Professional Documents

Culture Documents

Chap 2 PDF

Uploaded by

안혜영Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chap 2 PDF

Uploaded by

안혜영Copyright:

Available Formats

Chapter 2

PROBLEM 2.1

2.1 A steel rod is 2.2 m long and must not stretch more than 1.2 mm when a 8.5 kN load is applied to

it. Knowing that E = 200 GPa, determine (a) the smallest diameter rod which should be used, (b)

the corresponding normal stress caused by the load.

SOLUTION

(a) d =

A=

(b) s =

PL

AE

p 2

d

4

A=

ia f

8.5 10 3 2.2

PL

=

= 77.92 106 m2

Ed

200 10 9 1.2 10 -3

\ d=

4A

=

p

id

( 4 ) ( 77.92 10 -6 )

= 9.96 103 m

p

= 9.96 mm

8.5 10 3

p

=

= 109.1 106 Pa = 109.1 MPa

-6

A

77.92 10

PROBLEM 2.2

2.2 A 1.5 m long steel wire of 6 mm diameter steel wire is subjected to a 3.4 kN tensile load. Knowing

that E = 200 GPa, determine (a) the elongation of the wire, (b) the corresponding

normal stress.

SOLUTION

(a) L = 1.5 m = 1500 mm

d=

(b) s =

A=

p 2 p

d = (6)2 = 28.27 mm2

4

4

(3.4 1000 N ) (1500 mm)

PL

=

= 0.902 mm = 0.902 mm

AE ( 28.27 mm 2 ) (200 1000 N / mm 2 )

3400 N

P

=

= 120.26 N/mm2 = 120.26 MPa

28.27 mm 2

A

74 Mechanics of Materials

PROBLEM 2.3

2.3 Two gage marks are placed exactly 250 mm apart on a 12 mm diameter aluminium rod with

E = 70 GPa and an ultimate strength of 110 MPa. Knowing that the distance between the gage

marks is 250.230 mm after a load is applied, determine (a) the stress in the rod, (b) the factor of

safety.

SOLUTION

(a) d = 250.230 250 = 0.230 mm

d s

=

L E

ES ( 70000 N / mm 2 ) (0.230 mm)

=

= 64.4 N/mm2

L

250 mm

s=

= 64.4 MPa

(b) F.S. =

sU

110

=

= 1.708

s

64.4

PROBLEM 2.4

2.4 A control rod made of yellow brass must not stretch more than 3 mm when the tension in the wire

is 4 kN. Knowing that E = 105 GPa and that the maximum allowable normal stress is 180 MPa,

determine (a) the smallest diameter that can be selected for the rod, (b) the corresponding maximum length of the rod.

SOLUTION

(a) s =

A=

(b) d =

P

A

p 2

d

4

PL

AE

A=

4 10 3

P

=

= 22.222 106 m2

180 10 6

s

d=

\ L=

( 4) 22.222 10 -6

4A

=

p

id

i = 5.32 10

= 5.32 mm

id

22.222 10 -6 105 10 9 3 10 -3

AEd

=

P

4 10 3

= 1.750 m

PROBLEM 2.5

2.5 A 9 m length of 6 mm diameter steel wire is to be used in a hanger. It is noted that the wire

stretches 18 mm when a tensile force P is applied. Knowing that E = 200 GPa, determine (a) the

magnitude of the force P, (b) the corresponding normal stress in the wire.

Chapter 2

75

SOLUTION

(a) A =

d=

p 2 p

d = (0.006)2 = 28.274 106 m2

4

4

PL

AE

\ P=

28.274 10 -6 (200 10 9 ) 18 10 -3

AEd

=

L

9

= 11.31 103 N = 11.31 kN

(b) s =

11.31 10 3

P

=

= 400 106 Pa = 400 MPa

-3

A

28.274 10

PROBLEM 2.6

2.6 A 1.4 m aluminum pipe should not stretch more than 1.2 mm when it is subjected to a tensile load.

Knowing that E = 70 GPa and that the allowable tensile strength is 96 MPa, determine (a) the

maximum allowable length of the pipe, (b) the required area of the pipe if the tensile load is 560 kN.

SOLUTION

PL

(a) d =

AE

(b) s =

P

A

\

\

id

70 10 9 Pa 1.2 10 -3 m

EAd

Ed

L=

=

=

= 0.875 m

96 10 6 Pa

P

s

A=

560 103 N

P

=

= 5833.3 mm2

96 N / mm 2

s

PROBLEM 2.7

2.7 A nylon thread is subjected to a 8.5 N tension force. Knowing that E = 3.3 GPa and that the length

of the thread increases by 1.1%, determine (a) the diameter of the thread, (b) the stress in the

thread.

SOLUTION

(a)

d

11

.

L

=

\

= 90.909

L 100

d

(8.5) (90.909)

PL

PL

d=

\ A=

=

= 234.16 109 m2

AE

Ed

3.3 10 9

4A

p 2

d \ d=

= 0.546 103 m = 0.546 mm

p

4

8.5

P

(b) s =

=

= 36.3 106 Pa = 36.3 MPa

234.16 10 -9

A

A=

76 Mechanics of Materials

PROBLEM 2.8

2.8 A cast-iron tube is used to support a compressive load. Knowing that E = 70 GPa and that the

maximum allowable change in length is 0.025 percent, determine (a) the maximum normal stress

in the tube, (b) the minimum wall thickness for a load of 7 kN if the outside diameter of the tube

is 50 mm.

SOLUTION

d

0.025

=

= 0.00025

L

100

Ed

= (70 109) (0.00025) = 17.5 106 Pa = 17.5 MPa

s=

L

P

P

7000

(b) s =

\ A=

=

= 400 mm2

A

s

17.5

p

A=

do2 - di2

4

4A

( 4 ) ( 400 )

= 502

= 1990.7 mm2 \ di = 44.6 mm

di2 = do2

p

p

1

1

t = (do di) = (50 44.6) = 2.7 mm

2

2

(a)

PROBLEM 2.9

2.9 A block of 250 mm length and 45 40 mm cross section is to support a centric compressive load

P. The material to be used is a bronze for which E = 95 GPa. Determine the largest load which

can be applied, knowing that the normal stress must not exceed 124 MPa and that the decrease in

length of the block should be at most 0.12 percent of its original length.

