Professional Documents

Culture Documents

Engineering Journal Estimation of Rolling-Contact Bearings Operational Properties by Electrical Probe Method

Uploaded by

Engineering JournalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineering Journal Estimation of Rolling-Contact Bearings Operational Properties by Electrical Probe Method

Uploaded by

Engineering JournalCopyright:

Available Formats

International Journal of Engineering Research & Science (IJOER)

ISSN: [2395-6992]

[Vol-2, Issue-2, February- 2016]

Estimation of Rolling-Contact Bearings Operational Properties

by Electrical Probe Method

O.Rekhlitsky1, S.Korotkevich2, N.Solovei3, D.Rekhlitskaya4

1,3,4

JSC STCCE., Gomel, Belarus

RUP Gomelenergo, Gomel, Belarus

Abstract The substantiation of an electrical probe method using for diagnostic real bearing units on a boundary state is

given. The circuit diagram is developed and the way of estimation tribological properties of rolling-contact bearing races

surfaces by means of electrical probe methods is offered. Correlation between parameters of conductance, mechanical

strength and frictional metal surface characteristics is installed. It is shown, that application of the given methods allows to

control the rolling-contact bearing state.

Keywords boundary lubricating layer (BLL), metal surfaces, contact resistance, dislocation structure, fracture

mechanisms and surface deterioration, rolling-contact bearing.

I.

INTRODUCTION

Reliability and durability of agricultural machinery rolling-contact bearings are defined by many factors: bearing steel

quality, form and a roughness of balls, inner and outer races, type of their heat treatment, total product design (for example a

grain harvester straw rake) assembly technology and unit adjustment, and also antifriction and strength properties of greases

[1]. Durability of the rolling-contact bearing is defined by million cycles of multicyclic frictional loading [2].

The analysis of a boundary state means a metal surface state control without lubricant presence on it and interconnection

determination between state and tribotechnological properties, and reinforcement and destruction of a metal surface kinetics

[3].

Insufficient lubricant ability BLL in tribological conjunction leads to runout of grease from a contact zone in the beginning,

and then under the influence of multicyclic and, as a rule, low amplitude tensions, on real contact points microcracks are

formed. Fretting fatigue occurring at very small oscillatory amplitudes when only incipient sliding is present, i.e. the contact

area includes both, stick and slip zones [4]. Microcracks increase in size and under the influence of multicyclic fatigue unit

and form macrocracks that leads to material separation from a body surface in the form of a petal [5]. Proceeding activity of

low amplitude tensions leads to formation of developed dislocation structure on the surface, to its dispersing, that causes

petal-scaly wear of material [6]. On a place of the separated material, on a surface pits, tears, hollows are formed, i.e.

processes typical for pitting proceed. Energy pumping in the material subsurface layers at a multicyclic frictional loading

leads to interacting dislocation accumulations and their exit that promotes pores and strips sliding formation [7]. Progressing

ripping of the metal surface layer, related with increasing of fractures nucleus number occurs. At a stage of the maximum

dispersing this ripping, covering deeper layers causes sharp increasing exfoliated material mass in the form of the total layer.

This process acquires ripple character and leads to selective emissions of destruction products from a frictional contact zone

[8]. Selective wearing mechanism of material great volumes leads to scuffing, dripping of mated surfaces, separator

destruction and bearing wedging.

Forage- and grain-harvesting techniques work seasonally. Terms of grain harvesting and various root crops, preparations of

forages are restricted. In this connection any idle time of agricultural machinery leads to considerable material losses.

Therefore minimizing of the idle time related with repairing and working capacity restoration of the failed rolling-contact

bearings is the important problem at techniques designing.

The work purpose is an analysis of rolling-contact bearings working capacity and criteria of their work regimes estimation

with using of an electrophysical probing method.

II.

EXPERIMENTAL TECHNIQUE

It is possible use following way to estimate an operating mode of the rolling-contact bearing state, an outer race of which, as

a rule, is motionlessly fixed in the harvester unit, and the inner race is on the rotating axis.

Page | 79

International Journal of Engineering Research & Science (IJOER)

ISSN: [2395-6992]

[Vol-2, Issue-2, February- 2016]

The way consists in calculation of contact resistance value (Rc) between racers on the basis of Hertz theory relationships [3].

We will make an example theoretical calculation. In the capacity of an object of research was rolling-contact bearing ZVL

6302/16 manufactures Slovakia with an external diameter of a race 42 mm and an inner race diameter 16 mm is taken. Width

of races is 13 mm. Diameter of a ball is 8 mm. Quantity of balls is 7 pieces. The way width of an inner and outer race is 6

mm.

For methods of electrical probe the question on definition of the actual square of contact rubbing solids has key value.

Calculation of the nominal contact square of the conjugate solids is carried out from relationships of the classical Hertz

theory. The contact ball square (S) with a racer makes an ellipse with semiaxises a* and b (figure 1) where the major

semiaxis a* is directed perpendicularly to a rolling motion way (a rolling motion direction).

FIGURE 1. THE ROLLING-CONTACT BEARING. THE CONTACT SQUARE IN THE FORM OF AN ELLIPSE WITH SEMIAXIS A*

AND B

The contact point radius of the ball with a plane a* is defined by value of loading, mechanical properties of solids and their

geometrical sizes and estimates from relationships for an elastic deformation of solids (1):

a* = 1,11(NR/E)1/3

(1)

Where N is a loading, R, E is an effective radius and an elastic modulus, accordingly. An effective radius R is calculated by

the formula [9]:

1

1

1

R R1 R2

(2)

where R1 and R2 are radii of contacting solids, a sign plus (+) is taken at the contact of convex solids, and a sign minus (-) is

taken at the contact of the cylinder and a matching cylindrical groove. As races and balls are made of the same material (steel

-15 or its analogue is most often used) the effective modulus is equal to the steel elastic modulus 2.610 11 Pa. The

counted effective radius R for an outer and inner races makes accordingly 3.310 -3 and 2.810-3 m. Calculated radii values of

the contact point (a*) depending on loading (N) for the diagram ball-plane are given in the table 1, where P is a medium

contact pressure.

