Professional Documents

Culture Documents

Steelgrid Technical Paper Rock Soil Slope Protection

Uploaded by

Gema FajriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steelgrid Technical Paper Rock Soil Slope Protection

Uploaded by

Gema FajriCopyright:

Available Formats

SlopeStability2013P.M.

Dight(ed)

2013AustralianCentreforGeomechanics,Perth,ISBN9780987093752

Rock and soil slope protection using a high stiffness

geocomposite mesh system

D.CheerMaccaferriS.p.a.,Italy

G.GiacchettiAlpigeo,Italy

Abstract

One of the most common solutions adopted for the protection of vulnerable soil and rock slopes is wire

mesh,retainedbyasystemofanchorsandropes.Differenttypesofmeshesareavailablefromanumberof

manufacturersaroundtheworld.HexagonalDoubleTwisttypemesheshavebeenusedverysuccessfullyin

civil and geotechnical engineering projects for over 60 years but in the last 10 years many alternative

meshes have been brought into the market place. This can sometimes leave designers and contractors

struggling to choose the most suitable mesh for their project or having to install two different meshes

togetherinordertotakeadvantageofspecificdesirablebenefits,uniquetoeach.

Recently a revolutionary geocomposite mesh Steelgrid HR, has been developed, which is able to offer a

rangeofadvantageousmechanicalandpracticalbenefitscombinedwiththeconvenienceofasinglemesh.

Steelgrid HR is supplied as a complete mesh kit or system with tried and tested installation fittings to

enable the contractor, designer and client to benefit from the unique capabilities of the mesh while

overcominganyconceptualambiguityregardingsystemimplementation.Thesystemisavailablewithtwo

different corrosion protection specifications to suit a variety of different project sites from near marine

environmentstohighalpinecontinentalareas.

SteelgridHRhasbeensubjectedtorigoroustestingconductedbyanumberofhighlyrespectedindependent

testinstitutions;includingtestingtothenewUNI11347standard:TestsonMeshesforSlopeCoverage.This

testinghasallowedtheSteelgridHRsystemtogainboththeEuropeanTechnicalApproval(ETA)andtheCE

mark.ThetestdatahasbeenincorporatedintotheuniqueandrecentlyrevisedMacROsoftwarepackage

thatenablesengineeringprofessionalstocalculatetheperformanceofSteelgridHRunderavarietyofslope

stabilityconditions.

This paper will review existing meshes and full scale testing performed to date, provide design and

installationguidance,examinethetestsperformedonSteelgridHRmeshandmeshkitcomponentsandwill

alsolookintothedetailsoftherevisedlimitstatesapproachversionoftheMacROsoftwarepackage.

Introduction

Rock and soil slopes around the world are often found to exhibit instability. Additionally, the stability of

bothengineeredandnaturalslopescanchangeovertime.Rockslopeinstabilityisfrequentlycharacterised

bybulgingormovementofthematerialformingthefaceoftheslopeandthisleadstothelossofmaterial

fromthefacetypicallyintheformofarockfall(Giacchettietal.,2005).Causescanberelatedtointernal

factors concerning the rock mass; external factors concerning the rock mass; the local environmental

conditions including surface/groundwater water, drainage, vegetation and weathering; anthropogenic

factorsandseismicactivity(HigginsandAndrew,2012).

Thestabilityofsoilslopescanrequireaugmentationwhichcanbeachievedthroughtheuseofengineering

products.Soilslopesmayoftencontainlargerockswhichcanweatherfreefromtheslopeandrepresenta

rockfall hazard to the area below. It is therefore not uncommon to see soil slope drapery for rockfall

protectionpurposes.Soilnailingisacommonmethodology(BS80062,2011),usedtoartificiallyincrease

theslopeangleofanengineeredslope.Insoilnailingprojectsgeotechnicalmeshproducts,usedasflexible

SlopeStability2013,Brisbane,Australia

Rockandsoilslopeprotectionusingahighstiffnessgeocompositemeshsystem

D.CheerandG.Giacchetti

facings,workincooperationwiththesoilnailsinordertoprovidetherequiredsupporttothesurficialsoil

layerthatisdifficulttostabiliseusingonlythenails(Giacchettietal.,2010).

Figure 1

Rockfall protection offered to a road from a 90 m high unstable section of slope by Simple Drapery

installation of Steelgrid HR mesh in Tbilisi, Georgia

Whererockfallsoccurtheycanposearisktopeopleandinfrastructure(Figure1)andthetaskthenfallsto

engineering professionals to mitigate the identified risks (Hoek, 2000; Pierson, 2012) through the use of

carefully selected (Pierson and Vierling, 2012) engineering products, whether mesh products, flexible

catchfences(Cantarellietal.,2008;GottardiandGovoni,2009;Berendsetal.,2011;GiacchettiandZotti,

2012),reinforcedsoilembankments(Roncoetal.,2009;Brunetetal.,2009;Simonsetal.,2010)orothers

suchasHybrid/Attenuatorsystems(Arndtetal.,2009).

For over sixty years the installation of slope covering mesh has been the primary option selected by

designersanddespitemanydevelopmentsofassociatedproductsrockfallmesh/rockfallnettingisstillone

of the most common rockfall protection installation approaches in mining and civil engineering projects

acrosstheworld.