SOLUTION

Considering allowable stress

s = 124 MPa = 124 N/mm2

A = (45)(40) = 1800 mm2

s=

P

A

P = s A = (124)(1800) = 223.2 kN

Considering allowable deformation

d 0.12

=

= 0.0012

L 100

d=

Smaller value governs

PL

AE

\ P = AE

P = 205.2 kN

d

= (1800)(95 109) (0.0012) = 205.2 kN

L

Chapter 2

77

PROBLEM 2.10

2.10 A 9 kN tensile load will be applied to a 50 m length of steel wire with E = 200 GPa. Determine the

smallest diameter wire which can be used, knowing that the normal stress must not exceed

150 MPa and that the increase in the length of the wire should be at most 25 mm.

SOLUTION

Considering allowable stress s = 150 106 Pa

s=

P

A

A=

P

9 10 3

=

= 60 106 m2

150 10 6

s

Considering allowable elongation d = 25 103 m

d=

PL

AE

\ A=

6

ia f

9 10 3 50

PL

=

= 90 106 m2

-3

9

Ed

200 10 25 10

id

A = 90 10 m

Larger area governs

p

A = d2

4

d=

4A

=

p

( 4) 90 10 -6

p

i = 10.70 10

= 10.70 mm

PROBLEM 2.11

2.11 The 4-mm-diameter cable BC is made of a steel with E = 200 GPa.

Knowing that the maximum stress in the cable must not exceed

190 MPa and that the elongation of the cable must not exceed

6 mm, find the maximum load P that can be applied as shown.

B

2.5 m

P

3.5 m

SOLUTION

LBC = 6 2 + 4 2 = 7.2111 m

4.0 m

Use bar AB as a free body

S MA = 0

3.5 P (6)

F 4 F I =0

H 7.2111 K

BC

FBC

P = 0.9509 FBC

Considering allowable stress

s = 190 106 Pa

A=

s=

FBC

A

p 2

p

d =

(0.004)2 = 12.566 106 m2

4

4

Ax

Ay

FBC = sA = (190 106)(12.566 106) = 2.388 103 N

78 Mechanics of Materials

Considering allowable elongation d = 6 103 m

d=

\

FBC =

F LBC

AB

id

id

12.566 10 -6 200 10 9 6 10 -3

AES

=

LBC

7.2111

= 2.091 103 N

FBC = 2.091 103 N

Smaller value governs

P = 0.9509 FBC = (0.9509)(2.091 103) = 1.988 103 N = 1.988 kN

P= 580 kN

PROBLEM 2.12

2.12 Rod BD is made of steel (200 GPA) and is used to brace the axially

compressed member ABC. The maximum force that can be developed in

member BD is 0.02 P. If the stress must not exceed 124 MPa and the

maximum change in length of BD must not exceed 0.001 times the length of

ABC, determine the smallest diameter rod that can be used for member BD.

A

1.8 m

D

B

1.8 m

SOLUTION

FBD = 0.02 P = (0.02) (580) = 11.6 kN

Considering stress

s = 124 MPa = 124 106 N/m2

F

d = BD

A

Considering deformation

\

Larger area governs

or 124 N/mm2

1.35 m

F

11.6 10 3

A = BD =

= 93.54 mm2

s

124

d = (0.001)(3.6 103) = 3.6 mm

d=

FBD LBD

AE

A =

11.6 10 3 1.35 10 3

FBD LBD

=

= 21.75 mm2

9

6

Ed

200 10 /10

3.6

id

ia f

A = 93.54 mm

A=

p 2

d

4

\ d=

4A

=

p

( 4) ( 93.54)

= 10.91 mm

p

30 mm

PROBLEM 2.13

2.13 A single axial load of magnitude P = 58 kN is applied at end C of

the brass rod ABC. Knowing that E = 105 GPa, determine the

diameter d of portion BC for which the deflection of point C will

be 3 mm.

d

A

1.2 m

B

C

0.8 m

Chapter 2

SOLUTION

RS L + L UV

TA A W

d105 10 i d3 10 i =

dC =

Ed C

LBc

L

=

- AB

ABC

P

AAB

Pi Li

P

=

Ai E

E

AB

BC

AB

BC

-3

1.2

= 3.7334 103 m1

p

2

( 0.030 )

4

58 10 3

LBC

0.8

=

= 214.28 106 m2

3

3.7334 10

3.7334 10 3

ABC =

ABC =

p 2

d BC

4

4ABC

=

p

\ dBC =

( 4 ) (214.28 10 -6 )

= 16.52 103 m

p

= 16.52 mm

PROBLEM 2.14

30 mm

2.14 Both portions of the rod ABC are made of an aluminum for

which E = 73 GPa. Knowing that the diameter of portion BC is

d = 20 mm, determine the largest force P that can be applied if

sall = 160 MPa and the corresponding deflection at point C is

not to exceed 4 mm.

d

A

1.2 m

B

C

0.8 m

SOLUTION

p

(0.030)2 = 706.86 106 m2

4

p

ABC = (0.020)2 = 314.16 106 m2

4

s = 160 106 Pa

AAB =

Considering allowable stress

s=

P

A

P = As

Portion AB P = (706.86 106)(160 106) = 113.1 103 N

P = (314.16 106)(160 106) = 50.3 103 N

Portion BC

Considering allowable deflection dC = 4 103 m

dC =

P = EdC

79

FL

GH A

AB

AB

L

+ BC

ABC

Smallest value for P governs

I

JK

PLi

P

=

AE

E

-1

FL

GH A

LBC

ABC

I

JK

AB

AB

F 1.2

)G

H 706.86 10

= (73 10 ) (4 10

= 68.8 103 N

P = 50.3 103 N = 50.3 kN

-6

0.8

+

314.16 10 -6

IJ

K

-1

80 Mechanics of Materials

PROBLEM 2.15

2.15 The specimen shown is made from a 25 mm diameter

cylindrical steel rod with two 38 mm outer-diameter sleeves

bonded to the rod as shown. Knowing that E = 200 GPa,

determine (a) the load P so that the total deformation is 0.05

mm, (b) the corresponding deformation of the central

portion BC.

