Professional Documents

Culture Documents

Technical Specification Electrical

Uploaded by

nisargoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Specification Electrical

Uploaded by

nisargoCopyright:

Available Formats

Technical Specification of Electrical System for AR Jeans Producer Factory

Technical Requirement and Specification

Project Information:

AR Jeans Producer factory building.

ELECTRICAL INSTALLATION

1.

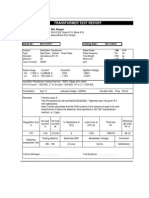

SCOPEOFWORK

This item covers all operations in connection with internal and external electrification works to connect

to the electrical mains as indicated on the drawings; all works shall be completely in conformity with

the Rules and Regulations of the concerned Authorities.

2.

GENERAL REQUIREMENTS

The drawings indicated the general arrangement of the electrical installation, Details of proposed

departures due to actual field condition or other pause shall be submitted with the ENGINEER

recommendation to the Employer for approval. The contractor shall carefully examine the drawings

and shall be responsible for the proper installation of materials, natures and equipments in each unit

as indicated, without substantial alteration.

2.1 Regulations: The installation in general shall be carried out in conformity with the Electricity Rules of the

Govt. of Bangladesh (Indian Electricity Rules and Act as adopted in Bangladesh) and the latest edition

of the wiring regulations of the institute of Electrical engineer (London), hereinafter referred as "l.E'E'

Wring Regulations" .and the British standard code of practice for tie relevant works. But where the

undercoated specification differ from these rules and standards, the specification written hereunder

shall be followed. Any special requirement of the Electrical inspector. Government of Bangladesh or

the Power Development Board by the Telegraph and Telephone Department. Government of

Bangladesh or the other legal authority shall also be complied with at no extra cost to the Employer.

2.2 Climatic and Atmospheric conditions: The installations, equipments and materials shall be installed

both externally and internally and shall therefore be designed and built to give efficient and reliable

service continuously at the normal voltage and current rating in the prevalent climatic and atmospheric

conditions at the relevant site.

2.3 Specifications: Material required which are not covered by the detailed specifications shall be as

recommended by the equipment manufacturer or consistent with good practice and approved by the

ENGINEER.

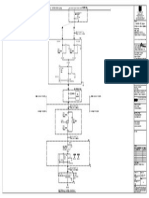

2.4 Drawings: The drawings show the general management of all circuitry, wiring, feeders, cables and race

ways, etc. however, where local conditions necessitate a re-arrangement, the Contractor shall prepare

and submit for approval, drawings of the proposed rearrangement. Because of tie small scale of the

drawings it is not possible to indicate all offsets, fittings and accessories as may be required. The

contractor shall carefully investigate the structural and finish conditions affecting all of his works and

shall arrange such works accordingly, furnishing such fittings, access traps, inspection boxes and

accessories as may be required to meet such conditions. The contractor shall prepare a shop drawing

indicating the exact location of conduits and wiring for approval of the ENGINEER prior to installation.

2.5 Cutting and Repairing: The work shall be carefully laid out in advance and any cutting of construction

shall be done only with the written permission of the ENGTNEER. Cutting shall be carefully done and

damage to the building as a result of cutting for installations, piping, wiring for equipment-s, shall be

repaired by skilled workers of the trade involved, at no additional expense to the Employer.

2.6 Protection of Fixture: Fitting, Materials and Equipment.

Page 1 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

Conduit and pipe openings shall be closed with caps of plugs during installation. Fixture fittings and

equipments shall be adequately protected against dirt, water and chemical or mechanical injury. At the

completion of the work fixture, materials and equipment shall be thoroughly cleaned and delivered in a

condition satisfactory to the Engineer.

2.7

Notice:

The contractor shall give all required notices to and maintain liaison with Electrical inspector,

Government of Bangladesh and to the metric supply Department of Power Development Board or any

other legal Authority regulating the electrical works or installation'

2.8

Execution and Superintendence:

The works shall be carried out only by licensed workmen authorized by the Government or any other

legal Authority set up for the purpose to undertake such works under the provision of the Indian

Electricity Act 1939 and Rules as adopted in Bangladesh, and under the direct supervision of a whole

time electrical supervisor having certificate of competency for the type of work under execution.

Particulars along with a Photostat copy of the competency certificate of the electrical supervisor shall

have to be submitted to the ENGINEER before commencing the work.

3.

APPROVAL AND LIST OF MATERIALS, FIXTURE AND EQUIPMENT

.As soon as practicable and within 30 days after date of receipt of executed contract and before any

materials fixtures or equipment are purchased, the contactor shall submit to the ENGINEER for

approval complete list, in triplicate, of materials, fixtures and equipment to be incorporated in the work,

together with the names and addresses of the manufactures and their catalogues/ numbers and trade

names with a forwarding letter. The ENGINEER will send the same with their recommendations to

Employer for final approval. The Contactor shall also furnish other detailed information where so

directed, under the various items. No consideration will be given to lists submitted from time to time.

Approval of materials will be based on manufacture/s published ratings. And materials, fixtures and

equipment listed which are not in accordance with the specification requirements may be rejected. The

product of any reputable manufacturer regularity engaged in the commercial production of equipments

will not be excluded on the basis of minor differences, provided all essential requirements of this

specification relative to materials, capacity and performance are met. The Contractor shall furnish a

statement giving a complete description of all points wherein the equipment be proposes to furnish

does not comply with the specifications. Failure to furnish such a statement will be interpreted to mean

that the equipment meets all requirements of the specifications. Tear sheets of catalogue shall be

furnished if such catalogues are not readily available to the ENGINEER.

4.

EXECAVATING, TRENCH MAKING AND BACKFILLING

Excavating, trench making and backfilling is specified under DIVISION 1B and 1C -'EXCAVATING &

FILLING AND GRADING.

5.

MATERIALS AND EQUIPMENT

5.1

Wires and Cables

5.1.1.

Wires and cables for installation in raceways for operation at less than 450/600 volts shall be of soft

copper properly refined and shall have a minimum conductivity of 90% with PVC insulation.

5.1.2

All wire and cable insulation, except as specifically noted elsewhere shall be rated for 450/600 volts

and shall conform to B.S.S. specification.

5.2

Conduits

5.2.1

Rigid PVC conduit shall be of 1.63 mm nominal wall thickness, conforming in all respect to B.S.S. of

regulation as amended to date.

Page 2 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

5.2.2.

Flexible PVC conduit shall be conforming in all respect to the latest BS Code as amended to date.

5.3

Outlet, Junction and Pull Boxes:

5.3.1

Outlet, Junction and pull boxes shall be manufactured from 18 SWG, (Min.) thick sheet steel

galvanized/not galvanized or mounded cast iron,

5.3.2

Circular Box:

All circular boxes and fittings shall be manufactured from PVC polymer material. The boxes and

fittings shall be so designed and constructed as to withstand rough use as may be expected during

and after installation. The inside and outside surfaces of the fittings shall be smooth; clean and uniform

and free from projections and other defects.

The interior of boxes and fittings shall be free from obstruction which might cause abrasion to cables

or interfere with the introduction and withdrawal of cables to be enclosed within the pipe. The inside

edge of all openings through which cables is intended to pass through shall be smoothly rounded in

order to prevent any damage to the cable.

5.3.3

Flexible Conduit

Flexible PVC conduit shall be conforming to the latest - under writers laboratory standards.

5.4

Switches

5.4.1

The switches shall be in accordance with B.S.S. 1299 Part-I, 1964 as amended to-date. The switches

shall be concealed type logic plus, 10A capacity mounted on G.P. sheet made board.

5.5

Panel Board

5.5.1

Panel boards shall consist of a factory completed dead front assembly of back pan, main buses, over

current and switching units, 1.63 mm thick sheet metal cabinet and kim

5.5.2

Bus bars for panel board mains shall be of copper, sized for the indicated capacity in accordance with

the Underwriter/Laboratory Standards.

