Professional Documents

Culture Documents

1543-07 Performance Evaluation of Asphalt Overlays On Broken and Seated Concrete Pavements PDF

Uploaded by

haitaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1543-07 Performance Evaluation of Asphalt Overlays On Broken and Seated Concrete Pavements PDF

Uploaded by

haitaoCopyright:

Available Formats

TRANSPORTATION RESEARCH RECORD 1543

55

Performance Evaluation of Asphalt

Overlays on Broken and Seated

Concrete Pavements

RAJAGOPAL S. ARUDI, ISSAM MINKARAH, KRISHNA KANDULA, AND

ARCHANA GOSAIN

Evaluating the effectiveness of breaking and seating concrete pavements

prior to asphalt overlay is a subject of great importance for pavement

rehabilitation. A number of studies reported that breaking and seating

delayed reflection cracking, but some indicated that, after 4 to 5 years,

the cracking of the asphalt overlays on broken and seated sections

increased and was about the same as in the other sections. Structural

analysis of these pavements confirmed a significant loss of structural

support. A controlled experimental project in Ohio investigated the

effectiveness of breaking and seating jointed reinforced concrete pavements before asphalt overlay. Four miles of in-service composite pavements carrying heavy traffic were rehabilitated by milling the original

asphalt layer, breaking and seating the concrete slabs, and constructing

new asphalt overlays. Four more miles of the same sections were constructed in the same way except for breaking and seating. After 21/2 years

of study, the results confirm the previous findings regarding the effectiveness of breaking and seating in delaying reflection cracks and reduction in structural capacity, increase in surface deflection, and loss of flexural strength. This study indicates that the type of breaking equipment

used and the extent of breaking are the most significant factors affecting the performance of these pavements.

In composite pavements, thermal movements of the underlying concrete slabs at joints and working cracks induce excessive strains in

the asphalt concrete (AC) overlay, which results in the development

of reflection cracking. The cracks form at the bottom of the asphalt

layer, above a joint or a crack, and propagate vertically to the surface. Such movements are directly proportional to the length of the

slab. This implies that the shorter the length, the better the chance

of reducing crack development and, in turn, reflection cracking.

Reflection cracks cause early deterioration of the overlay, increase

life-cycle costs, and reduce the useful life of the pavement.

The intent of pavement cracking and seating is to create concrete

pieces that are small enough to reduce horizontal slab movements to

a point at which thermal stresses that contribute to reflection cracking will be greatly reduced. These pieces should be large enough to

maintain the original structural strength of the portland cement concrete (PCC) pavement and to provide some aggregate interlock.

Seating of the broken slabs after cracking is intended to reestablish

support between the subbase and the slab.

Thorough slab cracking is essential to the success of breaking and

seating. The continuity of the PCC slab (and its ability to transmit

horizontal slab movement) must be broken to achieve the full potential of the breaking and seating rehabilitation technique.

Department of Civil and Environmental Engineering, University of Cincinnati, P.O. Box 210071, Cincinnati, Ohio 45221-0071.

PREVIOUS INVESTIGATIONS

A considerable range of performance has been achieved with the

breaking and seating procedure. It is apparent that a properly constructed section can alleviate (perhaps eliminate in some cases)

thermal-related reflective cracking in AC overlays.

A performance survey by FHWA found that breaking/cracking

and seating (B/C&S) as a rehabilitation alternative should be

approached with caution. A significant reduction in reflection cracking after 4 to 5 years occurred on only 2 of 22 projects reviewed (1).

The University of Illinois surveyed 70 projects in 12 states and

found that B/C&S treatment reduced reflection cracking in the early

years of the life of the overlay but its effectiveness diminished with

age (1,2). Kentucky surveyed and tested 451 lane-miles of B/C&Streated pavements and found only one section that displayed unexpected reflection cracking; an analysis of the test section revealed

that proper B/C&S had not been achieved. Kentucky reported, performance has been good, and as a result the practice continues routinely (2).

Overall, B/C&S appears to provide benefits by delaying reflection cracking. After 4 to 5 years, the B/C&S sections exhibit approximately the same degree of reflection cracks.

Pavements on reasonably firm subgrades or bases with cracked

pavement sizes of 0.6 to 0.9 m and a 7.6- to 12-cm overlay thickness

have performed the best to date. The actual overlay thickness will

depend on the expected traffic and other usual design parameters.

