Professional Documents

Culture Documents

Gek 103566 PDF

Uploaded by

jose Alberto uribe MinierOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gek 103566 PDF

Uploaded by

jose Alberto uribe MinierCopyright:

Available Formats

g

GEK 103566h

Revised, July 2012

GE Energy

Creating an Effective Maintenance Program

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible contingency to

be met in connection with installation, operation or maintenance. Should further information be desired or should particular

problems arise which are not covered sufficiently for the purchaser's purposes the matter should be referred to General Electric

Company. These instructions contain proprietary information of General Electric Company, and are furnished to its customer solely

to assist that customer in the installation, testing, operation, and/or maintenance of the equipment described. This document shall

not be reproduced in whole or in part nor shall its contents be disclosed to any third party without the written approval of General

Electric Company.

2012 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

GEK 103566h

Creating an Effective Maintenance Program

TABLE OF CONTENTS

I.

II.

III.

IV.

V.

VI.

BACKGROUND......................................................................................................................................... 3

MAINTENANCE FREQUENCY ............................................................................................................. 3

TESTING .................................................................................................................................................... 8

INSPECTION ............................................................................................................................................. 8

MAGIC INSPECTION .............................................................................................................................. 8

MAINTENANCE PLANNING ............................................................................................................... 10

LIST OF TABLES

Table 1. Recommended Stator Tests...................................................................................................................... 5

Table 2. Recommended Water Cooled Stator Leak Tests*.................................................................................... 6

Table 3. Recommended Field Tests ....................................................................................................................... 7

Table 4. Visual Inspection Areas ........................................................................................................................... 9

2012 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

Creating an Effective Maintenance Program

GEK 103566h

I. BACKGROUND

Implementing a thorough maintenance program is the most effective way to retain generator reliability

and avoid major failure expenses. However, it must be cost effective in that there are demonstrated

savings in improved availability and reliability to offset the cost of implementing the program. The three

important elements of a thorough program are maintenance frequency, electrical testing and visual

inspection. It is the intent of this instruction to provide information on each of these elements, which will

aid the owner/operator to establish a thorough and cost effective maintenance program.

II. MAINTENANCE FREQUENCY

There are a number of components, which require routine maintenance or inspections between scheduled

outages. The operator will find these recommendations in various equipment sections, and should also

include additional maintenance tasks as operating experience indicates. Results of this routine

maintenance should be retained in well-organized files readily available for reference. These routine

maintenance records coupled with the information from the monitored operating data are a good indicator

of pending service or operating problems that should be addressed at the next scheduled outage. The

monitored information alone is usually not sufficient for tracking or highlighting trends.

During the first several months of operation, the stator winding support system and some of the other

generator components experience a break-in period with more severe duty/wear than normal. Therefore,

the first major maintenance inspection is recommended for one year after it is placed in service.

Generator insulation and stator assembly components age at all temperatures, which can cause

compression, shrinkage and wear with time. This is not directly related to operation hours and

starts/stops. Delaying or omitting the first year inspection can cause increased maintenance outage time,

increased maintenance scope, or possibly a forced outage prior to the scheduled maintenance outage. If

the units operating experience has been unusual because of disoperation or very limited in-service hours,

etc. you may wish to discuss your particular circumstances with your local GE Field Service Office for

recommendations specific to your circumstances.

Subsequent planned outages must also be performed in a timely fashion. Experience has shown that

regularly scheduled maintenance outages are one of the most important steps in retaining unit reliability

and reducing major repair/failure expenses. A minor maintenance outage is recommended every 30

months. During these outages the end shields or end plates are removed to permit inspection from of the

end winding area, but the field remains in place. A major outage is recommended every 60 months. This

includes removing the field from the stator or using MAGIC (Miniature Air Gap Inspection Crawler) to

permit a thorough inspection of the core section of the stator and field. To inspect the field and stator

using MAGIC requires the removal of a few entrance gap baffles to allow access to the air gap with the

field in place. The inspection must include a comprehensive series of electrical tests and a thorough

visual inspection. Each has their particular advantage and neither alone is sufficient. See Section V for a

brief description of the capabilities of MAGIC and MAGIC Jr.

Older generators with asphalt insulated stator windings and core lengths greater than 150 inches [3810

mm] are subject to girth crack failures in the stator bars, and therefore, these generators should be

re-inspected twice as often (Minor Outage - 18 months; Major Outage - 36 months).

These recommended outage intervals have proven themselves over many years of use. Extending these

maintenance intervals could lead to extended maintenance durations and cost. In worst case situations

extending the intervals may result in forced outages.

2012 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

GEK 103566h

Creating an Effective Maintenance Program

Potential reasons for forced outages or increased maintenance costs are described in the following tables.

