Professional Documents

Culture Documents

Especificaciones Valvula Well Mark

Uploaded by

miguel mendozaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Especificaciones Valvula Well Mark

Uploaded by

miguel mendozaCopyright:

Available Formats

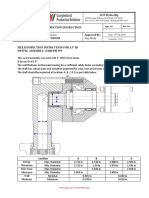

Section No. 4.1.

2600

Series

W2601 and W2602 Threaded Safety Relief Valves

Application

These valves are for general purpose gas and air services, and are

recommended for over-pressure protection on separators, compressors, pressure vessels, heater-treaters, gathering and transmission

lines, meter runs and other systems where the rated capacities of

the valve are commensurate with the requirements of the system.

All of these valves are manufactured in accordance with the ASME

Boiler and Pressure Vessel Code and have been capacity tested and

certified by the National Board to meet the requirements of Section

VIII of the ASME Code, as signified accordingly by the symbols UV

and NB on their nameplates.

NOTE: These valves are designed for relief to atmospheric pressure only on the downstream side, and are not intended for use in

a closed system. Any backpressure applied to the downstream side

of the valve will result in improper pressure relief.

Features

Choice Of Multiple Orifice Sizes

ASME Coded: UV Section VIII Air/Gas

Enhanced Guided Lift System: Optimum Performance

Trim Option: Soft Seat, Metal-to-Metal

High Volume Applications

Low Pressure Applications

Stainless Steel Internals

NACE Option Available

Specifications

Type W26011" Size

Type W26022" Size

Soft Resilient Seat or

Metal-to-Metal Available

Multiple Orifices Available:

C.295" Diameter (1" valve only)

D.400" Diameter (1" valve only)

E.534" Diameter (1" or 2" valve)

F.672" Diameter (2" valve only)

G.857" Diameter (2" valve only)

B

E

Dimensional Data

Model

W2601

2 3/ 8"

10 1 / 2 "

3 1/ 4 "

1 7/ 8"

W2602

2 7/ 8 "

13 1/ 4 "

4 5/8"

2 3/8 "

The

E

F

1" FNPT 31" MNPT STANDARD

/4" MNPT OPTIONAL

11/2" OPT. 1/2" MNPT OPTIONAL

2" MNPT STANDARD

2" FNPT 1 1/4" MNPT OPTIONAL

1 1/ 2" MNPT OPTIONAL

Company, L.L.C. Oklahoma City, Oklahoma Tel: (405) 672-6660 Fax: (405) 672-6661 wellmarkco.com

2011 The WellMark Company, L.L.C. Litho USA WM2600-2/11 All registered trademarks are the property of their respective owners.

Section No. 4.1.a

Series

2600

W2601 and W2602 Threaded Safety Relief Valves

Determining the Model Number

W2601 1"

W2602 2"

.295" Diameter (1" valve only)

.400" Diameter (1" valve only)

.534" Diameter (1" or 2" valve)

.672" Diameter (2" valve only)

.857" Diameter (2" valve only)

B

E

V

M

Buna N (Nitrile)

EPR

Viton

Metal-to-Metal

Specification

Orifice Diameter (in.)

Orifice Area (A) (sq. in.)

Inlet Size Available (in.)

Outlet Size Available (in.)

Pressure Ranges (psig)

Flow Coefficient (K)

1"

2"

Use Upper End of Spring Range

Options

G 1/4" Gauge Port

N NACE Compliant

Outlet Connection

1 Female NPT Threaded

Inlet Connection

1 Male NPT Threaded

Orifice Size

Other Connections Available. Consult Factory.

Other Connections Available. Consult Factory.