PRESENT STUDY: OBJECTIVES AND SCOPE

Since 1984, as one of many pavement rehabilitation alternatives, the

Ohio Department of Transportation (ODOT), has used fractured

slab techniques before asphalt overlays (3). Ten projects with a total

length of 63 miles have been rehabilitated with AC overlays after

breaking and seating the concrete pavements. Performance studies

of these projects were inconclusive. As a result, there is some disagreement in Ohio, from district to district, about the effectiveness

of this technique. Nevertheless, it is generally believed that the

breaking and seating method is more suitable for plain (nonreinforced) PCC pavements. Hence, ODOT initiated a study to investigate the effectiveness of breaking and seating jointed reinforced

concrete pavements (JRCP) before asphalt overlay.

Eight sections of in-service composite pavements were selected,

each about 1.6 km with AC over JRCP and carrying heavy traffic.

Four of these sections were rehabilitated by milling the original AC

56

TRANSPORTATION RESEARCH RECORD 1543

layer, breaking and seating the concrete slabs, and constructing new

AC overlays. Four sections adjacent to the break and seat (B/S) sections were rehabilitated in the same way but without breaking and

seating the concrete slabs.

Performance was evaluated by continuously monitoring the

test pavements using deflection measurements and a visual distress

survey.

This research was performed from 1992 through 1995. This paper

presents the details of the testing program and the findings.

TEST SECTIONS

The location and other details of the test sections are presented in

Table 1. Core samples of the concrete pavement and soil subgrade

were taken from each test section.

Tests on concrete cores revealed a large variation in the lab compressive strength. Strength values ranged from 20 685 kPa to 52 400

kPa. However, the compressive strength of most samples was

between 34 475 kPa and 48 265 kPa.

The liquid limit, plasticity index, and sieve analysis test results

were used to classify the subgrade soils using the AASHTO Soil

Classification System. The subgrade soils from the I-71 site were

classified as Type A-4 (silty soils). The soil samples from the SR-4

sections were classified as Type A-6 (clayey soils).

CONSTRUCTION

Construction involved removing the original 7.6-cm asphalt layer,

breaking and seating the PCC slabs (only on the B/S sections), and

placing an AC overlay. The I-71 sections were overlaid with a 21.6cm-thick AC overlay in three layers. The SR-4 sections received a

16.5-cm-thick AC overlay, in three layers. The overlay thickness

design was made by ODOT engineers using ODOT design procedures. In all sections, a 10.2-cm-diameter longitudinal underdrain

was installed along the shoulder at a depth of 0.9 m below the top of

the concrete pavement. Construction of the AC overlays on the I-71

sections was completed in September 1992, and the overlays on the

SR-4 sections were completed in September 1993. The performance

of the AC overlays on the I-71 sections were monitored for three

winter cycles and on the SR-4 sections for two winter cycles.

TABLE 1

Details of Test Sections

For about 300 m at the start of breaking and seating, the concrete

slabs on one section of I-71 were broken with a 2.4-m, 5440-kg guillotine hammer. This section was the passing lane on the northbound

lanes between Station 35100 and Station 88100. The 2.4-m-wide

hammer was dropped at the center of the lane, which is 3.6 m wide.

Because the width of the hammer was smaller than the lane, the

desired result was not achieved. Hence, use of the 2.4-m-wide

hammer was discontinued and further breaking was done with a 1.8m-wide hammer. Two passes of the 1.8-m-wide hammer were

required in each lane to cover the entire 3.6-m width. The hammer

was dropped at an interval of 0.45 m in the longitudinal direction.

The two sections on SR-4 were broken with a pile hammer on a

0.45- 3 0.45-m grid.

An attempt was made to achieve uniform breakage in each section; however, most of the pavements broken with the guillotine

hammer developed problems where drops overlapped, usually in

the middle of the lane. This area was cracked much more than

other parts. Breaking with all types of hammers resulted in thorough slab cracking, and no additional effort was made to break the

reinforcement. Breaking was also more extensive with the pile

hammer.

About 5 lane-miles of pavement could be broken on each working day with the guillotine hammer, while only about 1 lane-mile

was broken when using the pile hammer. Breaking caused some

traffic disruption. However, no data were collected on traffic behavior through the work zone during the breaking operation.