One potential way to overcome this limitation is through Condition Based Maintenance (CBM). CBM

relies on availability of reliable on-line instrumentation and evaluation techniques. As these evaluation

methods become proven and practical, they will be incorporated into recommended operation and

maintenance packages such that maintenance outages can be scheduled based on the condition of the unit.

2012 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

Creating an Effective Maintenance Program

GEK 103566h

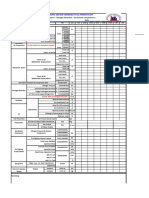

Table 1. Recommended Stator Tests

(a). STATOR

AIR

HYD

LCSW

MAGI

Minor C/RAC Major

Test

Component

Inspection Objectives and

Assessment

RTD Element Res.

Gas and Winding RTDs

Checks for calibration and poor

connections.

RTD Ground Insulation Stator Winding RTDs

Insulation condition of RTD.

Winding Copper Res.

Stator Winding

Checks for poor connections and breaks.

Insulation Resistance

(aka

Megger)

CE Bearing

Contamination and/or deterioration of

insulation.

Hydrogen Seal Casing

Contamination and/or deterioration of

insulation.

Polarization Index

Stator Winding

Contamination and/or deterioration of

insulation.

DC Leakage Current

Stator Winding

Contamination and/or deterioration of

insulation.

Stator Winding

Ground wall insulation integrity

Over Potential/Hipot

Wedge Tightness Map

Visual Inspections

Stator Wedges

Detect wedge tightness deterioration

Core Laminations

Foreign Object Damage

Space Blocks

Migration, cooling passage blockage

Gas Gap Baffles

Cracked welds, looseness

Stator Wedges

Evidence of abrasion or looseness

Stator Bars

Evidence of abrasion or looseness

End Windings and

connection

rings

Evidence of relative motion, dusting

and/or greasing, loose/broken ties, loose

hardware, corona activity

Copper Flux Shield

Overheating, hardware looseness

Overall cleanliness

Oil or other contamination

OPTIONAL TESTS

Partial Discharge

Analysis

Stator Winding Insulation Localized deterioration

Water Flow Verification

Water Cooled Stator

Winding

Restrictions in hydraulic circuit

Magnetic Scalar

Potential

(EL CID)

Stator Core Insulation

Weak or damaged core enamel.

Core Ring Test

Stator Core Insulation

Weak or damaged core enamel

Dynamic Freq.

Response

Stator End Winding

Potentially damaging resonance.

Bar Jacking

Slot Support System

Check slot clearance

Air Air Cooled Generator

HYD Hydrogen Cooled Generator

LCSW Hydrogen Cooled Generator with Liquid Cooled

Winding

O - Optional Test

X - Pertains only to type of unit selected

R - These tests are performed while the unit is running.

Note: Gas cooled bars use the hydrogen column. During high voltage testing the hollow conductors should be shorted to copper strand

Wedge Tightness Map This test may take the form of either a person performing the test with a 2 ounce hammer or piece of equipment used to

mechanically evaluate if the wedge is tight. The most critical wedges to test are the last 36 inches each end of the generator. If only the last 36 inches of

each end of the slot are tested then the rest of the wedges should be visually inspected for any indications that they are loose. This test does not apply to

units with asphalt stator windings or units with the camelback wedge system.

2012 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

GEK 103566h

Creating an Effective Maintenance Program

Table 2. Recommended Water Cooled Stator Leak Tests*

STATOR

Clip-Strand Braze: Phos Containing

Orig SLMS, Bagged

Vent, or No

Monitoring

Global Epoxy Injection or Clip-Strand

Braze: Phos-Free

Orig SLMS, Bagged

Vent, or No

SLMS HP

Monitoring

Installed

SLMS HP

H2 Leak Monitoring Method

Installed

Inspection Objectives and

Minor

Major

Minor

Major

Minor

Major

Minor

Major

(i). Test

Assessment

Checks the hydraulic

Vacuum Decay

integrity of the entire

X

X

X

X

winding.

Checks the hydraulic

Pressure Decay

integrity of the entire

X

X

X

X

winding.

Helium Tracer

Detects minute leaks in the

X

X

X

Gas

hydraulic circuit.

Capacitance

Wet ground wall bar

X

X

X

Mapping

insulation

WIM Wet

Wet ground wall bar

Insulation

insulation

X

X

X

Measurement

Ensure the electrical

Electrical Testing

X

X

X

X

X

X

X

X

insulation integrity of the

system

* These tests are required to detect hydrogen leaks in water cooled stator windings only and should be performed in conjunction with the recommended

tests in Table 1

2012 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

Creating an Effective Maintenance Program

GEK 103566h

Table 3. Recommended Field Tests

(b). FIELD

LCS

W

Minor

Turn shorts and speed sensitive turn shorts

Heating, arcing, foreign object damage

Body Weights

Looseness, staking

Field Wedges

Arcing, migration, cracking

Retaining Ring Nose

Wedge contact, arcing, foreign object damage

Coil End Turns

Blocked ventilation, damaged insulation, coil

distortion

Overall cleanliness

Oil or other contamination

Ground wall insulation integrity.