Seat Material

1 CS(WCB)/ CS(A105)

2 CS(WCB)/ 316 S.S.

3 S.S. (CF8M)/ 316 S.S.

C

D

E

E

F

G

Spring Size (See chart below)

Bonnet Group

C

D

E

F

G

Orifice

W2601 EV1-311N-400

1

2

3

4

5

6

7

Inlet x Outlet Size

Bonnet/Seat Frame

Material

C

0.295

0.068

1/2, 3/4, 1

1, 1 1 / 2 *

15-2500

0.859

Orifice Diameter Orifice Area (A)

0.295

0.068

0.400

0.126

0.534

0.224

0.534

0.224

0.672

0.355

0.857

0.577

D

0.400

0.126

1/2, 3/4, 1

1, 1 1 / 2 *

15-2500

0.859

Orifice Designation

E

0.534

0.224

1 / 2 , 3 / 4 , 1, 1 1 / 4 , 1 1 / 2 , 2

1, 1 1 / 2 *, 2

15-2500

0.859

1/2" x 1"

3/4" x 1"

1" x 1"

1" x 1 1/2"*

1 1/4" x 2"

1 1/2" x 2"

2" x 2"

F

0.672

0.355

1 1/4, 1 1/2, 2

2

15-1600

0.859

G

0.857

0.577

1 1/2, 2

2

75-1000

0.859

Spring Ranges (psig)- Use Upper End of Spring Range

15-80

80-250

250-400

400-800

800-1600

1600-2500

15-50

15-75

15-40

50-150

75-250

40-200

75-100

150-300

250-500

200-400

100-200

300-500

500-1200

400-800

200-600

500-1000

1200-2500

800-1600

600-1000

1000-2500

*When coupled with 1 1/4" or larger inlet, 1 1/2" outlet available by special order only.

The

6

Company, L.L.C. Oklahoma City, Oklahoma Tel: (405) 672-6660 Fax: (405) 672-6661 wellmarkco.com

2011 The WellMark Company, L.L.C. Litho USA WM2600-2/11 All registered trademarks are the property of their respective owners.

Section No. 4.1.a

Series

2600

W2601 and W2602 Threaded Safety Relief Valves

Relieving Capacity For Air (10% Overpressure) Capacities in standard cubic feet per minute at 60 F

Set

Pressure

15

20

25

30

40

50

60

70

75

80

90

100

125

150

175

200

250

275

300

350

400

450

500

550

600

650

700

720

750

800

850

900

950

1000

C

0.295/0.068

33

39

45

51

62

74

86

98

104

109

121

133

162

192

221

251

310

339

369

427

486

545

604

663

722

781

840

863

898

957

1016

1075

1134

1193

Orifice Diameter (in.) /Area (sq. in.)

D

E

F

0.400/0.126 0.534/0.224 0.672/0.355

61

110

174

72

129

205

83

148

235

94

168

266

116

207

328

138

245

389

160

284

451

181

323

512

192

342

543

203

362

573

225

400

635

247

439

696

301

536

850

356

633

1004

411

730

1158

465

827

1311

574

1021

1619

629

1118

1773

683

1215

1926

792

1409

2233

901

1603

2541

1011

1797

2848

1120

1991

3156

1229

2185

3463

1338

2379

3770

1447

2573

4078

1556

2767

4385

1600

2845

4509

1665

2961

4693

1774

3155

5000

1883

3349

5307

1993

3543

5615

2102

3737

5922

2211

3931

6230

G

0.857/0.577

NOT

AVAILABLE

882

932

1032

1132

1382

1632

1882

2132

2631

2881

3131

3630

4130

4630

5129

5629

6129

6628

7128

7329

7627

8127

8627

9126

9626

10,126

Set

Pressure

1050

1100

1150

1200

1250

1300

1350

1400

1440

1450

1500

1550

1600

1650

1700

1750

1800

1850

1900

1950

2000

2050

2100

2150

2160

2200

2250

2300

2350

2400

2450

2500

C

0.295/0.068

1252

1311

1370

1428

1487

1546

1605

1664

1711

1723

1782

1841

1899

1958

2017

2076

2135

2194

2253

2312

2371

2429

2488

2547

2559

2606

2665

2724

2783

2842

2900

2959

Orifice Diameter (in.) /Area (sq. in.)

