Professional Documents

Culture Documents

1570 (Part II Sec I) Revised - Wrought Steeks For Plates

Uploaded by

Kaushik SenguptaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1570 (Part II Sec I) Revised - Wrought Steeks For Plates

Uploaded by

Kaushik SenguptaCopyright:

Available Formats

IS : 1570 (Part 2/Sec 1) - 1979

(Reaffirmed 2004)

Edition 2.1

(1989-12)

Indian Standard

SCHEDULES FOR WROUGHT STEELS

PART 2

CARBON STEELS (UNALLOYED STEELS)

Section 1 Wrought Products (Other Than Wires) With

Specified Chemical Composition and Related Properties

( First Revision )

(Incorporating Amendment No. 1)

UDC

669.14 (083.4)

BIS 2005

BUREAU

OF

INDIAN

STANDARDS

MANAK BHAVAN , 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

Price Group 5

IS : 1570 (Part 2/Sec 1) - 1979

Indian Standard

SCHEDULES FOR WROUGHT STEELS

PART 2

CARBON STEELS (UNALLOYED STEELS)

Section 1 Wrought Products (Other Than Wires) With

Specified Chemical Composition and Related Properties

( First Revision )

Alloy Steels and Special Steels Sectional Committee, SMDC 19

Chairman

DR G. MUKHERJEE

Representing

Steel Authority of India Ltd (Alloy Steels Plant),

Durgapur

Members

Guest, Keen, Williams Ltd, Howrah

SHRI A. N. BISWAS

SHRI S. K. BASU ( Alternate )

SHRI B. C. BISWAS

National Test House, Calcutta

SHRI A. M. BISWAS ( Alternate )

SHRI P. K. CHAKRAVARTY

The Tata Iron & Steel Co Ltd, Jamshedpur

DR T. MUKHERJEE ( Alternate )

Ministry of Defence (DGI)

SHRI P. K. CHATTERJEE

SHRI P. K. GANGOPADHYAY ( Alternate )

SHRI K. M. CHAUDHURY

National

Metallurgical

Laboratory

(CSIR),

Jamshedpur

The Visvesvaraya Iron & Steel Ltd, Bhadravati

SHRI DASARATHA

SHRI B. C. BASAVARAJ ( Alternate )

SHRI S. V. DATAR

Ahmedabad Advance Mills Ltd, Navsari

SHRI M. K. GHOSH ( Alternate )

SHRI A. D. DIAS

The Indian Tool Manufacturers Ltd, Bombay

SHRI M. K. DATTA

Steel Authority of India Ltd (Alloy Steels Plant),

Durgapur

SHRI R. C. JHA ( Alternate )

SHRI S. B. GUPTA

Directorate General of Supplies & Disposals

(Inspection Wing), New Delhi

SHRI P. K. GYNE ( Alternate )

JOINT DIRECTOR (MET) RESEARCH Ministry of Railways

DESIGNS AND S T A N D A R D S

ORGANIZATION

DEPUTY DIRECTOR (MET-II),

RDSO ( Alternate )

( Continued on page 2 )

BIS 2005

BUREAU OF INDIAN STANDARDS

This publication is protected under the Indian Copyright Act (XIV of 1957) and

reproduction in whole or in part by any means except with written permission of the

publisher shall be deemed to be an infringement of copyright under the said Act.

IS : 1570 (Part 2/Sec 1) - 1979

( Continued from page 1 )

Members

Representing

SHRI S. R. KHARE

Indian Register of Shipping, Bombay

SHRI V. N. PANDAY ( Alternate )

Bharat Forge Co Ltd, Mundhwa, Pune

SHRI R. S. KOTHAWALE

SHRI S. S. LAKKUNDI ( Alternate )

Ministry of Defence (R & D)

DR D. P. LAHIRI

SHRI I. N. BHATIA ( Alternate )

Heavy Engineering Corporation Ltd, Ranchi

SHRI K. N. MEHRA

SHRI D. K. DAS ( Alternate )

Directorate General of Technical Development,

SHRI L. MISHRA

New Delhi

SHRI M. K. BANERJEE ( Alternate )

Ashok Leyland Ltd, Madras

SHRI A. PADMANABHAN

Firth India Steel Co Ltd, Thane

SHRI I. M. PAI

SHRI B. M. PAI ( Alternate )

Mahindra Ugine Steel Co Ltd, Bombay; and Alloy

DR R. V. PATHY

Steel Producers Association of India, Bombay

SHRI R. NARAYANA ( Alternate )Mahindra Ugine Steel Co Ltd, Bombay

Iron & Steel Control, Calcutta

SHRI M. K. PRAMANIK

SHRI S. S. SAHA ( Alternate )

Research & Development Centre for Iron and Steel

DR V. RAMASWAMY

(HSL), Ranchi

SHRI S. R. MEDIRATTA ( Alternate )

Hindustan Machine Tools Ltd, Bangalore

SHRI M. RANGASHAI

SHRI SANJIT SEN ( Alternate I )

SHRI P. RAMA PRASAD ( Alternate II )

The Tata Engineering and Locomotive Co Ltd,

SHRI A. K. ROY

Jamshedpur

DR S. K. MONDAL ( Alternate )

Steel Furnace Association of India, Calcutta

SHRI D. SRINIVASAN

DR S. K. CHATTERJEE ( Alternate )

Ministry of Defence (DGOF)

SHRI Y. C. SUBRAHMANYA

M. N. Dastur & Co Pvt Ltd, Calcutta

SHRI K. S. VAIDYANATHAN

SHRI C. J. DAVE ( Alternate )

Director General, ISI ( Ex-officio Member )

SHRI C. R. RAMA RAO,

Director (Struc & Met)

Secretary

SHRI VIJAY KUMAR

Assistant Director (Metals), ISI

Subcommittee for the Revision of Schedule for Wrought Steel for

General Engineering Purposes, SMDC 19 : 5

Convener

SHRI P. K. CHAKRAVARTY

Members

SHRI S. K. BASU

SHRI P. K. CHATTERJEE

SHRI M. K. SEN ( Alternate )

The Tata Iron & Steel Co Ltd, Jamshedpur

Guest, Keen, Williams Ltd, Howarh

Ministry of Defence (DGI)

( Continued on page 18 )

IS : 1570 (Part 2/Sec 1) - 1979

Indian Standard

SCHEDULES FOR WROUGHT STEELS

PART 2

CARBON STEELS (UNALLOYED STEELS)

Section 1 Wrought Products (Other Than Wires) With

Specified Chemical Composition and Related Properties

( First Revision )

0. F O R E W O R D

0.1 This Indian Standard (Part II) (First Revision) was adopted by the

Indian Standards Institution on 5 March 1979, after the draft finalized

by the Alloy Steels and Special Steels Sectional Committee had been

approved by the Structural and Metals Division Council.