P'

38 mm diameter

A

25 mm diameter

B

38 mm diameter

C

50 mm

D

75 mm

P

SOLUTION

50 mm

F LI

P = Ed G J

H AK

PL

P

L

(a) d = i i =

i

Ai Ei

E

Ai

Ai =

L, mm

d, mm

A, mm2

50

75

50

38

25

38

1134

491

1134

AB

BC

CD

-1

p 2

di

4

L /A, mm1

0.04409

0.1527

0.04409

0.2409

P = (200

(b) dBC =

10 9

1

6 )(0.05)(0.2409) = 41.511 kN = 41.5 kN

10

PL BC

P LBC

41.5 10 3

=

=

(0.1527) = 0.0317 mm

ABC E

E ABC

10 9

200 6

10

P

PROBLEM 2.16

2.16 Both portions of the rod ABC are made of an aluminum for which E

= 70 GPa. Knowing that the magnitude of P is 4 kN, determine (a)

the value of Q so that the deflection at A is zero, (b) the

corresponding deflection of B.

20-mm diameter

0.4 m

SOLUTION

B

p 2

p

d AB = ( 0.020 ) 2 = 314.16 106 m2

4

4

p 2

p

ABC = d BC

= ( 0.060 ) 2 = 2.8274 103 m2

4

4

Force in member AB is P tension

(a) AAB =

Elongation dAB =

ia f

4 10 3 0.4

PLAB

=

EAAB

70 10 9 314.16 10 -6

id

= 72.756 106 m

Q

0.5 m

60-mm diameter

Chapter 2

81

Force in member BC is Q P compression

Shortening dBC =

(Q - P) LBC

(Q - P)(0.5)

=

EABC

( 70 10 9 )(2.8274 10 -3 )

= 2.5263 109 (Q P)

For zero deflection at A

dBC = dAB

2.5263 109 (Q P) = 72.756 106

\ Q P = 28.8 103 N

Q = 28.3 103 + 4 103 = 32.8 103 N = 32.8 kN

(b) dAB = dBC = dB = 72.756 106 m = 0.0728 mm

PROBLEM 2.17

P

2.17 The rod ABC is made of an aluminum for which E = 70 GPa.

Knowing that P = 6 kN and Q = 42 kN, determine the deflection of

(a) point A, (b) point B.

SOLUTION

20-mm diameter

0.4 m

AAB =

(a)

P

p 2

p

d AB = (0.020)2 = 314.16 106 m2

4

4

p 2

p

ABC = d AC

= (0.060)2 = 2.8274 103 m2

4

4

PAB = P = 6 103 N

Q

0.5 m

60-mm diameter

PBC = P Q = 6 103 42 103 = 36 103 N

LAB = 0.4 m

dAB

LBC = 0.5 m

ia f

id

6 10 3 0.4

PAB L AB

=

=

AAB E A

314.16 10 -6 70 10 9

= 109.135 106 m

Q

ia f

id

i

-36 10 3 0.5

PBC LBC

d BC =

=

ABC E

2.8274 10 -3 70 10 9

PBC

= 90.947 106 m

d A = dAB + dBC = 109.135 106 90.947 106 m = 18.19 106 m

= 0.01819 mm

(b)

d B = dBC = 90.9 106 m = 0.0909 mm

82 Mechanics of Materials

PROBLEM 2.18

2.18 The 36-mm-diameter steel rod ABC and a brass rod CD of the

same diameter are joined at point C to form the 7.5-m rod

ABCD. For the loading shown, and neglecting the weight of

the rod, determine the deflection of (a) point C, (b) point D.

A

2m

Steel: E = 200 GPa

B

50 kN

SOLUTION

3m

p

p

A = d2 = (0.036)2 = 1.01787 103 m2

4

4

Portion

Pi

AB

BC

CD

150 kN

100 kN

100 kN

Li

2m

3m

2.5 m

Ei

Pi Li /AEi

1.474 103 m

1.474 103 m

2.339 103 m

200 GPa

200 GPa

105 GPa

(a) d C = dAB + dBC = 1.474 103 + 1.474 103

= 2.948 103 m = 2.95 mm

3

2.5 m

Brass: E = 105 GPa

100 kN

(b) dD = dC + dCD = 2.948 10 + 2.339 10

= 5.287 103 m = 5.29 mm

PROBLEM 2.19

2.19 The brass tube AB (E = 103 GPa) has a cross-sectional

area of 142 mm2 and is fitted with a plug at A. The tube

is attached at B to a rigid plate which it itself attached

at C to the bottom of an aluminum cylinder (E = 72

GPa) with a cross-sectional area of 258 mm2. The

cylinder is then hung from a support at D. In order to

close the cylinder, the plug must move down through

1.2 mm. Determine the force P that must be applied to

the cylinder.

375 mm

SOLUTION

Shortening of brass tube AB

LAB = 375 + 1.2 = 376.2 mm, AAB = 142 mm2

EAB = 72 109 Pa = 72000 MPa

dAB =

1.2 mm

PLAB

P(376.2)

=

= 2.572 105 P

EAB AAB (103 10 3 )(142)

B

C

Lengthening of aluminum cylinder CD

LCD = 375 mm,

ACD = 258 mm2, ECD = 72000 106 Pa

Chapter 2

dCD =

83

PLCD

P(375)

=

= 2.02 105 P

ECD ACD

( 72000) 258

a f

dA = dAB + dCD

Total deflection

1.2 = (2.57 105 + 2.02 105)P

P = 26.14 kN = 26.14 kN

PROBLEM 2.20

2.20

A 1.2-m section of aluminum pipe of cross-sectional area

1100 mm2 rests on a fixed support at A. The 15-mm-diameter

steel rod BC hangs from a rigid bar that rests on the top of the

pipe at B. Knowing that the modulus of elasticity is 200 GPa for

steel and 72 GPa for aluminum, determine the deflection of point

C when a 60 kN force is applied at C.