D

E

F

G

0.400/0.126 0.534/0.224 0.672/0.355 0.857/0.577

2320

4125

6537

2429

4319

6844

2538

4513

7152

2647

4706

7459

2756

4900

7767

2865

5094

8074

2974

5288

8381

3084

5482

8689

3171

5638

8936

3193

5676

8996

3302

5870

9304

3411

6064

9611

3520

6258

9918

3629

6452

3738

6646

3847

6840

3956

7034

4066

7228

4175

7422

4284

7616

4393

7810

4502

8004

NOT

4611

8198

AVAILABLE

4720

8392

4743

8432

4829

8586

4938

8780

5047

8974

5157

9168

5266

9362

5375

9556

5484

9750

Sizing of Safety Relief Valves

Given certain information as follows, Safety Relief Valves may be

sized by use of various formulas prescribed by Appendix 11, Section

VIII, Division I of the ASME Boiler and Pressure Vessel Code for

capacities of orifices. The information as shown below allows sizing

using the coefficient method.

Table I Molecular Weight and Values of C for Gases Relieving Capacity Formula Coefficient Method

Gas

AIR

ACETYLENE

AMMONIA

BUTANE

CARBON DIOXIDE

CHLORINE

ETHANE

ETHYLENE

FREON 22

HYDROGEN

HYDROGEN SULFIDE

METHANE

METHYL CHLORIDE

NATURAL GAS (0.6)

NITROGEN

OXYGEN

PROPANE

SULFUR DIOXIDE

The

M

28.97

26.04

17.03

58.12

44.01

70.91

30.07

28.05

86.48

2.02

34.08

16.04

50.48

17.40

28.02

32.00

44.09

64.06

C

356

345

351

324

345

352

339

337

355

356

348

346

337

344

356

356

331

342

Q (SCFM) = KACP

w x 60

M

T

A = Effective Flow Area (Orifice Area in sq. in.)

C = Gas Constant

K = Flow Coefficient

M = Molecular Weight

P = Flowing pressure (set pressure x 1.1+14 .7 psia)

Q = Flow Rate in SCFM for gases

T = Absolute temperature in degrees Rankin (F + 460)

w = Density of the gas in lb./ft.3 (Air =.0764 @ 14.7 psia)

Company, L.L.C. Oklahoma City, Oklahoma Tel: (405) 672-6660 Fax: (405) 672-6661 wellmarkco.com

2011 The WellMark Company, L.L.C. Litho USA WM2600-2/11 All registered trademarks are the property of their respective owners.

Section No. 4.1.a

2600

Series

W2601 and W2602 Threaded Safety Relief Valves

10

15

19

22

12

14

13

18

11

17

16

See Details

Parts List, W2602

Item Description

1 BONNET

Parts List, W2601

Item Description

1 BONNET

2

SEAT FRAME

1/2"

3/4"

Material

Qty.

SA-216 GR. WCB CS 1

SA-105 CS

1

SA-105 CS

1

SA-105 CS

1

SA-276 S.S.

1

SA-276 S.S.

1

SA-276 S.S.

1

SA-276 S.S.

1

SA-276 S.S.

1

VITON

1

VITON

1

SA-276 S.S.

1

SA-276 S.S.

1

SA-351 S.S.

1

SA-351 S.S.

1

SA-29 CS

2

302 S.S.

1

302 S.S.

1

302 S.S.

1

302 S.S.

1

17-7 S.S.

1

17-7 S.S.

1

302 S.S.

1

302 S.S.

1

302 S.S.

1

302 S.S.

1

17-7 S.S.

1

17-7 S.S.

1

307 CS

1

VITON

1

VITON

1

S.S./BUNA-N

1

STEEL

1

ALUMINUM

1

SA-29 CS

1

SA-29 CS

1

18-8 S.S.

1

18-8 S.S.

1

VITON

1

ALUMINUM

1

18-8 S.S.