Page | 80

International Journal of Engineering Research & Science (IJOER)

ISSN: [2395-6992]

[Vol-2, Issue-2, February- 2016]

TABLE 1

CALCULATED RADIUS VALUES OF CONTACT POINT (a*), MEDIUM CONTACT PRESSURE (P), CONTRACTION RESISTANCE

(Rs), OXIDE FILM (Rx) AND GENERAL (R).

N, H

a* , 10-6, m

S, 10-12, m2

P, GPa

Rs, mOm

Rx, mOm

R, mOm

20

74.90

17 615

1.1

2.0

56.8

58.8

100

128.10

51 526

1.9

1.2

19.4

19.6

200

161.30

81 696

2.5

0.9

12.2

13.1

400

203.30

129 779

3.1

0.74

7.7

8.4

600

232.70

170 029

3.5

0.64

5.9

6.5

800

256.10

205 944

3.9

0.58

4.9

5.5

1000

275.80

238 846

4.2

0.54

4.2

4.7

1200

293.10

270 118

4.4

0.51

3.7

4.2

1400

308.50

298 841

4.7

0.49

3.3

3.8

1600

322.60

326 782

4.9

0.47

3.1

3.6

1800

335.45

353 387

5.1

0.45

2.8

3.3

2000

347.40

378 956

5.3

0.43

2.6

3.0

Let's note, that the results given in the table 2, have an approximate character, that is connected on the one part with an

experimental estimation of imprint lengths, and on another part it is connected with using of Hertz theory relationships where

ideal smooth surfaces are observed, without the account of conjugate solids roughness, in our case of races and bearing balls.

TABLE 2

CALCULATED VALUES OF PARAMETERS FOR ROLLING-CONTACT BEARINGS

N, H

a, 10-6,

a*,10-6,

binner

bouter

Sinner

Souter

10-6, m

10-6, m

10-12, m2

10-12, m2

Pinner,

P

Pouter,

P

Rs,

mm

20

74,90

299,6

69,4

70,0

65288

65852

0,31

0,30

1,0

100

128,10

512,4

113,8

120,2

183097

193394

0,55

0,50

0,6

200

161,30

645,2

143,3

151,4

290316

306726

0,69

0,65

0,4

400

203,30

813,2

180,5

190,7

460897

486943

0,90

0,80

0,36

600

232,70

930,8

206,6

218,2

603832

637736

1,00

0,94

0,32

800

256,10

1024,4

227,4

240,2

731459

772631

1,10

1,00

0,30

1000

275,80

1103,2

244,9

258,7

848345

896149

1,20

1,10

0,28

1200

293,10

1172,4

260,3

274,9

958252

1011999

1,25

1,20

0,26

1400

308,50

1234

274

289,4

1061684

1121355

1,30

1,25

0,24

1600

322,60

1290,4

286,4

302,5

1160452

1225686

1,40

1,30

0,24

1800

335,45

1341,8

298

314,6

1255549

1325489

1,43

1,36

0,22

2000

347,4

1389,6

308,5

325,9

1346092

1422014

1,5

1,4

0,22

Indexes inner. outer are matched to the values, received for internal and outer races accordingly.

R,

mm

30,5

10,70

6,70

4,30

2,27

2,69

1,32

2,00

1,84

1,66

1,55

1,44

R,

mm

31,5

10,3

7,1

4,7

3,6

2,95

2,64

2,2

2,1

1,9

1,8

1,65

Result calculations, given in the table 2, coincide with values of contact pressure received in working process [2].

Registered contact resistance value (Rc) achievement to some critical value Rcr, means BLL destruction and decreasing Rc to

value, characteristic for the "dry" bearing, measured in the version one by experimental way and calculated in the version

two (see table 2).

We have offered the new basic scheme (fig. 2) to define tribotechnological properties of BLL which allows to carry out

voltage drop measurement in the bearing directly at its operation [3].

Page | 81

International Journal of Engineering Research & Science (IJOER)

ISSN: [2395-6992]

[Vol-2, Issue-2, February- 2016]

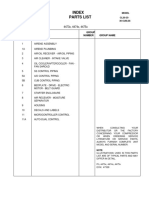

FIGURE 2. THE BLOCK SCHEME (DIRECT) OF THE DEVICE FOR ROLLING-CONTACT BEARING DIAGNOSTIC: 1 - SHAFT; 2 LOADING UNIT; 3 - LOAD CELL; 4 - FIRST CURRENT COLLECTOR; 5 - SECOND CURRENT COLLECTOR; 6 - CONSTANTCURRENT SOURCE; 7 - ANALOG-DIGITAL CONVERTER (ADC); 8 - PERSONAL COMPUTER; 9 - INNER (OUTER) RACE; 10 LUBRICANT; 11 - INNER RACE; R1 - RESISTANCE; R2 - CALIBRATING RESISTANCE.

The bearing of the USA manufacture 6202-2RS d16 C3 (Perfect fit industries, inc. Florida, U.S.A.) was used as the second

bearing. External diameter of a race is 35 mm. An inner diameter of a race is 16 mm. Balls number is 8 pieces Ball diameter

is 4 mm. Width of races is 11 mm.