Seating the sections was accomplished with five passes of a

40 350-kg pneumatic roller.

FIELD EVALUATION

Falling weight deflection measurements were made on the original

AC surface, on the exposed concrete surface after milling the AC,

and periodically on the AC overlay. On each section, 30 to 40 measurements were made during each phase.

The intensity of transverse cracks on each section was visually

observed and recorded in conformity with ODOTs Pavement Condition Rating Manual (4). The location of the cracks was measured

with reference to established benchmarks. Crack mapping was performed on the original AC surface, on the exposed concrete surface

Arudi et al.

57

TABLE 2

Comparison of Structural Condition of Original Pavement Sections

after milling, and several times after the AC overlay. When the concrete pavement was exposed, the location of the joints and permanent patches was also recorded. Several benchmarks were established to locate the exact position of cracks, joints, and permanent

patches. On the AC overlays, the date when a crack was first noticed

was noted along with its location. Also, a photographic record of the

condition of the joints and cracks was kept. Many photographs

depicting the condition of joints and cracks before overlay and the

new cracks in the AC overlay were obtained. These photographs

were used to countercheck the location of joints and cracks and to

ascertain the severity of the cracks.

COMPARING CONDITION OF ORIGINAL

PAVEMENT SECTIONS

Structural Condition

Table 2 provides a comparison of the structural parameters of the

control sections and the sections marked for breaking and seating.

FIGURE 1

Spreadability and maximum deflection values have long been used

to define the structural condition of a pavement. Arudi et al. (5) indicated that the ratio of W1/W5 can also be used as a good indicator of

the structural behavior of the pavement. Table 2 indicates that the difference in structural response with respect to maximum deflection,

spreadability, and the W1/W5 ratio between two adjacent sections is

very small, indicating the sections were structurally homogeneous.

Surface Condition

Figures 1 through 4 illustrate the extent of reflection cracking in the

original pavements. The plots in Figures 1 through 4 indicate that

the sections selected are fairly homogeneous from an extent-ofcracking point of view. For comparison, each section was subdivided into five equal subsections of about 320 m. In general, about

35 cracks were present in each subsection on I-71. The SR-4 sections had extensive cracks with 60 to 100 cracks in each subsection.

In most instances, the cracks were sealed; hence, the severity of the

cracks could not be observed.

I-71, Stations 726163 to 779143 (crack density along roadway).

58

TRANSPORTATION RESEARCH RECORD 1543

FIGURE 2

I-71, Stations 35100 to 88100 (crack density along roadway).

After milling the original AC layer and exposing the concrete surface, the exact location of the cracks and joints with respect to the

benchmarks was recorded. More than 80 percent of the slabs had

one to three cracks. Rarely were there slabs with four or more

cracks. The average spacing of cracks varied from 3 to 9 m. This survey also assisted in establishing how many of the cracks in the original AC layer were reflected from the joints and how many from the

cracks.

as B/S sections. These sections survived the winter of 1993 without

developing any cracks, but the pavement exhibited an increase in

deflection characteristics during the first year. The monthly summarized station and divisional data available in the climatological

data of Ohio (6) were studied for the winter months of the past 10

years. The winter of 1993 was mild with normal temperatures prevailing during the entire season.

Performance After Winter 1994

PERFORMANCE OF ASPHALT OVERLAYS

A performance evaluation was made by studying the change in

structural response and surface characteristics of the pavement sections investigated.

Performance After Winter 1993

Construction of the AC overlay was completed on only 4 miles of

I-71 by fall 1992. The completed pavement included control as well

FIGURE 3

Construction of the AC overlay on SR-4 was completed by fall

1993. As a result, all sections were now available for monitoring.

Figures 5 through 8 present changes in the deflection characteristics

of the pavements with time. For all the test sections, the breaking

and seating procedure resulted in an increased surface deflection, a

reduced spreadability, and an increased W1/W5 ratio. The increased

surface deflection was from a loss of the flexural strength. The lower

spreadability and higher W1/W5 of the B/S pavements indicate a

behavior similar to flexible pavements (5). These values on the

SR-4 sections, on which a pile hammer was used, were considerably

SR-4, Stations 217100 to 267100 (crack density along roadway).

Arudi et al.