1.2 m

A

0.9 m

SOLUTION

Rod BC:

LBC = 2.1 m,

ABC =

EBC = 200 109 Pa

p 2 p

d =

(0.015)2 = 176.715 106 m2

4

4

dC/B =

ia f

60 10 3 2.1

PLBC

=

= 3.565 103 m

E BC ABC

200 10 9 176.715 10 -6

id

Pipe AB: LAB = 1.2 m, EAB = 72 10 Pa, AAB = 1100 mm = 1100 10 m

dB/A =

ia f

60 10 3 1.2

PLAB

=

= 909.1 106 m2

-6

9

EAB AAB

72 10 1100 10

id

dC = dB/A + dC/B = 909.1 10 + 3.565 103 = 4.47 103

= 4.47 mm

P

PROBLEM 2.21

2.21 The steel frame (E = 200 GPa) shown has a diagonal brace

BD with an area of 1920 mm2. Determine the largest

allowable load P if the change in length of member BD is

not to exceed 1.6 mm.

6m

SOLUTION

dBC = 1.6 103 m,

LBC =

5 +6

ABD = 1920 mm2 = 1920 106 m2

= 7.810 m,

EBC = 200 10 Pa

5m

84 Mechanics of Materials

dBC =

FBC L BC

EBC ABC

FBC =

E BC ABCd BC

( 200 109 ) (1920 10 -6 ) (1.6 10 -3 )

=

7.81

LBC

= 78.67 103 N

Use joint B as a free body:

S Fx = 0

+

5

FBC P = 0

7.810

P=

FBC

FAB

( 5)( 78.67 10 3 )

5

FBC =

7.810

7.810

= 50.4 103 N = 50.4 kN

PROBLEM 2.22

2.22

228 kN

For the steel truss (E = 200 GPa) and loading shown,

determine the deformations of members AB and AD,

knowing that their cross-sectional areas are 2400 mm2 and

1800 mm2, respectively.

B

2.5 m

C

SOLUTION

Statics: Reactions are 114 kN upward at A and C.

Member BD is a zero force member

4.0 m

4.0 m

4.0 2 + 2.52 = 4.717 m

LAB =

Use joint A as a free body: +SFy = 0

114

2.5

FAB = 0

4.717

FAB

FAB = 215.10 kN

+

Member AB:

S Fx = 0

FAD

4

FAB = 0

4.717

FAD =

( 4) ( 215.10 )

= 182.4 kN

4.717

dAB =

FAB L AB

( 21510

. 103 ) ( 4.717)

=

E AAB

( 200 10 9 ) (2400 10 -6 )

FAD

114 kN

= 2.11 103 m = 2.11 mm

dAD =

FAB L AB

(182.4 10 3 ) ( 4.0)

=

= 2.03 103 m = 2.03 mm

E AAD

( 200 10 9 ) (1800 10 -6 )

85

Chapter 2

PROBLEM 2.23

2.23

1.8 m

1.8 m

Members AB and BC are made of steel (E = 200 GPa) with

cross-sectional areas of 516 mm2 and 412 mm2,

respectively. For the loading shown, determine the

elongation of (a) member AB, (b) member BC.

1.5 m

A

D

SOLUTION

125 kN

240 kN

(a) LAB = 1.82 + 1.5 2 = 2.34 m = 2340 mm

FAB

Use joint A as a free body

+ SFy = 0

1.5

FAB 125 = 0

2.34

FAD

FAB = 195 kN

125 kN

F L

(125 10 3 ) (2340)

dAB = AB AB =

= 2.83 mm

E AAB

(200 000) (516)

(b) Use joint B as a free body

+ SF = 0

FBC

1.8

FAB = 0

2.34

FBC =

(1.8) (195)

= 150 kN

2.34

dBC =

FBC LBC

(150 10 3 )(1800)

=

= 3.27 mm

E ABC

(200 000)( 412)

FAB

FBC

FBD

PROBLEM 2.24

2.24

Members AB and CD are 28-mm-diameter steel rods, and

members BC and AD are 22-mm-diameter steel rods. When the

turnbuckle is tightened, the diagonal member AC is put in

tension. Knowing that E = 200 GPa and h = 1.2 m, determine

the largest allowable tension in AC so that the deformations in

members AB and CD do not exceed 1.0 mm.

SOLUTION

dAB = dCD = 1.0 mm

h = 1.2 m = LCD

p

p

ACD = d 2 = (28)2 = 615.8 mm2

4

4

0.9 m

86 Mechanics of Materials

dCD =

FCD LCD

EACD

FCD =

E ACDd CD

( 200 000 )(615.8)(1.0 )

=

LCD

1200

= 102.63 kN

FBC

Use joint C as a free body

+S Fy = 0:

FAC

FCD

4

FAC = 0 \

5

FAC =

5

FCD

4

4

3

FCD

FAC

5

= (102.63) = 128.29 kN

4

PROBLEM 2.25

2.24 Members AB and CD are 28-mm-diameter steel rods, and members

BC and AD are 22-mm-diameter steel rods. When the turnbuckle is

tightened, the diagonal member AC is put in tension. Knowing that

E = 200 GPa and h = 1.2 m, determine the largest allowable tension in AC so that the deformations in members AB and CD do not

exceed 1.0 mm.

2.25 For the structure in Prob. of 2.24, determine (a) the distance h so

that the deformations in members AB, BC, CD and AD are all equal

to 1.0 mm, (b) the corresponding tension in member AC.