Mesh installation typologies

Around the world; rockfall mesh products are installed in one of two general ways: (1) Simple

Drapery/UnsecuredDraperyand(2)SecuredDrapery/PinnedDrapery(BadgerandDuffy,2012).

Simple drapery installation (Giacchetti and Grimod, 2013) involves the covering of the slope using a

continuous curtain of mesh that is anchored to the crest of the slope (Figure 2) with the crest rope and

crestanchorsformingacriticalloadbearingpartoftheinstallation(Sasiharanetal.,2006).

SlopeStability2013,Brisbane,Australia

Wallcontrol

Figure 2

Simple drapery diagram showing crest line and toe line anchoring of the mesh

In simple drapery installations, the mesh may be anchored along the toe of the slope (Figure 3) or

alternativelyitmaybeweighteddownandinsomecasesitwillbeleftunsecured.Asmaterialfallsfromthe

slope face the mesh directs it down towards the toe of the slope in a controlled way. If the base of the

meshisfreethenthematerialwillfalloutontothetoeareabelowthemeshfromwhereitcanbecleared

duringmaintenanceworks(Muhunthanetal.,2005).Ifthebaseofthemeshisrestrainedthenthematerial

willaccumulateasabulgebehindthemesh.Thisloading,combinedalsowithanyotherloadsincluding

accumulationofsnowwillexertalongtermloadonthe meshandthemagnitudeofthisloadisusedto

determine the strength of mesh required. In order to prevent the debris bulge from becoming

unacceptablylargeandimpingingonactivitiesorinfrastructurebelow,astiffmeshisconsideredtobeof

highimportance(Bertoloetal.,2009)forasimpledraperyinstallation.

Figure 3

Simple drapery installation of Maccaferri double twist mesh, Rubicon Pit, Kalgoorlie

The second way to install the mesh is as a Secured Drapery/Pinned Drapery (Figure 4). In this type of

installationthemeshisfirstinstalledasforSimpleDrapery,thenthesecondary/faceanchorsareinstalled

and the mesh held back against the slope face by anchor plates, sometimes used in combination with a

networkofropesthatformaregularpatternacrosstheslopeface(Figure5).

SlopeStability2013,Brisbane,Australia

Rockandsoilslopeprotectionusingahighstiffnessgeocompositemeshsystem

D.CheerandG.Giacchetti

Figure 4

Secured drapery diagram showing the mesh anchored back against the slope face by a network of ropes

and anchorages

A designer may choose to use a secured drapery for a variety of reasons including maintenance safety

issues,availablespaceatthebaseoftheslope,irregulartopographyoftheslopeface(Figure5),etc.Inthis

typeofapplication,oneofthekeyobjectivesistocontainunstableorloosematerialinsituontheslope

andprevent/limititfrommovingfromitsoriginalposition(BadgerandDuffy,2012).Inordertoretainthe

materialinplacethemeshmustbeastiffaspossibletoexhibitthelowestpossibleoutwarddeformation

atsmallpunchingforces(seeSection4).

Figure 5

Secured drapery installation showing the mesh anchored back against the highly irregular topography of

the slope face; Valle DAosta, Italy

Wheresecureddraperyisusedonsoilslopesaspartofasoilnailingprojectthemeshinstallationwouldbe

consideredtobeasoilnailfacing(Giacchettietal.,2011).Intheseapplications,stiffnessofthemeshfacing

is again of paramount importance. The mesh facing is the primary component of the installation that is

acting to support the surface layers of the soil. As these layers begin to fail, the mesh, working together

SlopeStability2013,Brisbane,Australia

Wallcontrol

withtheanchors,actstoresistthefailure.Itisthereforeselfevidentthatameshwhich offersagreater

stabilisingeffectatlowerdisplacementastiffermeshisthereforemoreeffective(Bertoloetal.,2009)

forthisapplicationthanameshthatcanonlyofferthesamesupportatagreaterdisplacement,evenifits

ultimatestrengthishigh.

Geocomposite meshes can be engineered to offer this performance and Steelgrid HR is a good example.

The extensive use of high tensile steel wire ropes in the mesh helps it to offer excellent stiffness that is

reflectiveofthehighstiffnessofthecomponentropeswiththeirultimatestrainofaroundonly6%.

Itshouldbenotedthattheliteraturecontainstheoreticalworkrelatingtothepurportedstabilisingeffects

ofmeshesarisingfromtheirabilitytoactivelyexerta[stabilising]forceontothesurfaceofanunstable

slope,therebyaugmentingstabilityandreducingthelikelihood offailure.Littleevidence hasbeenfound

forthiseffectingeotechnicallysignificantordersofmagnitudedespiteextensivefieldandlaboratory

based analysis by Maccaferri and others (Badger and Duffy, 2012, Section 3.1, pp. 569570). It could

therefore be concluded that consideration of mesh stiffness within a passive support design is more

importantthanasupposedactivecontributionwithinanactivesupporthypothesis.