We have offered the new basic diagram to define tribotechnological properties which allows to carry out voltage drop

measurement in the bearing directly at its operation in full-sized unit [3]. The test bench is realized on the basis of the

produced friction test machine S. Speed makes 0.5 m/s. Resource test "dry" (without lubricant) bearings were carried

out at the maximum radial load 2000 N [10]. Electronic microscopic pictures and qualitative and also quantitative analysis

of element composition of race surfaces was carried out in SC BELMICROANALYSIS. Electronic microscopic pictures

are gained on transmission electron microscope H-800 (Hitachi, Japan). AFM surface images are gained with using scanning

probing microscope NT-206 manufactured by ODO Microtestmachines.

III.

RESULTS AND DISCUSSION

The schedule of contact resistance (Rc) dependence from time (fig. 3) for two bearings at loading 2000 N is various. The

surface of races, manufactured by Slovakia, passes following stages: steams adsorption of solvent elements moisture

accompanied by insignificant increasing of Rc level; destruction of adsorbed steams and oxide film to level, characteristic for

contraction resistance; intensive surface oxidation with change of chemical compound and structure of oxide film with Fe2O3 (white colour) on -Fe2O3 and Fe34 [10]; elastic energy accumulation in the subsurface layer and formation

developed dislocation structure, accompanied by an union of microcracks in macrocracks and sliding strips; the selective

mechanism of surface deterioration, proceeding by means of great material volumes separating in the form of petals and a

juvenile surface revealing, that leads to level Rc decreasing to the contraction resistance level, wedging of the bearing [12].

FIGURE 3. THE DEPENDENCE OF CONTACT RESISTANCE (RC) FROM TIME FOR "DRY" BEARINGS AT LOADING 2000 N:

ZVL 6302/16 AND

6202-2RS D16 C3. A CALCULATED CONTRACTION RESISTANCE VALUE FOR LOADING 2000 N IS

SHOWN BY A DOTTED LINE (

).

Page | 82

International Journal of Engineering Research & Science (IJOER)

ISSN: [2395-6992]

[Vol-2, Issue-2, February- 2016]

We can assume the following bearing process technology 6202-2RS d16 C3. It is known, that the less grain size, the above

steel strength and back-to-back endurance. The initial microstructure of bearing steel, characteristic for fine-grained pearlite

is represented on fig. 4, arrow 3, reinforced layer ( 20 microns) arrow 1 and transitive structure, arrow 2.

High hardness on the surface provides low propensity to scuffing; high fatigue limit; high cavitations durability and good

resistance to corrosion in atmosphere. Besides the reinforced layer is well ground and polished, about what the electronic

microscopic picture of race surface (fig. 4,) and parameters analysis of surface roughness with using AFM (fig. 5) testifies.

FIGURE 4: A AND B. ELECTRONIC MICROSCOPIC PICTURE: A - RACE CLEAVAGE; B - TOOL MARKS ON RACE SURFACE

6202-2RS D16 C3.

On the electronic microscopic picture of the race surface we can observe clearly visible characteristic parallel each other tool

marks along rolling paths on treated surface (fig. 4, b). The distance between them makes 8-12 microns (fig. 4, b, arrows).

It is known, that the above a roughness class of inner race surfaces, the less is mechanical component of friction factor and

therefore is more long a resource of bearing work [1-2]. Analysis AFM of the outer race surface image (fig. 5) shows, that

the maximum heights spread (Rq) makes 2.8 microns.

FIGURE 5. AFM THE INNER SURFACE IMAGE OF THE OUTER RACE 6202-2RS D16 C3.

The multicyclic radial bearing loading (2000 N) 6202-2RS d16 C3 leads to microcracks formation on races surface which

will increase in sizes, to unit and form macrocracks. As a result of wear fragments separation pits, and hollows are formed on

the surface, i.e. the pitting is observed [1-2]. The mechanical component of friction factor increases, that leads to an

unimportant increasing of friction factor on a time section t = 11 - 16 ks (fig. 6).

Page | 83

International Journal of Engineering Research & Science (IJOER)

ISSN: [2395-6992]

[Vol-2, Issue-2, February- 2016]

FIGURE 6. DEPENDENCE OF FRICTION FACTOR (F) FROM TIME (T) AT LOADING 2000 N FOR "DRY" BEARINGS:

6302/16 AND

ZVL

6202-2RS D16 C3.

Sharp temperature drop and friction factor (fig. 6) at time of order 20 ks it is possible to explain by destruction of first

mechanically strong coating layer. It is obvious, that heat conductivity of the second layer is above, than at first layer that has

led to substantial growth of the heat removal and as consequence to temperature decreasing 50 . This layer does not

possess high strength properties that lead to its destruction and increasing of friction factor and temperature. The adhesive

and mechanical component of friction factor monotonously increases. Losses for displacement between molecules of a

lubricant layer increase that leads to monotonous increasing of temperature. It is observe bearing wedging at t = 25.2 ks,

accompanied by sharp increasing of friction factor. It is necessary to note, that to reduce bearing 6202-2RS d16 C3 test time

speed of its turning (in terms of linear speed from 0.5 m/s to 1.5 m/s) has been increased three times.

Bearing 6202-2RS d16 C3 operating modes differ from operating modes of bearing ZVL 6302/16. The first stage is

characterised by elastic energy accumulation in the subsurface layer and formation developed dislocation structure,

accompanied by an union of microcracks in macrocracks and a sliding

strip, at that contact resistance level increases monotonously, that can be caused of simultaneously proceeding surface

oxidation process (fig. 3). The level Rc decreasing, but not to contraction resistance level (fig. 3) with simultaneous friction

factor increasing at bearing wedging to 0.45, instead of to 0.8 (fig. 6) testify that steel surface destruction (the second stage)

proceeds, but not so intensively, as at the selective wearing mechanism as the metal juvenile surface is not revealing (the

contraction resistance level will not attain and the friction factor is well below, than for the bearing ZVL 6302/16). At the

juvenile surface revealing the adhesive component of friction factor is considerably above for account of conjugate surfaces.