4

STEEL & LEAD

1

1"

"C" ORIFICE

3 SEAT

"D" ORIFICE

"E" ORIFICE

"C", "D" ORIFICE

4 PLUG

"E" ORIFICE

"C", "D" ORIFICE

5 O-RING

"E" ORIFICE

"C", "D" ORIFICE

6 O-RING HOLDER

"E" ORIFICE

"C", "D" ORIFICE

7 PLUG GUIDE

"E" ORIFICE

8 SPRING GUIDE

15-80#

80-250#

250-400#

SPRING FOR C OR D

400-800#

800-1600#

1600-2500#

9

15-50#

50-150#

150-300#

SPRING FOR E

300-500#

500-1000#

1000-2500#

10 ADJUSTING SCREW

11 O-RING

12 O-RING

13 SEAL WASHER

14 JAM NUT

15 CAP

16 GUIDE

17 GUIDE STEM

"C", "D" ORIFICE

18 SCREW

"E" ORIFICE

19 O-RING

20* NAMEPLATE

21* DRIVE SCREW

22 SEAL WIRE & LEAD

*Not Shown

Note: Optional Seal Materials Available. Consult Factory.

The

8

Part No.

40986

21293

21294

21222

21223

21242

21283

21224

21282

11180

11182

21226

21275

21225

21284

21227

11188

11189

11190

11192

11194

11195

11188

11189

11190

11192

11194

11195

21229

11181

10402

10578

10174

21211

21279

21292

10001

11184

05000-0223

11066

10075

10178

SEAT FRAME

SEAT

PLUG

O-RING

O-RING HOLDER

PLUG GUIDE

SPRING GUIDE

"E"

"F"

"G"

"E"

"F"

"G"

"E"

"F"

"G"

"E"

"F"

"G"

"E"

"F"

"G"

1 1/ 4 "

1 1/ 2 "

2"

ORIFICE

ORIFICE

ORIFICE

ORIFICE

ORIFICE

ORIFICE

ORIFICE

ORIFICE

ORIFICE

ORIFICE

ORIFICE

ORIFICE

ORIFICE

ORIFICE

ORIFICE

Material

SA-216 GR. WCB CS

SA-105 CS

SA-105 CS

SA-105 CS

SA-276 S.S.

SA-276 S.S.

SA-276 S.S.

SA-276 S.S.

SA-276 S.S.

SA-276 S.S.

VITON

VITON

VITON

SA-276 S.S.

SA-276 S.S.

SA-276 S.S.

SA-351 S.S.

SA-351 S.S.

SA-351 S.S.

SA-29 CS

302 S.S.

302 S.S.

302 S.S.

302 S.S.

17-7 S.S.

302 S.S.

302 S.S.

302 S.S.

302 S.S.

17-7 S.S.

302 S.S.

302 S.S.

302 S.S.

17-7 S.S.

307 CS

VITON

VITON

S.S./BUNA-N

STEEL

ALUMINUM

SA-29 CS

SA-29 CS

18-8 S.S.

18-8 S.S.

VITON

ALUMINUM

18-8 S.S.

STEEL & LEAD

15-75#

75-250#

SPRING FOR E

250-500#

500-1200#

1200-2500#

15-40#

40-200#

9 SPRING FOR F

200-400#

400-800#

800-1600#

75-100#

100-200#

SPRING FOR G

200-600#

600-1000#

10 ADJUSTING SCREW

11 O-RING

12 O-RING

13 SEAL WASHER

14 JAM NUT

15 CAP

16 GUIDE

17 GUIDE STEM

"E" ORIFICE

18 SCREW

"F", "G" ORIFICE

19 O-RING

20* NAMEPLATE

21* DRIVE SCREW

22 SEAL WIRE & LEAD

*Not Shown

Note: Optional Seal Materials Available. Consult Factory.

Qty.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

1

Part No.

40996

31061

31062

31056

21274

21259

21265

21273

21260

21267

11182

11183

11186

21275

21261

21271

21278

21258

21376

21263

10296

10297

10298

10301

10304

10296

10297

10298

10301

10304

10297

10298

10301

10304

21264

10645

10379

10578

10598

21212

21279

21280

11184

11185

10278

11066

10075

10178

Company, L.L.C. Oklahoma City, Oklahoma Tel: (405) 672-6660 Fax: (405) 672-6661 wellmarkco.com

2011 The WellMark Company, L.L.C. Litho USA WM2600-2/11 All registered trademarks are the property of their respective owners.