59

FIGURE 4

SR-4, Stations 105150 to 160150 (crack density along roadway).

lower than those on I-71 on which a guillotine hammer was used.

This finding was caused by the higher degree of breakage in these

sections. The structural response of the sections was fairly consistent during the study period.

After the winter of 1994, cracking was noticed in all control

sections, but only two cracks were noticed in the 4 miles of B/S

sections. These cracks were in areas where the breaking was

not done to the desired specifications. All these cracks were of

low severity. The I-71 sections were overlaid in the fall of 1992

and the SR-4 sections in the fall of 1993. The I-71 sections

survived the winter of 1993 without developing any cracks.

However, the winter 1993 was mild, whereas the winter of

FIGURE 5 I-71, Stations 726163 to 779143 (variation of

structural parameters with time).

FIGURE 6 I-71, Stations 35100 to 88100 (variation of

structural parameters with time).

60

FIGURE 7 SR-4, Stations 217100 to 267100 (variation of

structural parameters with time).

1994 was very severe. The data collected from weather reports (6)

indicate very low temperatures persisting over a long period during the winter of 1994.

The position of the cracks on the AC overlay was compared with

the location of joints and cracks in the underlying concrete slabs. A

summary of these results is presented in Table 3.

Some of the cracks that appeared in the control section are

reflected from either joints or cracks in the PCC layer, while others

that span both lanes have no relation to the cracking of the underlying layer. Core samples taken at the location of the nonreflected

cracks indicated cracking in only the top few inches of the AC overlay. More studies are being conducted to investigate the causes of

these additional cracks.

Thus, it was concluded that breaking and seating concrete pavements delays reflection cracking.

Performance After Winter 1995

All the sections were revisited after the winter of 1995. On average,

there were six to eight new cracks on all the control sections.

Cracks also appeared on the two B/S sections on I-71. There were

no cracks on the B/S sections on SR-4. Figures 1 through 4 and

Table 3 present a comparative study of cracks on the control and

the B/S sections. It is interesting to observe that the sections broken with the pile hammer have been more successful in delaying

cracks than those broken with the guillotine hammer. This finding

TRANSPORTATION RESEARCH RECORD 1543

FIGURE 8 SR-4, Stations 105150 to 160150 (variation of

structural parameters with time).

is obviously caused by the higher degree of breakage achieved with

the pile hammer. However, the total number of cracks on the B/S

sections is still small compared with the number of cracks on the

control sections.

FACTORS THAT SIGNIFICANTLY AFFECTED

PERFORMANCE OF AC OVERLAYS

The primary variables introduced in this study are type of equipment for breaking and extent of breaking. The other variables present are traffic volume and AC overlay thickness.

Three types of breakers were used. Part of one section on

I-71 between Stations 35100 and 45100 was broken with a

2.4-m-wide guillotine hammer. The rest of the sections on I-71

were broken with two passes of a 1.8-m-wide guillotine hammer

in each lane. The two B/S sections on SR-4 were broken with a

pile hammer.

Breaking with the 2.4-m-wide hammer did not produce the

desired effect. Cracks in the longitudinal direction were hardly visible. The sections broken with the 1.8-m-wide hammer produced

cracking in both longitudinal and transverse directions. Breaking

was more extensive with the pile hammer compared with sections

broken with the guillotine hammer. The pile hammer produced

more uniform transverse and longitudinal cracks although pavements broken with the guillotine hammer exhibited severe breaking where drops overlapped, usually in the middle of the lane. Both

Arudi et al.

61

TABLE 3 Summary of Cracks on AC Overlay

the 1.8-m guillotine hammer and the pile hammer produced slab

fragments of the desired size. Breaking with all types of hammers

resulted in thorough slab cracking, but the reinforcement was damaged more by the pile hammer.

Breaking and seating concrete pavements before AC overlay had

the following effects:

Increase in surface deflection

Reduction in spreadability

Loss of flexural strength

Delay in reflection cracking

Reduction in number of reflection cracks

The difference in the mean values of the structural parameters

investigated for the B/S sections and the control sections was

found to be statistically significant (5). There is no evidence of

higher maximum deflections on sections broken with the pile

hammer compared with those broken with the guillotine hammer.

The spreadability values of broken and seated pavements were

lower than the values for the control sections. Concrete pavements,

in general, exhibit higher spreadability than flexible pavements.