0.2 Schedules for wrought steels for general engineering purposes (IS :

1570-1961) was first published in 1961. On the basis of the experience

gained in the production and use of steels, the Sectional Committee

has decided to revise the standard and issue it in parts. The other

parts of the standard are as follows:*

Part I

Part III

Part IV

Part V

Part VI

Steels specified by tensile and/or yield properties

Carbon and carbon manganese free cutting steels

Alloy steels (excluding stainless and heat-resisting steels)

Stainless and heat-resisting steels*

Tool steels

0.3 The following major modifications have been made in this revision:

a) Steel designations have been modified in accordance with

IS : 1762 (Part I)-1974. However, for the sake of easy

identification old designations are also given within brackets.

b) New grades 2C2, 50C8, 60C6 have been added.

c) Manganese content of grades C05 (5C4), C55 (55C4), and C60

(60C4) have been modified.

d) Mechanical properties for cold-drawn bars given in Table 3 have

been modified on the basis of experience gained.

0.4 This schedule does not give limits for sulphur and phosphorus.

These have to be specified in the detailed specifications. The standard

ranges for sulphur and phosphorus and the method for designating steel

*Already published as IS : 1570 (Part V)-1972.

Code for designation of steels: Part I Based on letter symbols.

IS : 1570 (Part 2/Sec 1) - 1979

according to its sulphur and phosphorus content, steel making practice

and method of deoxidation is detailed in Appendix A for information.

0.5 This edition 2.1 incorporates Amendment No. 1 (December 1989).

Side bar indicates modification of the text as the result of

incorporation of the amendment.

0.6 For the purpose of deciding whether a particular requirement of

this standard is complied with, the final value, observed or calculated,

expressing the result of a test or analysis, shall be rounded off in

accordance with IS : 2-1960*. The number of significant places

retained in the rounded off value should be the same as that of the

specified value in this standard.

1. SCOPE

1.1 This schedule (Part II) is applicable to standards for carbon steels

when it is necessary for the steel to be supplied to a composition within

reasonably defined limits. This schedule is not intended to be used as a

standard.

1.1.1 This schedule may be used for ordering steels provided no

detailed specification is available for the particular steel.

2. GENERAL

2.1 While preparing Indian Standards, or revising existing standards,

steels listed in this schedule shall be selected. The specification of

mechanical properties different from those given in this schedule

should not be made unless special conditions of service render this

essential. In that event, full reasons for the proposed departure from

the steels specified in this schedule shall be submitted to the Alloy

Steels and Special Steels Sectional Committee, SMDC 19, and its

approval obtained.

2.2 In addition to specified mechanical properties, ranges for carbon

and manganese are, laid down in the schedule ( see Table 1 ), but as in

many cases, the steels of lower carbon content are required as

rimming, semikilled or killed steel depending on the subsequent

manipulation and conditions of service, the silicon content has not

been specified. Where necessary, the silicon content or the type of

steel, for example, killed, semi-killed, etc, should be included in the

standard. Since different levels of sulphur and phosphorus are

required according to the severity of the conditions in service, limits

for these elements are also not included in the schedule but should be

specified in a specification at levels appropriate to the method of steel

production, conditions of service, etc.

*Rules for rounding off numerical values ( revised ).

IS : 1570 (Part 2/Sec 1) - 1979

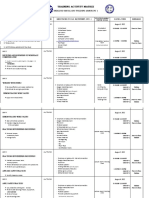

TABLE 1

SPECIFIED CARBON AND MANGANESE LIMITS FOR THE

STANDARD STEELS

( Clause 2.2 )

C

PERCENT

Mn

PERCENT

REFERENCE TO

RELEVANT

INDIAN STANDARD

STEEL DESIGNATION

[ see IS : 1762 (Part I)-1974 ]

New

(1)

Old

(2)

(3)

(4)

(5)

2C2

4C2

5C4

7C4

10C4

14C6

()

(C04)

(C05)

(C07)

(C10)

(C14)

0.05 Max

0.08 Max

0.10 Max

0.12 Max

0.15 Max

0.10-0.18

0.40 Max

0.40 Max

0.50 Max

0.50 Max

0.30-0.60

0.40-0.70

15C4

15C8

(C15)

(C15Mn75)

0.20 Max

0.10-0.20

0.30-0.60

0.60-0.90

20C8

25C4

25C8

(C20)

(C25)

(C25Mn75)

0.15-0.25

0.20-0.30

0.20-0.30

0.60-0.90

0.30-0.60

0.60-0.90

30C8

(C30)

0.25-0.35

0.60-0.90

35C4

35C8

(C35)

(C35Mn75)

0.30-0.40

0.30-0.40

0.30-0.60

0.60-0.90

40C8

45C8

(C40)

(C45)

0.35-0.45

0.40-0.50

0.60-0.90

0.60-0.90

50C4

50C8

50C12

55C4

(C50)

()

(C50Mn1)

(C55)

0.45-0.55

0.45-0.55

0.45-0.55

0.50-0.60

0.30-0.60

0.60-0.90

1.10-1.40

0.30-0.60

55C8

(C55Mn75)

0.50-0.60

0.60-0.90

60C4

60C6

65C6

(C60)

()

(C65)

0.55-0.65

0.55-0.65

0.60-0.70

0.30-0.60

0.50-0.80

0.50-0.80

70C6

75C6

80C6

85C6

98C6

113C6

(C70)

(C75)

(C80)

(C85)

(C98)

(C113)

0.65-0.75

0.70-0.80

0.75-0.85

0.80-0.90

0.90-1.05

1.05-1.20

0.50-0.80

0.50-0.80

0.50-0.80

0.50-0.80

0.50-0.80

0.50-0.80

IS : 4882, 4397

IS : 1812, 2879, 4432

IS : 1875, 2004, 4432,

5489

IS : 1812

IS : 2100, 6967, 1875,

2004, 4432

IS : 1875, 2004

IS : 1875, 2004, 3930,

5517, 6967

IS : 1875, 2004, 3930,

5517, 6967

IS : 1875, 2004, 3930,

5517

IS : 5517, 7226, 7283

IS : 1875, 2004, 2507,

3930, 3261, 5517

IS : 5517

IS : 2507, 3885, 3930

7226, 8054, 8055

IS : 1875, 3445, 5517,

7494

IS : 1875, 2004, 2507

4072

IS : 2507, 4072, 7226

IS : 2507, 3885

IS : 2507, 4072

IS : 2507, 7226

IS : 2507, 3195, 7226

IS : 3195

IS : 1570 (Part 2/Sec 1) - 1979

2.3 This schedule includes specified tensile properties applicable to the

different conditions, for example, Table 2 gives values for the hot-rolled

or normalized conditions. These values are based on ruling sections up

to 150 mm and for larger sizes some adjustment of the specified tensile

range for a particular range of composition, or conversely, of the

specified composition for a particular range of tensile strength, may be

necessary. Mechanical properties for cold-drawn bars and for hardened

and tempered bars and forgings, together with the sizes to which these

properties are applicable are given in Tables 3 and 4. Table 5 gives the

properties for case-hardening steels, that is, the properties obtainable

in the core of case-hardened parts after refining and quenching. Some

of the steels are used in the form of sheet and strip and tubes and the

tensile properties of these are given in Tables 6, 7 and 8. For some

purposes, a minimum yield stress is regarded as specification

requirement and minimum yield stress values are, therefore, given for

some of the physical conditions for inclusion in specifications, if

required. Information on the assessment of the ruling section of bars,

forgings and parts is given in Tables 9 and 10.