You might also like

- Erapol EHP95ADocument2 pagesErapol EHP95AMohammad Doost MohammadiNo ratings yet

- 07-01 MafDocument5 pages07-01 MafJuan Roberto López BetanzosNo ratings yet

- Lavadora Secadora LG WD15EGS6 PDFDocument100 pagesLavadora Secadora LG WD15EGS6 PDFK-Search100% (1)

- Rineer Hydraulics: GeneralDocument2 pagesRineer Hydraulics: Generalwilo100% (1)

- ERZG Blanking Plug Technical DatasheetDocument3 pagesERZG Blanking Plug Technical DatasheetEvolution Oil ToolsNo ratings yet

- HH 102 SemitrailerDocument6 pagesHH 102 SemitrailerleoNo ratings yet

- HeatecDocument10 pagesHeatecMogtaba Osman100% (1)

- TB27a ENDocument4 pagesTB27a ENandy131078No ratings yet

- Overfill Prevention: Automation Solutions For Oil & Gas, Defense and Aviation ApplicationsDocument4 pagesOverfill Prevention: Automation Solutions For Oil & Gas, Defense and Aviation ApplicationsAntonio FullerNo ratings yet

- Assembly-Install STD Control Dryer PDFDocument106 pagesAssembly-Install STD Control Dryer PDFdonyaNo ratings yet

- Series: Submersible Sewage PumpsDocument9 pagesSeries: Submersible Sewage PumpsJOHNNY CALERONo ratings yet

- Atom Arc 7018-B2L: Typical Tensile PropertiesDocument1 pageAtom Arc 7018-B2L: Typical Tensile PropertiesPubcrawlNo ratings yet

- Xyq2 6Document26 pagesXyq2 6Jesús MéndezNo ratings yet

- 4150K-4160K Controladores Fisher PDFDocument40 pages4150K-4160K Controladores Fisher PDFrichardNo ratings yet

- 2652 Duplex Piston Pump Mud PumpDocument2 pages2652 Duplex Piston Pump Mud Pumpalfonsoar447370100% (1)

- Panx-350 SPCDocument64 pagesPanx-350 SPCbhaskar reddyNo ratings yet

- Features: Position Control (Pid) With Min/Max Sele (Ars) 69229S904ADocument13 pagesFeatures: Position Control (Pid) With Min/Max Sele (Ars) 69229S904AWasim AhmedNo ratings yet

- Xylem Flygt 2640 Datasheet 60hz PDFDocument2 pagesXylem Flygt 2640 Datasheet 60hz PDFJorge CarvajalNo ratings yet

- Canalta DCOF Product Manual LR PDFDocument13 pagesCanalta DCOF Product Manual LR PDFBelkhir GuerracheNo ratings yet

- Analizadores de Presion de Vapor Analizador RVPDocument6 pagesAnalizadores de Presion de Vapor Analizador RVPLuis OsorioNo ratings yet

- Pulptec: VBW-1000 Basis Weight ValveDocument6 pagesPulptec: VBW-1000 Basis Weight ValveAnup SundareswaranNo ratings yet

- ER-105-3 Digital No-Flow Timer (DNFT)Document8 pagesER-105-3 Digital No-Flow Timer (DNFT)EzequielNo ratings yet

- Camlift: Hydraulic Pumping Unit - 40-192 SeriesDocument2 pagesCamlift: Hydraulic Pumping Unit - 40-192 SeriesJose Jaime Garcia Reyes100% (1)

- NBR O-Rings and Seals Product ListingDocument12 pagesNBR O-Rings and Seals Product Listingcorsini999No ratings yet

- MPFM-401CM Series Instruction Manual OR110424.3Document64 pagesMPFM-401CM Series Instruction Manual OR110424.3Pedro NuñezNo ratings yet

