Professional Documents

Culture Documents

Engineering Journal Exploring The Possibility of Using E-Glass /epoxy in The Design of Single Toggle Jaw Crusher

Uploaded by

Engineering JournalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineering Journal Exploring The Possibility of Using E-Glass /epoxy in The Design of Single Toggle Jaw Crusher

Uploaded by

Engineering JournalCopyright:

Available Formats

International Journal of Engineering Research & Science (IJOER)

ISSN: [2395-6992]

[Vol-2, Issue-6 June- 2016]

Exploring the Possibility of using E-glass /Epoxy in the design of

single toggle jaw crusher

Sankar.M1, Balaji.K2

1

Department of Mechanical Engineering & Post Graduate studies VEMU INSTITUTE OF TECHNOLOGY,

ANDHRAPRADESH, INDIA

2

Assistant Professor, Department of Mechanical Engineering, VEMU INSTITUTE OF TECHNOLOGY,

ANDHRAPRADESH, INDIA

Abstract Jaw crusher is a kind of size reduction machine that is wide utilized in mineral, aggregates and metallurgy

fields. The interaction between jaw plates and material particles brings the inevitable and high wear to the jaw plates

throughout the jaw crusher operation, that not only decreases the efficiency, however also will increase the price and also

the energy consumption of the jaw crusher. Obtained results from the kinematic analysis of the moving jaw and also the

crushing force distribution analysis, the jaw plates wear is analyzed on a macroscopical level. Its useful to design the

crusher for improved performance. Efforts to decrease energy consumed in crushing have cause thought of decreasing the

weight of the swing plate of jaw crushers. Design of lighter weight jaw crusher would require a lot of precise accounting of

the stress and deflections within the crushing plates than is available with ancient technique. The objective of this project is

to present modeling and analysis of single toggle jaw crusher and comparison of deformation and stress, load and weight

savings results between manganese steel single toggle jaw crusher and composite single toggle jaw crusher under same

conditions. This study gives information about the replacement of manganese steel jaw crusher with composite jaw crusher

made of E glass/epoxy. The single toggle jaw crusher is to be solid modeled in proE and analysis is to be carried out by

using ANSYS workbench13 for effective comparison.

Keywords single toggle jaw crusher, manganese steel, E glass/Epoxy, stiffeners, Auto CAD, ANSYS 13.0

I.

INTRODUCTION

Crushing is that the process of reducing the dimensions of the lump of ore or over size rock into definite smaller sizes. Based

on the mechanism used devices are of three types particularly Cone crusher, Jaw crusher and Impact crusher. The first stage

of size reduction of hard and huge lumps of run of mine (ROM) ore is to crush and reduce their size. The mechanism of

crushing is either by applying impact force, pressure or a combination of each.

Jaw crushers are usually used as primary crushers, or the primary step within the method of reducing rock. They typically

crush using compression. The rock is dropped between two rigid pieces of metal, one in all that then move inwards towards

the rock, and therefore the rock is crushed as a result of it's a lower breaking point than the opposing metal piece. Jaw device

movement is obtained by employing a pivot point located at one end of the swing jaw, and an eccentric motion located at

the opposite finish.

FIG 1: SINGLE TOGGLE JAW CRUSHER.

Page | 34

International Journal of Engineering Research & Science (IJOER)

ISSN: [2395-6992]

[Vol-2, Issue-6 June- 2016]

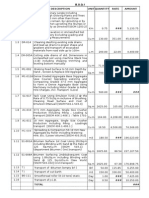

TABLE 1

SPECIFICATIONS OF SINGLE TOGGLE JAW CRUSHER WITHOUT STIFFENERS

S.NO

PARAMETER

VALUE

LENGTH OF THE JAW

1200(MM)

WIDTH OF THE JAW

900(MM)

THICKNESS OF THE JAW

215(MM)

LOAD

8700N

TABLE 2

SPECIFICATIONS OF SINGLE TOGGLE JAW CRUSHER WITH STIFFENERS

S.NO

PARAMETER

VALUE

Length of the jaw

1200(MM)

Width of the jaw

900(MM)

Thickness of the jaw

215(MM)

Height of stiffeners

50 (MM)

Width of stiffeners

50 (MM)

Load

8700N

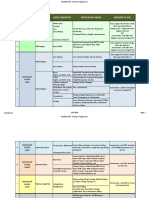

II.