5.6

Distribution Board

5.6.1

Distribution boards shall be of safety type with double pole/ three pole isolator or circuit breaker, opera

table on a 400 volts 3-phase, 4-wire system conforming to B.S.S. 214 as amended to-date.

5.7

5.7.1

Fixtures, Fittings and Appliances

All electrical fixtures, fittings and appliances including accessories shall conform to latest B.S.S.

regulation No. 301 and as amended to-date.

6.

GENERAL INSTALLATION REQUIREMENTS

6.1

Concealed Installations

6.1.1.

The conduit shall be completely concealed in the walls, columns, R.C.C. slabs, floors and shall be

nicely finished. The conduits are to be continued between all floors and access shall be provided by

access traps or inspection boxes made of cast iron or steel, as required at such places and as

recommended by l.E.E. Regulation and approved by the ENGINEER

6.1.2

Where conduit is shown on the drawings or is otherwise specified as being concealed, such conduit

may be embedded in structural slabs or in concrete fill laid on top of structural slabs, or concealed

Page 3 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

within hollow spaces. Where embedded in structural slabs conduits shall not exceed 38mm trade

sizes, unless there are specific identification to the canary in areas where the slab is less than 125mm

thick, the overall diameter of the largest conduit shall not exceed one third of slab thickness.

6.1.3

All the conduits running through the boxes and columns shall be laid with the innermost reinforcement

case with suitable effect in conduit so to make the outer surface of junction box cover for switch box

edge flush with the finished surface level or beam of columns as approved.

6.1.4

All conduit running through slab-beams, slab-column and slab-wall junction shall be connected

through a bend and junction box provided with offset, if necessary, to make the outer surface of the

junction box cover flush with the finished surface.

6.1,5

Care shall be taken when making concealed installation to see that adequate clearance is provided

over the thickness elements, such as coupling etc. so that fill or architectural finishes may be applied

which will be smooth, flat and not subject to sapling or cracking.

6.1.6

Raceways runs embedded in slab shall be spaced not less than three outside diameter centre to

centre unless they are so co-ordinate with the structures as not cause weakness,

6.2

Exposed Installation

6.2.1

Raceways or other wiring methods shall be run exposed only:

a. In specially assigned electric riser closets,-shafts or switch board room,

b. In mechanical equipment spaces.

c. Where specially indicated on the drawing or otherwise, with the expressed permission of the

ENGINEER .

6.2.2

Exposed raceways of other wiring method shall be run parallel to building walls, column lines, etc.

throughout.

6.2.3

All exposed heavy conduits are to be fastened to masonry walls, floor or partitions, use of wooden

plugs will not be permitted instead rowel plugs should be used. Metal saddles of approved type not

more than 600mm apart, shall be used for fixing exposed conduit,

6.2.4

Composition supports of cables installed in vertical raceways shall be provided where indicated on the

drawings and as otherwise necessary to meet code requirements.

6.3

Routing / Raceways

6.3.1

Every effort shall be made to route raceways or other wiring so as to prevent wiring from being subject

to high ambient temperature condition. Minimum clearance from heated pipes, ducts or surface such

as breechings, flush, etc. shall be maintained as follows:a. Crossing uninsulated pipes or ducts

b. Crossing insulated pipes or ducts

c. Running parallel to uninsulated pipes ducts or surfaces

d. Running parallel to insulated pipes, ducts or surfaces

- 75mm

- 25mm

- 900mm

-150mm

6.3.2

Regarding of any routing shown on the places, raceways or other wiring method shall not run exposed

over a boiler or embedded in construction under a boiler, unless special provisions for wiring through

these specific high ambient temperature areas have been indicated

6.3.3

Raceways or other wiring methods run in suspended ceiling may be installed as the draw files, except

that, where such raceways etc and being installed prior complete information regarding the final layout

Page 4 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

of all trade occupying the suspended ceiling plenum, they shall be installed in a co-ordinate "Square

manner so as to minimize future conflicts.

6.3.4

Under no condition raceways or other wiring methods be installed in elevator shafts and hoist ways.

Where outlets are being provided for such items as tri cables, pit lights, run by lift, etc. only the outlet

boxes themselves shall be located within the confines of the shaft.

6.4

Miscellaneous Requirements

6.4.1

The installation of raceways or other wiring methods requiring the notching, cutting or drilling of

structural elements shall be co- ordinate with the other trades, to ensure that no weakening of the

structure is caused.

6.4.2

Except as otherwise noted in raceways intended for the pulling in wires or cables, no more than four

90" bends will be permitted between outlets boxes, pull boxes or other points

6.4.3

When fishing or snaking raceways to set up for pulling in wires and cables, fish tapes with ball types

means shall be used.

6.5

Wires and cables shall not be pulled into raceways until:a. The project has procedures which are not likely to injure electrical wires or cables,

b. The project has progressed to a point where raceways are dry and moisture is no longer likely to

get into them.

c. Wires or cables shall be pulled into raceways utilizing a suitable brush, followed by an 85%

diameter ball mandrel ahead of the wires or cables in the pulling assembly.

6.5.1

The only permissible pulling lubricant is powered soap-stones.

6.5.2

Sufficient slack shall be left on all rooms or wires and cables to permit the proper connection of

devices, equipment etc.

6.6

Mounting Height

6.6.1

Mounting height of outlet and fixtures shall be in accordance with the following list of bottom line

dimension above finished floors unless otherwise shown on drawings.

a. Light and fan switch boards

1200mm from finish floor level on wall

b. LED Tube Light at Ceiling suspened 2100mm from finish floor level.

c. Socket outlet on wall

225mm

""

d. Socket outlet above the lab table

1050mm

e. Telephone and intercom

225mm

f. Cal bell outlets

1200mm

""

g. Call bell indicator

2400mm

""

h. Electric clock outlet

2400mm

""

i. Fire alarm outlet

2400mm

""

"'

""

Page 5 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

j. Fire alarm bell

2100mm

""

k. Ceiling Fan

2550mm

""

l. Television antenna outlet

225mm from finish level.

m. Coiling suspended Fluorescent light fitting

2550mm " "

7.

WIRING METHODS

7.1

General wiring methods permissible for the various parts and elements of the system operating at

450/ 600 volts or less shall be as hereinafter specified. All surface cable / wire shall run through

metallic conduit.

7.1.1

Rigid standard weight metal led / PVC conduit shall be used for feeders and sub-feeders and

appliance branch circuiting throughout,

7.1.2

Rigid standard weight metallic / PVC conduit shall be used for lighting and appliance branch circuiting

throughout.

Where non flexible wiring methods are specified it shall be understood that the following exceptions

are to be made for final connections without claiming any extra cost.

7.2

a.

Final connections to motors and motor operated equipment shall be made with 38mm of flexible

metallic conduit.

b.

Final connection to recessed lighting fixtures shall be made with not more than 500mm long flexible

metallic conduit or flexible wire.

7.2

Surface wiring

7.2.1

Conduit for surface wiring shall be metallic and secured with wall ceiling or any other structure by

means of saddle at a distance of 600mm c/c, and all the bends will be made by mechanical bender.

No elbows will be allowed, where necessary pull boxes of inspection Boxes as specified shall be used.

7.3

Switch

7.3.1

Furnish and install all wiring devices as shown on the plans and as hereinafter specified. Switch for

lighting control in rooms having single door entrance shall be located at striking of the door regards

less of their position on the plans.

1.3.2

The switches shall be in accordance with B.S.S. 1299 Part-|, 1964 and shall be flush or surface

mounted as mentioned. The switch shall be finished in color approved by the ENGINEER .

3-pin 13amp and 15 amp. Sockets shall be switched and shuttered and recessed type suitable for

concealed mounting and will be suitable for fixing flushed plugs,

7.33

8.