SOLUTION

0.9 m

(a) Statics: Use joint B as a free body

FBC

FAB

FBD

FBD

FAB

FBC

Force triangle

Geometry

From similar triangles

F

F

FAB

= BC = BD

b

LBC

h

FAB =

LBD

h

FBC

b

Chapter 2

87

For equal deformations

dAB = dBC \

FAB h

F b

= BC

E AAB

E ABC

FAB =

b AAB

FBC

h ABC

Equating expressions for FAB

h

b AAB

FBC =

FBC

b

h ABC

p 2

d AB

AAB

d2

h2

= 4

= AB

2 =

2

p 2

ABC

b

d BC

d BC

4

d

h

28

= AB =

= 1.273

b d BC

22

b = 0.9 m

h = 1.273 b = 1.273 (0.9) = 1.146 m

(b) Setting dAB = dBC = 1.0 mm

F b

dBC = BC

E ABC

p

( 200 000) ( 22)(1.0)

E ABC d BC

4

FBC =

=

b

900

= 84.473 kN

FAB =

h

FBC = 1.273 (84.473) = 107.535 kN

b

From the force triangle

FBD = FAC =

2

2

= 136.746 kN

+ FAB

FBC

PROBLEM 2.26

2.26 Members ABC and DEF are joined with steel links (E =

200 GPa). Each of the links is made of a pair of 25 35-mm

plates. Determine the change in length of (a) member BE,

(b) member CF.

180 mm

260 mm

SOLUTION

C

FCF

Use member ABC as a free body

S MB = 0

B

FBE

A

18 kN

(0.260) (18 103) (0.180) FCF = 0

FCF =

( 0.260)(18 10 3 )

= 26 103 N

0.180

18 kN

240 mm

18 kN

88 Mechanics of Materials

S MC = 0

FBE =

(0.440) (18 103) + (0.180) FBE = 0

( 0.440)(18 103 )

= 44 103 N

0.180

Area for link made of two plates

A = (2)(0.025) (0.035) = 1.75 103 m2

(a) dBE =

FBE LBE

( - 44 10 3 )(0.240)

=

= 30.2 106 m = 0.0302 mm

EA

( 200 10 9 )(1.75 10 3 )

(b) dCF =

FCF LCF

(26 10 3 )(0.240)

=

= 17.83 106 m = 0.01783 mm

EA

( 200 10 9 )(1.75 10 3 )

PROBLEM 2.27

2.27 Each of the links AB and CD is made of aluminum (E =

75 GPa) and has a cross-sectional area of 125 mm2.

Knowing that they support the rigid member BC, determine

the deflection of point E.

D

P = 5 kN

0.36 m

E

SOLUTION

B

Use member BC as a free body

0.20 m

FAB

0.44 m

FCD

C

5 103 N

S MC = 0

(0.64)FAB + (0.44)(5 103) = 0

FAB = 3.4375 103 N

S MB = 0

(0.64)FCD (0.20)(5 103) = 0

FCD = 1.5625 103 N

For links AB and CD

A = 125 mm2 = 125 106 m2

dAB =

(3.4375 10 3 )(0.36)

FAB L AB

=

= 132.00 106 m = dB

-6

9

EA

( 75 10 )(125 10 )

dCD =

FCD LCD

(1.5625 10 3 )(0.36)

=

= 60.00 106 m = dC

EA

( 75 10 9 )(125 10 -6 )

Chapter 2

Slope q =

dB - dC

72.00 10 -6

=

= 112.5 106 rad

0.64

l BC

dE = dC + lEC q

C

dC

dE

dB

q

6

= 60.00 10

89

+ (0.44) (112.5 10 )

= 109.5 106 m = 0.1095 mm

Deformation diagram

PROBLEM 2.28

2.28 Link BD is made of brass (E = 103 GPa) and has a crosssectional area of 258 mm2. Link CE is made of aluminum (E =

72 GPa) and has a cross-sectional area of 322 mm2. Determine

the maximum force P that can be applied vertically at point A if

the deflection of A is not to exceed 0.35 mm.

D

225 mm

C

A

SOLUTION

B

150 mm

Use member ABC as a free body.

FBD

C

225 mm

125 mm

B

FCE

S MC = 0,

350 P 225 FBD = 0,

FBD = 1.5556 P

S MB = 0,

125 P 225 FCB = 0,

FCB = 0.5556 P

dB = dBD =

(1.5556 P)(225)

FBD LBD

=

= 13.17 106 P

(103000)(258)

EBD ABD

dC = dCE =

FCE LCE

( 0.5556 P)(150)

=

= 3.5 106 P

ECE ACE

( 72000)(322)

From the deformation diagram

Slope

SA

q=

SB

dB + dC

16.67 10 -6 P

=

= 0.074 106 P

225

lBC

dA = dB + lAB q

= 13.17 106 P + (125)(0.074 106) P = 22.42 106 P

Apply displacement limit

dA = 0.35 mm = 22.42 106 P

P=

0.35

= 15.611 kN

22.42 10 -6

SC

90 Mechanics of Materials

PROBLEM 2.29

2.29 A homogenous cable of length L and uniform cross section is suspended

from one end. (a) Denoting by r the density (mass per unit volume) of the

cable and by E its modulus of elasticity, determine the elongation of the

cable due to its own weight. (b) Assuming now the cable to be horizontal,

determine the force that should be applied to each end of the cable to obtain

the same elongation as in part a.

y

P

L

Ly

SOLUTION

(a) For element at point identified by coordinate y

P = weight of portion below the point

= rg A (L y)

dd =

Pdy

rgA( L - y)dy r g( L - y)

=

=

dy

EA

EA

E

z

L

d=

(b) For d =

rL

EA

P=

rg ( L - y)

rg

dy =

E

E

rg

E

FG L

H

L2

2

IJ = 1

K 2

F Ly - 1 y I

H 2 K

rgL2

E

EAd

EA rgL2

1

1

=

= rgL = W

L

L 2E

2

2

PROBLEM 2.30

2.30 Determine the deflection of the apex A of a homogenous circular cone of height h, density r, and

modulus of elasticity E, due to its own weight.

SOLUTION

A

Let b = radius of the base and

y

Element

h

r

r=

b

Volume of portion above element

V=

r = radius at section with

coordinate y.