The third stage is the bearing wedging.

Thus, the bearing 6202-2RS d16 C3 work resource is six times above in comparison with the bearing ZVL 6302/16, that

testifies about dominant role of method and thermal treatment of friction surfaces taking into account constructional features.

IV.

CONCLUSION

The substantiation of electrophysical probing methods using for an estimation of operational properties rolling-contact

bearings on a condition of the steel bearing surface is given. Electric circuits and techniques are developed. With using of

Hertz theory relationships a calculation of contact pressures in system ball races is executed. Dependence of contraction

resistance and oxide film on medium contact pressure is installed. On the basis of model surface boundary, estimation

techniques of rolling-contact bearings condition control are developed.

Operating modes of rolling-contact bearings depending on steel surfacing process technology are defined. Following

condition stages of rolling-contact bearings are installed: formation monomolecular and polymolecular chemisorbed

lubricant layers on races; a dynamic equilibrium condition between formation and wearing of lubricant layers; destruction of

layers and predominance of the "dry" not greased contacting mode, intensive oxidation of conjugate surfaces and

accumulation of elastic energy mode; surfaces wearing mode, mode of intensive selective surfaces wearing; bearing

wedging. Definite form of contact resistance dependence, friction factor and temperature are suitable to each stage or a

Page | 84

International Journal of Engineering Research & Science (IJOER)

ISSN: [2395-6992]

[Vol-2, Issue-2, February- 2016]

bearing state. So, contact resistance decreasing to level characteristic for the initial "dry" bearing, in each case depending on

a surface treatment method it accepts specific value (or a definite values range), for example, for the bearing type ZVL

6302/16 0.2-0.5 Om means fracture initiation of monomolecular BLL, and decreasing to 1 mOm means the beginning of

intensive oxidation, dispersing, formation of developed dislocation structure, leading to time local intensive surface wearing

and wedging of the rolling-contact bearing. Determination of these criterion values allows at an early stage, before initiation

of bearing destruction critical behavior modes, to carry out its condition control at operation. The given criterion can be used

at rolling-contact bearings diagnostic. The recommendation to replace lubricant or machines and mechanisms operating

modes restriction can be these diagnostic method results, to prevent their catastrophic destruction.

REFERENCES

[1] V.I.Anurev, Handbook of the designer-mechanician, V.2, M.: Mashinostroenie, 2001, 912 p.

[2] M.A.Galahov,A.N.Burmistrov, Calculation of bearing units, M.: Mashinostroenie, 1988, 272 p.

[3] S.V.Korotkevich, V.G.Pinchuk, S.O.Bobovich, Wear resistance of metals at boundary friction, Gomel, Gomel State University of F.

Skoriny, 2011, 237 p.

[4] D.Fritzson, J.Stahl and G.Morales-Espejel, Simulation of fretting fatigue in conformal and concentrated contacts, World Tribology

Congress 2009, Kyoto, 6-11 september, 2009, Japanese Society of Tribologists Science Council of Japan, Japan, P. 598.

[5] V.G.Pinchuk, S.V.Korotkevich, Kinetics of hardening and destruction of a surface of metals at friction, LAP Lambert Academic

Publishing, 2012, 416 p.

[6] V.G.Pinchuk and S.V.Korotkevich, Microstructure evolution in friction-loaded layers of nickel, Indian Journal of Research,Vol. 4,

Issue 2, 2015, p. 8-10.

[7] V.G.Pinchuk, S.V.Korotkevich, Physical patterns of dislocation structure kinetics in friction loaded surface layers, Global Journal For

Research Analysis, Vol. 4, Issue 5, 2015, p. 255-257.

[8] V.G.Pinchuk, I.A.Buyanovskiy and S.V.Korotkevich, Kinetics of Microstructure and Selective Mechanism of Fracture of Metal

Surface Layer under Friction, Inorganic Materials: Applied Research, 2015, Vol. 6, 5, p. 355-359.

[9] N.K.Myshkin, M.I.Petrokovets, Tribology basics and applications, Gomel: MPRI NASB, 2002, 304 p.

[10] A.A.Djuzhev, S.V.Korotkevich, N.F.Solovej, O.V.Holodilov, Analysis of tribotechnical characteristics of engine oils boundary

lubricating layers Balttrib 2009, Kaunas, 19-21 november, 2009, Aleksandras Stulginskis University, Lithuanian, P. 52-58.

[11] S.V.Korotkevich, ..Dubravin, S..artinenko, Influence of the chemical composition and structure of oxidic films on their

tribotechnical properties, Friction and wear, V. 21, 2000, 5,

p. 518 526.

[12] R.Holm, Electrical Contacts (Russian translation), Moscow, 1961, 464 p.

Page | 85

You might also like

- The Contact Analysis For Deep Groove Ball Bearing Based On ANSYSDocument6 pagesThe Contact Analysis For Deep Groove Ball Bearing Based On ANSYSAnonymous PufNjgNo ratings yet

- 159e 16 (1) .PdfyeryerDocument6 pages159e 16 (1) .PdfyeryerankitsarvaiyaNo ratings yet

- Slab Analysis of Ring Rolling AssumingConstantShearFrictionDocument7 pagesSlab Analysis of Ring Rolling AssumingConstantShearFrictionMatteo Dalla Vecchia100% (1)

- Failure Analysis of A Coupled Shaft From A Shredder: Luis.g.reis@tecnico - Ulisboa.ptDocument12 pagesFailure Analysis of A Coupled Shaft From A Shredder: Luis.g.reis@tecnico - Ulisboa.ptMulugetaNo ratings yet

- Icces 2008 007 023Document20 pagesIcces 2008 007 023charles_boyle_3No ratings yet