RIGID CONDUITS FITTINGS AND CONNECTIONS

(Not applicable in this work)

9.

FLEXIBLE PVC CONDUIT, FITTINGS AND CONNECTIUI{S

9.1

Conducting

9.1.1

Flexible PVC conduit shall be conforming to the latest Standards.

9.1.2

The minimum size of flexible conduit-permissible for the various parts and elements of the electrical

work shall be 25mm throughout except otherwise specified.

Page 6 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

9.2

Installation

9.2.1

The ends of all flexible conduits shall be carefully reamed out free from burrs-before installation.

9.2.2

All cuts shall be made square and shall be done with hacksaws.

9.2.3

Termination of flexible conduit shall be continuous between terminations without the use of coupling.

9.2.4

Runds of flexible conduit shall be continuous between terminations without the use of coupling.

9.2.5

Flexible conduit shall not be bent so that its radius is less than five times the trade sizes.

10.

JUNCTION AND PULL BOXES

10.1

Where indicated in the drawings and specification or where necessary for compliance with code

requirement for cable installation, junction and pull boxes of the proper sizes shall be provided.

10.2

Junction and pull boxes shall be manufactured from 18 SWG. (Min.) thick sheet steel or moulded cast

iron and shall be furnished with flat screwed covers.

Where boxes are set flush in walls and ceiling, cover screws shall be flat head type and properly

counter skunked. Cover shall be arranged to completely cover openings in buildings finish.

10.3

10.4

Where suitable standard outlet boxes may be used as junction and pull boxes.

10.5

lf required by the building construction, junction and pull boxes of special sizes and shapes determined

from field measurements shall be provided in order to make neat installations.

10.6

Should the utility company or any other agency require carriers between groups or feeders in pull

boxes, they shall be provided at no additional cost.

10.7

lf feeders and other wiring following the same routing are indicated on the plans as running through

separate pull boxes, it shall be understood that is intended to maintain a segregation of the wires and

cables. Separately indicated pull boxes may be incorporated into single boxes, only on condition that

segregation is maintained by means of approved asbestos carriers.

10.8

Pull boxes having any single horizontal dimension larger than 150mm shall be filled with cable support

racks consisting of 19mm diameter steel pipes with flanged ends bolted to the sides or frame of the

pull boxes. Each pipe support shall be filled with a continuous fiber insulating sleeve.

10.9

Where a junction or pull box is installed in a furred ceiling or space, and where due to building finish,

the sheet metal cover of the pull box exposed to view is not acceptable, on approved access panel

with suitable frame and supports in the furring in front of the pull boxes cover shall be provided.

11.

OUTLET BOXES

Outlet boxes shall be provided as hereinafter specified, where shown on the drawings, and all

locations where required. When installing outlet boxes particular attention shall be paid to the

following:

11.1

Outlet boxes shall be of such sizes and depth as to allow for easy wire pulling and installation of wiring

devices, and shall comply with code minimum capacity requirements.

Page 7 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

11.2

All mild sheet steel and cast boxes shall have suitable knockouts.

11.3

All cast boxes shall be provided with properly drilled and tapped holes,

11.4

There shall be no more holes in any outlet boxes than required for the crucify entering the same

unused opening in boxes shall be provided with approved cast threaded plugs.

1 1.5

The sheet steel boxes shall have threaded ears for fixing the covers.

11.6

Sheet steel boxes used for flush outlets in walls or partitions shall be set such that not more than 3mm

exists between the front edge of the boxes and the rear surface of the device plates which will be

finally installed.

11.7

Sheet steel outlet boxes and covers shall be hot-dipped galvanized and cast iron boxes and covers

shall be electro-galvanized.

11.8

In case of non-availability of galvanized sheet steel outlet boxes 18 SWG, thick M.S, sheet made

outlet boxes spray painted with two coats of synthetic enamel paint over a prime coat may be

accepted subject to prior approval of samples by the ENGINEER .

11.9

In case of non-availability of C.l. circular boxes cast brass circular boxes may be accepted subject to

prior approval of samples by the ENGINEER.

11.10

FLOOR BOXES (FB)

Floor boxes shall be provided and shown on the drawing and all locations where as required

a.

FB shall be of such size and depth as to allow easy installation of sockets / female jacks and

easy pulling of wire in conformity to related port.

b.

FB shall be made of G.P. sheet of 1.63mm thickness and DUCU painted.

c.

All FB shall have suitable knockouts for entry and exit of cable / cord.

d.

All FB shall be MK brand or equivalent.

12.

WIRE AND CABLES INSTALLATION

12.1

Wiring: Wires and cables for installation in conduits/ raceways for operation at less than 600 volts shall

conform to the following:

12.1.1 Conductors shall be of soft copper properly refined and shall have a minimum conductivity of 90% with

PVC insulation.

12.1.2 All wires and cable insulation except as specifically noted elsewhere, shall be rated for 600 volts and

shall conform to B.S. Specification,

12.1.3 All portion of electrical system utilizing PVC insulated conductors shall be guaranteed against grounds,

shorts and other insulation failures for a period 5 years regardless of any other indication, with regard

to the guaranteed period for electric work.

12.1.4 Wires and cables shall be delivered to the site of the projects original packaging or in factory reels,

fully identified with tage or levels, indicating the manufacturer's name and the date of manufacture.

12.1.5 Wires and cables shall bear repetitive marking along the entire length of their outer covering, indicating

conductor size, insulation type, voltage rating etc, as necessary for compliance with code

requirements.

Page 8 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

12.1.6 The outer covering of wires and cables shall be color coded by means of factory applied approved

code methods so as to provide a clear differentiation between each phase and neutral. The phases

and neutral shall be colored red, yellow, blue and black respectively. ln case of single phase two wire

system red, yellow or blue shall be for the phase line and black for neutral.

12.1.7 All wires shall be of standard construction.

12.2

Installation

12.2.1 The maximum number of conductors in any conduit shall be as per drawing conforming with the

regulations of l.E.E. No joints in the conductor will be made throughout the installation and looping

system shall be followed.

12.2,2 The conductor shall be tested for continuity and insulation before energizing and conform to the

standard laid down by the local Engineering Authority and institution of Electrical Engineer (England).

12.2.3 Generally, single core cable (non-sheathed) are to be installed in metal conduits. The conduits sizes

shall be as specified in the drawings. lt must be ensured that the cables are not damaged during

pulling. For long lengths, pull boxes must be used even if not indicated in the drawings. Cables shall

not be drawn round more than two 90' bend between drawing-in-boxes and any single bend must not

be less than 90".

12.2.4 The cable upto 2.5mm2, shall be solid conductor and therefore, jointing are to be done through

porcelain connector and the connection shall be wound with PIB tape before placing in the boxes.

Termination of cable upto 2.5mm2 shall be done by making a hook at the end and for higher sizes,

brass cable terminations must be used. Tee-off joints in the cable to lighting-point, switches, etc,

should not be made. Looping in system of wiring is to be followed for recessed and surface wiring and

the joints are to be made in the switch boards only. All 3 to 4 core PVC cable shall be terminated using

brass cable glands of proper size.

13.

FEEDERS, LIGHTING AND APPLIANCE CIRCUITRY

13.1

Sizing and other pertinent data regarding main feeders, sub- feeders, branch feeders, operating at 600

volts or less and any branch circuitry protected by different ratings, circuit breakers are fully delineated

on the plans. All such feeders and circuitry shall be provided in accordance with the indication on the

plan and shall be connected for correct phase sequence and proper operation of the equipment

served.

13.2

Each individual lap off feeders which is called with multiple cables per phase shall be arranged so that

all of the feeders are connected to the corresponding phase leg of the individual tap.