- Pulsa Series BrochureDocument8 pagesPulsa Series Brochurewhatdidijustwatch manNo ratings yet

- Fluid EndDocument1 pageFluid EndpabloasotoNo ratings yet

- Rineer Hydraulics Inc, Specifications PDFDocument2 pagesRineer Hydraulics Inc, Specifications PDFTulio Andres CoyNo ratings yet

- RB2 Standing Valve Parts and Sizes GuideDocument3 pagesRB2 Standing Valve Parts and Sizes GuideLuis ChavarroNo ratings yet

- Bombas TriplexDocument98 pagesBombas TriplexYiikii CueLlo GonzsaLeszNo ratings yet

- NEMA Premium® Motors for Hazardous LocationsDocument2 pagesNEMA Premium® Motors for Hazardous LocationsEvelyn Hachiri CoricazaNo ratings yet

- Tilt Switch OldDocument2 pagesTilt Switch OldAngel Francisco NavarroNo ratings yet

- Pegaso 650 - '97 - Service ManualDocument311 pagesPegaso 650 - '97 - Service ManualMihai MafteianuNo ratings yet

- BD GD CatalogDocument10 pagesBD GD CatalogjosueNo ratings yet

- Hoja Tecnica BartonDocument4 pagesHoja Tecnica BartonjairoNo ratings yet

- REDA Genel Centrifughe 2012 EngDocument7 pagesREDA Genel Centrifughe 2012 EngAlanNo ratings yet

- Cement Metering ValveDocument11 pagesCement Metering ValveWise SoNo ratings yet

- MANUAL DE PARTES REBANADORA BERKEL 829-A MX January 2016Document10 pagesMANUAL DE PARTES REBANADORA BERKEL 829-A MX January 2016ivan reyes TorresNo ratings yet

- NitrogenoDocument139 pagesNitrogenoEmanuelLopezNo ratings yet

- HGDocument45 pagesHGmohamed hamedNo ratings yet

- Douglas Chero Catalogue Valve 6-2003Document89 pagesDouglas Chero Catalogue Valve 6-2003Yurizki LhzNo ratings yet

- NutsDocument8 pagesNutsGerry Dan ChanliongcoNo ratings yet

- HD 2250Document47 pagesHD 2250- Emslie100% (1)

- Swivel Interface - CD420160Document1 pageSwivel Interface - CD420160ralphNo ratings yet

- ABEM Terrameter LS-2PDocument2 pagesABEM Terrameter LS-2PPromise NyamhuteNo ratings yet

- Shot Blasting Machine GA DrawingDocument1 pageShot Blasting Machine GA DrawingToniNo ratings yet

- F40 61 ESE 4x3x13FM Electric SubmittalDocument1 pageF40 61 ESE 4x3x13FM Electric Submittalwili_ab8040No ratings yet

- Instalacion Bombas de Presion CatDocument2 pagesInstalacion Bombas de Presion CatTito Zenon100% (1)

- Empaquetaduras Bombas Triplex.Document40 pagesEmpaquetaduras Bombas Triplex.pabloasotoNo ratings yet

- SSV Control System SHUT DOWN VALVEDocument12 pagesSSV Control System SHUT DOWN VALVEglobal3tNo ratings yet

- Man TC 032 PDFDocument10 pagesMan TC 032 PDFVendro MunajadNo ratings yet

- Bearing-Conn Rod Kit PDFDocument1 pageBearing-Conn Rod Kit PDFKapil TiwariNo ratings yet

- Series 5100Document12 pagesSeries 5100HectorMaldonadoNo ratings yet

- Eaton AirflexDocument12 pagesEaton AirflexagusNo ratings yet

- GD Qf450sb FeDocument11 pagesGD Qf450sb FeCesar MoraNo ratings yet

- 1847 A Duplex Piston Pump Mud PumpDocument2 pages1847 A Duplex Piston Pump Mud PumpÆmanuel J SilvaNo ratings yet