- A Study of Spur Gear Pitting Formation and Life Prediction: Wear December 2004Document10 pagesA Study of Spur Gear Pitting Formation and Life Prediction: Wear December 2004abraham silva hernandezNo ratings yet

- Rubber Roller DesignDocument20 pagesRubber Roller DesignGaneshNo ratings yet

- 2021 CherlioDocument28 pages2021 Cherlioamin bentaherNo ratings yet

- Prensa BriquetasDocument8 pagesPrensa BriquetasMatiasMorzilliNo ratings yet

- IJREI - Fabrication and Analysis of Spring Testing MachineDocument6 pagesIJREI - Fabrication and Analysis of Spring Testing MachineIjrei JournalNo ratings yet

- 1 s2.0 S221201731630069X MainDocument8 pages1 s2.0 S221201731630069X MainRidho Bela NegaraNo ratings yet

- Effect of Heat Exchange During Vulcanization On Possible Fabrication of Rubberized Entities by Methods of Plastic DeformationDocument8 pagesEffect of Heat Exchange During Vulcanization On Possible Fabrication of Rubberized Entities by Methods of Plastic DeformationAldi IgnielNo ratings yet

- Formation of Roll Contact in Four-High Mill Stand: R o L L I N GDocument7 pagesFormation of Roll Contact in Four-High Mill Stand: R o L L I N GAli VarmazyarNo ratings yet

- (23005319 - Acta Mechanica Et Automatica) A Study of The Preload Force in Metal-Elastomer Torsion SpringsDocument6 pages(23005319 - Acta Mechanica Et Automatica) A Study of The Preload Force in Metal-Elastomer Torsion Springsstefan.vince536No ratings yet

- Contact Stress Distribution of Deep Groove Ball Bearing Using AbaqusDocument13 pagesContact Stress Distribution of Deep Groove Ball Bearing Using AbaqusDr-Nouby Mahdy GhazalyNo ratings yet

- Defect Analysis in Hot RollingDocument11 pagesDefect Analysis in Hot RollingVashishth KushwahaNo ratings yet

- 284 JECS16 BallmillingDocument8 pages284 JECS16 BallmillingsumohiNo ratings yet

- Characterization and ModellingDocument4 pagesCharacterization and Modellingnarayananx5No ratings yet

- Stress Intensity Factor of Brass PlateDocument6 pagesStress Intensity Factor of Brass PlateEsmael AdemNo ratings yet

- Metals 10 00513 v2Document9 pagesMetals 10 00513 v2Pedro JuarezNo ratings yet

- Proc Deform UGM KainzA 18052004Document11 pagesProc Deform UGM KainzA 18052004Syed HasanNo ratings yet

- Analysis of Stress Distribution Around Pin Loaded Holes in Orthotropic PlatesDocument6 pagesAnalysis of Stress Distribution Around Pin Loaded Holes in Orthotropic Plateskhudhayer1970No ratings yet

- Simulation of Kinetic Friction in L Bending of Sheet MetalsDocument5 pagesSimulation of Kinetic Friction in L Bending of Sheet Metalsmaziar60No ratings yet

- Xiaoyang Lu, Yaru Wang, Xiaoxiao Wang, Hao Zhang, Silu XieDocument5 pagesXiaoyang Lu, Yaru Wang, Xiaoxiao Wang, Hao Zhang, Silu Xiesawmag123No ratings yet

- Mechanics of Cold Rolling Thin StripDocument25 pagesMechanics of Cold Rolling Thin StripcristobalmonopeluoNo ratings yet

- 3-D Stress Analysis Generator Rotor Styudy PDFDocument24 pages3-D Stress Analysis Generator Rotor Styudy PDFdkymqNo ratings yet

- 1 s2.0 S0020740316308189 MainDocument24 pages1 s2.0 S0020740316308189 Mainnadeemq_0786No ratings yet

- Estimation of Rock Mass Strength in Open-Pit MiningDocument8 pagesEstimation of Rock Mass Strength in Open-Pit MiningNadia SafnaNo ratings yet

- F 031032038Document7 pagesF 031032038researchinventyNo ratings yet

- Karafillis 1992Document19 pagesKarafillis 1992Deep AhireNo ratings yet

- CRITICAL REVIEW ON DESIGN OF ROLLING PROCESS Kondapalli Siva Prasad1Document16 pagesCRITICAL REVIEW ON DESIGN OF ROLLING PROCESS Kondapalli Siva Prasad1Samir BoseNo ratings yet

- Numerical and Experimental Study of Frictional Behavior in Bending Under Tension TestDocument9 pagesNumerical and Experimental Study of Frictional Behavior in Bending Under Tension Testsergio_rollaNo ratings yet

- Bearing Deformation Impact on Pressure Field and Hydrodynamic CharacteristicsDocument8 pagesBearing Deformation Impact on Pressure Field and Hydrodynamic CharacteristicsSirajuddin ANo ratings yet

- 6940 21524 1 PBDocument10 pages6940 21524 1 PBSanthosh KumarNo ratings yet

- An Overview of Solder Bump Shape Prediction Algorithms With ValidationsDocument5 pagesAn Overview of Solder Bump Shape Prediction Algorithms With Validationskhers_zalNo ratings yet

- Impact Failure Analysis of Re-Circulating Mechanism in Ball ScrewDocument13 pagesImpact Failure Analysis of Re-Circulating Mechanism in Ball ScrewJigar M. UpadhyayNo ratings yet

- Design and Validation of High-Energy Impact TesterDocument10 pagesDesign and Validation of High-Energy Impact TesterorlandompsilvaNo ratings yet

- Paper James FlatDeckPlates PDFDocument27 pagesPaper James FlatDeckPlates PDFcewaleed2590No ratings yet

