. Self-closing door at upper and A-deck not closing under remote release. (VIQ Ch. 5)

g) PSC USCG

1. The PSCO discovered that the vessel has been operating within the North American ECA

from 16/02/15 to 17/02/15 utilizing fue l oil that does not comply with the Marpol Annex VI

ECA sulfur limits. (VIQ Ch. 6)

2. The PSCO discovered that the recording device for inert gas pressure and oxygen content

had been previously turned off of cargo tanks and not permanently recording past inert gas

pressures and oxygen content levels. Provide documentation from certificate authority that

the vessel has developed an adequate plan to address the proper operation of the inert gas

recorder. (VIQ Ch. 8)

3. The vessel's IOPP form B stated the vessel is equipped with a MEPC 60 (33) oil content

meter; while the PSCO discovered that the oil content meter installed is a MEPC 107 (49)

model. (VIQ Ch. 6)

4. The PSCO upon inspection of the inert gas blower #2 found inert gas leaks emanating from

the blower inspection cover. The crew replaced the gasket on the inspection cover and the

system was then found to have no noticeable leaks. (VIQ Ch. 8)

5. PSCO observed that 3 of the ship's 5 fireman outfits were not serviceable. Vessel has

procurement request in for 2 coats and 1 pair of pants, and will request 1 additional pair of

pants, but will not receive during this port call. Provide proof of replacement with

concurrence from certificate issuing authority. (VIQ Ch. 5)

6. The tank overfill alarm must have visible alarm indicators that can be seen on the vessel

where cargo transfer is controlled and in the cargo deck area. The vessel on deck overfill

visible indicator did not operate on testing of overfill device. (VIQ Ch. 8)

7. The cargo tank venting system shall be provided with devices to prevent the passage of

flame into the cargo tanks. #3 cargo tank vent line was holed due to wastage above the

Attachment No. 1 to Circ. OT/PSC/2016/001

Port State Control Inspection Findings 2015

flame screen on the vacuum side of the P/V which would allow a flame to enter the vent line

and tank. (VIQ Ch. 8)

8. The means for securing and maintaining weather tightness. The 2 STBD cargo hatch is

missing a dog. (VIQ Ch. 12)

9. Condition of ship equipment shall be maintained to proceed to sea without danger to ship

or person on board. Ramp over deck piping is wasted and poses a safety hazard to ships

crew. (VIQ Ch. 5)

10. Cofferdam and void space vent must have flame screens in the vents. Flame screens on

the 1STBD and 2PORT ballast tanks flame screen were wasted and not working properly.

(VIQ Ch. 12)

11. No electrical equipment shall be installed in any space where flammable mixtures are liable

to collect including those on board tankers or in compartments assigned principally to

accumulator batteries, in paint lockers, acetylene stores or similar spaces, unless the

administration is satisfied that such equipment is, 1. Essential for operational purposes, 2.

Of a type which will not ignite the mixture concerned, 3. Appropriate to the space concerned

and 4. Appropriately certified for safe usage in dusts, vapours or gases likely to be

encountered. Temperature sensor wiring on cargo pump #2 and #3 is pulled back from the

stuffing boxes and is not gas tight. (VIQ Ch. 5)

12. Suitable means shall be provided for the zero and span calibration of both fixed and portable

gas concentration measurement instruments. Unable to calibrate O2 meter on IG system to

the required 2.0 as indicated on the span bottle. (VIQ Ch. 5)

End of Document

Attachment No. 1 to Circ. OT/PSC/2016/001

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Operating Check List For Disel Generator: Date: TimeDocument2 pagesOperating Check List For Disel Generator: Date: TimeAshfaq BilwarNo ratings yet

- Motor Driver Board Tb6560-5axisDocument14 pagesMotor Driver Board Tb6560-5axisAli Asghar MuzzaffarNo ratings yet

- Director, Policy and Research (SEG 3 Et Al - Ministry of Culture, Gender, Entertainment and Sport PDFDocument12 pagesDirector, Policy and Research (SEG 3 Et Al - Ministry of Culture, Gender, Entertainment and Sport PDFvernon whiteNo ratings yet