2.4 In addition, values for the specified minimum percentage

elongation corresponding to the specified tensile ranges are included.

Different types of test pieces are used for the tensile test depending on

the form of the material; for example, flat test pieces for thin plates,

sections and flat bars; unmachined round test pieces for small size

round bars; and machined round test pieces for thicker plates, for

larger size round bars and for square bars, and forgings. Since the

percentage elongation depends on the relation between the gauge

length and the cross-sectional area of the test piece, specified minimum

values for the percentage elongation for the different types of test

pieces are included in the schedule. These elongation values given are

based on a gauge length of 5.65 A which is now internationally

accepted. If test pieces of other than 5.65 A gauge length are used,

elongation conversion may be obtained from IS : 3803-1974*.

2.5 For tensile tests on tubes, the specified percentage elongation

should be based on the recently adopted formulae of either 950 divided

by the actual tensile strength in kgf/mm2 when using a gauge length

equivalent to 5.65 A or of 1 100 divided by the actual tensile

strength in kgf/mm2 when using a gauge length equivalent to 4 A .

2.6 The notch toughness of steels after hardening and tempering is

sometimes assessed by an impact test and values for incorporation in

specifications; if required, are given in the relevant tables of the

schedule.

*Method for elongation conversions for steel ( first revision ).

IS : 1570 (Part 2/Sec 1) - 1979

TABLE 2 SPECIFIED TENSILE LIMITS FOR PLATES, SECTIONS, BARS,

BILLETS AND FORGINGS IN THE HOT-ROLLED OR NORMALIZED

CONDITION

( Clause 2.3 )

DESIGNATION

New

Old

(1)

(2)

TENSILE

STRENGTH

ELONGATION PERCENT, Min

(3)

(4)

MPa*

7C4

(C07)

320-400

27

10C4

(C10)

340-420

26

14C6

(C14)

370-450

26

15C4

(C15)

370-490

25

15C8

(C15Mn75)

420-500

25

20C8

(C20)

440-520

24

25C4

(C25)

440-540

23

25C8

(C25Mn75)

470-570

22

30C8

(C30)

500-600

21

35C4

(C35)

520-620

20

35C8

(C35Mn75)

550-650

20

40C8

(C40)

580-680

18

45C8

(C45)

630-710

15

50C4

(C50)

660-780

13

50C13

(C50Mn1)

720 Min

11

55C8

(C55Mn75)

720 Min

13

60C4

(C60)

750 Min

11

65C6

(C65)

750 Min

10

NOTE Minimum values for the yield stress may be required in certain

specifications and in such cases a minimum yield stress of 55 percent of the

minimum tensile strength should be satisfactory.

*1MPa = 1N/mm2 = 0.102 0 kgf/mm2.

2.7 The specified mechanical properties are applicable to test samples

taken from a standard location which should be included in the

specification.

2.8 Any tests, for example, bend test, flattening tests on tube, etc,

additional to the tests given in this schedule should also be specified in

the standard as appropriate.

7

SPECIFIED TENSILE LIMITS FOR COLD-DRAWN BARS

UP TO 20 mm

(1)

(2)

OVER 40 mm

UP TO 63 mm

OVER 63 mm

Tensile

Elongation

Tensile

Elongation

Elongation

Tensile

Elongation Strength Percent, Min

Strength Percent, Min Tensile

Strength Percent, Min Strength Percent, Min

Min

Min

Min

Min

(3)

(4)

MPa*

(5)

(6)

MPa*

Old

New

OVER 20 mm

UP TO 40 mm

DESIGNATION

[ Clauses 0.3 (d) and 2.3 ]

(7)

(8)

MPa*

(9)

(10)

MPa*

10C4

(C10)

490

11

450

13

410

15

360

18

15C8

(C15Mn75)

540

11

510

13

470

15

430

18

20C8

(C20)

540

10

510

12

470

15

430

18

30C8

(C30)

610

570

10

530

12

490

15

40C8

(C40)

640

610

570

10

540

12

50C4

(C40)

670

630

610

590

10

55C8

(C55Mn75)

730

690

670

630

10

*1MPa = 1N/mm2 = 0.102 0 kgf/mm2.

IS : 1570 (Part 2/Sec 1) - 1979

TABLE 3

IS : 1570 (Part 2/Sec 1) - 1979

TABLE 4 SPECIFIED MECHANICAL PROPERTIES FOR BARS AND

FORGINGS IN THE HARDENED AND TEMPERED CONDITION

( Clause 2.3 )

DESIGNATION

New

Old

(1)

(2)

30C8

35C8

40C8

45C8

50C4

55C8

TENSILE

STRENGTH

YIELD

ELONGATION,

STRESS

PERCENT,

Min

Min

(IF SPECIFIED)

(3)

(4)

MPa*

MPa*

(C30)

(C35Mn75)

600-750

600-750

400

400

(C45)

(C50)

(C55Mn75)

600-750

700-850

(C40)

IZOD

LIMITING

IMPACT

RULING

VALUE,

SECTION

Min

(IF SPECIFIED)

(5)

(6)

(7)

Joules

mm

18

18

55

55

30

63

380

480

18

17

41

35

100

30

600-750

700-850

380

480

17

15

41

35

100

30

700-850

800-950

460

540

15

13

63

30

700-850

800-950

460

540

15

13

63

30

*1MPa = 1N/mm2 = 0.102 0 kgf/mm2.

TABLE 5

SPECIFIED MECHANICAL PROPERTIES FOR CASE-HARDENING

STEELS IN THE REFINED AND QUENCHED CONDITION

(CORE PROPERTIES)

( Clause 2.3 )

DESIGNATION

ELONGATION,

TANSILE

STRENGTH, PERCENT, Min

Min

(3)

(4)

IZOD IMPACT

VALUE, Min

(IF SPECIFIED)

(5)

LIMITING

RULING

SECTION

(6)

Joules

mm

New

Old

(1)

(2)

10C4

(C10)

500

17

55

15

14C6

(C14)

500

17

55

Over 15

Up to 30

15C8

(C15Mn75)

500

17

55

30

20C8

(C20)

500

16

55

30

MPa*

*1MPa = 1N/mm2 = 0.102 0 kgf/mm2.

IS : 1570 (Part 2/Sec 1) - 1979

TABLE 6 SPECIFIED TENSILE LIMITS FOR MILD STEEL SHEET AND

STRIP IN THE COLD-ROLLED AND ANNEALED CONDITION

( Clause 2.3 )

DESIGNATION

ELONGATION, PERCENT,

Min, TEST PIECE,

WIDTH 12.5 mm,

GAUGE LENGTH

50 mm

(4)

Old

(1)

(2)

(3)

7C4

(C07)

300-380

28

10C4

(C10)

320-400

28

15C4

(C15)

320-440

25

390-510

25

New

TENSILE

STRENGTH

Min

MPa*

20C8

(C20)

2

*1MPa = 1N/mm = 0.102 0 kgf/mm .