13.3

General circuitry operating at less than 600 volts and called for or indicated without specific details as

to sizing, etc. shall be underitood to be lighting or less. Such circuitry is to be provided in accordance

with the ground rules hereinafter specified.

13.4

Where lighting and appliances outlets are shown on the drawings without fully delineated circuitry such

shall be provided in accordance with the "Ground Rules" listed below.

13.5

All lighting and appliance branch circuitry protected as 20amp or less shall be performed in

accordance with the following ground rules unless there are specific indications to the contrary.

13.5.1 Unless otherwise noted minimum conductor size shall be No. 1.63mm. dia copper.

13.5.2 Conductors for circuitry operating in the range of 230 to 250 volts to neutral and extending in excess of

60 Meter from the point of supply to the last outlet or fixture tap, shall be 3.25mm dia copper

throughout.

13.5.3 Raceway sizes shall be adequate for the number of conductors contained as required by code.

Page 9 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

13.5.4 Unless otherwise noted, circuitry shall be multi-wise utilizing common neutrals arranged so that no

neutral conductor acts as common wire more than one circuit conductor connected to the same phase

leg of the supply system.

135.5

Circuit shall be balanced on phases at supply point as evenly as possible.

13.5.6 Except as hereinafter differently specified standard type of metallic outlet box shall be provided for

each and every wiring device, lighting fixtures, etc.

13.5.7 Where more than one switch is shown on the plans or a single location their switches shall be gangmounted to a single suitable outlet box.

13.5.8 A switch and receptacle shall not be gang-mounted in a single outlet box unless the plan specifically

indicate such a communication.

13.5.9 Where buried-in outlet boxes are required by code authorities to separate wiring devices wired off

different phase legs of the supply system, to separate wiring of different voltage system or for other

reasons, such barriers shall be provided at no additional cost.

13.5.10 Under no condition shall any switch break any neutral conductor.

13.5.11 Quttet boxes for switches shall be located at the strike side of doors. Door swing indicated on plans

are subject to field change. Outlet boxes for switches shall be located on the basis of the final door

swing arrangement.

13.5.12 Unless made accessibly by other means, boxes for recessed ceiling fixture be mounted near to the

ceiling fixture.

13.5.13 Final connection from outlet boxes to recessed ceiling fixtures shall be means of suitable flexible

fixtures pigtails not less than 1200mm and not more than 1800mm long. ln all cases enough slack

shall be left in pig{ails to permit removal of fixtures from ceiling for inspection with disconnection'

13.5.14 Where the specifications for drawing implicates no specific requirements as to the loading or

connections of outlets in lighting and appliance branch circuit, the following maximum limitations shall

be followed: No more than 12 outlets or 1650 watts shall be applied to any single 10 amps circuit and

no more than 24 outlets or 3200 total watts to any single 20 amps circuit in the range of 230 to 250 volt

to neutral.

13.5.15 At any location where lighting and appliance branch circuitry is provided extending from a flush

mounted panel board to a suspended ceiling immediately above, at least 6mm empty conduit shall be

provided (in addition those required for active circuitry) to permit future wiring escape from panel

board. The empty conduit shall extend up from the panel and shall terminate in a threaded conduit cap

immediately after turning out into the hung ceiling planers space.

13.5.16 Emergency wiring shall be run in a completely separate raceway conduit system containing no wires

of "Normal" lighting and appliance.

13.6

The following space shall be interpreted as being damaged locations, regardless of high ambient

moisture level is found to exist:

1 3.6.1 Space where any designation indicating weather proof (WP) or Vapour-proof (VP) appear on the

drawings.

13.6.2 'Within air conditioning ducts;

13.6.3 In cooling tower areas, regardless of whether interior or exterior.

13.6.4 In kitchen area.

Page 10 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

13.7

Wire for exterior lighting fixture and/or receptacle not mounted on the birding shall be having a neat

moisture resisting rubber insulation and poly chloroprene jacket of sufficient thickness to ensure its

adequacy for direct burial installations. The PVC double coated wire shall be in G,l. pipe with two coats

of water-proof bitumen compound installed 450mm minimum below ground.

14.

UNDERGROUND TRANSMISSION AND DISTRIBUTION SYSTEM

14.1

Cables shall be either, 4-core/3-core PVC insulated PVC sheathed type or 4-core/3-core PVC

insulated and PVC sheathed and armored type as specified in the Schedule of Work.

14.2

Cable Boxes

14.2.1 All types of cable and boxes shall be of cast iron and shall comply with latest Bangladesh Government

Specification and as per drawing. All other accessories shall be of approved type and design and shall

be approved by the ENGINEER

14.3

The excavation shall be 1050mm deep and 450mm wide, The bed surface shall be free from any point

sharp, materials, Breadth of the trench shall be increased by 600mm on a joint point.

14.4

Laying of Cable

14.4.1 150mm thick sand shall be spread and the cable laid. Another layer of sand shall be spread on top of

the cable and then covered with bricks and tiles as per drawling the remaining portion of the trenches

will then be filled in with earth and well rammed in layer of 150mm.

14.5

Crossing road, Pavement, Culvert, etc.

14.5.1 In crossing road or pavement, a hume pipe of suitable size shall be provided in the trench shall be

covered with pre-cast slabs or blocks of sufficient strength to withstand the load over them. .

14.6

Joint Cable

14.6.1 While laying the cable it shall be so arranged that cables to be jointed overlap each other by about

450mm to provide ample length for jointing. Metal serving and armoring shall be removed from both

cable to conform to the dimension of the box. The lead sheath (if there by any) is then to be cut off

from both cables to box dimension. The belt paper shall be removed to within 25mm of the lead

sheathing at each and exposing the insulated core. The insulation shall " be removed to the required

length. All points shall be sweathed, wiped clean and properly insulated.

14.6.2 At least 25mm clearance shall be allowed between the centre of each pair or joints. A wad of

impregnated tape shall be provided between each core and in tee joints, the armoring shall be

properly bound and the box shall be replaced in the filling holes. Necessary tapping up shall be carried

out after the compound has cooled.

14.6.3 Cables are to be terminated with the cable glands or end box as the case may be with the cable lugs

of appropriate size and ratings.

14.6.4 Markers shall be provided along the cable routes at each turning point of the trench.

14.6.5 Markers shall be made of 3mm thick M.S, sheet welded to M.S. angle as shown in the drawing or shall

be made of cast iron.

15.

PANEL BOARD

15.1

Panel board shall be provided where shown on the plans. They shall be suitable for supply

characteristics as shown on the plans and shall have branches of the number and size indicated, Main

Page 11 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

over current devices shall be provided as indicated on plans. Devices fro over current protection and

switching in the various panel board shall be as called for under the title over current.

15.2

Each panel board shall consist of a factory completed dead front assembly of backpan, main bushes,

over current and switching units, sheet metal cabinet and trim.

15.3

Cabinets shall be fabricated from 1.63 mm thick sheet steel with corner lapped and reveted of

fastened by other approved methods. Cabinets shall be of such size as to permit a suitable wiring

gutter space all around. Where feeders cables supplying the panel mains are through the panel board

in order to supply other electrical equipments, the cabinets shall be so sized as to provide a wiring

space having at least five times the total cross DIVISION area of the feeders cables in addition to the

gutter required for branch wiring connections.

15.4

Panel board cabinets and trims shall be suitable for the type of mounting shown on the plan. All trims

shall be fastened to the cabinet by indicating trim clamp and shall be of a type that it self supporting on

the cabinet after the trim clamps have been released.

15.5

Bus bars for panel board mains, shall be of copper having the current carrying capacity indicated on

plans and sizes for such capacity in accordance with Underwriter Laboratory Standards. Where

required and unless otherwise noted on the plans, neutral bars shall be full size Bus bar or panels with

single pole branches shall be drilled so as to provide sequence phasing of the branch circuit devices.