Geocomposite mesh kit

In order to answer the needs of designers who are requiring higher and higher strength meshes, at the

same time as providing for their needs of providing a high stiffness mesh, a geocomposite mesh called

SteelgridHRmeshhasbeendeveloped.

SteelgridHRisbasedonthehexagonal,doubletwistmeshtechnologybutisaccompaniedbytheinclusion

of high tensile steel wire ropes to form an extremely high strength but also high stiffness mesh. An

important and notable advantage of the inclusion of longitudinal ropes in drapery mesh was recently

stated: Their addition nearly eliminated the stress concentration on the mesh around the anchors.

(Sasiharan et al., 2006). In addition to the evident stiffness effects, the presence of the interwoven steel

wireropesimpartsanextremelyhighlevelofmechanicaldurabilityonthemeshandtheabilitytoresistthe

kind of abrasive impacts that can often result from rock falls occurring behind the simple drapery

installations used on the large slopes found in the open pit mining environment (Giacchetti and Grimod

2013).

Themeshisavailableinarangeofstrengths(Table1)toensurethatameshwithstrengthcommensurate

withloadcalculationsarisingfromtheengineerscalculationsisalwayschosen.

Table 1

Steelgrid HR meshes and nominal ultimate tensile strength (UTS) values

SteelgridHRVariant

UltimateTensileStrength

SteelgridHR30

180kN/m

SteelgridHR50

125kN/m

SteelgridHR100

80kN/m

Thishelpstoeliminateoverspecificationofmeshproductsandgivesthedesignertheopportunitytooffer

theappropriatemeshforthemajorityofapplications.Thevariationofstrengthisachievedbycontrolling

thespacingoftheropesandalthoughthischangemodifiesthestrengthofthemeshitdoesnotnotably

changethestiffness/strainperformanceaccordingtotheEuropeanTechnicalApprovalETA:130524.

SlopeStability2013,Brisbane,Australia

Rockandsoilslopeprotectionusingahighstiffnessgeocompositemeshsystem

D.CheerandG.Giacchetti

Figure 6

Detailed views of wire and rope, with Galmac and PVC coating, as used in Steelgrid HR-PVC meshes

Corrosionprotectionisabasicrequirementofallengineeringdesignsandtomeettheeverhigherdemands

of modern engineering projects, all variants of the mesh are supplied with both wires and ropes coated

with zinc/aluminium 5% (Galmac) galvanising to Class A levels (EN102442 Table 2). For sites where

corrosionisasignificantproblem,suchasopenpitmineswheregroundwaterscanbehighaggressive,a

second type of the mesh is available that have an additional, continuous coating of PVC (Figure 6) in

additiontothezinc/aluminiumgalvanisation.TherangeofmeshesisshowninTable2:

Table 2

Full range of standard Steelgrid HR meshes

SteelgridHR

(ClassAZn/AlGalvanisedWiresandRopes)

SteelgridHRPVC

(ClassAZn/AlGalvanised+PVCWiresandRopes)

SteelgridHR30

SteelgridHR30PVC

SteelgridHR50

SteelgridHR50PVC

SteelgridHR100

SteelgridHR100PVC

Theuseofaropeenhanceddoubletwistbasedmesh(Figure7)meansthattheadvantagesofdoubletwist

typemeshareretainedinthenewmeshwhilsttakingfulladvantageofthebenefitsofwireropeproperties

(Sasiharan et al., 2006). These advantages include the ability to fit the mesh easily onto the slope, the

abilitytocut,patch,joinandrepairthemeshasrequired(aswithdoubletwistmesh)andfinallytheclassic

unravellingresistantbehaviourandretentionofstrengthintheeventofdamage.

Figure 7

Steelgrid HR30 mesh rolls, with integrally woven wires clearly visible

SlopeStability2013,Brisbane,Australia

Wallcontrol

Byvirtueofitsnature,itisnecessarytofollowcertainsimplebutspecificrules(seesection2)inorderto

installthemeshinthebestwaytoachievetheoptimumperformanceandtherebytakefulladvantageof

thepropertiesofthemesh.Tothisendthemeshissuppliedaspartofacompletekit,featuringarangeof

testedaccessoriesthatarededicatedtomakinginstallationasquick,simpleandeffectiveaspossible.

Theaccessories(Figure8)includeHRPlateanchorplatesforuseinsecureddraperyapplications,HRGrip

ropegripstoconnecttheropesoverthecrest/toeanchorropes,HRLinkconnectorstoformtheselvedge

selvedgeconnectionsandtheHRCapswhichcanbeusedwithmeshinextremelyaggressiveenvironments.

Alloftheaccessorieshavebeensubjecttoextensivetestingtoensuretheyareabletooffertheoptimum

levelofperformancewithandcompatibilitytothemesh.

Figure 8

Accessory items listed from the left: HR-Plate anchor plate, HR-Grip rope grip, HR-Link selvedge connectors

(shown in position joining two mesh panels)

The complete mesh kit enables installers to swiftly and easily install the Steelgrid HR mesh using similar

techniquesasforaninstallationofdoubletwistrockfallnettingbutwithminimalmodificationstoworking

methodstatementsandriskassessments,whichcanbeaconsiderablecost/timesavinginmanysituations.