TABLE 7

SPECIFIED TENSILE LIMITS FOR MILD STEEL SHEET AND

STRIP IN THE COLD-ROLLED CONDITION

( Clause 2.3 )

CONDITION

TENSILE

STRENGTH

(3)

(4)

DESIGNATION

New

Old

(1)

(2)

MPa*

15C4

(C15)

Quarter hard

Half hard

Hard

*1MPa = 1N/mm2 = 0.102 0 kgf/mm2.

10

390-470

470-570

570 Min

IS : 1570 (Part 2/Sec 1) - 1979

TABLE 8 SPECIFIED TENSILE LIMITS FOR TUBES IN THE COLD-DRAWN

AND ANNEALED CONDITION AND IN THE COLD-DRAWN ON COLD-DRAWN

AND TEMPERED CONDITION

( Clause 2.3 )

COLD-DRAWN

COLD-DRAWN OR

AND ANNEALED

COLD-DRAWN

AND TEMPERED

Tensile Yield Tensile Yield

Strength, Stress, Strength, Stress,

Min

Min

Min

Min

Old

(1)

(2)

14C6

15C4

15C8

20C8

25C4

25C8

35C4

35C8

45C8

50C12

(C14)

(C15)

(C15Mn75)

(C20)

(C25)

(C25Mn75)

(C35)

(C35Mn75)

(C45)

(C50Mn1)

New

ELONGATION PERCENT,

Min

DESIGNATION

(3)

MPa*

(4)

MPa*

(5)

MPa*

(6)

MPa*

320

170

440

38

370

220

390

250

440

280

520

340

*1MPa = 1N/mm2 = 0.102 0 kgf/mm2.

520

42

560

46

580

47

700

60

(7)

950

---------- on gauge length

TS

= 5.65 A

or

1 100

--------------- on gauge length

TS

= 4 A

TABLE 9 CONVERSION OF RECTANGULAR AND SQUARE SECTIONS

INTO EQUIVALENT RULING SECTIONS, OIL QUENCHING

( Clause 2.3 )

THICKNESS OF SECTION

WIDTH OF

SECTION

10

mm

20

mm

(3)

(1)

(2)

mm

mm

mm

10

10

20

14

21

30

16

26

40

17

29

50

17

31

60

17

32

80

17

32

100

17

33

120

17

33

140

17

33

160

17

33

180

17

33

200

17

33

225

17

33

250

17

33

300

17

33

350 and over

18

33

Greater than 160 mm.

30

40

50

60

80

100

mm

mm

mm

mm

mm

mm

DIAMETER OF EQUIVALENT ROUNDS

(4)

(5)

(6)

(7)

(8)

(9)

mm

mm

mm

mm

mm

mm

32

37

43

40

48

54

43

51

59

65

46

57

66

74

87

47

60

71

80

96

108

48

62

74

85

102

117

48

63

76

88

108

125

48

63

77

90

112

131

48

63

77

91

115

136

48

63

78

92

117

140

48

63

78

92

119

143

48

63

78

92

120

145

48

63

78

92

121

148

49

63

78

92

121

150

11

120

mm

140

mm

(10)

mm

130

140

148

154

(11)

mm

152

IS : 1570 (Part 2/Sec 1) - 1979

TABLE 10 CONVERSION OF RECTANGULAR AND SQUARE SECTIONS

INTO EQUIVALENT RULING SECTIONS, AIR COOLING

( Clause 2.3 )

(1)

mm

10

20

30

40

50

60

80

100

120

140

160

180

200

225

250

300

350 and over

THICKNESS OF SECTION

WIDTH OF

SECTION

10

mm

20

mm

(2)

mm

(3)

mm

10

13

15

16

16

17

17

17

17

17

17

18

18

18

18

18

20

20

24

27

29

30

32

33

34

34

34

35

35

35

36

37

39

30

mm

40

mm

50

mm

60

mm

80

100

mm

mm

DIAMETER OF EQUIVALENT ROUNDS

(4)

(5)

(6)

(7)

(8)

(9)

mm

mm

mm

mm

mm

mm

30

34

38

41

45

47

49

50

51

51

52

52

53

54

59

40

45

49

54

58

62

64

66

67

68

69

70

71

78

51

55

62

68

72

76

79

81

83

85

86

88

97

Greater than 160 mm.

12

61

70

76

82

86

90

93

95

98

100

104

115

81

90

98

104

109

114

117

121

125

131

152

102

111

119

126

132

137

142

147

155

120

mm

140

mm

(10)

mm

(11)

mm

122

132

140

148

154

142

152

IS : 1570 (Part 2/Sec 1) - 1979

APPENDIX A

( Clause 0.4 )

NEW SYSTEM OF DESIGNATION OF STEELS

A-1. GENERAL

A-1.1 The new system of designation of steel is based on the draft ISO

proposal submitted by India to ISO/TC 17 Steel for formulation of an

international standard. Details of the new designation system are

given in IS : 1762 (Part I)-1974*.

A-2. STEELS DESIGNATED ON THE BASIS OF CHEMICAL

COMPOSITION

A-2.1 Unalloyed Steels (as Defined in IS : 7598-1974) The code

designation shall consist of the following in the order given:

a) Figure indicating 100 times the average percentage of carbon

content,

b) Letter C, and

c) Figure indicating 10 times the average percentage of manganese

content. The figure after multiplying shall be rounded off to the

nearest integer according to the rules given in IS : 2-1960.

d) If necessary, symbols indicating special characteristics as follows:

1) Method of designation Depending on whether the steel is

killed, semi-killed or rimming variety, the following symbols

shall be used to indicate the steel making practice:

i) R = rimming steel, and

ii) K = killed steel.

NOTE If no symbol is used, it shall mean that the steel is of semi-killed type.

2) Steel quality The following symbols shall be used to indicate

steel quality:

Q1 =

Q2 =

Q3 =

Q4 =

Q5 =

non-ageing quality,

freedom from flakes,

grain size controlled,

inclusion controlled, and

internal homogeneity guaranteed.

*Code for designation of steels: Part I Based on letter symbols.

Classification of steels.

Rules for rounding off numerical values ( revised ).

13

IS : 1570 (Part 2/Sec 1) - 1979

3) Degree of purity The sulphur and phosphorus levels (ladle

analysis) shall be expressed as follows:

Maximum Content in Percent

Symbol

Phosphorus

Sulphur

P25

0.025

0.025

P35

0.035

0.035

P50

0.050

0.050

P70

0.070

0.070

No symbol will mean

0.055

0.055

The above symbols use the letter P followed by 1 000 times the

maximum percentage of sulphur and phosphorus. In case the

maximum contents of sulphur and phosphorus are not same, the

following procedure shall be followed:

Symbol SP shall be used to indicate the levels followed by:

a) 100 times the maximum sulphur rounded off* to the nearest

integer.

b) 100 times the maximum phosphorus rounded off* to the nearest

integer.