15.6

The inside and outside of panel board cabinets and trims, shall be provided with one rust proofing

prime coat and one finish shop coat of an approved paint. Such finished paint shall be of a type which

provide a surface suitable for a possible application of a field coat paint which is to be provided by the

Contractor free of cost.

15.7

Where called for on the plans, or as required to assure ready accessibility of top switching and over

current device, power or distribution panel boards shall be provided as multiple adjacent DIVISION. An

single overall cabinet shall be provided for such multiple adjacent panel board divisions, with approved

ebonite or asbestos barriers between Divisions. The entire assembly shall be such as to provide wiring

gutter space for each Division as if it were as individual panel board. Common bussing shall be

provided for adjacent division unless the plans indicate the individual DIVISION as being separately

supplied. Sub-feeder lugs with full capacity cable caps to adjacent panel DIVISION will be accepted as

the bussing method.

15.8

Power or distribution panel boards shall have gutters for branch wiring connections not less-than

125mm in width, where the largest device does not exceed 225 amps. Under no conditions shall the

width of a cabinet for a single DIVISION of power or distribution panel board exclusive of any auxiliary

feed through gutters, exceed 1050mm nor shall its depth exceed 325mm.

15.9

Lighting or appliance panel board shall have side wiring gutters for branch wiring connections not less

than 100mm in width. Under the condition the overall width of a lighting appliance panel board cabinet,

exclusive of any auxiliary through feeders gutter shall exceed 500mm nor shall its depth exceed

119mm where main over current protection is not called for or 150mm where main over current

protection is called for.

15.10

Approved a hinged doors covering and all switching devices handles shall be provided in the trims of

all panel boards.

15.11

Doors in panel boards trims shall conform to the following.

15.12

When providing access to switch handles, doors shall not uncover any live part.

15.13

Door shall have flush type paracentric cylinder lock and catches, except that door over 12mm height

shall have a vault handle anO a S-point catch, complete with lock arrangement to fasten door at top,

bottom and centre. Two keys shall be provided for each lock and each key shall open panel board.

Page 12 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

15.14

Doors shall be provided with directly holders having metal frames and transparent plastic covers on

their inside faces. Complete type-written schedule denoting the panel designation the circuit number,

the designation of branches controlled and the local services by each branch shall be inserted in the

directory holder.

15.15

The handle of circuit breakers controlling circuits which must be constantly energized (e.9. stair,

corridor and other night lighting emergency connection) shall be provided with locking devices to

prevent then from being de-energized inadvertently and shall be grouped together at each panel

board, Similar circuit breakers controlling circuits with are to be de-energized at right shall also be

grouped together.

16.

DISTRIBUTION BOARD

16.1

The electrical contractor shall furnish, install and connect all distribution boards where shown on the

drawings and /or indicated in the plan conforming to B.S.S 214

16.2

The distribution board shall be of the safety type with double pole isolator or circuit breaker as

mentioned in schedule of quantities. Ampere rating and number of branch miniature circuit breakers

shall be as shown on the drawing. The distribution boards shall be opera table on 415/230 volts 3

phase, 4 wire system. Where required solid neutral buses shall be provided.

16.3

Miniature circuit breakers, shall be moulded type quick make quick break and shall have inverse time

limit characteristics with instantaneous/magnetic trip elements functioning on over load above the

normal operating range. All miniature circuit breakers shall be "Trip-free" rating of breakers shall be as

shown on the drawings.

16.4

Heavy M.S. sheet cabinets with finished hammered tone shall be used for surface or flush mounting

with standard concentric knockouts all around at suitable places. Doors shall be provided with flush

locks, The Contractor shall use pipe clips with suitable expansion sleeves. The arrangement and

method of fastening all conduit shall be subject to the direction of the ENGINEER

16.5

The distribution boards shall be installed surface flush as per drawing 1350mm above the finished

floor level, unless specified otherwise. The distribution boards shall be mounted in a concealed cabinet

type switch board cover with the locking arrangement.

17.

ENCLOSURES, BUSBAR & CIRCUIT BREAKERS

17.1

The panels shall conform to the Damp heat, constant , to IEC 68 part 2-3.The construction of steel

board shall be from. one-piece rolled steel DIVISION, welded, steel thickness minimum 1.63mm, semitextured powder spray finish of approved colour, welded back plate with four holes for wall fixing bolts,

earth on mounting plates (hot galvanized, minimum 3mm thick), top plate and bottom plate with flange

apertures, sides and back plate without apertures door hinged on the right, turn lock, fastening with

3mm double ward key, all hinged shall be concealed, predrilled mounting rails with distance between

centre of rails 125mm minimum insulating flanges for cable entry, etc. The steel enclosure shall be

with support frame for mounting units, with cover, glazed door , insulating surround, and insulating

surrounds covering the terminals, connecting struts, stuck-in door gasket, cable grommets, cable

glands, ctc.

17.2

Alternatively, the panel may be made of self-extinguishing polystrol and polycarbonate of thermoplastic

of approved colour and resistant to water , acid, saline solutions, alcohol's, petrols, etc. with necessary

wall fixing straps, sellable brackets, cable entry flanges with a mounded PG knockouts, mounting rails

component shrouds, blanking plates connecting links, mounting plates, cable gland, cable grommet,

quick release fastener, etc,

17.3

BUSBAR

The busbar shall be of copper having the rating as per schedule of items and the unrestricted short

circuit of 25KA at 0.25PF for 1 sec, including colour as per IEC code

17.4

CIRCUIT BREAKERS:

Page 13 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

The MCB/MCCB's shall be quick-make, quick break, trip-free, indicating type and shall have inversetime limit characteristics with adjustable overload and adjustable short circuit release. All lugs must be

of the solder less mechanical type. The MCB must comply with IEC 157-1, IEC-898 rated voltage

2401415V, A.C.50 Hz, interrupting capacities minimum 6M in all SDBs ESDBs, and minimum 1OKA in

all FDBs and EDBs, current limiting class 3, finger proof, protection through Terminal and Magnetic

Trip DIVISIONs respectively, temperature rating at 40oC , preferably trivialized (moisture-fungus

correction treated), with contracts of silver alloy, terminal capability as per requirement. The MCCB

must comply with IEC 157-1 having rated voltage 600 A.C.,50 Hz with terminal overload, and

instantaneous magnetic tripping action interrupting capacities minimum 25KA, in destitution boards,

temperature rating 400C, preferable trivialized (moisture-fungus correction treated), terminal capability

as per requirement. The bidder may offer MCCB to meet requirement of the specification.

18.

LIGHTING FIXTURE AND LAMPS

18.1

All lighting fixtures, indoor, and outdoor complete with lamps, supports, appurtenance, etc. shall be

furnished and installed as part of the electric work as per drawings or specified otherwise the fittings

shall be designed and built to give efficient and reliable service continuously at the normal voltage and

current rating in climatic and atmospheric condition prevalent at the site,

18.2

All lighting fixture are located, listed detailed, specified and identified by type reference on the plans.

18.3

All lighting fixture furnished as part of the electric work conform to the following :

18.3.1 All electrical components of lighting fixtures (sockets, discharge lamp auxiliaries, wires, etc.) shall have

the prior approval of the ENGINEER before final installation and must fulfill the requirement of

standard specification.

18.3.2 All fixtures wire utilized for connection or wiring between electrical components, as well as circuit tap

or discharge lamp auxiliaries shall be minimum of 1.63mm thick and insulating rating shall meet the

standard and local requirements for the temperature, current and voltage conditions.

18.3.3 Lighting fixtures shall be constructed with the minimum possible number of joints. Joint shall be made

only by means of approved welded brazed. Screwed or bolted construction method, soldered joints will

not be permitted.