DESIGN OF JAW PLATES

Recently, concern for energy consumption in crushing has led to the consideration of decreasing the weight (and

consequently the stiffness) of the swing plate of jaw crushers to match the strength of the rock being crushed. An

investigation of the energy saving of plate rock interaction when point load deformability and failure relationships of the rock

are employed to calculate plate stresses. In order to conduct this investigation, a model has been created in the modeling

software PROE and then with the help of finite element analysis software ANSYS analysis it. The model is made firstly

without stiffeners and analyzed then for further analysis numbers of stiffeners are added in the model and again it analyzed.

2.1

2D Model of Single Toggle Jaw Crusher

FIG 2: CORRUGATED JAW CRUSHER 2D MODEL

Page | 35

International Journal of Engineering Research & Science (IJOER)

2.2

ISSN: [2395-6992]

[Vol-2, Issue-6 June- 2016]

Solid Modeling of Corrugated Swing Jaw Plate Using proe

FIG 3: BOTTOM SUPPORT FOR THE JAW CRUSHER

FIG 4: CORRUGATED JAW CRUSHER WITHOUT

STIFFENERS

FIG 5: CORRUGATED JAW CRUSHER WITH ONE

FIG 6: CORRUGATED JAW CRUSHER WITH TWO

STIFFENERS

STIFFENERS

FIG 7: CORRUGATED JAW CRUSHER WITH THREE

FIG 8: CORRUGATED JAW CRUSHER WITH FOUR

STIFFENERS

STIFFENERS

Page | 36

International Journal of Engineering Research & Science (IJOER)

2.3

ISSN: [2395-6992]

[Vol-2, Issue-6 June- 2016]

Solid Modeling of Curved Swing Jaw Plate Using Proe

FIG 9: CURVED JAW CRUSHER WITHOUT

FIG 10: CURVED JAW CRUSHER WITH ONE STIFFENER

STIFFENERS

FIG 11: CURVED JAW CRUSHER WITH TWO

FIG 12: CURVED JAW CRUSHER WITH THREE

STIFFENERS

STIFFENERS

FIG 13: CURVED JAW CRUSHER WITH FOUR STIFFENERS

Page | 37

International Journal of Engineering Research & Science (IJOER)

III.

3.1

ISSN: [2395-6992]

[Vol-2, Issue-6 June- 2016]

SWING JAW PLATES STATIC STRUCTURAL ANALYSIS USING ANSYS (MANGANESE STEEL)

Assumptions

Analysis was undertaken based on the assumption that the point load strength of the disk and irregularly shaped particles to

be equal and tensile point loads of different particle sizes are acting normal to the plate. For the analysis of the of swing jaw

plate, the model of the swing jaw plate is converted into STEP file and then this file is called for the analysis

3.2

Applying Material

Before the Structural Analysis module used for the FEA model, it must have material assigned to it. Each material in ANSYS

has mechanical properties for computing the analysis for different materials but it has a facility to edits and add some

material properties for other parts.

TABLE 3

PROPERTIES OF MANGANESE STEEL

3.3

PROPERTIES

VALUE

Density

7838 KG/MM3

Elastic modulus

210*103 MPA

Shear modulus

80.76*103 MPA

Poisons ratio

0.3

Yield strength

550 MPA

Apply Boundary Conditions

Boundary condition for Swing jaw plate is simply supported i.e. the support at bearing location hinge support and at the free

end toggle force acting. Due to which this plate is acts as a simply supported, figure shows the fixed point of plate. Fig

showing Swing Jaw Plate Model Boundary Condition.

3.3.1

Applying Meshing

FIG 14: SHOWING JAW CRUSHER MESHING

3.3.2

Applying Supports

FIG 15: SHOWING JAW CRUSHER FIXED SUPPORT

Page | 38

International Journal of Engineering Research & Science (IJOER)

3.3.3

ISSN: [2395-6992]

[Vol-2, Issue-6 June- 2016]

Applying Loads

FIG 15: SHOWING APPLYING LOADS ON JAW CRUSHER

3.3.4

Linear Static Stress Analysis

FIG 16: SHOWING SWING JAW PLATE STRESS

ANALYSIS

FIG 17: SHOWING SWING JAW PLATE

DISPLACEMENT

3.4

Swing Jaw Plates Static Structural Analysis Using ANSYS (E Glass/ Epoxy)

3.4.1

Applying Material

TABLE 4

PROPERTIES OF E GLASS/EPOXY

Page | 39

International Journal of Engineering Research & Science (IJOER)