Example:

Maximum sulphur

= 0.045 percent

Maximum phosphorus = 0.035 percent

Designation: SP 44.

4) Weldability guarantee Guaranteed weldability of steel as

determined by tests mutually agreed between the supplier and

the manufacturer shall be indicated by the following symbols:

W = fusion weldable, and

W1 = weldable by resistance welding but not fusion weldable.

5) Resistance to brittle fracture Symbol B, B0, B2 or B4

indicating resistance to brittle fracture based on the results of

the V-notch Charpy impact test.

For steels B, B0, B2 and B4 a test should be made with Charpy

V-notch specimens, taken in the direction of rolling with the notch

perpendicular to the surface of the plate or product.

*Rounding off shall be done according to the rules given in IS : 2-1960 Rules for

rounding off numerical values ( revised ).

14

IS : 1570 (Part 2/Sec 1) - 1979

Steels B, B0, B2 and B4 are characterized by an average V-notch

Charpy impact value according to the following table:*

Specified UTS Range

370 to 520 MPa*

500 to 700 MPa*

Steels

Energy

Temperature

Energy

Temperature

(1)

(2)

(3)

(4)

(5)

28

27

40

27

B0

28

28

40

10

0

B2

28

20

28

40

30

20

B4

28

40

28

40

50

40

6) Surface condition The following symbols shall be used to

indicate surface condition:

S1

S2

S3

S4

S5

S6

S7

=

=

=

=

=

=

=

deseemed or scarfed;

descaled;

pickled (including washing and neutralizing);

shot, grit or sand blasted;

peeled (skinned);

bright drawn or cold rolled; and

ground.

NOTE If no symbol is used, it shall mean that the surface is in as-rolled or asforged condition.

7) Formability ( applicable to sheet only ) The following symbols

shall be used to indicate drawability:

D1 = drawing quality,

D2 = deep drawing quality, and

D3 = extra deep drawing quality.

NOTE If no symbol is used, it shall mean that the steel is of commercial quality.

*1MPa = 1N/mm2 = 0.102 0 kgf /mm2.

15

IS : 1570 (Part 2/Sec 1) - 1979

8) Surface finish ( applicable to sheet only ) The following

symbols shall be used to indicate the surface finish:

F1 =

F2 =

F3 =

F4 =

F5 =

F6 =

F7 =

F8 =

F9 =

F10 =

F11 =

F12 =

F13 =

F14 =

general purpose finish,

full finish,

exposed,

unexposed,

matt finish,

bright finish,

plating finish,

unpolished finish,

polished finish,

polished and coloured blue,

polished and coloured yellow,

mirror finish,

vitreous enamel finish, and

direct annealed finish.

9) Treatment The following symbols shall be used to indicate

the treatment given to the steel:*

T1 =

T2 =

T3 =

T4 =

T5 =

T6 =

T7 =

T8 =

T9 =

T10 =

T11 =

T12 =

T13 =

T14 =

shot-peened,

hard-drawn,

normalized*,

controlled rolled,

annealed,

patented,

solution-treated,

solution-treated and aged,

controlled cooled,

bright annealed,

spherodized,

stress-relieved,

case-hardened*, and

hardened and tempered.

NOTE If no symbol is used, it means that the steel is hot-rolled.

*Includes tempering, if done.

16

IS : 1570 (Part 2/Sec 1) - 1979

10) Elevated temperature properties For guarantee with regard

to elevated temperature properties, the letter H shall be

used. However, in the designation only the room temperature

properties shall be shown. Elevated temperature properties

shall be intimated to the purchaser separately by the

manufacturer.

11) Cryogenic quality For guarantee with regard to low

temperature properties, the letter L shall be used. However,

only the room temperature properties shall be indicated in

the designation.

Examples:

24C5B0 Semi-killed steel with average 0.25 percent carbon

and 0.5 percent manganese content and resistance to

brittle fracture grade B0.

45C10W Steel with average 0.45 percent carbon, 1 percent

manganese and guaranteed fusion weldable.

17

IS : 1570 (Part 2/Sec 1) - 1979

( Continued from page 2 )*

Members

SHRI M. K. DUTTA

Representing

Steel Authority of India Ltd (Durgapur Steel Plant),

Durgapur

SHRI R. C. JHA ( Alternate )

J O I N T D I R E C T O R (MET), Ministry of Railways

R E S E A R C H DESIGNS &

STANDARDS ORGANIZATION

ASSISTANT DIRECTOR (MS) ( Alternate )

Bhabha Atomic Research Centre, Trombay

DR N. KONDAL RAO

SHRI K. BALARAMAMOORTHY ( Alternate )

Bihar Alloy Steels Ltd, Ranchi

DR N. MOHAN

Alloy Steels Producers Association of India, Bombay

DR R. V. PATHY*

SHRI M. K. PRAMANIK

Iron & Steel Control, Calcutta

Heavy Engineering Corporation Ltd, Ranchi

SHRI R. C. PRASAD

SHRI D. K. DAS ( Alternate )

SHRI A. K. ROY

Association of Indian Automobile Manufacturers,

Bombay

Mahindra Ugine Steel Co Ltd, Khopoli

SHRI A. R. V. SUBRAMANIAN

Bharat Heavy Electricals Ltd. Tiruchchirappalli

DR G. VENKATARAMAN

*Dr R. V. Pathy is also alternate to Shri A. R. V. Subramanian representing

Mahindra Ugine Steel Co Ltd, Khopoli.

18

Bureau of Indian Standards

BIS is a statutory institution established under the Bureau of Indian Standards Act, 1986 to promote

harmonious development of the activities of standardization, marking and quality certification of

goods and attending to connected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these publications may be reproduced in any

form without the prior permission in writing of BIS. This does not preclude the free use, in the course

of implementing the standard, of necessary details, such as symbols and sizes, type or grade

designations. Enquiries relating to copyright be addressed to the Director (Publications), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also

reviewed periodically; a standard along with amendments is reaffirmed when such review indicates

that no changes are needed; if the review indicates that changes are needed, it is taken up for

revision. Users of Indian Standards should ascertain that they are in possession of the latest

amendments or edition by referring to the latest issue of BIS Catalogue and Standards : Monthly

Additions.

This Indian Standard has been developed by Technical Committee : SMDC 19

Amendments Issued Since Publication

Amend No.

Amd. No. 1

Date of Issue

December 1989

BUREAU OF INDIAN STANDARDS

Headquarters:

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002.

Telephones: 323 01 31, 323 33 75, 323 94 02

Regional Offices:

Central

: Manak Bhavan, 9 Bahadur Shah Zafar Marg

NEW DELHI 110002

Eastern

: 1/14 C. I. T. Scheme VII M, V. I. P. Road, Kankurgachi

KOLKATA 700054

Telegrams: Manaksanstha

(Common to all offices)

Telephone

323 76 17

323 38 41

337 84 99, 337 85 61

337 86 26, 337 91 20

Northern : SCO 335-336, Sector 34-A, CHANDIGARH 160022

60 38 43

60 20 25

Southern : C. I. T. Campus, IV Cross Road, CHENNAI 600113

235 02 16, 235 04 42

235 15 19, 235 23 15

Western : Manakalaya, E9 MIDC, Marol, Andheri (East)

MUMBAI 400093

832 92 95, 832 78 58

832 78 91, 832 78 92

BANGALORE.