The mesh can be installed as a simple drapery or secured drapery and in the latter case the mesh is

versatileandcanbeinstalledbeforeorafter(Figure9)theinstallationoftheslopefaceanchors;thiscanbe

aconsiderableadvantagetotheoperationalprogressoftheinstallation,especiallyontimesensitiveworks

asiscommonintheminingenvironment.Thisfeatureisalsousefulonworkscarriedoutbysmallteams,

typicalofremoteminingandinfrastructureprojects.

Figure 9

Installation of secured drapery Steelgrid HR30 kit (HR-Plate visible lower left) with mesh installed after

the completion of anchoring operations

SlopeStability2013,Brisbane,Australia

Rockandsoilslopeprotectionusingahighstiffnessgeocompositemeshsystem

D.CheerandG.Giacchetti

Mesh testing

Allofthemesheshavebeensubjecttoarangeoftestscarriedoutbyanumberofhighlyrespectedthird

partytechnicaltestingbodies.Thestandardrangeoftestshavebeenperformedinaccordancewiththe

new standard UNI 11437 (2012), including large sample tensile tests (Figure 10) and a new standardised

punchtestperformedon9m2samples(Figure11)usingabespoketestapparatus.Inaddition,arangeof

industrystandard(nonharmonised)testshavealsobeencarriedoutaccordingtotherelevantprotocols.

Figure 10 Computerised tensile testing on sample of Steelgrid HR30 according to UNI 11437 (2012) a particularly

severe form of testing due to the lack of lateral mesh restraints

Figure 11 Computerised punch testing of Steelgrid HR30 sample (9 m 2) according to UNI 11437 (2012)

The testing described was performed in accordance with a European harmonised standard (UNI 11437,

2012)andtheresultsfromthistestingwerecollatedandsubmittedtoEuropeanOrganisationofTestand

Approval (EOTA). Assessment in accordance with the relevant processes has resulted in the kit

(mesh+accessorycomponents)beingawardedtheprestigiousETA.

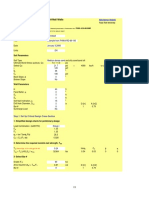

Table 3

Sample performance values for Steelgrid HR30

MeshType

Ultimate

Strength

Ultimate

Strain

PunchingDisplacement

at15kN

UltimatePunching

Strain

SteelgridHR30

180kN/m

6%

245mm(9m2sample)

400mm(9m2sample)

SlopeStability2013,Brisbane,Australia

Wallcontrol

Another significant benefit of the EOTA approved testing process is that the results can be directly

incorporated into the performance databases used by Maccaferris inhouse software package MacRO

Studio,whichisbaseduponobservationsmadeduringinnovative,inhousesiteanaloguetests(Bertoloet

al.,2009),howeverthenewdatawillhavetheadvantagethattheyarederivedfromcommon,harmonised

standards making comparison of meshes according to mechanical desirable properties a much easier

processforengineers.

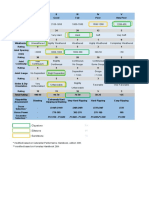

MacRO Studioissplitintothreesections,eachof whichisusedtodesignasuitablemeshforadifferent

typeofinstallation:MacRO1,MacRO2andBIOS.

MacRO1(Figure12)isbasedonthedesignofsecureddraperyforrockfaces(GiacchettiandBertolo,2010).

It assumes the cooperative function of mesh and anchors. The new limit state approach (Brunet and

Giacchetti, 2012) allows the user to input geotechnical and geometric data, choose mesh from a menu,

configure the anchor layout and properties and then select sitespecific partial factors (with guidance on

values from UNI EN 112114, 2012) before performing a verification check on the capacity of the

anchorages,andmesh.

Figure 12 Screen shot of MacRO1 (secured drapery) section of Maccaferris MacRO Studio rockfall design software

package

TheMacRO2(Figure13)sectionofMacROStudioisusedfortheverificationoftheperformanceofamesh

used in a simple drapery scenario (Giacchetti and Grimod, 2013). The programmes geotechnical

foundationsaretheextensiveandwellregardedworkoftheWashingtonStateDepartmentofTransport

(Muhunthanetal.,2005).Thepackagehasbeenrevisedtoincludealimitstatestyleapproachandincludes

the new ETA test data. The package now features a new catenary based calculation methodology which

allowstheusertodesignandthenverifytheperformanceofacrestropeandanchoragelayout(Sasiharan

etal.,2006)forthechosensimpledraperyinstallation.

SlopeStability2013,Brisbane,Australia

Rockandsoilslopeprotectionusingahighstiffnessgeocompositemeshsystem

D.CheerandG.Giacchetti

Figure 13 Screen shot of MacRO2 (simple drapery) section of the MacRO Studio rockfall design software package

ThefinalsectionoftheMacROStudiopackageisBIOS(Giacchettietal.,2011),designedfortheverification

oftheperformanceofameshforuseasaflexiblestructuralfacingforasoilnailedslope(Figure14).The

package checks both the ultimate limit capacity of the mesh (resistance to failure) and the serviceability

limit capacity of the mesh (resistance to low stress bulging in effect a stiffness check) for the given

geotechnicalconditions.Thepackageusespartialfactorsfromauserdefinedtableandisbaseduponthe

twopartwedgemethodingeneralaccordancewithBS8006Part2(2011).