- AIS - 007 - Rev 5 - Table - 1Document21 pagesAIS - 007 - Rev 5 - Table - 1Vino Joseph VargheseNo ratings yet

- RGNQA Parameters ConsolidatedDocument186 pagesRGNQA Parameters ConsolidatedpendialaNo ratings yet

- DataDocument85 pagesDataMyk Twentytwenty NBeyond100% (1)

- Quick Operation Guide of DS-7200-ST DVR (V1.2.0)Document40 pagesQuick Operation Guide of DS-7200-ST DVR (V1.2.0)Roman MayurNo ratings yet

- Philips Accent LightingDocument37 pagesPhilips Accent LightingCecila Torrez BenitezNo ratings yet

- Building A Custom Rifle StockDocument38 pagesBuilding A Custom Rifle Stock24HR Airgunner Channel100% (1)

- 6.3. Example of Transmission Ratio Assessment 6.3.1. Power-Split Hydro-Mechanical TransmissionDocument2 pages6.3. Example of Transmission Ratio Assessment 6.3.1. Power-Split Hydro-Mechanical TransmissionNita SebastianNo ratings yet

- Performance of Trinidad Gas Reservoirs PDFDocument11 pagesPerformance of Trinidad Gas Reservoirs PDFMarcus ChanNo ratings yet

- IGCC-OPM-QUA-FMT-0095 Rev.0 - EARTHING SYSTEM INSTALLATION CHECKSHEETDocument1 pageIGCC-OPM-QUA-FMT-0095 Rev.0 - EARTHING SYSTEM INSTALLATION CHECKSHEETAhmedNo ratings yet

- ProKlima Entfeuchter ManualDocument336 pagesProKlima Entfeuchter ManualJonNo ratings yet

- Cep Matlab CodeDocument5 pagesCep Matlab CodeMuhammad FurqanNo ratings yet

- MotRadar System PrinciplesDocument26 pagesMotRadar System PrinciplesReadmotNo ratings yet

- Fopid Controller and It's ApplicationDocument6 pagesFopid Controller and It's Applicationshreeja dasguptaNo ratings yet

- Yamaha Model Index 1958 2010 PDFDocument442 pagesYamaha Model Index 1958 2010 PDFSanja Krajinovic100% (2)

- Challenges in Providing Leisure and RecreationDocument6 pagesChallenges in Providing Leisure and RecreationAnalyn CabilloNo ratings yet

- IEEE Conf 2018 TrackNet - A - Deep - Learning - Based - Fault - Detection - For - Railway - Track - InspectionDocument5 pagesIEEE Conf 2018 TrackNet - A - Deep - Learning - Based - Fault - Detection - For - Railway - Track - InspectionkaruldeepaNo ratings yet

- Evoque Owners Club Manual PDFDocument258 pagesEvoque Owners Club Manual PDFmihai12moveNo ratings yet

- Lesson Plan 2Document3 pagesLesson Plan 2api-260894328No ratings yet

- B31.3 Process Piping Course - 08 FlexibilityDocument23 pagesB31.3 Process Piping Course - 08 FlexibilityRyan Goh Chuang HongNo ratings yet

- 5th Issue October 10Document12 pages5th Issue October 10The TartanNo ratings yet

- Best Answer For Each Conversation. You Will Hear Each Conversation TwiceDocument4 pagesBest Answer For Each Conversation. You Will Hear Each Conversation TwiceQuang Nam Ha0% (1)

- Method Statement For PaintDocument5 pagesMethod Statement For Paintxxx100% (2)

- Der 484Document84 pagesDer 484Rohit SainiNo ratings yet

- "Truthland": Chesapeake S Rebuttal To GaslandDocument14 pages"Truthland": Chesapeake S Rebuttal To GaslandJames "Chip" NorthrupNo ratings yet

- Modern Love - The New York TimesDocument23 pagesModern Love - The New York TimesPearl Sky100% (1)

- Updated Resume Kelly oDocument2 pagesUpdated Resume Kelly oapi-254046653No ratings yet

- Heat Rate EpriDocument48 pagesHeat Rate EpritbfakhrimNo ratings yet