BHOPAL.

BHUBANESHWAR.

COIMBATORE.

Branches : AHMEDABAD.

FARIDABAD. GHAZIABAD. GUWAHATI. HYDERABAD. JAIPUR. KANPUR. LUCKNOW.

NAGPUR. NALAGARH. PATNA. PUNE. RAJKOT. THIRUVANANTHAPURAM.

VISHAKHAPATNAM

You might also like

- SAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentDocument2 pagesSAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentAnush Swaminathan100% (1)

- CWB FCAW Prequalified SetDocument77 pagesCWB FCAW Prequalified Setרונן לבNo ratings yet

- Aisi 1008Document2 pagesAisi 1008GANESH GNo ratings yet

- JIS G3452 PipeDocument0 pagesJIS G3452 PipefaridyeniNo ratings yet

- A1088-13 Standard Specification For Steel, Sheet, Cold-Rolled, Complex Phase (CP), Dual Phase (DP) and Transformation Induced Plasticity (TRIP)Document5 pagesA1088-13 Standard Specification For Steel, Sheet, Cold-Rolled, Complex Phase (CP), Dual Phase (DP) and Transformation Induced Plasticity (TRIP)tjt47790% (1)

- RT Interpretation-SignedDocument88 pagesRT Interpretation-SignedFouad OudinaNo ratings yet

- Astm A31 (1995)Document4 pagesAstm A31 (1995)gsb2100% (1)

- Automotive Gray Iron Castings: Standard Specification ForDocument5 pagesAutomotive Gray Iron Castings: Standard Specification ForJosé Ramón GutierrezNo ratings yet

- Ductile Iron Castings: Standard Reference Radiographs ForDocument2 pagesDuctile Iron Castings: Standard Reference Radiographs ForJorge ToribioNo ratings yet

- Training Matrix Smaw NC IDocument10 pagesTraining Matrix Smaw NC IEdward LyleNo ratings yet

- ASME SA240 304 (S30400) Stainless Steel Plate - A516Gr70 - S355J2 - SA516GR70 - A516 Grade 70 - SA516 Grade 70 - A572GR50 Steel Plate PDFDocument7 pagesASME SA240 304 (S30400) Stainless Steel Plate - A516Gr70 - S355J2 - SA516GR70 - A516 Grade 70 - SA516 Grade 70 - A572GR50 Steel Plate PDFJA KNo ratings yet

- Is 1570Document164 pagesIs 1570Sumit Shyamal63% (8)

- Spherical TankDocument6 pagesSpherical Tankhgag selimNo ratings yet

- Asme Section II A Sa-276Document10 pagesAsme Section II A Sa-276Anonymous GhPzn1xNo ratings yet

- WPS - 2Document3 pagesWPS - 2aleventNo ratings yet

- Astm A293-2022Document10 pagesAstm A293-2022CarlosNo ratings yet

- Material SpecificationDocument12 pagesMaterial SpecificationmehrNo ratings yet

- Hardfacing Wires: For The Cement IndustryDocument20 pagesHardfacing Wires: For The Cement Industrymarlon peña romero100% (1)

- CA6NMDocument2 pagesCA6NMjoene3No ratings yet

- En 10268-2006 - Cold Rolled High Strength - Dual Phase SteelsDocument16 pagesEn 10268-2006 - Cold Rolled High Strength - Dual Phase SteelsSuvro ChakrabortyNo ratings yet

- JTB RJJ 000 L0 Spe 900 10001 2 1 2Document788 pagesJTB RJJ 000 L0 Spe 900 10001 2 1 2Ro DiroNo ratings yet

- Api-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Document4 pagesApi-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Ahmed ElsharkawNo ratings yet

- ASTM A276-98bDocument7 pagesASTM A276-98bNadhiraNo ratings yet

- Sa 325 PDFDocument12 pagesSa 325 PDFMo'men Abu-SmaihaNo ratings yet

- Hot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesDocument11 pagesHot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesNilton Santillan OrtegaNo ratings yet

- Metric Heavy Hex Nut DimensionsDocument3 pagesMetric Heavy Hex Nut DimensionsSenthillkumar BalasubramaniamNo ratings yet

- A434Document3 pagesA434alirioNo ratings yet

- Is 1079 - 2009Document10 pagesIs 1079 - 2009Shradha SinghaniaNo ratings yet

- Is 1608-1995Document24 pagesIs 1608-1995Rakesh Srivastava100% (2)

- Specification For Carbon Structural Steel: SA-36 /SA-36MDocument7 pagesSpecification For Carbon Structural Steel: SA-36 /SA-36MBowo Edhi Wibowo100% (2)

- 513-Part 1-2016Document17 pages513-Part 1-2016Shaheen MaveNo ratings yet

- IS 5517 - 1993-Hardening & Tempering GradesDocument15 pagesIS 5517 - 1993-Hardening & Tempering GradesMohanrajMJ100% (1)

- SAE-J995 Steel NutsDocument9 pagesSAE-J995 Steel Nutsgaso99No ratings yet

- BS en 10084-2008Document40 pagesBS en 10084-2008Martijn Groot100% (1)

- A319Document2 pagesA319malika_000% (1)

- Asme Section Ii A-2 Sa-675 Sa-675mDocument6 pagesAsme Section Ii A-2 Sa-675 Sa-675mdavid perezNo ratings yet

- A493 00 PDFDocument3 pagesA493 00 PDFJohano AraújoNo ratings yet

- Disclosure To Promote The Right To Information: IS 4432 (1988) : Case Hardening Steels (MTD 16: Alloy Steels and Forgings)Document15 pagesDisclosure To Promote The Right To Information: IS 4432 (1988) : Case Hardening Steels (MTD 16: Alloy Steels and Forgings)Selvaraji Muthu50% (2)

- Astm A106 1999Document13 pagesAstm A106 1999Rolando CastilloNo ratings yet

- How To Read STD IS 2062 (2011)Document17 pagesHow To Read STD IS 2062 (2011)AkshayNo ratings yet

- Alloy286 - ASTM A453 660 DatasheetDocument2 pagesAlloy286 - ASTM A453 660 Datasheetn1ghtfallNo ratings yet

- Is 209 - 1992 Zinc Ingot - SpecificationDocument5 pagesIs 209 - 1992 Zinc Ingot - SpecificationRam NiwasNo ratings yet

- MildSteel AISI 1018Document2 pagesMildSteel AISI 1018ramanamurtytv7176No ratings yet

- Disclosure To Promote The Right To InformationDocument34 pagesDisclosure To Promote The Right To InformationSainath AmudaNo ratings yet