1

1 b2

p r 2y = p 2 y3

3

3 h

b

y

h

Chapter 2

prgb 2 y 3

3h 2

P = rgV =

z

h

P Dy

d=

=

EA

rg y 2

=

3E 2

=

0

A = pr2 =

P dy

=

EA

p b2 2

y

h2

p r gb 2 y 3

3 h2

91

h2

E p b2 y 2

z

h

dy =

rgy

dy

3E

rgh 2

6E

PROBLEM 2.31

2.31 The volume of a tensile specimen is essentially constant while plastic deformation occurs. If the

initial diameter of the specimen is d1, show that when the diameter is d, the true strain is

t = 2 ln (d1/d).

SOLUTION

If the volume is constant

p 2

p 2

d1 L0

dL=

4

4

F I

H K

d

d2

L

= 12 = 1

d

L0

d

et = ln

F I

H K

d

L

= ln 1

d

L0

= 2 ln

d1

d

PROBLEM 2.32

2.32 Denoting by e the engineering strain in a tensile specimen, show that the true strain is

et = ln (l + e).

SOLUTION

et = ln

L

L +d

= ln 0

L0

L0

FG

H

= ln 1 +

Thus

d

L0

IJ = ln (1 + e)

K

et = ln (1 + e)

PROBLEM 2.33

2.33 An axial force of 60 kN is applied to the assembly shown by means of rigid end plates. Determine

92 Mechanics of Materials

(a) the normal stress in the brass shell, (b) the corresponding

deformation of the assembly.

5 mm

20 mm

5 mm

5 mm

20 mm

5 mm

SOLUTION

Let

Pb = portion of axial force carried by brass shell

Steel core

E = 200 GPa

Ps = portion of axial force carried by steel core

PL

d= b

Ab Eb

d=

Ps L

As Es

Brass shell

E = 105 GPa

E Ad

Pb = b b

L

Ps =

250 mm

Es Asd

L

P = Pb + Ps = (Eb Ab + Es As)

d

L

d

P

=e=

L

Eb Ab + Es As

As = (0.020) (0.020) = 400 106 m2

Ab = (0.030) (0.030) (0.020) (0.020) = 500 106 m2

d

60 10 3

=e=

= 452.83 106

L

(105 10 9 )(500 10 6 ) + (200 10 9 )(400 10 -6 )

(a) sb = Ebe = (105 109) (452.83 106) = 47.5 106 Pa

= 47.5 MPa

(b) d = Le = (250 103) (452.83 106) = 113.2 106 m

= 0.1132 103 m

= 0.1132 mm

PROBLEM 2.34

2.34 The length of the assembly decreases by 0.15 mm when an axial force is applied by means of rigid

end plates. Determine (a) the magnitude of the applied force, (b) the corresponding stress in the

steel core.

Chapter 2

5 mm

20 mm

5 mm

5 mm

20 mm

5 mm

Steel core

E = 200 GPa

Brass shell

E = 105 GPa

250 mm

SOLUTION

Pb = portion of axial force carried by brass shell.

Let

Ps = portion of axial force carried by steel core.

d=

Pb L

Ab Eb

Pb =

Eb Ab d

L

d=

Ps L

As Es

Ps =

Es Asd

L

P = Pb + Ps = (Eb Ab + Es As)

d

L

As = (0.020) (0.020) = 400 106 m2

Ab = (0.030) (0.030) (0.020) (0.020) = 500 106 m2

(a) P = [(105 109) (500 106) + (200 109) (400 106)]

0.15 10 -3

250 10 -3

= 79.5 103 N = 75.9 kN

(b) ss = Ese =

E sd

( 200 10 9 )( 0.15 10 -3 )

=

= 120 106 Pa

-3

L

250 10

= 120 MPa

93

94 Mechanics of Materials

PROBLEM 2.35

2.35 The 1.35 m concrete post is reinforced with six steel bars, each with a

28 mm diameter. Knowing that Es = 200 GPa and Ec = 29 GPa,

determine the normal stresses in the steel and in the concrete when a

1560 kN axial centric force P is applied to the post.

1.35 m

SOLUTION

Let

0.45 m

Pc = portion of axial force carried by concrete

Ps = portion carried by the six steel rods

d=

Pc L

Ec Ac

Pc =

Ec Acd

L

d=

Ps L

Es As

Ps =

Es Asd

L

P = Pc + Ps = (Ec Ac + Es As)

e=

d

P

=

L Ec Ac + Es As

As = 6

Ac =

d

L

p 2 6p

ds =

(28)2 = 3694.5 mm2

4

4

p 2

p

dc As = (450)2 3694.5 = 155348.6 mm2

4

4

L = 1.35 m = 1350 mm

e=

-1560 10 3

FG 29 10 IJ (155348.6)FG 200 10 IJ (3694.5) = 297.48 10

H 10 K

H 10 K

9

FG 200 10 IJ ( 297.48 10 ) = 59.5 N/mm = 59.5 MPa

H 10 K

F 10 IJ ( 297.48 10 ) = 8.627 N/mm = 8.627 MPa

= E e = G 29

H 10 K

9

s s = E se =

sc

Chapter 2

PROBLEM 2.36

2.36 An axial centric force of magnitude P = 450 kN

is applied to the composite block shown by

means of a right end plate. Knowing that h =

10 mm, determine the normal stress in (a) the

brass core, (b) the aluminum plates.

95

Brass core

(E = 105 GPa)

P

Aluminum plates

(E = 70 GPa)

Rigid

end plate

SOLUTION

Let

Pb = portion of axial force carried by

brass core

300 mm

Pa = portion carried by two aluminum plates

d=

Pb L

Eb Ab

Pb =

Eb Abd

L

60 mm

h

d=

Pa L

Ea Aa

Pa =

Ea Aad

L

P = Pb + Pa = (Eb Ab + Ea Aa)

e=

40 mm

h

d

L

d

P

=

L Eb Ab + Ea Aa

Ab = (60) (40) = 2400 mm2 = 2400 106 m2

Aa = (2) (60) (10) = 1200 mm2 = 1200 106 m2

e=

450 10 3

= 1.3393 103

-6

9

6

(105 10 )(2400 10 ) + ( 70 10 )(1200 10 )

9

(a) sb = Ebe = (105 109) (1.3393 103) = 140.6 106 Pa = 140.6 MPa

(b) sa = Ea e = (70 109) (1.393 103) = 93.75 106 Pa = 93.75 MPa

PROBLEM 2.37

2.37 For the composite block shown in Prob. 2.36, determine (a) the value of h if the portion of the load

carried by the aluminum plates is half the portion of the load carried by the brass core, (b) the

total load if the stress in the brass is 80 MPa.