Figure 14 Screen shot of BIOS (flexible facing for soil nailed slopes) section of the MacRO Studio rockfall design

software package

10

SlopeStability2013,Brisbane,Australia

Wallcontrol

Conclusions

ThenewSteelgridHRmeshkitformsastrongandversatileslopeprotectionsolutionthatisapplicabletoa

broadrangeofrockandsoilslopeinstabilityproblemsthatarecommonlyencounteredinboththeopenpit

miningandcivilengineeringenvironments.Thehighstrengthandhighstiffnessmeshoffersahighlevelof

performance and its geocomposite construction offers a host of functional and practical advantages that

are not possible from conventional mesh types. The mesh kit includes the geocomposite mesh, bespoke

anchorplatesandarangeofspecificallydevelopedconnectors.ThemeshhasgainedtheETAandthemesh

kitiscomplimentedbythefullyverifieddesignsoftwarepackageMacROStudiothat,usingETAderivedtest

data, allows engineering designers to calculate the performance of the Steelgrid HR meshes in three

different types of stabilisation scenario: as a simple drapery on rock slopes, as secured drapery on both

rockandsoilslopesandasastructuralsoilnailfacing.

References

Arndt, B., Ortiz, T. and Turner, A.K. (2009) Colorados FullScale Field Testing of Rockfall Attenuator Systems, Transportation

ResearchCircularEC141.TheTransportResearchBoard(TRB)oftheNationalAcademies,Washington,USA.

Badger,T.C.andDuffy,J.D.(2012)RockfallCharacterizationandControl,TheTransportResearchBoardoftheNationalAcademies,

A.K.TurnerandR.LSchuster(eds),TheNationalAcademyofSciences,USA,Chapter16,DraperySystemspp.553577.

Berends,J.,Chaychuck,D.andGiacchetti,G.(2011)Techniquesforreducingriskandincreasingsafetyfromrockfallsinopenmines

inAustralia,inProceedings22ndWorldMiningCongressandExpo,Istanbul2011,Vol.1,pp.563569.

Bertolo,P.,Oggeri,C.andPeila,D.(2009)Fullscaletestingofdrapednetsforrockfallprotection,CanadianGeotechnicalJournal,

Vol.46,pp.306317.

Brunet,G.andGiacchetti,G.(2012)DesignSoftwareforsecureddrapery,inProceedingsHighwayGeologySymposium,USA.

Brunet, G., Giacchetti, G., Bertolo, P. and Peila, D. (2009) Protection from High Energy Rockfall Impacts using Terramesh

Embankments:DesignandExperiences,inProceedings90thHighwayGeologySymposium,September2009.

BS 80062 (2011) Code of Practice for Reinforced Soils, Part 2, Soil Nail Design, viewed 16/08/2013,

http://shop.bsigroup.com/en/ProductDetail/?pid=000000000030161660.

Cantareli, G., Giani, G., Gottardi, G. and Govoni, L. (2008) Modeling Rockfall Protection Fences, Nota Tecnica, Vol. 222, Distart,

UniversitaDegliStudiDiBologna.

Giacchetti, G., Morandi, S. and Granito, A. (2005) Contributo della modellazione numerica nella progettazione della messa in

sicurezza di una grande frana in roccia: il caso scascoli (bo) (The contribution of numerical modelling in the design of

securingsystemsforalargerockslopefailureinthecaseofScascoli,Bologna).

Giacchetti,G.andBertolo,P.(2010)Approccioalcalcolodeisistemidireticonchiodiperilconsolidamentodelleparetirocciose,

GeoingegneriaAmbientaleeMineraria(Calculationapproachformeshandanchornetworks/systemsforconsolidationof

rockslopes),Vol.XLVII(1),pp.3334.

Giacchetti,G.,Grimod,A.andCheer,D.(2011)SoilNailingwithflexiblestructuralfacing:designandexperiences,inProceedings

SecondWorldLandslideForum,37October2011,Rome,Italy.

Giacchetti, G. and Zotti, I.M. (2012) Design approach for rockfall barriers, in Proceedings XI CONGEO, Congreso Nacional de

Geotecnia,CostaRica,910August2012.

Giacchetti,G.andGrimod,A.(2013)Designofsimpledraperysystemstoguiderockfallsalongtheslope,submittedtoEurock2013

www.eurock2013pwr.wroc.pl.

Grimod, A. and Giacchetti, G. (2012) New design software for rockfall simple drapery systems, in Proceedings World Mining

Congress,Istanbul.

Gottardi,G.andGovoni,L.(2009)FullscaleModellingofFallingRockProtectionBarriers,RockMechanicsandRockEngineering,

15April2009.

Higgins, J.D. and Andrew, R.D. (2012) Rockfall Characterization and Control, A.K. Turner and R.L Schuster (eds), The Transport

ResearchBoardoftheNationalAcademies,TheNationalAcademyofSciences,USA,Chapter2,RockfallTypesandCauses,

pp.2055.