3.4.2

ISSN: [2395-6992]

[Vol-2, Issue-6 June- 2016]

Applying Meshing

FIG 18: JAW CRUSHER MESHING

3.4.3

Applying Supports

FIG 17: SHOWING JAW CRUSHER SUPPORT

3.4.4

Applying Loads

FIG 18: SHOWING SWING JAW PLATE LOAD

Page | 40

International Journal of Engineering Research & Science (IJOER)

3.4.5

ISSN: [2395-6992]

[Vol-2, Issue-6 June- 2016]

Linear Static Stress Analysis

FIG 19: SHOWING SWING JAW PLATE STRESS

ANALYSIS

IV.

FIG 20: SHOWING SWING JAW PLATE DISPLACEMENT

RESULTS

FEA models using ANSYS are employed to calculate maximum tensile stresses for the jaw crusher. By using E-glass/Epoxy

we can reduce weight of the jaw crusher up to 66.82%.

TABLE 5

CORRUGATED JAW MANGANESE STEEL STATIC STRUCTURAL ANALYSIS

No Of Stiffer

Von mess stress

(MPA)

TOTAL DEFORMATION

(mm)

Weight of jaw

(KG)

2.0742

0.026908

1580.1

2.8917

0.082075

1024.6

2.2182

0.053149

1121.6

2.2151

0.052376

1174.5

2.2415

0.051505

1227.4

TABLE 6

CORRUGATED JAW E GLASS/EPOXY STRUCTURAL ANALYSIS

No Of Stiffer

Von mess stress

(MPA)

TOTAL DEFORMATION

(mm)

Weight of jaw

(KG)

2.1151

0.51669

524.16

2.8533

1.5304

339.88

2.2329

0.69842

372.06

2.255

0.69489

389.61

2.2651

0.69226

407.16

TABLE 7

CURVED JAW MANGANESE STEEL STATIC STRUCTURAL ANALYSIS

No Of stiffer

Von mess stress

(MPA)

TOTAL DEFORMATION

(mm)

Weight of jaw

(KG)

2.1335

0.028723

1614.4

3.7328

0.080046

1088.1

2.2869

0.051472

1163.9

2.2779

0.050716

1231

Page | 41

International Journal of Engineering Research & Science (IJOER)

ISSN: [2395-6992]

[Vol-2, Issue-6 June- 2016]

TABLE8

CURVED JAW E GLASS/EPOXY STATIC STRUCTURAL ANALYSIS

No Of Stiffer

Von mess stress

(MPA)

Total deformation

(mm)

Weight of jaw

(KG)

2.0979

0.58084

535.86

3.59392

1.533

360.95

2.1695

0.73357

386.1

2.1669

0.73421

408.33

2.0121

0.71836

425.88

V.

CONCLUSION

From this we concluded that single toggle jaw crusher made by composite material will give better results regarding

deformation and weight savings and stress and life the component compared to manganese steel. This is proved by

analytically and FEA at 8700N for manganese steel and E glass/Epoxy composite material and also we made attempt for

optimizing single toggle jaw crusher with multiple stiffeners and that FEA results are also included in results.

REFERENCES

[1] Pollitz H C, Crusher Jaw Plates United States Patent, Patent Number 3,140,057, Issued on July, 1982

[2] Bharule Ajay Suresh, M.Tech Thesis Computer Aided Design and Analysis of Swing Jaw Plate of Jaw Crusher, NIT Rourkela, June

2009.

[3] Cao Jinxi, Qin Zhiyu, Wang Guopeng, Investigation on Kinetic Features of Multi- Liners in Coupler Plane of Single Toggle Jaw

Crusher, Journal of Taiyuan Heavy Machinery Institute, July200.

[4] Lytwynyshyn G. R., MS Thesis-Jaw Crusher Design, Northwestern University, Evanston, August1990.

[5] Cao Jinxi, RongXingfu, Yang Shichun, Jaw Plate Kinematical Analysis For Single Toggle Jaw crusher Design, Journal of Taiyuan

Heavy Machinery Institute, 2006.

[6] Tickoo Sham Catia for Engineers and Designers V5R20, DreamTech Press, Germany, 2000

[7] Dowding Charles H, Molling R, Ruhl C," Application of point load-deformation relationships and design of jaw crusher plates,

International Journal of Rock Mechanics and Mining Sciences & Geo mechanics, Volume 20, Issue 2, April 1983,Pages 277-286.