18.3.4 All ferrous parts and supports of lighting fixtures other than parts manufactured of stainless steel shall

be completely rust proof after fabrication and before finishing coats and applied. All screws, bolts nuts

and other fastening latching hardware shall be cadmium or equivalent plated.

18.3.5 Finished thickness of all cast parts shall not be less than 3mm except where specifically indicated to

the contrary, all fixtures shall be provided with a final synthetic high temperature stove enameled

coating of color and finished as specified or directed. Unless otherwise specified all stove enameled

reflective surface shall be white, with a minimum reflectance of 85%.

18.3.6 Where stainless steel or non-ferrous metal or aluminum is to be utilized as a reflector surface the

stainless steel or non-ferrous metal will be baked on clear lacquer to preserve the surface and the

aluminum shall be treated as specified with alzak or anodizing process to ensure a permanent

reflective surface with a minimum 95% reflectance.

18.3.7 Recessed fixtures shall be designed so as to properly coordinate with the ceiling construction they are

to be mounted on.

18.3.8 Fixture shall be furnished with all appurtenance (trim, plastic frame, etc.) necessary for the proper

support of the fixture. Plaster frame shall either by manufactured of non-ferrous metal or if

manufactured of steel shall be suitably rust proofed after fabrication as herein above described. All

support for lighting fixture (strim chain, anchors, etc.) shall be adequate for the support of the weight of

the fixtures. All strim hangers shall be furnished with suitable aligner canopies or outlet box covers that

the fixtures hang vertically irrespective of the angle of the surface they are mounted from. When

fixtures, or hanger canopies are mounted flush to the coiling or wall and where raceways and outlet

boxes serving the fixtures are surface mounted to the ceiling or wall, finishing rings shall be provided

Page 14 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

to concealed the outlet box. All visible fixture hanging devices and appurtenances shall have the same

finish as the fixture unless specifically otherwise indicated.

18.3.9 Fixture for use in outdoors or in areas designated on plans and damp locations shall be suitably

gasketted to prevent access of moisture into electrical components or enclosing diffusers, lenses, or

globes. All metal parts of fixtures for use in damp locations that are specified as requiring paintings,

shall be painted with suitable weather proof and moisture resistant paints exhibiting moisture resisting

qualities equal to eposy based coatings. All aluminium parts of fixture for use in damp locations that

are specified as requiring as unpainted finish, shall be anodized.

18.3.10 Lighting Management is to ienderity a system flexible enough to have energy efficient Lighting and

quality Control that may be integrated into other building management system. Trio is a

comprehensive Lighting Control System which is applicable for wide range of indoor application.

Based on installation standard Trio with installer Box above false ceiling is applicable. The

configuration shall be when

a. only movement detector is connected, it will automatically switch the lighting ON or OFF;

b. but people in the room, will be able to trun the lights 0N or KEEP it in certain level manually when

there is movement detector including an lR Receiver. Trio will automatically switch the lights OFF

when no one is present in the room.

18.4

Compact Fluorescent, sodium discharge lamps, etc.

18.4.1 All discharge lamp lighting fixtures furnished as part fittings shall be suitable to operate on the main

par of the electrical work shall conform to the following and is of which are given below:

a. Number of Phase

- Single phase

b. Voltage

- 230 volts + / - 5%

c. Frequency

- 50 Hz.

d. Type

- Alternating current

18.4.2 The fluorescent lamp shall be high power factor operation, tubular in shape for general lighting service

18.4.3 The color shall be cool white.

18.4.4 Electronic Ballasts and capacitors shall be rigidly mounted to the inside of the top of the fxture housing

with ballasts surface and housing in complete contact for efficient conduction of ballast heat. Ballast

mounting shall be permanently affixed to the housing.

18.4.5 The diffusers shall be glare free, moulded out of 3mm thick opal plexi material of uniform density and

sturdy construction. The diffusers shall be quick detachable type and shall be supplied as asked for in

the schedule of quantities.

18.4.6 Sockets shall be suitable for the specified lamps and so that lamps are positions in opticatty correct

relation to lenses, reflector, baffles, etc.

18.4.7 All lenses, louvers, or other light diffusing elements contained in fixtures frame shall be removable but

positively held within the frame so that the hinging motion of the frame will not cause the diffusing

elements to drop down.

18.4.8 All glass elements, Ienses, diffusers, etc. shall be made of thermospane material equal in

characteristic to that of pyrex.

19.

TELEPHONE SYSTEM

19.1

Telephone Cables

Page 15 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

19.1..1 The telephone cable shall be installed in indoor in conduits and outdoor in G.l' pipe and shall be

designed and built to give efficient and reliable service continuously at the normal voltage, current and

audio frequency rating in the climatic and atmospheric conditions prevalent at site.

19.1.2 The telephone cable shall be as made by Telephone Cable industries of Bangladesh and will be of 100

pair

19.1.3 All connections shall be made, marked and identified on the terminals strips provided in junction

boxes, cabinets and posts. No connection or joint of the conductor shall be made in the outlet /pull 'out

or the conduit.

19.1.4 The conductor shall be tested for continuity and insulation before making connection to the entire

satisfaction of the Telephone Department, Government of Bangladesh.

20.

LIGHTNING PROTECTION SYSTEM

20.1

The system of lightning protection shall be installed so as to protect the building against lightning

conforming to B.S.S. code or practice 326.1 01 of 1 948.

20.2

The installation shall comprise the following:

a. Net work of air terminals

b. Bonds

c. Roof conductors

d, Down conductors

e, Earth Terminals

f. Testing Points

20.3

There shall be air termination points on the building installed 750mm above the finished level or as per

drawing.

20.4

The air terminals shall be cast and machined electrolytic copper complete with single pointer rod and

150mm x 100mm 12mm brass plate and to be reinforced so as to withstand the excessive air pressure

during storm.

20.5

The roof and down conductor shall be of soft annealed electrolytic copper conductor of 2 SWG unless

otherwise specified. There shall be number of down conductor as specified and each down conductor

shall have independent testing points, earth termination lead and earth.

20.6

Fixing of cable in vertical shaft. Wall and U/G Trenches.

20.6.1 The cable shall be fixed in vertical shaft and on wall as per drawing and regulation and with standard

cable fixing accessories.

20.6.2 The cable hanger shall be fixed on the vertical shaft and on walls at regular interval as per l.E.E.

regulation and cable entry for floor to floor shall be fire proof.

20.6.3 The trench shall be absolutely clean while the cable is laid.

20.6.4 The pull-box of the trench as per drawing shall be left open till cable is laid in the position, Thereafter

the trench shall be covered with R.C.C. slab. The trench inside the building shall be covered with 9mm

thick mild steel checkered plate.

20.6.5 The Contractor shall ensure that he or his authorized representative is present while the cable is laid.

He shall ensure 'that the cable is laid according to the requirement and the prescribed specification.

20.7

Earthing

20.7.1 Earthing system shall be provided in accordance with lS:3043-1987 with latest amendments and other

statutory regulation and as per drawing and schedule.

Page 16 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

20.7.2 The whole of the lightning protective system shall have a combined residence to earthling not

exceeding 10 ohms before any bonding has been affected to metal iron on a structure or to surface

below ground.

20.7.3 Copper earthing system shall be provided. For the single transformer substation, the total number of

earth electrodes shall be four numbers (two for neutral and two for body earthing). AII the bus

ducts/cable trays shall be provided with suitable size of 2 nos. Cu strips in the full length. All electrical

equipment shall be earthed with 2 nos. Cu strips/wires and non-current carrying metallic parts with 1

no. of Cu strips/writes. Every power outer, switch, lighting flxture shall be provided with insulated

copper conductor of required size for earthing. The UPS main distribution board shall be connected to

separate copper earth pits with PVC insulated copper tape, Each UPS distribution board shall be

connected to the UPS main distribution board with runs of PVC insulated copper conductor wire. The

UPS neutral shall be earthed separately with 2 nos. of copper earth pits.