Hoek, E. (2000) Practical rock engineering (course notes), viewed 15 July 2013, www.rocscience.com/hoek/practical

RockEngineering.asp.

Muhunthan,B.,Shu,S.,Sasiharan,N.,Hattamleh,O.A.,Badger,T.C.,Lowell,S.M.andDuffy,J.D.(2005)Analysisanddesignofwire

meshcablenetslopeprotectionFinalresearchreport,WashingtonStateTransportationCommissionU.S.Department

ofTransportationFederalHighwayAdministration.

Pierson,L.A.(2012)RockfallCharacterizationandControl,A.K.TurnerandR.L.Schuster(eds),TheTransportResearchBoardofthe

NationalAcademies,TheNationalAcademyofSciences,USA,Chapter3,RockfallHazardRatingSystems,pp.5671.

Pierson, L.A. and Vierling, M.P. (2012) Rockfall Characterization and Control, A.K. Turner and R.L Schuster (eds), The Transport

Research Board of the National Academies, The National Academy of Sciences, USA, Chapter 1, Mitigation Selection,

pp.319.

Ronco,C.,Oggeri,C.andPeila,D.(2009)Designofreinforcedgroundembankmentsusedforrockfallprotection,NaturalHazards

andEarthSciences,Vol.9,pp.11891199.

SlopeStability2013,Brisbane,Australia

11

Rockandsoilslopeprotectionusingahighstiffnessgeocompositemeshsystem

D.CheerandG.Giacchetti

Sasiharan,N.,Muhunthan,B.,Badger,T.C.,Shu,S.andCarradine,D.M.(2006)Numericalanalysisoftheperformanceofwiremesh

andcablenetrockfallprotectionsystems,EngineeringGeology,Vol.88,pp.121132.

Simons,M.J.,Pollak,S.andPeirone,B.(2010)DesignandconstructionofahighenergyrockfallembankmentontheTransCanada

Highway,inProceedingsofGEO2010,Calgary,Alberta.

UNIEN112114(2012)Rockfallprotectivemeasures:definitiveandexecutivedesign,

http://www.uni.com/index.php?option=com_content&view=article&id=1704:laprogettazionedelleoperedidifesadalla

cadutamassi&catid=111:generale&Itemid=546.

UNI11437(2012)OperedidifesadallacadutamassiProvesuretiperrivestimentodiVersanti,

http://www.uni.com/index.php?option=com_content&view=article&id=1564:cadutamassieretidirivestimentodei

versanti&catid=111:generale&Itemid=546.

12

SlopeStability2013,Brisbane,Australia

You might also like

- Steelgrid HR Installation Manual NZDocument28 pagesSteelgrid HR Installation Manual NZoscar rodriguezNo ratings yet

- Vsip - Info - Fhwa Design For Soil Nail Walls SLD Method 4 PDF FreeDocument5 pagesVsip - Info - Fhwa Design For Soil Nail Walls SLD Method 4 PDF FreeSri RamprasathNo ratings yet

- Design of Soil Nail HeadsDocument8 pagesDesign of Soil Nail HeadsHuy Le QuangNo ratings yet

- Stellgrid HR 30 - GeofabricsDocument2 pagesStellgrid HR 30 - GeofabricsMario CordovaNo ratings yet

- DCP ANALYSISDocument2 pagesDCP ANALYSISHendro WidagdoNo ratings yet

- Deep Excavation via Soil Nailing Saves CostsDocument19 pagesDeep Excavation via Soil Nailing Saves CostsgahsoonNo ratings yet

- Determining Situ Deformation Modulus Using A Flexible Volumetric DilatometerDocument26 pagesDetermining Situ Deformation Modulus Using A Flexible Volumetric DilatometerelenaNo ratings yet

- Stabilisation Measures for SlopesDocument30 pagesStabilisation Measures for SlopesYUK LAM WONGNo ratings yet

- Secured drapery system designDocument4 pagesSecured drapery system designanggaxkusumaNo ratings yet

- Soil Nailing - Where When and WhyDocument27 pagesSoil Nailing - Where When and WhyarshashajiNo ratings yet

- Soil Nail ManualDocument63 pagesSoil Nail ManualGnabBangNo ratings yet

- TDS STEELGRID HR SYSTEM - Rev 08 - Jun 2014Document2 pagesTDS STEELGRID HR SYSTEM - Rev 08 - Jun 2014mandeep571No ratings yet

- Soil Nailing For Stabilization of Steep Slopes NeaDocument216 pagesSoil Nailing For Stabilization of Steep Slopes NeanidhisasidharanNo ratings yet

- Bentomat Installation GuidelinesDocument16 pagesBentomat Installation GuidelinesAlessandraDaRochaFonsecaNo ratings yet

- S10-Specification For Gabion Reinforced Earth SystemDocument9 pagesS10-Specification For Gabion Reinforced Earth SystemwongtianhuiNo ratings yet

- Brosur Tensar Ground Stabilisation With Geogrid BiaxialDocument5 pagesBrosur Tensar Ground Stabilisation With Geogrid BiaxialIsparmoNo ratings yet