[8] M.Enamul Hossain Journal of Composite Materials 45(20) 21332144.

[9] William D. Callister, Material science and engineering.

[10] International Journal of Innovative Research in Science, Engineering and Technology (An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 1, January 2015

Page | 42

You might also like

- Engineering Journal Role of Indian Spices in Cancer Prevention: A ReviewDocument2 pagesEngineering Journal Role of Indian Spices in Cancer Prevention: A ReviewEngineering JournalNo ratings yet

- Engineering Journal A Professional PID Implemented Using A Non-Singleton Type-1 Fuzzy Logic System To Control A Stepper MotorDocument8 pagesEngineering Journal A Professional PID Implemented Using A Non-Singleton Type-1 Fuzzy Logic System To Control A Stepper MotorEngineering JournalNo ratings yet

- Engineering Journal The Microorganism Contamination Affect The Physical and Chemical Composition of MilkDocument7 pagesEngineering Journal The Microorganism Contamination Affect The Physical and Chemical Composition of MilkEngineering JournalNo ratings yet

- Engineering Journal Online Tuning of The Fuzzy PID Controller Using The Back-Propagation AlgorithmDocument8 pagesEngineering Journal Online Tuning of The Fuzzy PID Controller Using The Back-Propagation AlgorithmEngineering JournalNo ratings yet

- Engineering Journal Micromechanics of Thermoelastic Behavior of AA6070 Alloy/Zirconium Oxide Nanoparticle Metal Matrix CompositesDocument3 pagesEngineering Journal Micromechanics of Thermoelastic Behavior of AA6070 Alloy/Zirconium Oxide Nanoparticle Metal Matrix CompositesEngineering JournalNo ratings yet

- Engineering Journal Isomorphic Transformation of The Lorenz Equations Into A Single-Control-Parameter StructureDocument9 pagesEngineering Journal Isomorphic Transformation of The Lorenz Equations Into A Single-Control-Parameter StructureEngineering JournalNo ratings yet

- Engineering Journal Thermo-Mechanical Fatigue Behavior of A Copper-Alumina Metal Matrix Composite With Interpenetrating Network StructureDocument9 pagesEngineering Journal Thermo-Mechanical Fatigue Behavior of A Copper-Alumina Metal Matrix Composite With Interpenetrating Network StructureEngineering JournalNo ratings yet

- Engineering Journal Preparation and Characterization of Cross-Linked Polymer Supports For Catalysts ImmobilizationDocument24 pagesEngineering Journal Preparation and Characterization of Cross-Linked Polymer Supports For Catalysts ImmobilizationEngineering JournalNo ratings yet

- Engineering Journal Estimation of Rolling-Contact Bearings Operational Properties by Electrical Probe MethodDocument7 pagesEngineering Journal Estimation of Rolling-Contact Bearings Operational Properties by Electrical Probe MethodEngineering JournalNo ratings yet

- Engineering Journal Comparative Study of Various Pre-Treatments Coupled To Vacuum Drying in Terms of Structural, Functional and Physical Properties of Carrot DaucusCarotaDocument15 pagesEngineering Journal Comparative Study of Various Pre-Treatments Coupled To Vacuum Drying in Terms of Structural, Functional and Physical Properties of Carrot DaucusCarotaEngineering JournalNo ratings yet

- Engineering Journal Numerical Study of Microbial Depolymerization Process With The Newton-Raphson Method and The Newton's MethodDocument12 pagesEngineering Journal Numerical Study of Microbial Depolymerization Process With The Newton-Raphson Method and The Newton's MethodEngineering JournalNo ratings yet

- Engineering Journal Effects of Soil Physical and Chemical Properties On The Distribution of Trees in Some Ecological Zones of Zalingei-Darfur SudanDocument9 pagesEngineering Journal Effects of Soil Physical and Chemical Properties On The Distribution of Trees in Some Ecological Zones of Zalingei-Darfur SudanEngineering JournalNo ratings yet

- Engineering Journal Alteration of Pelvic Floor Biometry in Different Modes of DeliveryDocument7 pagesEngineering Journal Alteration of Pelvic Floor Biometry in Different Modes of DeliveryEngineering JournalNo ratings yet

- Engineering Journal Strategic and Operational Scope of Foreign Subsidiary UnitsDocument11 pagesEngineering Journal Strategic and Operational Scope of Foreign Subsidiary UnitsEngineering JournalNo ratings yet