- TubingDocument12 pagesTubingJose Marval RodriguezNo ratings yet

- Portals 0 Product Catalog Section 4.1 W9500Document3 pagesPortals 0 Product Catalog Section 4.1 W9500Roberto EsparzaNo ratings yet

- "Sewage-Waste": 600 SeriesDocument4 pages"Sewage-Waste": 600 Series2009tamerNo ratings yet

- Zoeller M267Document2 pagesZoeller M267123john123No ratings yet

- Check List 2022Document2 pagesCheck List 2022miguel mendozaNo ratings yet

- Minster PM4 FullDocument14 pagesMinster PM4 Fullmiguel mendozaNo ratings yet

- Ilide - Info Roscas BSPT PRDocument2 pagesIlide - Info Roscas BSPT PRmiguel mendozaNo ratings yet

- API 570 Exam Publications Effectivity Sheet: June 2021 and October 2021Document1 pageAPI 570 Exam Publications Effectivity Sheet: June 2021 and October 2021pmkarNo ratings yet

- Sterett VersaLift 25 35Document2 pagesSterett VersaLift 25 35miguel mendozaNo ratings yet

- Single Geared, Twin Drive Specifications & Dimensions: All Dimension in InchesDocument2 pagesSingle Geared, Twin Drive Specifications & Dimensions: All Dimension in Inchesmiguel mendozaNo ratings yet

- API Standards For Pipe Inspections PDFDocument38 pagesAPI Standards For Pipe Inspections PDFajayghosh3140100% (8)

- Minster PM4 FullDocument14 pagesMinster PM4 Fullmiguel mendozaNo ratings yet

- Minster P2-150-60 150-Ton Straight Side Press w/Feed & StraightenerDocument2 pagesMinster P2-150-60 150-Ton Straight Side Press w/Feed & Straightenermiguel mendoza0% (1)

- Minster PM3 FullDocument10 pagesMinster PM3 Fullmiguel mendozaNo ratings yet

- Minster PM3 FullDocument10 pagesMinster PM3 Fullmiguel mendozaNo ratings yet

- Minster P2-150-60 150-Ton Straight Side Press w/Feed & StraightenerDocument2 pagesMinster P2-150-60 150-Ton Straight Side Press w/Feed & Straightenermiguel mendoza0% (1)

- Innovations in Drill Stem Safety Valve TechnologyDocument22 pagesInnovations in Drill Stem Safety Valve Technologymiguel mendoza0% (1)

- HPV ConfigurationDocument13 pagesHPV Configurationmiguel mendozaNo ratings yet

- Townsend CatalogDocument88 pagesTownsend CatalogVictor89% (9)

- GW Cup-Type Packers Tubing Casing PackingDocument2 pagesGW Cup-Type Packers Tubing Casing Packingmiguel mendozaNo ratings yet

- API 570 Exam Publications Effectivity Sheet: June 2021 and October 2021Document1 pageAPI 570 Exam Publications Effectivity Sheet: June 2021 and October 2021pmkarNo ratings yet

- Product Catalog: Guiberson Quality Products and ServicesDocument63 pagesProduct Catalog: Guiberson Quality Products and ServicesTitanBOPNo ratings yet

- TPWSD Catalog 2010Document36 pagesTPWSD Catalog 2010miguel mendozaNo ratings yet

- GuibersonCatalog PDFDocument66 pagesGuibersonCatalog PDFtictacal100% (2)

- Swivel Rope Socket Assembly Parts GuideDocument1 pageSwivel Rope Socket Assembly Parts Guidemiguel mendoza100% (1)

- Bab 2 - LPGDocument175 pagesBab 2 - LPGSatria KenariNo ratings yet

- Nozzle Stiffness and Stress Computation Using A Parametrically Controlled Finite Element Modeling ApproachDocument4 pagesNozzle Stiffness and Stress Computation Using A Parametrically Controlled Finite Element Modeling ApproachkysucoNo ratings yet

