Professional Documents

Culture Documents

Expt 3 - Shear Test

Uploaded by

Ravi ParkheOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Expt 3 - Shear Test

Uploaded by

Ravi ParkheCopyright:

Available Formats

Pravara Rural Education Societys Pravara Rural Engineering college, Loni

Department of Mechanical Engineering

EXPERIMENT NO. 3

TITLE:

Shear test.

AIM:To determine the shear strength of given specimen on Universal testing machine.

.

LEARNING OBJECTIVES:

1. To learn how to conduct shear test on a material.

2. To learn difference between single and double shear.

EQUIPMENTS REQUIRED:

Universal Testing Machine (U.T.M.)

THEORY:

The force acting tangentially to the surface is known shear force. The ratio of shear force

to surface area over which it acts is known as shear strength /stress. The design of riveted joint is

governed by the shear strength of the metal rivets. Generally the specimen is subjected to either

single or double shear. Therefore it is necessary to test the shear strength of the material for

single as well as double shear.

SPECIMEN:

The specimen is prepared of 20 mm diameter and 50 mm length of MS material.

PROCEDURE:

1) The diameter of the specimen is noted down. The specimen is then placed in shear

assembly for single/double shear.

2) The shear attachment is placed in the universal testing machine & load is applied gradually till

the failure occurs for single/double shear.

3) The maximum load at failure for single/double shear is noted down.

LIMITATIONS:

It is not possible to calculate modulus of rigidity owing to impossibility of measuring

strain during the test.

OBSERVATIONS:

MILD STEEL Specimen

1) Diameter of the specimen = . mm

2) C/s area of the specimen = mm2.

CALCULATION:

Shear strength = maximum load (N)/C/s area subjected to shear (mm2)

RESULT:

Pravara Rural Education Societys Pravara Rural Engineering college, Loni

Department of Mechanical Engineering

MILD STEEL shear strength = .. MPa

CONCLUSION:

Thus we have conducted a shear test on a given specimen and determined shear strength

of a material and compared with standard value.

You might also like

- Simultaneous EquationsDocument32 pagesSimultaneous EquationsRavi ParkheNo ratings yet

- Presented by Parkhe Ravindra Ambadas: Parkhe R A Interpolation 1Document12 pagesPresented by Parkhe Ravindra Ambadas: Parkhe R A Interpolation 1Ravi ParkheNo ratings yet

- SCILAB Solver NMOP PDFDocument11 pagesSCILAB Solver NMOP PDFRavi ParkheNo ratings yet

- Gauss Quadrature 2 Point and 3 Point Formula PDFDocument9 pagesGauss Quadrature 2 Point and 3 Point Formula PDFRavi ParkheNo ratings yet

- Gauss Quadrature 2 Point and 3 Point FormulaDocument9 pagesGauss Quadrature 2 Point and 3 Point FormulaRavi ParkheNo ratings yet

- Interpolation Methods ExplainedDocument12 pagesInterpolation Methods ExplainedRavi ParkheNo ratings yet

- Presented by Parkhe Ravindra Ambadas: Parkhe R A Interpolation 1Document12 pagesPresented by Parkhe Ravindra Ambadas: Parkhe R A Interpolation 1Ravi ParkheNo ratings yet

- Dynamics of Machinery (2012 Course) Class Test - II Academic Year-2017-2018. (Total 1 Hour) (Max. Marks:30)Document2 pagesDynamics of Machinery (2012 Course) Class Test - II Academic Year-2017-2018. (Total 1 Hour) (Max. Marks:30)Ravi ParkheNo ratings yet

- Expt 3 - Shear TestDocument2 pagesExpt 3 - Shear TestRavi ParkheNo ratings yet

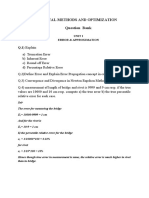

- Numerical Methods and Optimization Question Bank: Q.1) ExplainDocument9 pagesNumerical Methods and Optimization Question Bank: Q.1) ExplainRavi ParkheNo ratings yet

- Numerical Integration PPT PRADocument16 pagesNumerical Integration PPT PRARavi ParkheNo ratings yet

- Flexural TestDocument2 pagesFlexural TestRavi Parkhe100% (1)

- Matlab programs to fit common curves using least squares methodDocument5 pagesMatlab programs to fit common curves using least squares methodRavi ParkheNo ratings yet

- T e 2013 PDFDocument295 pagesT e 2013 PDFMOHAMAMED BOSSNo ratings yet

- Practice Examples For Cad CamDocument4 pagesPractice Examples For Cad CamRavi ParkheNo ratings yet

- Index For NBA File FinalDocument10 pagesIndex For NBA File FinalRavi Parkhe100% (1)

- InterpolationDocument10 pagesInterpolationRavi ParkheNo ratings yet

- Tensile TestDocument8 pagesTensile TestRavi ParkheNo ratings yet

- FEA Elec-IV Syllabus ImplementationDocument20 pagesFEA Elec-IV Syllabus ImplementationRavi ParkheNo ratings yet

- B.E. (Mechanical Engineering) (Semester - I) : Ite E: Oo SR M XM Se 00 Inst Octions To The C Ndid Tes EDocument4 pagesB.E. (Mechanical Engineering) (Semester - I) : Ite E: Oo SR M XM Se 00 Inst Octions To The C Ndid Tes ERavi ParkheNo ratings yet

- Numerical Methods and Optimization Practical Exam QuestionsDocument12 pagesNumerical Methods and Optimization Practical Exam QuestionsRavi ParkheNo ratings yet

- B E mechanicalSandwich2008CourseDocument30 pagesB E mechanicalSandwich2008CourseRavi ParkheNo ratings yet

- 2d TransformationDocument15 pages2d TransformationRavi ParkheNo ratings yet

- Syllabus TE Numerical MethodsDocument2 pagesSyllabus TE Numerical MethodsRavi ParkheNo ratings yet

- G & M Codes (All CNC)Document24 pagesG & M Codes (All CNC)Fanuc21T100% (4)

- Expt 1 Tension TestDocument5 pagesExpt 1 Tension TestRavi ParkheNo ratings yet

- Milling ProgramDocument25 pagesMilling ProgramRavi ParkheNo ratings yet

- 03 TransformationsDocument45 pages03 TransformationsRavi ParkheNo ratings yet

- BE Computer 2012 Course 27-8-15Document64 pagesBE Computer 2012 Course 27-8-15Bhavik ShahNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)