- Texturing of Rollers For The Production of Auto-Industry SheetDocument4 pagesTexturing of Rollers For The Production of Auto-Industry SheetAnoop KizhakathNo ratings yet

- Texturing Methods PDFDocument4 pagesTexturing Methods PDFAnoop KizhakathNo ratings yet

- Investigation of Springback of Metallic Sheets at Small StrainsDocument17 pagesInvestigation of Springback of Metallic Sheets at Small Strainskhudhayer1970No ratings yet

- New Directional Drilling Simulation Tool Reveals Link Between Dynamic Stability and Tool Face ControlDocument17 pagesNew Directional Drilling Simulation Tool Reveals Link Between Dynamic Stability and Tool Face ControlBOURECHAK TayebNo ratings yet

- Crack Propagation in EBW JointsDocument8 pagesCrack Propagation in EBW JointsEidertxuNo ratings yet

- Analyzing Some Behavior of A Cracked Beam Under Pressure: B. YazdizadehDocument8 pagesAnalyzing Some Behavior of A Cracked Beam Under Pressure: B. YazdizadehMustafa MoussaouiNo ratings yet

- 1 s2.0 S0168874X98000572 MainDocument13 pages1 s2.0 S0168874X98000572 MainDevarajuNo ratings yet

- Simulation of Bolt Prestressing in Steel Shear Connections: Emistaki@Document10 pagesSimulation of Bolt Prestressing in Steel Shear Connections: Emistaki@Anis SuissiNo ratings yet

- A Method of Approximate Tool Wear Analysis in Cold Roll FormingDocument6 pagesA Method of Approximate Tool Wear Analysis in Cold Roll FormingAly MahdyNo ratings yet

- The Study of Contact Pressure Analyses and Prediction of Dynamic Fatigue Life For Linear Guideways SystemDocument8 pagesThe Study of Contact Pressure Analyses and Prediction of Dynamic Fatigue Life For Linear Guideways SystemankitsarvaiyaNo ratings yet

- Metals: Generation of A Layer of Severe Plastic Deformation Near Friction Surfaces in Upsetting of Steel SpecimensDocument9 pagesMetals: Generation of A Layer of Severe Plastic Deformation Near Friction Surfaces in Upsetting of Steel SpecimensyesullenNo ratings yet

- Analysis of Compression of Hollow Circular Elastomeric Bearings 1992Document9 pagesAnalysis of Compression of Hollow Circular Elastomeric Bearings 1992ciscoNo ratings yet

- Goncz 2015Document11 pagesGoncz 2015Anonymous LaMda8EXNo ratings yet

- Sistema de Enderezado CTLDocument15 pagesSistema de Enderezado CTLmantenimientoNo ratings yet

- Lee2008 Elbow LWTDocument5 pagesLee2008 Elbow LWTKurra SrikanthNo ratings yet

- 03.2019 - Effect of Shock and Vibration Preloading On The Parameters of Tear Dimples and Their ConglomeratesDocument11 pages03.2019 - Effect of Shock and Vibration Preloading On The Parameters of Tear Dimples and Their ConglomeratesFlick TornNo ratings yet

- A Review On Springback Effect in Sheet Metal Forming ProcessDocument7 pagesA Review On Springback Effect in Sheet Metal Forming ProcessantonytechnoNo ratings yet

- EFFECT OF THE NOTCH OPENING ANGLE On The Mechanical Properties and Fractrue Morphology of Mild Steel Samples at Different Strain RatesDocument8 pagesEFFECT OF THE NOTCH OPENING ANGLE On The Mechanical Properties and Fractrue Morphology of Mild Steel Samples at Different Strain RatesSatish Kumar GautamNo ratings yet

- Springback Prediction in Sheet Metal Forming, Based On Finite Element Analysis and Artificial Neural Network ApproachDocument14 pagesSpringback Prediction in Sheet Metal Forming, Based On Finite Element Analysis and Artificial Neural Network ApproachMagesh BNo ratings yet

- Contact Stress Analysis of Deep Groove Ball Bearing 6210 Using Hertzian Contact TheoryDocument9 pagesContact Stress Analysis of Deep Groove Ball Bearing 6210 Using Hertzian Contact Theoryswapnil kaleNo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- Engineering Journal Preparation and Characterization of Cross-Linked Polymer Supports For Catalysts ImmobilizationDocument24 pagesEngineering Journal Preparation and Characterization of Cross-Linked Polymer Supports For Catalysts ImmobilizationEngineering JournalNo ratings yet

- Engineering Journal Analysis of Vibro-Isolated Building Excited by The Technical Seismicity of Traffic EffectsDocument6 pagesEngineering Journal Analysis of Vibro-Isolated Building Excited by The Technical Seismicity of Traffic EffectsEngineering JournalNo ratings yet

- Engineering Journal Role of Indian Spices in Cancer Prevention: A ReviewDocument2 pagesEngineering Journal Role of Indian Spices in Cancer Prevention: A ReviewEngineering JournalNo ratings yet

- Engineering Journal A Professional PID Implemented Using A Non-Singleton Type-1 Fuzzy Logic System To Control A Stepper MotorDocument8 pagesEngineering Journal A Professional PID Implemented Using A Non-Singleton Type-1 Fuzzy Logic System To Control A Stepper MotorEngineering JournalNo ratings yet

- Engineering Journal Study of Different Surface Pre-Treatment Methods On Bonding Strength of Multilayer Aluminum Alloys/Steel Clad MaterialDocument9 pagesEngineering Journal Study of Different Surface Pre-Treatment Methods On Bonding Strength of Multilayer Aluminum Alloys/Steel Clad MaterialEngineering JournalNo ratings yet

- Engineering Journal Online Tuning of The Fuzzy PID Controller Using The Back-Propagation AlgorithmDocument8 pagesEngineering Journal Online Tuning of The Fuzzy PID Controller Using The Back-Propagation AlgorithmEngineering JournalNo ratings yet