The lower spreadability of the B/S sections indicates a behavior

similar to flexible pavements. The spreadability values of sections

on SR-4, on which a pile hammer was used, were considerably

lower than those on I-71, on which a guillotine hammer was used.

This finding is because of the higher degree of breakage in these

sections.

Breaking and seating resulted in higher W1/W5 values compared

with the control sections. Also, SR-4 sections had very high W1/W5

ratios. This result is to be expected because these sections, broken

with the pile hammer, were almost rubblized.

Reflection cracking was observed in all the control sections monitored in this study. On I-71 sections, the first set of cracks was

noticed about 15 months after construction of the AC overlay.

On SR-4 sections, cracks were observed within 7 months of AC

overlay construction. The cracking in both sections occurred after

the severe winter of 1994. No cracking was noticed on any of

the broken and seated sections during this time. However, two

cracks were noticed on the B/S section on I-71, which was broken

with the 2.4-m-wide hammer. This was because the slabs were

not broken extensively. Breaking and seating not only delayed

cracking on the AC overlays but also resulted in a reduced

number of cracks.

Traffic intensity, soil type, and AC thickness had no effect on

performance with respect to either structural effectiveness or

development of reflection cracking. The construction of the I-71

sections was completed in the fall of 1992 while the sections on

SR-4 were completed in the fall of 1993. Reflection cracks on the

SR-4 section appeared after the first winter, whereas cracks in sections on I-71 did not appear until the second winter. However, the

first winter after the completion of I-71 was normal, whereas the

1994 winter was very severe. The early appearance of reflection

cracks on control sections of SR-4 is therefore attributed to the

severity of the winter of 1994 instead of to the age or thickness of

the overlay.

It is thus observed that type of breaking equipment and extent of

breaking are the most important factors governing the early behavior of AC overlays on B/S sections.

62

TRANSPORTATION RESEARCH RECORD 1543

SUMMARY AND CONCLUSIONS

REFERENCES

The following conclusions are drawn on the basis of the results of

a 3-year study of a controlled B/S research project.

1. Thompson, M. R. NCHRP Synthesis of Highway Practice 144: Breaking/

Cracking and Seating Concrete Pavements. TRB, National Research

Council, Washington, D.C., March 1989, 39 pp.

2. Pavement Consultancy Services. Guidelines and Methodologies for the

Rehabilitation of Rigid Highway Pavements Using Asphalt Concrete Overlays. National Asphalt Pavement Association, Beltsville, Md., June 1991.

3. Garnes, A., and B. McQuiston. Pavement Rehabilitation Study on the

National Highway System in Ohio: 19921993. Ohio Division, FHWA,

U.S. Department of Transportation, May 1994.

4. Resource International Inc. Implementation and Revision of Developed

Concepts for ODOT Pavement Management Program. Volume 2 of Pavement Condition Rating Manual. Report FHWA/OH-89/013. FHWA, U.S.

Department of Transportation, Feb. 1987.

5. Arudi, R. S., K. Kandula, I. A. Minkarah, and M. Bhupalam. Categorization of Asphalt Overlays on Broken and Seated Pavements. In Transportation Research Record 1473, TRB, National Research Council, Washington, D.C., 1995, pp. 131137.

6. National Climatic Data Center, Asheville, N.C.

Breaking and seating delayed reflection cracking on the AC

overlays.

The B/S sections exhibited significantly less reflection cracking than the control sections.

As observed from the FWD tests, breaking and seating

resulted in loss of structural capacity of the pavement.

Type of breaking equipment and extent of breaking have a

significant effect on the performance of AC overlays.

ACKNOWLEDGMENTS

The authors gratefully acknowledge the assistance of William F.

Edwards and Roger Green of ODOT for their help in conducting

this study.

The opinions and conclusions expressed in this report are those of the authors.

This report does not constitute a standard, specification, or regulation.