- International Society for Rock Mechanics: List of Members 1980From EverandInternational Society for Rock Mechanics: List of Members 1980Rating: 3.5 out of 5 stars3.5/5 (2)

- RE wall review checklistDocument21 pagesRE wall review checklistGDRPL NHAINo ratings yet

- Tunnel Full Paper Id Number 306Document10 pagesTunnel Full Paper Id Number 306Bosko SarenacNo ratings yet

- Reno MattressDocument2 pagesReno MattressnathychidazNo ratings yet

- Design Guide for Rockfall FencesDocument45 pagesDesign Guide for Rockfall FencesShawn HopperNo ratings yet

- Technical Data Sheet TECHSTRAP 2020Document1 pageTechnical Data Sheet TECHSTRAP 2020BalrajNo ratings yet

- Calculo Soil Nail FHWADocument91 pagesCalculo Soil Nail FHWAdiana cristina arias aldanaNo ratings yet

- Barton-High Pressure Pre-Grouting. TTI Sept 2004 p28-30 PART IDocument3 pagesBarton-High Pressure Pre-Grouting. TTI Sept 2004 p28-30 PART Icastille1956No ratings yet

- JRU Rock Mechanics Lab ManualDocument20 pagesJRU Rock Mechanics Lab ManualgizeaNo ratings yet

- 07-02-157 Practical Soil Nail Wall Design and Constructability IssuesDocument11 pages07-02-157 Practical Soil Nail Wall Design and Constructability Issuesben indrawanNo ratings yet

- 05 Geobag (Terra Sack)Document4 pages05 Geobag (Terra Sack)dixmitNo ratings yet

- Slide SlopeStabilityVerification PDFDocument327 pagesSlide SlopeStabilityVerification PDFSRINIVAS DNo ratings yet

- Numerical Analysis of Performance of Soil Nail Walls in Seismic ConditionsDocument10 pagesNumerical Analysis of Performance of Soil Nail Walls in Seismic ConditionsDeepthiNo ratings yet

- Specification of Soil NailingDocument11 pagesSpecification of Soil NailingdonnyNo ratings yet

- Sci - Lift Calculation - 1Document6 pagesSci - Lift Calculation - 1Simon LsmNo ratings yet

- TheStability of A Laminated Voussoir Beam PDFDocument17 pagesTheStability of A Laminated Voussoir Beam PDFDaniel SantanaNo ratings yet

- 1973 Bieniawski Engineering Classification of Jointed Rock MassesDocument9 pages1973 Bieniawski Engineering Classification of Jointed Rock MassesNicolas Pino Torres0% (1)

- Rock Bolting Techniques and ApplicationsDocument17 pagesRock Bolting Techniques and ApplicationsMarkusMakuAldoNo ratings yet

- 32-01E Deep Soil Mixing - KELLER PDFDocument8 pages32-01E Deep Soil Mixing - KELLER PDFvickneshj9406No ratings yet

- 2 Stability AnalysisDocument93 pages2 Stability AnalysisSathya Putra WijayaNo ratings yet

- Bearing Capacity2Document34 pagesBearing Capacity2Shepherd NhangaNo ratings yet

- Review of Plane Failure in Rock SlopesDocument9 pagesReview of Plane Failure in Rock Slopespggopal_85No ratings yet

- Pre-Excavation GroutingDocument7 pagesPre-Excavation GroutingDavid marpaungNo ratings yet

- Applications of Tromino (R) and SoilSpy ENG 2.0Document12 pagesApplications of Tromino (R) and SoilSpy ENG 2.0NurhadiNo ratings yet

- Deep Compaction of Granular SoilsDocument2 pagesDeep Compaction of Granular SoilslnanescuNo ratings yet

- Polimac Gabion - 0303042018 PDFDocument2 pagesPolimac Gabion - 0303042018 PDFSuntharathevan RamasamyNo ratings yet

- The Earth Pressure ProblemDocument28 pagesThe Earth Pressure ProblemAliMuhammedTekinNo ratings yet

- Weaver's Rippability Rating Chart (Weaver, 1975. Adapted From Bieniawski 1973)Document18 pagesWeaver's Rippability Rating Chart (Weaver, 1975. Adapted From Bieniawski 1973)santosoNo ratings yet

- New Steelgrid HR Rockfall NettingDocument2 pagesNew Steelgrid HR Rockfall NettingMario CordovaNo ratings yet

- As4678 Soil NailingDocument54 pagesAs4678 Soil NailingC BNo ratings yet

- Functions of GeosyntheticsDocument24 pagesFunctions of GeosyntheticsAzaz AhmedNo ratings yet

- Landslide Debris Mobility AssessmentDocument47 pagesLandslide Debris Mobility AssessmentYUK LAM WONGNo ratings yet

- Tutorial 14 Cofferdam SeepageDocument12 pagesTutorial 14 Cofferdam SeepageCarlos Eduardo TorresNo ratings yet

- 9 TBM Boreability I Hard BergmasseDocument43 pages9 TBM Boreability I Hard BergmassepabulumzengNo ratings yet

- Soil Classification SystemDocument2 pagesSoil Classification Systemchinhon0% (1)