- Engineering Journal Comparative Study of Various Pre-Treatments Coupled To Vacuum Drying in Terms of Structural, Functional and Physical Properties of Carrot DaucusCarotaDocument15 pagesEngineering Journal Comparative Study of Various Pre-Treatments Coupled To Vacuum Drying in Terms of Structural, Functional and Physical Properties of Carrot DaucusCarotaEngineering JournalNo ratings yet

- Engineering Journal Micromechanics of Thermoelastic Behavior of AA6070 Alloy/Zirconium Oxide Nanoparticle Metal Matrix CompositesDocument3 pagesEngineering Journal Micromechanics of Thermoelastic Behavior of AA6070 Alloy/Zirconium Oxide Nanoparticle Metal Matrix CompositesEngineering JournalNo ratings yet

- Engineering Journal Thermo-Mechanical Fatigue Behavior of A Copper-Alumina Metal Matrix Composite With Interpenetrating Network StructureDocument9 pagesEngineering Journal Thermo-Mechanical Fatigue Behavior of A Copper-Alumina Metal Matrix Composite With Interpenetrating Network StructureEngineering JournalNo ratings yet

- Engineering Journal Strategic and Operational Scope of Foreign Subsidiary UnitsDocument11 pagesEngineering Journal Strategic and Operational Scope of Foreign Subsidiary UnitsEngineering JournalNo ratings yet

- Engineering Journal Effects of Soil Physical and Chemical Properties On The Distribution of Trees in Some Ecological Zones of Zalingei-Darfur SudanDocument9 pagesEngineering Journal Effects of Soil Physical and Chemical Properties On The Distribution of Trees in Some Ecological Zones of Zalingei-Darfur SudanEngineering JournalNo ratings yet

- Engineering Journal Securing of Elderly Houses in Term of Elderly's Vision DisordersDocument10 pagesEngineering Journal Securing of Elderly Houses in Term of Elderly's Vision DisordersEngineering JournalNo ratings yet

- Engineering Journal The Microorganism Contamination Affect The Physical and Chemical Composition of MilkDocument7 pagesEngineering Journal The Microorganism Contamination Affect The Physical and Chemical Composition of MilkEngineering JournalNo ratings yet

- Engineering Journal Numerical Study of Microbial Depolymerization Process With The Newton-Raphson Method and The Newton's MethodDocument12 pagesEngineering Journal Numerical Study of Microbial Depolymerization Process With The Newton-Raphson Method and The Newton's MethodEngineering JournalNo ratings yet

- Engineering Journal Isomorphic Transformation of The Lorenz Equations Into A Single-Control-Parameter StructureDocument9 pagesEngineering Journal Isomorphic Transformation of The Lorenz Equations Into A Single-Control-Parameter StructureEngineering JournalNo ratings yet

- Engineering Journal Alteration of Pelvic Floor Biometry in Different Modes of DeliveryDocument7 pagesEngineering Journal Alteration of Pelvic Floor Biometry in Different Modes of DeliveryEngineering JournalNo ratings yet

- Engineering Journal Power Improvement in 32-Bit Full Adder Using Embedded TechnologiesDocument8 pagesEngineering Journal Power Improvement in 32-Bit Full Adder Using Embedded TechnologiesEngineering JournalNo ratings yet

- Engineering Journal A Systematic Approach To Stable Components Synthesis From Legacy ApplicationsDocument10 pagesEngineering Journal A Systematic Approach To Stable Components Synthesis From Legacy ApplicationsEngineering JournalNo ratings yet

- Engineering Journal Salicylic Acid Enhanced Phytoremediation of Lead by Maize (Zea Mays) PlantDocument7 pagesEngineering Journal Salicylic Acid Enhanced Phytoremediation of Lead by Maize (Zea Mays) PlantEngineering JournalNo ratings yet

- Engineering Journal Extracorporal Shock Wave Induced Mechanical Transduction For The Treatment of Low Back Pain - A Randomized Controlled TrialDocument6 pagesEngineering Journal Extracorporal Shock Wave Induced Mechanical Transduction For The Treatment of Low Back Pain - A Randomized Controlled TrialEngineering JournalNo ratings yet

- Engineering Journal Controller Design For Nonlinear Networked Control Systems With Random Data Packet DropoutDocument6 pagesEngineering Journal Controller Design For Nonlinear Networked Control Systems With Random Data Packet DropoutEngineering JournalNo ratings yet

- Engineering Journal A Silicon-Containing Polytriazole Resin With Long Storage TimeDocument9 pagesEngineering Journal A Silicon-Containing Polytriazole Resin With Long Storage TimeEngineering JournalNo ratings yet

- Engineering Journal Impact of Texturing/cooling by Instant Controlled Pressure Drop DIC On Pressing And/or Solvent Extraction of Vegetal OilDocument12 pagesEngineering Journal Impact of Texturing/cooling by Instant Controlled Pressure Drop DIC On Pressing And/or Solvent Extraction of Vegetal OilEngineering JournalNo ratings yet

- Engineering Journal Bio-Oil Production by Thermal Cracking in The Presence of HydrogenDocument20 pagesEngineering Journal Bio-Oil Production by Thermal Cracking in The Presence of HydrogenEngineering JournalNo ratings yet

- Engineering Journal A Novel Oxygenator-Right Ventricular Assist Device Circuit Using The SYNERGY Micropump As Right Heart Support in A Swine Model of Pulmonary HypertensionDocument8 pagesEngineering Journal A Novel Oxygenator-Right Ventricular Assist Device Circuit Using The SYNERGY Micropump As Right Heart Support in A Swine Model of Pulmonary HypertensionEngineering JournalNo ratings yet