20.7.4 Separate copper earth rods in earth pits shall be provided for PABX and Network equipment. The

PABX and the Network equipment shall have separate insulated earthing conductors, which shall both

terminate at the earth pit. Engineering conductors shall be provided for the Transient Voltage surge

suppressor for the satellite antenna structure.

The raceways shall not be used as an earthing conductor.

The resistance to each earthing system shall not exceed 1.0 ohm.

20.7.5 Pipe Earthling:

a. 38mm dia G.l. pipe shall be sunk up to a depth of 36M by tube-well sinking method unless

otherwise mentioned in the schedule.

b, An earth inspection pit shall be constructed

c. A brass clamp of size 100mm x 50mm x 19mm shall be made of 19mm thick brass plate by

properly, bending, machining and drilling unless otherwise mentioned in the schedule.

d. 19mm dia brass bolt nuts with washers shall be used for fixing the clamp on top of the earth

electrode G.l. pipe and for connecting the earth lead wires with the earth electrode'

21.

21.1

INSULATION TEST

The contractor shall carry out insulation test of the complete installation in presence of authorized

representative of the authority using required voltage meggar and the test result should be submitted

to the authority for approval.

21.2

lf the test results show any fault in the installation, the Contractor shall make necessary rectifications

to fulfill the requirements at no cost to the Employer.

22.

TESTINGS

22.1

Transformer and OCB oils shall be tested for insulation properties before energisation by the

Contractor from the recognized Testing Laboratory and the test result should be submitted to the

Authority for approval. lithe test result be not satisfactory, then the contractor shall arrange centrifuging

of the oil until satisfactory result is obtained.

22.2

Beggaring of the transformer, H.T. panel, L.T. Panel and all electrical installations shall be arranged by

the contractor with proper range insulation testers in the presence of the representative of the

Engineer.

DIVISION- 11 B

SUPPLY OF ELECTRICAL CABLES

Page 17 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

A.

SCOPE OF WORK

These item covers all supply items which are required in connection with internal and external

electrification works.

B.

GENERAL REQUIREMENTS

Regulations: The supply in general shall be carried out in conformity with the Electricity Rules of the

Govt. of Bangladesh (lndian Electricity Rules and Act as adopted in Bangladesh) and the latest edition

of the British Standard Code of practice for the relevant works. But where the under noted

specification differ from these rules and standards, the specification written hereunder shall be

followed. Any special requirement of the Electrical inspector, Government of Bangladesh or the Power

Development Board or the Telegraph and Telephone Department, Government of Bangladesh or other

legal authority shall also be complied.

C.

Climatic and Atmospheric Conditions:

The supply of equipments and materials shall be installed both externally and internally and shall

therefore, be designed and built to give efficient and reliable service continuously at the normal voltage

and current rating in the prevalent climatic and atmospheric conditions at the relevant site.

D.

Specifications:

Material required which are not covered by the detailed specifications shall be as recommended by the

equipment manufacturer, or consistent with good Engineering practice.

1.

Cables

1.1

Cables for installation in raceways for operation at not less than 45Ol 750 volts shall be of soft copper

properly refined and shall have a minimum conductivity of 90% with PVC insulation confirming to BS

6004, 1 975.

1.2

AII cable insulation, except as specifically noted elsewhere shall be rated for 450/ 750 volts and shall

conform to B,S.S. specification.

1.3

Underground cables shall be PVC insulated, PVC sheet with plain annealed copper conductor, type

NYY of rated voltage 600/1000 volts conforming to VDE 027113.69.

Page 18 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

DIVISION- 11 C

SUPPLY OF SWITCHES, SOCKETS, DB/SDB, MCB/MCCB & BBT.

A.

SCOPE OF W0RK

These items cover all supply items which are required in connection with internal and external

electrification works.

B.

GENERAL REQUIREMENTS

Regulations: The supply in general shall be carried out in conformity with the Electricity Rules of the

Govt. of Bangladesh (lndian Electricity Rules and Act as adopted in Bangladesh) and the latest edition

of the British Standard Code of practice for the relevant works. But where the under noted

specification differ from these rules and standards, the specification written hereunder shall be

followed. Any special requirement of the Electrical inspector, Government of Bangladesh or the Power

Development Board or the Telegraph and Telephone Department, Government of Bangladesh or other

legal authority shall also be complied.

C.

CLIMATIC AND ATMOSPHERIC CONDITIONS

The supply of equipments and materials shall be installed both externally and internally and shall

therefore, be designed and built to give efficient and reliable service continuously at the normal voltage

and current rating in the prevalent climatic and atmospheric conditions at the relevant site.

D.

SPECIFICATIONS

Material required which are not covered by the detailed specifications shall be as recommended by the

equipment manufacturer, or consistent with good Engineering practice.

1.

SWITCHES

1.1

The switches shall be in accordance with B.S.S. 1299 Part-|, 1964 as amended to-date / BS EN

60669-1 colour white RAL 9010 plates and rockers materials: Polycarbonate unless otherwise stated

elsewhere. The switches shall be concealed type, 10 A /30A capacity mounted on G,P. sheet made

board.

2.

FIXTURES, FITTINGS AND APPLIANCES

AII electrical fixtures, fittings and appliances including accessories shall conform to latest B.S.S.

regulation No. 301 and as amended to-date.

2.1

SOCKETS

2.1.1

The sockets shall be in accordance with BS 1363 part-2 and BS 546 as amended till{o-date Colour

white RAL 9010 plates and rockers materials: Polycarbonate. The sockets shall be concealed type

with switch & shutter including LED/ NEON indicator, capacity 13A and 15A mounted on GP sheet

made board,

2.2

HRC FUSE CARTRIDGE

2.2.1

HRC Fuse Cartidge with LED indicator along with the fuse carrier shall be in accordance with IEC

60269-1, 2 and 2.1 lEC 60439-1 and NFC 63-210/ 211 , EN 60269-1 & 2, single pole, 100 KA 10 x 38

32A cylindrical type gG HRC fuse to be as amended till-to-date to be fitted on DIN rail with 5A-230V

NO+NC auxiliary for remote signaling.

3.

DISTRIBUTION / FLOOR DISTRIBUTION BOARD / SUB-DISTRIBUTION BOARD

3.1

Sub-Distribution boards shall be of safety type with double pole/ three pole isolator or circuit breaker,

operatable on a 400 volts 3-phase, 4-wire system conforming / EN 60439-3 as amended to date. The

board shall be of plastic flush mounting with transparent flip or push with removable pan assembly with

2 neutral 1-earth plates, 1-supply bus bar, isolating shield, self extinguishing, 16 modules nominal,

228mm depth.

3.2

Floor Distribution / Distribution Board shall be of safety type with three pole isolator / circuit breaker

operable on 400V 3-phase 4-wire system conforming to IEC 60695-2-1 flush mounting metal box with

operable transparent Perspex door, plastic face plate, detachable, chasis, face plate, door assembly,

DIN rain for MCCB, incoming looped busbar with door lock, slef extinguishing 650 0 C, 228 mm depth,

4.

CIRCUIT BREAKERS

Page 19 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

4.1

The MCB/MCCB 's shall be quick-make, quick break, trip-free, indicating type and shall have inversetime limit characteristics with adjustable overload and adjustable 60947-2short circuit release. All lugs

must be of the solder less mechanical type. The MCB must comply with IEC 157-1, IEC-898 rated

voltage 230V, A.C. 50 Hz, interrupting capacities 6M to 10M, current limiting class 3, finger proof,

protection through Thermal and Magnetic Trip DIVISIONs respectively, temperature rating at 40 O C ,

tropicalzed (moisture-fungus correction treated), with contact of silver alloy, terminal capability as per

requirement . The MCCB must comply with IEC 60947-2 having rated voltage 400V A.C., 50 HZ with

thermal overload, and instantaneous magnetic tripping action interrupting capacities 1OKA to 50M,

temperature rating 400C, tropicalized (moisture-fungus correction treated), terminal capability as per

requirement..