You might also like

- Solucionario 1 - 1 A 1 - 28Document30 pagesSolucionario 1 - 1 A 1 - 28Lucas Warley86% (7)

- Kunci Jawaban Hidrolik Chapter 2Document10 pagesKunci Jawaban Hidrolik Chapter 2Slamet Wahyudi100% (3)

- Chap 1Document32 pagesChap 1안혜영No ratings yet

- FinalsDocument20 pagesFinalschristian pagtama100% (1)

- CEMDEF40 - Practice Problems 1 PDFDocument2 pagesCEMDEF40 - Practice Problems 1 PDFEldridge EastNo ratings yet

- Thermal StressDocument19 pagesThermal StressDarren Ian MaalihanNo ratings yet

- Design Examples - Instructors PDFDocument24 pagesDesign Examples - Instructors PDFAlan Peter100% (2)

- Maahflmery: TR (Uf, DDocument55 pagesMaahflmery: TR (Uf, DChristian John Paul LijayanNo ratings yet

- 2 Simple StrainDocument21 pages2 Simple StrainFelix Violeta0% (1)

- II. Multiple Choice Problem Solving Compilations With SolutionsDocument55 pagesII. Multiple Choice Problem Solving Compilations With SolutionsRamel DionzonNo ratings yet

- PhyDocument56 pagesPhyJohn Ray CuevasNo ratings yet

- Clutches (Lec7)Document50 pagesClutches (Lec7)Niño Jhim Andrew80% (5)

- Stress On Thin-Walled Vessel (Sample Problem)Document5 pagesStress On Thin-Walled Vessel (Sample Problem)Li ReNo ratings yet

- 02 01ChapGereDocument17 pages02 01ChapGereChristina Buckle100% (1)

- Power Screw Example ProblemsDocument2 pagesPower Screw Example ProblemsJosafatNo ratings yet

- MEC2213 - Shearing Force IDocument26 pagesMEC2213 - Shearing Force IAlex Chee100% (2)

- Chapter 03 PDFDocument7 pagesChapter 03 PDFKyro100% (1)

- English For Hospitality-HotelDocument6 pagesEnglish For Hospitality-Hotelardeleanicolaie100% (3)

- Strength of MaterialsDocument29 pagesStrength of MaterialsMeennnNo ratings yet

- Solution Manual - MGere P1Document15 pagesSolution Manual - MGere P1Diego Bonfim0% (1)

- Torsion - SolvedDocument10 pagesTorsion - SolvedFirzana AmiraNo ratings yet

- Homework 4 SolutionDocument5 pagesHomework 4 SolutionJennifer100% (1)

- Mechanics of Materials Chap 05-02 PDFDocument17 pagesMechanics of Materials Chap 05-02 PDFkaru320No ratings yet

- chapter 1 Fluid MechanicsDocument37 pageschapter 1 Fluid MechanicsHe YapNo ratings yet

- Flanged CouplingDocument15 pagesFlanged CouplingJoshua ApiladoNo ratings yet

- ColumnasDocument15 pagesColumnasandreinarodNo ratings yet

- Section 6 - Combined Stresses PDFDocument133 pagesSection 6 - Combined Stresses PDFGlënnLibönTäbiölö100% (1)

- Cap. 13Document284 pagesCap. 13Ent Qa NepalNo ratings yet

- Torsion of Thin-Walled TubeDocument4 pagesTorsion of Thin-Walled TubeRalph Castillo100% (1)

- Section 6Document133 pagesSection 6ILAYAPERUMAL K100% (2)

- SolvedProblemsinShearandMomentDiagrams403 422Document33 pagesSolvedProblemsinShearandMomentDiagrams403 422Chandra MouliNo ratings yet

- Column Base PlateDocument10 pagesColumn Base PlateVon San JoseNo ratings yet

- W/M - °K °K: Both Sides of The PlateDocument4 pagesW/M - °K °K: Both Sides of The Platebryant SiboaNo ratings yet

- Solution 304: Hide Click Here To Show or Hide The SolutionDocument21 pagesSolution 304: Hide Click Here To Show or Hide The SolutionRommell Bacos100% (1)

- JJ309 Chapter 1Document49 pagesJJ309 Chapter 1Amar ZalleeNo ratings yet

- Ce 135 Problem Set 1Document3 pagesCe 135 Problem Set 1johannes100% (1)

- Variable StressesDocument19 pagesVariable StressesSyed Naveed Jamal100% (2)

- U7 l43 Numericals On TorsionDocument4 pagesU7 l43 Numericals On TorsionRoxanneNo ratings yet

- Solution To Problem Set Fluid Mech PressureDocument6 pagesSolution To Problem Set Fluid Mech PressureMark Augusto V. AgusNo ratings yet

- Properties of Areas:: A T T T T Acceleration DiagramDocument8 pagesProperties of Areas:: A T T T T Acceleration DiagramRetro GamerNo ratings yet

- Damped Free Vibration ProblemsDocument7 pagesDamped Free Vibration ProblemsLeo Mark Sevilla100% (1)

- Problem Set#8 PDFDocument29 pagesProblem Set#8 PDFMark Genesis VelonzaNo ratings yet

- FinallDocument175 pagesFinallremeceldo dagamac100% (1)

- This Study Resource Was: MIDTERM ACTIVITIES: Pressure Vessels (Problem Set)Document2 pagesThis Study Resource Was: MIDTERM ACTIVITIES: Pressure Vessels (Problem Set)osas pasas100% (1)

- Simple TensionDocument40 pagesSimple Tensionponcatoera83% (6)

- Solution: Problem Set No. 2 Title: Shear Stress Page No.Document5 pagesSolution: Problem Set No. 2 Title: Shear Stress Page No.Noven VillaberNo ratings yet