- Engineering Journal Study of Different Surface Pre-Treatment Methods On Bonding Strength of Multilayer Aluminum Alloys/Steel Clad MaterialDocument9 pagesEngineering Journal Study of Different Surface Pre-Treatment Methods On Bonding Strength of Multilayer Aluminum Alloys/Steel Clad MaterialEngineering JournalNo ratings yet

- Engineering Journal Controller Design For Nonlinear Networked Control Systems With Random Data Packet DropoutDocument6 pagesEngineering Journal Controller Design For Nonlinear Networked Control Systems With Random Data Packet DropoutEngineering JournalNo ratings yet

- Engineering Journal Securing of Elderly Houses in Term of Elderly's Vision DisordersDocument10 pagesEngineering Journal Securing of Elderly Houses in Term of Elderly's Vision DisordersEngineering JournalNo ratings yet

- Engineering Journal Analysis of Vibro-Isolated Building Excited by The Technical Seismicity of Traffic EffectsDocument6 pagesEngineering Journal Analysis of Vibro-Isolated Building Excited by The Technical Seismicity of Traffic EffectsEngineering JournalNo ratings yet

- Engineering Journal A Systematic Approach To Stable Components Synthesis From Legacy ApplicationsDocument10 pagesEngineering Journal A Systematic Approach To Stable Components Synthesis From Legacy ApplicationsEngineering JournalNo ratings yet

- Engineering Journal A Silicon-Containing Polytriazole Resin With Long Storage TimeDocument9 pagesEngineering Journal A Silicon-Containing Polytriazole Resin With Long Storage TimeEngineering JournalNo ratings yet

- Engineering Journal Impact of Texturing/cooling by Instant Controlled Pressure Drop DIC On Pressing And/or Solvent Extraction of Vegetal OilDocument12 pagesEngineering Journal Impact of Texturing/cooling by Instant Controlled Pressure Drop DIC On Pressing And/or Solvent Extraction of Vegetal OilEngineering JournalNo ratings yet

- Engineering Journal Salicylic Acid Enhanced Phytoremediation of Lead by Maize (Zea Mays) PlantDocument7 pagesEngineering Journal Salicylic Acid Enhanced Phytoremediation of Lead by Maize (Zea Mays) PlantEngineering JournalNo ratings yet

- Engineering Journal Studies On Stigma Receptivity of Grewia Asiatica L. With Reference To Esterase and Peroxidase ActivityDocument4 pagesEngineering Journal Studies On Stigma Receptivity of Grewia Asiatica L. With Reference To Esterase and Peroxidase ActivityEngineering JournalNo ratings yet

- Engineering Journal Power Improvement in 32-Bit Full Adder Using Embedded TechnologiesDocument8 pagesEngineering Journal Power Improvement in 32-Bit Full Adder Using Embedded TechnologiesEngineering JournalNo ratings yet

- Engineering Journal Bio-Oil Production by Thermal Cracking in The Presence of HydrogenDocument20 pagesEngineering Journal Bio-Oil Production by Thermal Cracking in The Presence of HydrogenEngineering JournalNo ratings yet

- Engineering Journal Estimation of Global Solar Radiation Using Artificial Neural Network in Kathmandu, NepalDocument9 pagesEngineering Journal Estimation of Global Solar Radiation Using Artificial Neural Network in Kathmandu, NepalEngineering JournalNo ratings yet

- Engineering Journal Extracorporal Shock Wave Induced Mechanical Transduction For The Treatment of Low Back Pain - A Randomized Controlled TrialDocument6 pagesEngineering Journal Extracorporal Shock Wave Induced Mechanical Transduction For The Treatment of Low Back Pain - A Randomized Controlled TrialEngineering JournalNo ratings yet

- Engineering Journal A Novel Oxygenator-Right Ventricular Assist Device Circuit Using The SYNERGY Micropump As Right Heart Support in A Swine Model of Pulmonary HypertensionDocument8 pagesEngineering Journal A Novel Oxygenator-Right Ventricular Assist Device Circuit Using The SYNERGY Micropump As Right Heart Support in A Swine Model of Pulmonary HypertensionEngineering JournalNo ratings yet

- Engineering Journal The Sinkhole Hazard Study at Casalabate (Lecce, Italy) Using Geophysical and Geological SurveysDocument11 pagesEngineering Journal The Sinkhole Hazard Study at Casalabate (Lecce, Italy) Using Geophysical and Geological SurveysEngineering JournalNo ratings yet