RCD: TP+N RCD conforming to IEC 61008-1 for detection of AC component and AC-DC component

fault with 5A-230V, NO+NC auxiliary for remote signaling.

4.2

ENCLOSURES, BUSBAR & CIRCUIT BREAKERS

The panels shall conform to the Damp heat, constant , to IEC 68 part 2-3.The construction of steel

board shall be from one-piece rolled steel DIVISION, welded, steel thickness minimum 1.63mm, semi

textured powder spray finish of approved colour, welded back plate with four holes for wall fixing bolts,

earth on mounting plates (hot galvanized, minimum 3mm thick), top plate and bottom plate with flange

apertures, sides and back plate without apertures door hinged on the right, turn lock, fastening with

3mm double ward key, all hinged shall be concealed, predrilled mounting rails with istance between

centre of rails 125mm minimum insulating flanges for cable entry, etc. The steel enclosure shall be

with support frame for mounting units, with cover, glazed door , insulating surround, and insulating

surrounds covering the terminals, connecting struts, stuck-in door gasket, cable grommets, cable

glands, etc.

4.3

PANEL

Alternatively the panel may be made of self extinguishing polystrol and polycarbonate of thermoplastic

of approved colour and resistant to water , acid, saline solutions, alcohol's, petrols, etc with necessary

wall fixing straps, brackets, cable entry flanges with a moulded PG knockouts, mounting rails

component shrouds, blanking plates connecting links, mounting plates, cable gland, cable grommet,

quick release fastener, compatible to good Engineering practice.

4.4

BUSBAR

The busbar shall be of copper having the rating as per schedule of items and the unrestricted short

circuit of 25KA at 0.25PF for 1 sec, including colour as per IEC code

4.5

4.5.1

CABLE TRUNKIN

Full xlose flexi / Aluminum adaptable cable trunking system, 2 meter length for cable drawing from

BBT Tap-off to SDB and or SDB to Raceways confirming to NFC 68-104 including necessary

DIVISIONs and accessories.

4.5.2

CABLE TRUNKING COLUMN

Column plexi (14-compartment aluminum base cable trunking for cable trunking to race ways including

all necessary Articles and accurace ways including all necessary accessories race ways including to

RAT 9010 with 2-oin socket (3 nos.) to be included.

4.6

4.6.1

BUSBAR TRUNKING

Vertical riser Low impedance, low reactance, factory assembled type tested, totally enclosed, nonventilated distribution Busbar Trunking System consists of required Tap off points and reducer

DIVISION including all necessary fixing arrangement complete as per specification..

- Rate insulation Voltage

- System Frequency

- No. of live conductors

- Neutral

- Conductor

- TAP-Off Box

- Protection Degree

- Cooling

- insulation Materials

- Fire withstand capacity

- Standard

1000 v

:50H2

3-phase + Neutral + PE (as liousing)

100%

Aluminium

3 Meter interval

IP 55

Self Cooling

2-layers of polypropheline, 3 layers of B-Class Mylar

120 minutes

IEC/VDE/BS

DIVISION- 11 D

SUPPLY OF LIGHT FIXTURES AND LAMPS

Page 20 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

A.

SCOPE OF WORK

These items cover all supply items which are required in connection with internal and external

electrification works.

B.

GENEML REQUIREMENTS

Regulations: The supply in general shall be carried out in conformity with the Electricity Rules of the

Govt. of Bangladesh (lndian Electricity Rules and Act as adopted in Bangladesh) and the latest edition

of the British Standard Code of practice for the relevant works. But where the under noted

specification differ from these rules and standards, the specification written hereunder shall be

followed. Any special requirement of the Electrical inspector, Government of Bangladesh or the Power

Development Board or the Telegraph and Telephone Department, Government of Bangladesh or other

legal authority shall also be complied.

C.

CLIMATIC AND ATMOSPHERIC CONDITIONS

The supply of equipments and materials shall be installed both externally and internally and shall

therefore, be designed and built to give efficient and reliable service continuously at the normal voltage

and current rating in the prevalent climatic and atmospheric conditions at the relevant site. d.

Specifications: Material required which are not covered by the detailed specifications shall be as

recommended by the equipment manufacturer, or consistent with good Engineering practice,

1.

LIGHT FIXTURE AND LAMPS

1.1

Lighting fixtures shall be constructed with the minimum possible number of joints, Joint shall be made

only by means of approved welded brazed. Screwed or bolted construction method, soldered joints will

not be permitted.

1.2

All ferrous parts and supports of lighting fixtures other than parts manufactured of stainless steel shall

be completely rust proof after fabrication and before finishing coats applied. All screws, bolts nuts and

other fastening latching hardware shall be cadmium or equivalent plated.

1.3

Finished thickness of all cast parts shall not be less than 3mm except where specifically indicated to

the contrary, all fixtures shall be provided with a final synthetic high temperature stove enamelled

coating of white color and finished. Unless otherwise specified all stove enamelled reflective surface

shall be white, with a minimum reflectance of 85%,

1.4

Where stainless steel or non-ferrous metal or aluminum is to be utilized as a reflector surface the

stainless steel or non-ferrous metal will be baked on clear lacquer to preserve the surface and the

aluminium shall be treated as specified with alzak or anodizing process to ensure a permanent

reflective surface with a minimum 95% reflectance.

1.5

Recessed fixtures shall be designed so as to properly coordinate with the ceiling construction 1'-0" x 4

-0 or as per ceiling design are to be mounted on.

1.6

Fixture shall be furnished with all appurtenance (trim, plastic frame, etc.) necessary for the proper

support of the fixture. Plaster frame shall either by manufactured of non-ferrous metal or if

manufactured of steel shall be suitably rust proofed after fabrication. All support for lighting fixture

(strim chain, anchors, etc,) shall be adequate for the support of the weight of the fixtures. All skim

hangers shall be furnished with suitable aligner canopies or outlet box covers that the fixtures hang

vertically irrespective of the angle of the surface they are mounted from. When fixtures, or hanger

canopies are mounted flush to the coiling or wall and where raceways and outlet boxes serving the

fixtures are surface mounted to the ceiling or wall, finishing rings shall be provided to concealed the

outlet box. All visible fixture hanging devices and appurtenances shall have the same finish as the

fixture unless specifically other wise indicated.

Page 21 of 23

Consultant: Electro-Mechanical Control Services (eMcS)

Technical Specification of Electrical System for AR Jeans Producer Factory

1.7

Fixture for use in outdoors or in damp locations shall be suitably gasketted to prevent access of

moisture into electrical components or enclosing diffusers, lenses, or globes. All metal parts of fixtures

for use in damp locations that are specified as requiring paintings, shall be painted with suitable

weather proof and moisture resistant paints" exhibiting moisture resisting quilities equal to epoxy

baseo coatings. All aluminium parts of fixture for use in damp locations that are specified as requiring

as unpainted finish shall be anodized.

1.8

Lighting Management is to identify a system flexible enough to have energy efficient Lighting and

Quality Control that may be integrated into other building management system. Trio is a

comprehensive Lighting Control System which is applicable for wide range of indoor application. The

configuration shall be when

a. only movement detector is connected, it will automatically switch the lighting 0N or OFF;

b. but people in the room, will be able to trun the lights 0N or KEEP it in certain level manually

when there is movement detector including an lR Receiver. Trio will automatically switch the

lights OFF when no one is present in the room.

1.9

Compact Fluorescent, sodium discharge lamps, etc.

1.9.1

All discharge lamp lighting fixtures furnished shall conform to the following and the fittings shall be