- Assignment No.3 Bolted JointsDocument6 pagesAssignment No.3 Bolted JointsYash SahuNo ratings yet

- Lesson 1 Exercises Problem No. 1Document2 pagesLesson 1 Exercises Problem No. 1Ariel Gamboa100% (1)

- Introduction To ThermodynamicsDocument66 pagesIntroduction To ThermodynamicsMikaela Dela Cruz0% (1)

- Lesson 7 Kinetics of Curvilinear Translation, Dynamic EquilibriumDocument6 pagesLesson 7 Kinetics of Curvilinear Translation, Dynamic EquilibriumNadjer C. AdamNo ratings yet

- Chapter 04Document78 pagesChapter 04Bikash Chandra DasNo ratings yet

- Strength July2019Document13 pagesStrength July2019Allan Añavisa Ostique Jr.100% (1)

- UnlockedDocument35 pagesUnlockedLucas Emanuel Soeira100% (1)

- Algebraic MethodDocument3 pagesAlgebraic Methodstephen james100% (1)

- BODY OF THE BOOK-Statics PDFDocument110 pagesBODY OF THE BOOK-Statics PDFChristian J SebellinoNo ratings yet

- Chap 2pdf 3 PDF FreeDocument23 pagesChap 2pdf 3 PDF FreeMarwa OmarNo ratings yet

- CE 302-Lecture-6 - Stress and Strain Under Axial Loading-Additional ProblemsDocument21 pagesCE 302-Lecture-6 - Stress and Strain Under Axial Loading-Additional ProblemsMujahid StNo ratings yet

- Chap 1aDocument10 pagesChap 1aSeunghoJungNo ratings yet

- WDocument11 pagesWShrey PandeyNo ratings yet

- HW01 SolutionsDocument4 pagesHW01 SolutionsLoong Cheng NingNo ratings yet

- Design of Rectangular Water TankDocument268 pagesDesign of Rectangular Water Tankchetanmale89% (28)

- How I Hacked Facebook With A Word DocuemntDocument7 pagesHow I Hacked Facebook With A Word DocuemntleoblackpereiraNo ratings yet

- IRSE Paper 4 - R Salson and H RevellDocument18 pagesIRSE Paper 4 - R Salson and H RevellArun SapkalNo ratings yet

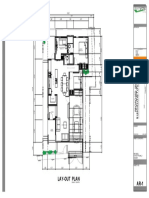

- AR-1 Lay-Out Plan: Master'S Bedroom Home Theater Bedrm. 3Document1 pageAR-1 Lay-Out Plan: Master'S Bedroom Home Theater Bedrm. 3dante mortelNo ratings yet

- Traffic Signal Design: Dr. Terrance M. RengarasuDocument32 pagesTraffic Signal Design: Dr. Terrance M. RengarasuAngel HasnaNo ratings yet

- E1 Lab 11 5 5Document19 pagesE1 Lab 11 5 5Chris LeeNo ratings yet

- WinCUPL GuideDocument2 pagesWinCUPL Guidepra_sad50% (2)

- Monthly Reports 01-03-17Document42 pagesMonthly Reports 01-03-17L. A. PatersonNo ratings yet

- Himel Productos 10 1Document58 pagesHimel Productos 10 1yasserfouda100% (1)

- MOZZA TILE - Katalog JAN 2020Document28 pagesMOZZA TILE - Katalog JAN 2020Dunia AnakNo ratings yet

- Seminar On Mivan Technology The Aluminium FormworkDocument36 pagesSeminar On Mivan Technology The Aluminium FormworkCivilTY09Aditya GavaliNo ratings yet

- Enclosures For Automation PDFDocument210 pagesEnclosures For Automation PDFnazeerNo ratings yet

- LDAP TutorialDocument28 pagesLDAP Tutorialzorrito26No ratings yet

- ZXUR 9000 GSM (V6.50.10) Base Station Controller Radio Parameter ReferenceDocument1,981 pagesZXUR 9000 GSM (V6.50.10) Base Station Controller Radio Parameter ReferenceRaven Zaven100% (4)

- CE-121 Civil Engineering Materials Lecture 4Document59 pagesCE-121 Civil Engineering Materials Lecture 4Anonymous 0ClbS49QkuNo ratings yet

- CTMS Admin GuideDocument490 pagesCTMS Admin GuideArshiya BathoolNo ratings yet

- Handbuch GEObox Bag 00140404 MAILDocument44 pagesHandbuch GEObox Bag 00140404 MAILvojammNo ratings yet

- Hitachi PLCDocument8 pagesHitachi PLCTeck Soon TeoNo ratings yet

- Advanced Network Analysis TechniqueDocument222 pagesAdvanced Network Analysis TechniqueSyahrial100% (1)

- Chapter 4-Timer For Optimization GSMDocument35 pagesChapter 4-Timer For Optimization GSMtechnobrat_guy100% (1)

- Rs232 Control: How To Find Audia/Nexia Ip Settings Using HyperterminalDocument4 pagesRs232 Control: How To Find Audia/Nexia Ip Settings Using Hyperterminalvpinambiar7453No ratings yet

- Anselm KieferDocument22 pagesAnselm Kieferchnnnna100% (1)

- Concept Plan 2011 REviewDocument24 pagesConcept Plan 2011 REviewLina NgNo ratings yet

- LOad On Bridge 2Document140 pagesLOad On Bridge 2shamsukarim2009No ratings yet

- SimCity Exception Report 2011.03.27 16.59.58Document4 pagesSimCity Exception Report 2011.03.27 16.59.58pmears_2No ratings yet

- Power Generation: Application of AutomationDocument20 pagesPower Generation: Application of AutomationABVSAINo ratings yet

- RCD Columns UpdatedDocument9 pagesRCD Columns UpdatedGerald CatiponNo ratings yet

- Window Server 2016 KeyDocument2 pagesWindow Server 2016 Keylemankreo homseNo ratings yet

- StaircasesDocument65 pagesStaircasesMohammad AkmalNo ratings yet

- Software Defined Network SDNDocument3 pagesSoftware Defined Network SDNMarkMedovichNo ratings yet