- Lab ReportDocument3 pagesLab ReportmahiraNo ratings yet

- Bhel VisDocument11 pagesBhel VissanjeevchhabraNo ratings yet

- Rupture Disc Main PDFDocument4 pagesRupture Disc Main PDFdumpuuNo ratings yet

- (Gulf) Piping Stress Handbook - Part.1 (V.helguero - 2nd - 1986)Document207 pages(Gulf) Piping Stress Handbook - Part.1 (V.helguero - 2nd - 1986)bakkali_bilalNo ratings yet

- Inspection Pressure Vessels Heads PDFDocument4 pagesInspection Pressure Vessels Heads PDFKarthikeyan GanesanNo ratings yet

- Mechanical Engineering For Static and Rotating Equipment: The Delegates Will CoverDocument4 pagesMechanical Engineering For Static and Rotating Equipment: The Delegates Will CoverRashedNo ratings yet

- ASME Training CoursesDocument6 pagesASME Training Coursesmalperg100% (2)

- Milestones in Pressure Vessel TechnologyDocument30 pagesMilestones in Pressure Vessel TechnologyNuri KelNo ratings yet

- Api 653Document1 pageApi 653Mahesh KumarNo ratings yet

- Mechanical Engineering Tools, Manufacturing Tools, Design and Manufacturing Calculators Design Reference, GD&T Training Resources - Engineers EdgeDocument6 pagesMechanical Engineering Tools, Manufacturing Tools, Design and Manufacturing Calculators Design Reference, GD&T Training Resources - Engineers Edgejohn reyesNo ratings yet

- Diaphragm Accumulators: 1. DescriptionDocument8 pagesDiaphragm Accumulators: 1. DescriptionDAHMOUCHE Fatma ZohraNo ratings yet

- Serious Bodily Injury and Dangerous Occurrences in Mines, Quarries, Forestry and AgricultureDocument24 pagesSerious Bodily Injury and Dangerous Occurrences in Mines, Quarries, Forestry and AgricultureSalihah AbdullahNo ratings yet

- Mechanical Code ComplianceDocument16 pagesMechanical Code ComplianceNemoNo ratings yet

- Final Exam With AnswersDocument7 pagesFinal Exam With AnswersHatem RagabNo ratings yet

- Pressure Vessel 1Document66 pagesPressure Vessel 1gst ajahNo ratings yet

- Notes in Machine Design: Insert The Title of Your Presentation HereDocument221 pagesNotes in Machine Design: Insert The Title of Your Presentation HerePatrick MarcaidaNo ratings yet

- Asme Code Elliptical Handholes ManwaysDocument4 pagesAsme Code Elliptical Handholes Manwayssamil68No ratings yet

- HI - 962 Centrifugal & PDFDocument46 pagesHI - 962 Centrifugal & PDFFernando RangelNo ratings yet

- E2G Training Catalog 2023Document40 pagesE2G Training Catalog 2023kapsarcNo ratings yet

- JKKP PMTDocument14 pagesJKKP PMTarepNo ratings yet

- TWI CSWIP 3.1 Welding InspectorDocument81 pagesTWI CSWIP 3.1 Welding Inspectormahmoeng100% (2)

- DFFDocument25 pagesDFFcsolanki6586No ratings yet

- Cped: Take-Home Activity: General InstructionsDocument1 pageCped: Take-Home Activity: General InstructionsOnyx XynoNo ratings yet

- B09 - BGS-MU-006 RevB7Document45 pagesB09 - BGS-MU-006 RevB7Gaurav BedseNo ratings yet

- TCE Consulting Engineers Process Data Sheet for Ammonia Storage and Compression VesselsDocument59 pagesTCE Consulting Engineers Process Data Sheet for Ammonia Storage and Compression Vesselsrotatic_engineerNo ratings yet

- Onshore Pipe Traps for Hydrocarbon TransportationDocument30 pagesOnshore Pipe Traps for Hydrocarbon TransportationamerNo ratings yet

- Process Equipment Cost EstimationDocument80 pagesProcess Equipment Cost EstimationKSSri100% (3)

- Pressure Vessel Repair ProcedureDocument7 pagesPressure Vessel Repair ProcedureAndy UgohNo ratings yet