Publication of this paper sponsored by Committee on Flexible Pavement Construction and Rehabilitation.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Valvula FM 8pol ZSFZ PDFDocument8 pagesValvula FM 8pol ZSFZ PDFglobaldisNo ratings yet

- C2!6!455 Grout and Adhesive Rev.BDocument50 pagesC2!6!455 Grout and Adhesive Rev.BAreaya mahetemNo ratings yet

- Wagner2011 Glass Rail PDFDocument26 pagesWagner2011 Glass Rail PDFthe_dehumanizerNo ratings yet

- 200 3PS E00x 00001 000Document30 pages200 3PS E00x 00001 000Henry MontenegroNo ratings yet

- Green Sand Testing for Strength and PermeabilityDocument3 pagesGreen Sand Testing for Strength and Permeabilityabubakaratan50% (2)

- 03 48 00clcDocument6 pages03 48 00clcmp4 ghad mp4No ratings yet

- Manual EN HydraCell Pump D04 G04Document20 pagesManual EN HydraCell Pump D04 G04Nhã PhanNo ratings yet

- CMO Aluminium Tank Vent Check Valve With Overflow PipeDocument2 pagesCMO Aluminium Tank Vent Check Valve With Overflow Piped13g0bcNo ratings yet

- TDS Hydrocell XL India2Document2 pagesTDS Hydrocell XL India2Shakil AkhterNo ratings yet

- Electrical Wiring WorkbookDocument40 pagesElectrical Wiring Workbookrob yeley100% (2)

- Worthington D1022 Pump DataSheet P-701Document10 pagesWorthington D1022 Pump DataSheet P-701Andrey Pulido Barrera100% (1)

- Cawi 2618Document2 pagesCawi 2618richardNo ratings yet

- Trocal Stone Floor Sheet 1.2Document3 pagesTrocal Stone Floor Sheet 1.2the pilotNo ratings yet

- M002-RLR-MEP-SPE-27005 Rev 3Document611 pagesM002-RLR-MEP-SPE-27005 Rev 3wagwahkiabathe100% (1)

- CIAT Melody MTDocument12 pagesCIAT Melody MTInviairNo ratings yet

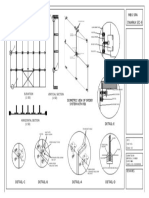

- Transversal and Longitudinal Prospects of Support Structures General Plot Plan Preliminary Calculation Report For FoundationsDocument1 pageTransversal and Longitudinal Prospects of Support Structures General Plot Plan Preliminary Calculation Report For FoundationsAbdenour YahiNo ratings yet

- Catálogo EC200DDocument912 pagesCatálogo EC200DCasa da Madeira100% (1)

- Hardie Reveal Panel Installation Instructions 1597005Document29 pagesHardie Reveal Panel Installation Instructions 1597005David TorskeNo ratings yet

- Internship presentation on Mutual Builder Pvt. LtdDocument14 pagesInternship presentation on Mutual Builder Pvt. LtdSoo CealNo ratings yet

- Reference Data: Schedule 40 Steel Pipe DataDocument2 pagesReference Data: Schedule 40 Steel Pipe DataKareem HelalNo ratings yet

- 05-05 Vikarabad Shops V Venkatesh - 001Document55 pages05-05 Vikarabad Shops V Venkatesh - 001deerangareddyofficeNo ratings yet

- AWC SDPWS 2015 WithCommentaryDocument108 pagesAWC SDPWS 2015 WithCommentaryJoséFilibertoSantosAguilar100% (1)

- AHP Balubaid, Rami Alamoudi 2015Document9 pagesAHP Balubaid, Rami Alamoudi 2015ChristinaTriAstutiPauNo ratings yet

- Champion r30d BreakdownDocument32 pagesChampion r30d Breakdowncav4444No ratings yet

- Soil Investigation Report: Item Page NoDocument6 pagesSoil Investigation Report: Item Page NoWai LinnNo ratings yet

- Astm A182 - Astm A182Document7 pagesAstm A182 - Astm A182phresendeNo ratings yet

- Fastener Torque Table SAE Grade - Engineers Edge PDFDocument1 pageFastener Torque Table SAE Grade - Engineers Edge PDFnate anantathatNo ratings yet

- Catalogue Pipe Hangers SupportsDocument111 pagesCatalogue Pipe Hangers SupportsIlija Runjajic100% (1)

- Concrete New Mix DesignsDocument2 pagesConcrete New Mix DesignsPrabhakar Sv100% (1)

- Mbs Spa: Isometric View of Spider System With RibDocument1 pageMbs Spa: Isometric View of Spider System With RibSuman Kumari100% (5)