- Sfa-5.7Document10 pagesSfa-5.7vannie_yundaNo ratings yet

- Astm 401Document4 pagesAstm 401JOSEPH REFUERZONo ratings yet

- Subject: STI For Hollow Steel Sections For Structural Use (Doc: STI /4923/9/october 2017) As Per IS 4923:2017Document6 pagesSubject: STI For Hollow Steel Sections For Structural Use (Doc: STI /4923/9/october 2017) As Per IS 4923:2017TARUNKUMARNo ratings yet

- Astm A319Document2 pagesAstm A319Mailson RochaNo ratings yet

- Asme Sec II Part B 2017Document1 pageAsme Sec II Part B 2017Lipika Gayen0% (1)

- 2370 Ed1 ENDocument5 pages2370 Ed1 ENanhthoNo ratings yet

- Domex 100 XF Data SheetDocument2 pagesDomex 100 XF Data Sheetzubblwump5063No ratings yet

- Copper and Copper Alloy Forging Rod, Bar, and Shapes: Standard Specification ForDocument8 pagesCopper and Copper Alloy Forging Rod, Bar, and Shapes: Standard Specification Foralucard375No ratings yet

- Astm A484-A484m-00Document12 pagesAstm A484-A484m-00Razvan Andrei GiuscaNo ratings yet

- 14H, 22H DetailsDocument1 page14H, 22H DetailsmshNo ratings yet

- IS Code 1731-1971Document2 pagesIS Code 1731-1971kaustavNo ratings yet

- ISO1133 Melt Volume Flow Rate MVRDocument2 pagesISO1133 Melt Volume Flow Rate MVRMichele Preghenella100% (1)

- C K201 PDFDocument21 pagesC K201 PDFManoj KumarNo ratings yet

- Is 513 Amendment-1Document2 pagesIs 513 Amendment-1sanjeev00747488No ratings yet

- Asme Section II A-2 Sa-592 Sa-592mDocument4 pagesAsme Section II A-2 Sa-592 Sa-592mAnonymous GhPzn1xNo ratings yet

- BS2789 Grade 700-2 SG Iron: Form of SupplyDocument2 pagesBS2789 Grade 700-2 SG Iron: Form of SupplySama UmateNo ratings yet

- 253 MA Austenitic - High - Temperature - Grades - Datasheet PDFDocument12 pages253 MA Austenitic - High - Temperature - Grades - Datasheet PDFAbdulNo ratings yet

- Al Busbar 6060 DatasheetDocument1 pageAl Busbar 6060 DatasheetpiirsaluNo ratings yet

- Specification For Seamless Red Brass Pipe, Standard SizesDocument8 pagesSpecification For Seamless Red Brass Pipe, Standard SizesVCNo ratings yet

- 1570 (Part II)Document20 pages1570 (Part II)Kaushik SenguptaNo ratings yet

- 1570 (Part V)Document18 pages1570 (Part V)Kaushik SenguptaNo ratings yet

- 1278 - Filler Rods For Gas WeldingDocument20 pages1278 - Filler Rods For Gas WeldingKaushik SenguptaNo ratings yet

- Is 1570 1Document17 pagesIs 1570 1Raj K Sharma100% (1)

- Review On Different Trends in FSWDocument27 pagesReview On Different Trends in FSWKaushik SenguptaNo ratings yet

- The Effect of Pin Profiles On The Microstructure and Mechanical Properties of Underwater Friction Stir Welded AA2519-T87 Aluminium AlloyDocument6 pagesThe Effect of Pin Profiles On The Microstructure and Mechanical Properties of Underwater Friction Stir Welded AA2519-T87 Aluminium AlloyKaushik SenguptaNo ratings yet

- Book FrictionStir WeldingDocument239 pagesBook FrictionStir WeldingKaushik SenguptaNo ratings yet

- Numerical Analysis of Effect of Coolant On The Transient Temperature in Underwater Friction Stir Welding of Al6061-T6Document101 pagesNumerical Analysis of Effect of Coolant On The Transient Temperature in Underwater Friction Stir Welding of Al6061-T6Kaushik SenguptaNo ratings yet

- Underwater Friction Stir Welding: An OverviewDocument6 pagesUnderwater Friction Stir Welding: An OverviewKaushik SenguptaNo ratings yet

- Optimization of Process Parameters of Friction Stir Welding For Dissimilar Aluminium Alloys AA5083-0 and 6061 - T6Document5 pagesOptimization of Process Parameters of Friction Stir Welding For Dissimilar Aluminium Alloys AA5083-0 and 6061 - T6Kaushik SenguptaNo ratings yet

- Underwater Friction Stir Welding of Ultrafine Grained 2017 Aluminum Alloy PDFDocument5 pagesUnderwater Friction Stir Welding of Ultrafine Grained 2017 Aluminum Alloy PDFKaushik SenguptaNo ratings yet

- Microstructure and Mechanical Characterization of Friction Stir Welded High Strength Low Alloy SteelsDocument8 pagesMicrostructure and Mechanical Characterization of Friction Stir Welded High Strength Low Alloy SteelsKaushik SenguptaNo ratings yet

- Feasibility of Underwater Friction Stir Welding of Hardenable Alloy SteelDocument56 pagesFeasibility of Underwater Friction Stir Welding of Hardenable Alloy SteelKaushik SenguptaNo ratings yet

- Study of Mechanical Properties of Aluminium Alloys On Normal Friction Stir Welding and Underwater Friction Stir Welding For Structural ApplicationsDocument5 pagesStudy of Mechanical Properties of Aluminium Alloys On Normal Friction Stir Welding and Underwater Friction Stir Welding For Structural ApplicationsKaushik SenguptaNo ratings yet

- Overview of Underwater Friction Stir WeldingDocument9 pagesOverview of Underwater Friction Stir WeldingKaushik SenguptaNo ratings yet

- Some Investigations On Thermal Analysis of Aluminium Alloys in Underwater Friction Stir WeldingDocument5 pagesSome Investigations On Thermal Analysis of Aluminium Alloys in Underwater Friction Stir WeldingKaushik SenguptaNo ratings yet

- On The Immersed Friction Stir Welding of Aa6061-T6 A Metallurgic and Mechanical Comparison To Friction Stir WeldingDocument5 pagesOn The Immersed Friction Stir Welding of Aa6061-T6 A Metallurgic and Mechanical Comparison To Friction Stir WeldingKaushik SenguptaNo ratings yet

- Optimization of Process Parameters of Friction Stir WeldedDocument8 pagesOptimization of Process Parameters of Friction Stir WeldedKaushik SenguptaNo ratings yet

- Review On Underwater Friction Stir Welding A Variant of Friction Stir Welding With Great Potential of Improving Joint PropertiesDocument4 pagesReview On Underwater Friction Stir Welding A Variant of Friction Stir Welding With Great Potential of Improving Joint PropertiesKaushik SenguptaNo ratings yet

- Modelling and Optimization of Submerged Friction Stir Welding Parameters For AA6061-T6 Alloy Using RSMDocument12 pagesModelling and Optimization of Submerged Friction Stir Welding Parameters For AA6061-T6 Alloy Using RSMKaushik SenguptaNo ratings yet