- Engineering Journal Factors Influencing Grid Interactive Biomass Power IndustryDocument12 pagesEngineering Journal Factors Influencing Grid Interactive Biomass Power IndustryEngineering JournalNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hazemag Hpi HPC EngDocument16 pagesHazemag Hpi HPC EngMohammed ElhayloufiNo ratings yet

- Sample BOQDocument150 pagesSample BOQkanishkaNo ratings yet

- ASRi SandvikDocument5 pagesASRi Sandviklucia VasquezNo ratings yet

- India Power coal mine infrastructure auditDocument22 pagesIndia Power coal mine infrastructure auditChandan MukherjeeNo ratings yet

- Research Proposal Adviser (S) EndorsementDocument50 pagesResearch Proposal Adviser (S) EndorsementMiñoza, Maverick Albert P.No ratings yet

- Klarifikasi Mechanical SamplerDocument4 pagesKlarifikasi Mechanical Samplerhengki_fsukresnoNo ratings yet

- Comminution Ore TestingDocument35 pagesComminution Ore TestingHarrison Antonio Mira NiloNo ratings yet

- Can Crusher InstructionsDocument10 pagesCan Crusher Instructionsgary.nolan100% (3)

- Shanbao PEX150x750 Crusher Parts ManualDocument1 pageShanbao PEX150x750 Crusher Parts ManualTomas ChienNo ratings yet

- Bond F.C., 1961. Crushing and Grinding CalculationsDocument17 pagesBond F.C., 1961. Crushing and Grinding Calculationsitapui86% (7)

- NanoGuard-ProductsDocument2 pagesNanoGuard-ProductsSunrise VenturesNo ratings yet

- Method Statement To Construct Concrete RoadDocument2 pagesMethod Statement To Construct Concrete RoadSyafiq ZakiNo ratings yet

- Impact of Small Scale Mining On Rural LivelihoodsDocument14 pagesImpact of Small Scale Mining On Rural LivelihoodsMuhammad Yazid AbubakarNo ratings yet

- Chapter 4 EquipmentDocument63 pagesChapter 4 EquipmentMYB360 guitarNo ratings yet

- Working and Maintenance of Crushing EquipmentDocument53 pagesWorking and Maintenance of Crushing EquipmentKeshav ChhawchhariaNo ratings yet

- Tentative BTech - Mining 4TH Sem Syllabus 2018-19Document22 pagesTentative BTech - Mining 4TH Sem Syllabus 2018-19jitun kumarNo ratings yet

- Pit & Quarry June 2010 OK PDFDocument45 pagesPit & Quarry June 2010 OK PDFmassensure trialNo ratings yet

- BBS E00584Document8 pagesBBS E00584gloohuis463No ratings yet

- Bauma Preview: Comminution & FragmentationDocument7 pagesBauma Preview: Comminution & FragmentationJaime Magno Gutierrez RamirezNo ratings yet

- Summer Training Project on Labor Welfare at HEC LtdDocument100 pagesSummer Training Project on Labor Welfare at HEC LtdGaurav KumarNo ratings yet

- Canica VSI Feature Benefits V3Document56 pagesCanica VSI Feature Benefits V3Luis Antonio Vega Parangueo100% (1)

- Ballast VolumetricDocument42 pagesBallast VolumetricVenu GadadasuNo ratings yet

- Transfer Chute For Bulk MaterialDocument131 pagesTransfer Chute For Bulk Materialmishra_1982100% (8)

- Impact MasterDocument5 pagesImpact Masterdjenan0% (1)

- Handbook Edicion 20Document232 pagesHandbook Edicion 20Luis Vallecillo100% (1)

- Minas Demoproject en PDFDocument61 pagesMinas Demoproject en PDFDragoslav DzolicNo ratings yet

- Control Panel Overview and OperationDocument71 pagesControl Panel Overview and OperationAnonymous OfU0JS100% (1)

- 118-7126-Brokk-Katalog 2018 19 En14Document72 pages118-7126-Brokk-Katalog 2018 19 En14Luis Martín Torres MuhechNo ratings yet

- Binani Cement Limited, SirohiDocument47 pagesBinani Cement Limited, SirohivikassspaceNo ratings yet

- Chemical Engineering Department: Chapter Two: Size ReductionDocument28 pagesChemical Engineering Department: Chapter Two: Size Reductionabdisa birruNo ratings yet