- Engineering Journal Studies On Stigma Receptivity of Grewia Asiatica L. With Reference To Esterase and Peroxidase ActivityDocument4 pagesEngineering Journal Studies On Stigma Receptivity of Grewia Asiatica L. With Reference To Esterase and Peroxidase ActivityEngineering JournalNo ratings yet

- Engineering Journal The Sinkhole Hazard Study at Casalabate (Lecce, Italy) Using Geophysical and Geological SurveysDocument11 pagesEngineering Journal The Sinkhole Hazard Study at Casalabate (Lecce, Italy) Using Geophysical and Geological SurveysEngineering JournalNo ratings yet

- Engineering Journal Estimation of Global Solar Radiation Using Artificial Neural Network in Kathmandu, NepalDocument9 pagesEngineering Journal Estimation of Global Solar Radiation Using Artificial Neural Network in Kathmandu, NepalEngineering JournalNo ratings yet

- Engineering Journal Factors Influencing Grid Interactive Biomass Power IndustryDocument12 pagesEngineering Journal Factors Influencing Grid Interactive Biomass Power IndustryEngineering JournalNo ratings yet

- MECHANICAL SEALS FAILURE CAUSESDocument26 pagesMECHANICAL SEALS FAILURE CAUSESFaruque Khan Yumkhaibam100% (6)

- Characteristics Series CE, CP, C: 2 Way Slip-In Cartridge ValvesDocument17 pagesCharacteristics Series CE, CP, C: 2 Way Slip-In Cartridge Valvess_waqarNo ratings yet

- Gastec Qa 198Document24 pagesGastec Qa 198CristianNo ratings yet

- Design Criteria For Exposed Hydro Penstocks - Gordon1978 PDFDocument12 pagesDesign Criteria For Exposed Hydro Penstocks - Gordon1978 PDFDavid DelgadoNo ratings yet

- Wagner Brake Supplemental Catalog 4-2-02Document72 pagesWagner Brake Supplemental Catalog 4-2-02Edinson Camba NucetteNo ratings yet

- Kic API X70Document8 pagesKic API X70Ivan SilveiraNo ratings yet

- CompAir LeROI CL20-25-30SS,CUB Parts ListDocument59 pagesCompAir LeROI CL20-25-30SS,CUB Parts ListDiana Zar100% (1)

- 793F, 793F, WTR, Oem PDFDocument18 pages793F, 793F, WTR, Oem PDFDennis OlayaNo ratings yet

- Permanent Magnet DC MotorDocument4 pagesPermanent Magnet DC MotorSourav Kumar100% (1)

- Leser US Order Price Information 2012Document204 pagesLeser US Order Price Information 2012Matheus de AlmeidaNo ratings yet

- Light Duty 600 8k (Lit 122 00)Document123 pagesLight Duty 600 8k (Lit 122 00)miab1No ratings yet

- ASTM A615 Grade 70 PDFDocument2 pagesASTM A615 Grade 70 PDFAnonymous vRtCW4hszNo ratings yet

- ElectricianSemIICITSQB PDFDocument82 pagesElectricianSemIICITSQB PDFmarvin2008No ratings yet

- TEFC vs WPII Motors in Harsh Petrochemical EnvironmentsDocument3 pagesTEFC vs WPII Motors in Harsh Petrochemical EnvironmentsJhonatan OyolaNo ratings yet

- Válvula de Alivio Vicking - AGF 7000Document2 pagesVálvula de Alivio Vicking - AGF 7000Maurilio Batista de LimaNo ratings yet

- 2022.08.08 Fabrication and Installation Steel StructureDocument21 pages2022.08.08 Fabrication and Installation Steel StructureArifian NugrohoNo ratings yet

- FiatDocument10 pagesFiatrgi178100% (1)

- Mechanical, Plumbing, Electrical Materials ListDocument3 pagesMechanical, Plumbing, Electrical Materials ListMohamedNo ratings yet

- Chapter 3Document17 pagesChapter 3Mintesnot TadeleNo ratings yet

- Maintenance ScheduleDocument22 pagesMaintenance ScheduleDen100% (2)

- Mechanical ASTM D2196Document1 pageMechanical ASTM D2196VasaNo ratings yet

- Maintain Anesthesia Machine Performance with Maintenance KitsDocument2 pagesMaintain Anesthesia Machine Performance with Maintenance KitsRoberto SierraNo ratings yet

- Io 360 A, Ab, C, CB, D, DB, G, GB, H, HB, HB9, J, JB, K, KB, EsDocument94 pagesIo 360 A, Ab, C, CB, D, DB, G, GB, H, HB, HB9, J, JB, K, KB, EsTatiana Chacon100% (3)

- LS Circuit IntroductionDocument18 pagesLS Circuit IntroductionMuhammad DaniNo ratings yet

- Elasticity Ee PDFDocument13 pagesElasticity Ee PDFravi0% (1)

- Sectional Properties of Rolled Steel Joists (Ref: Is: 808 - 1989 & Is: 12778 - 2004)Document49 pagesSectional Properties of Rolled Steel Joists (Ref: Is: 808 - 1989 & Is: 12778 - 2004)rohitnrgNo ratings yet

- Properties of Natural Gas and Condensate SystemsDocument80 pagesProperties of Natural Gas and Condensate SystemsHashem HashemNo ratings yet

- Katalog WF 2007Document92 pagesKatalog WF 2007Ing István-Mátyás Tupper MátéNo ratings yet

- Katalog Case Traktor 7230 Case Ih Magnum Diesel TractorDocument488 pagesKatalog Case Traktor 7230 Case Ih Magnum Diesel TractorAlexey petrovich100% (2)

- Dcmotors601 0241Document42 pagesDcmotors601 0241Afrida Fazira MNo ratings yet