- Optimizations of Welding Strength of Joining by FSW of Aluminum Alloy A6068 Using Response Surface Methodology - IIDocument3 pagesOptimizations of Welding Strength of Joining by FSW of Aluminum Alloy A6068 Using Response Surface Methodology - IIKaushik SenguptaNo ratings yet

- Modeling and Optimization of Submerged Friction Stir Welding of AA 2219-T6 AlloyDocument8 pagesModeling and Optimization of Submerged Friction Stir Welding of AA 2219-T6 AlloyKaushik SenguptaNo ratings yet

- Microstructure, Mechanical Properties and Corrosion of Friction Stir Welded 6061 Aluminum Alloy PDFDocument25 pagesMicrostructure, Mechanical Properties and Corrosion of Friction Stir Welded 6061 Aluminum Alloy PDFKaushik SenguptaNo ratings yet

- Underwater Friction Stir Welding: An OverviewDocument6 pagesUnderwater Friction Stir Welding: An OverviewKaushik SenguptaNo ratings yet

- Microstructure, Mechanical Properties and Corrosion of Friction Stir Welded 6061 Aluminum AlloyDocument4 pagesMicrostructure, Mechanical Properties and Corrosion of Friction Stir Welded 6061 Aluminum AlloyKaushik SenguptaNo ratings yet

- Investigation of Submerged Friction Stir Welding of Marine-Grade Aluminum AlloyDocument75 pagesInvestigation of Submerged Friction Stir Welding of Marine-Grade Aluminum AlloyKaushik SenguptaNo ratings yet

- Experimental and Numerical Investigation On Under-Water Friction Stir Welding of Armour Grade AA2519-T87 Aluminium AlloyDocument10 pagesExperimental and Numerical Investigation On Under-Water Friction Stir Welding of Armour Grade AA2519-T87 Aluminium AlloyKaushik SenguptaNo ratings yet

- Friction Stir Welding of 5052 PHD Thesis by Iit DelhiDocument39 pagesFriction Stir Welding of 5052 PHD Thesis by Iit DelhiKaushik SenguptaNo ratings yet

- Fabrication and Characterization of Friction Stir Welding Using Al 3105Document13 pagesFabrication and Characterization of Friction Stir Welding Using Al 3105Kaushik SenguptaNo ratings yet

- Feasibility of Underwater Friction Stir Welding of HY-80 SteelDocument53 pagesFeasibility of Underwater Friction Stir Welding of HY-80 SteelKaushik SenguptaNo ratings yet

- Influences of Tool Travel Speed On Tensile Properties of Underwater Friction Stir Welded High Strength Armour Grade Aluminium Alloy JointsDocument7 pagesInfluences of Tool Travel Speed On Tensile Properties of Underwater Friction Stir Welded High Strength Armour Grade Aluminium Alloy JointsKaushik SenguptaNo ratings yet

- Friction Stir Welding of 6mm Thick Carbon Steel Underwater and in AirDocument13 pagesFriction Stir Welding of 6mm Thick Carbon Steel Underwater and in AirKaushik SenguptaNo ratings yet

- Influence of Tool Geometry and Processing Parameters On Welding Defects and Mechanical Properties For Friction Stir Welding of 6061 Aluminium AlloyDocument10 pagesInfluence of Tool Geometry and Processing Parameters On Welding Defects and Mechanical Properties For Friction Stir Welding of 6061 Aluminium AlloyKaushik SenguptaNo ratings yet

- An Experimental Insight On The Selection of The Tool Tilt Angle For Friction Stir Welding of 7075 T651 Aluminum AlloysDocument11 pagesAn Experimental Insight On The Selection of The Tool Tilt Angle For Friction Stir Welding of 7075 T651 Aluminum AlloysKaushik SenguptaNo ratings yet

- Esab - rt62 TorchDocument50 pagesEsab - rt62 TorchZMCNo ratings yet

- Na2xsf2y 3x 10kv enDocument3 pagesNa2xsf2y 3x 10kv enAnonymous v1oFsM6igNo ratings yet

- Engineering and Capital Goods: January 2018Document50 pagesEngineering and Capital Goods: January 2018Ankush Soni KatailihaNo ratings yet

- Science of The Total EnvironmentDocument16 pagesScience of The Total EnvironmentEDEN PAVING Group P/LNo ratings yet

- Cisco Pallet Rack GuideDocument20 pagesCisco Pallet Rack GuideAri WibisonoNo ratings yet

- MESC - SPE - 74-053 - February-2019 - SMLS Cu-Ni Pipe & Tube Amm. To ASTM B466Document8 pagesMESC - SPE - 74-053 - February-2019 - SMLS Cu-Ni Pipe & Tube Amm. To ASTM B466wbauernhofNo ratings yet

- Conditions in Asia in The 19th CenturyDocument15 pagesConditions in Asia in The 19th CenturyRoann Lador BendebelNo ratings yet

- Tandem Submerged Arc Tank Car Seams Welds, From Each Side, For 7/16" Thick Material With Control ReinforcementDocument8 pagesTandem Submerged Arc Tank Car Seams Welds, From Each Side, For 7/16" Thick Material With Control Reinforcementlemuel bacsaNo ratings yet

- China Limits Exports of Rare Earth MaterialsDocument1 pageChina Limits Exports of Rare Earth Materialscr7 bestNo ratings yet

- OPSS - PROV 1441 Nov17Document2 pagesOPSS - PROV 1441 Nov17P ScribedNo ratings yet

- Specification For Jackets of Pipe: Rev. Date Revision Description Issued by Checked by Approved byDocument10 pagesSpecification For Jackets of Pipe: Rev. Date Revision Description Issued by Checked by Approved byvishal bhamreNo ratings yet

- The Properties, Benefits, and Applications of Arlon HF-50 PCB MaterialDocument4 pagesThe Properties, Benefits, and Applications of Arlon HF-50 PCB MaterialjackNo ratings yet

- SANS1200MMDocument15 pagesSANS1200MMKyle MoolmanNo ratings yet

- Hand Tube Bender ManualDocument19 pagesHand Tube Bender ManualNeilton JuniorNo ratings yet

- The Complete Technology BookDocument4 pagesThe Complete Technology Bookaakhyar_2No ratings yet

- Kingspan Installation Guide: Scan The Code and Visit The Product PageDocument42 pagesKingspan Installation Guide: Scan The Code and Visit The Product PageBranZzZzZNo ratings yet

- Door & WindowDocument1 pageDoor & WindowAMIT KUMARNo ratings yet

- BS 00240 1962 - PQ (En)Document18 pagesBS 00240 1962 - PQ (En)Mahendran MNo ratings yet

- SCRATADocument2 pagesSCRATAamit100% (1)

- WSS-M21P36 10-09-2014Document4 pagesWSS-M21P36 10-09-2014Ronald AraujoNo ratings yet

- Gis 18 014 - ADocument25 pagesGis 18 014 - Amulldoctor1No ratings yet

- Safety Chucks: Available Socket ShapesDocument6 pagesSafety Chucks: Available Socket ShapesQuan PhanNo ratings yet