- Retaining Walls - Failure ModesDocument8 pagesRetaining Walls - Failure ModesAbukalam MullaNo ratings yet

- RockfallDocument6 pagesRockfallkaustubhNo ratings yet

- GeoCops V1.0 PDFDocument58 pagesGeoCops V1.0 PDFAdry SarijaNo ratings yet

- Curriculum Vitae: Adrian Thabiso MogotsiDocument5 pagesCurriculum Vitae: Adrian Thabiso MogotsiDavid H. Butar ButarNo ratings yet

- Stability AnalysisDocument6 pagesStability AnalysisDaanyal UmarNo ratings yet

- Geo Textiles: Perspective From The Construction Sector: A PresentationDocument22 pagesGeo Textiles: Perspective From The Construction Sector: A PresentationChristine ReedNo ratings yet

- Danish Energy Agency - 2013 - DSEN 1990 DK NA2013 Version 2 - National Annex To Eurocode Basis of Structural DesignDocument16 pagesDanish Energy Agency - 2013 - DSEN 1990 DK NA2013 Version 2 - National Annex To Eurocode Basis of Structural DesignCenascenascenascenasNo ratings yet

- Sika - AG GroutDocument4 pagesSika - AG GroutBill MurrayNo ratings yet

- Hit Hy 70Document12 pagesHit Hy 70Rahim GhorbaniNo ratings yet

- Technical Data: HST M10, M12, M16Document5 pagesTechnical Data: HST M10, M12, M16Benjaminhuynh08No ratings yet

- 40 KL DesignDocument10 pages40 KL DesignSung Woong MoonNo ratings yet

- What Is A Flexural Modulus - Definition From CorrosionpediaDocument5 pagesWhat Is A Flexural Modulus - Definition From Corrosionpediamaterial manNo ratings yet

- Modern Shaft CalculationDocument8 pagesModern Shaft CalculationNajaf HussainNo ratings yet

- En 13445 Background To The Rules in Part 3 Design (2004)Document87 pagesEn 13445 Background To The Rules in Part 3 Design (2004)David CubillosNo ratings yet

- Steel Frame Design Manual: Italian NTC 2008Document99 pagesSteel Frame Design Manual: Italian NTC 2008Angel VargasNo ratings yet

- RC-SEODocument200 pagesRC-SEOMeverlyn RoqueroNo ratings yet

- Fatigue Failure Theories ExplainedDocument32 pagesFatigue Failure Theories Explainedlth770310No ratings yet

- Lab Manual 2019Document44 pagesLab Manual 2019se ruNo ratings yet

- B 6a Aircraft Materials and Corrosion SRDocument156 pagesB 6a Aircraft Materials and Corrosion SRSumit SamanyaNo ratings yet

- Analysis Report Tensile Canopy - HOCKEY STADIUM - R0 - ADocument23 pagesAnalysis Report Tensile Canopy - HOCKEY STADIUM - R0 - ANeeraj KumarNo ratings yet

- How Mechanics is Relevant to Electrical EngineeringDocument3 pagesHow Mechanics is Relevant to Electrical EngineeringJerome EstradaNo ratings yet

- Homework 6 Solutions: (4 Points)Document7 pagesHomework 6 Solutions: (4 Points)Arthur DingNo ratings yet

- MOC - Ullmann'sDocument48 pagesMOC - Ullmann'sacer_asdNo ratings yet

- Astm D2837 (2001)Document14 pagesAstm D2837 (2001)Muzammil Khalil100% (3)

- Flexible Pavement Design - AashtoDocument17 pagesFlexible Pavement Design - AashtoFarhanah Binti Faisal0% (1)

- Journal of Building Engineering: Jian Li, Feng Li, Caiwei Liu, Jijun MiaoDocument13 pagesJournal of Building Engineering: Jian Li, Feng Li, Caiwei Liu, Jijun MiaoSeban ACNo ratings yet

- Download Cold Formed Steel Design Fifth Edition Chen full chapterDocument67 pagesDownload Cold Formed Steel Design Fifth Edition Chen full chapterjose.marshall190100% (5)

- Monolux®-500 & - 800 - Technical Data Sheet - EnglishDocument2 pagesMonolux®-500 & - 800 - Technical Data Sheet - EnglishcocoNo ratings yet

- 171129-Army Technical Manual Tm5 856 3 - TextDocument158 pages171129-Army Technical Manual Tm5 856 3 - Textvivek100% (1)

- EC2 Beam DesignDocument4 pagesEC2 Beam Designikanyu79No ratings yet

- New Composite Material Low Cost Underground Water Tanks 2006Document11 pagesNew Composite Material Low Cost Underground Water Tanks 2006CoevicNo ratings yet

- EGR 2206-Mechanical PropertiesDocument25 pagesEGR 2206-Mechanical PropertiesSolomonNo ratings yet

- Aws Cross Tensile TestDocument8 pagesAws Cross Tensile TestDhandapani MetallionNo ratings yet

- CH1 Casing2Document90 pagesCH1 Casing2Muhammad Amirullah SanadiNo ratings yet

- Determining The Redundancy FactorDocument6 pagesDetermining The Redundancy FactorEdris Salehi GolsefidiNo ratings yet