Air Gap Flux Probe

Field Inter-Turn Insulation Shorted turns at operating speed.

Bore Pressure Test

Chevron Seals

AIR HYD

Test

Component

Inspection Objectives and Assessment

Winding Copper

Res.

Field Winding

Checks for poor connections and breaks.

Contamination and/or deterioration of insulation.

Polarization Index Field Winding

AC Impedance

Field Inter-Turn

Insulation

Visual Inspection Field Surface

MAGIC/

RAC

Major

OPTIONAL TESTS

Over Potential/Hipot Field Winding

Sealing capability of the Chevron seals.

Air Air Cooled Generator

HYD Hydrogen Cooled Generator

LCSW Hydrogen Cooled Generator with Liquid Cooled

Winding

O - Optional Test

X - Pertains only to type of unit

selected

R - These tests are performed while the unit is running.

Note: Gas cooled bars use the hydrogen column. During high voltage testing the hollow conductors should be shorted to copper strand

2012 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

GEK 103566h

Creating an Effective Maintenance Program

III. TESTING

Generator electrical testing is focused on the insulation systems. However, there are other tests used to

monitor for degradation in other components. A list of the typical tests recommended and the test purpose

is shown in Tables 1, 2 and 3. Historical records of test results should be maintained and compared to the

new test results. Changes between outage test results may point to needed repairs/rework that may not be

evident from the absolute test values themselves.

Many of the tests require special equipment. Test results may be misleading and useless if the right

equipment is not used, or it has not been properly maintained and calibrated to assure accurate results.

IV. INSPECTION

A visual inspection performed by an experienced individual can disclose unit conditions not detected by

monitoring equipment or indicated by tests. In some instances electrical testing will only detect issues

when the stator and field insulation systems have been significantly. Also, for example, there is no

definitive test for contamination, rust or oil, and water leaks; yet the presence of any of these could

significantly adversely affect reliability and operation. A typical inspection should include those items

listed in Table 4.

As important as it is, visual inspection is limited to areas that can be accessed for view either directly or

with mirrors, borescopes, cameras, etc., and therefore, it must be combined with testing to give a

complete picture of generator condition.

V. MAGIC INSPECTION

GEs MAGIC and MAGIC Jr. robots provide a thorough visual inspection of the stator and field using the

robots on-board high-resolution video cameras. Additionally, it is capable of providing quantitative

wedge tightness and Electromagnetic Core Imperfection Detection (ELCID) assessments. Coupled with

the Remote Access Camera (RAC), the MAGIC or MAGIC Jr inspection can provide a comprehensive

stator and field inspection. The customer may opt to utilize the MAGIC robot to perform the

recommended inspection tasks that normally require the removal of the rotor. As a result, the customer

may substitute a MAGIC for a major inspection providing the major inspection tasks outlined in Tables 1,

2, and 3 that dont require the removal of the rotor are performed during the outage as well.

In order to use MAGIC and MAGIC Jr., the generator must meet the following minimum entrance gap

dimensions:

MAGIC

Retaining ring to core minimum gap 1.13

inches [28.7 mm]

Field to core minimum gap of 2.0 inches

[50.8 mm]

MAGIC Jr.

Retaining ring to core minimum gap 0.5

inches [12.7 mm]

Field to core minimum gap 0.75 inches

[19.05 mm]

2012 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

Creating an Effective Maintenance Program

GEK 103566h

Stator

Slot Support

System

Conn. Rgs and

Lower Lds.

High Voltage

Bushings

All components

X

X

Ventilation

Ducts

X

X

Body and

Wedges

Retaining Rings

Fans

Spindles

Winding

Collectors

Journals

X

X

Key Bars

Field

Laminations

All Components

X

X

Core End

Core

Dusting and/or Greasing

EW Support

System

Core Tightness

Shorted Core Punchings

Broken Ties

Tape Migration

Bar Sparking

Bars

Blocked Ventilation

Burning

Worn Parts

Deterioration (General)

Cracks

Mechanical Damage

Water Leaks (Water-Cooled Winding

Movement

Surface Condition and Wear

Loose or Displaced Parts

Corrosion

Cleanliness

All Components

Foreign Material/Contamination

Table 4. Visual Inspection Areas

X

X

2012 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

GEK 103566h

Creating an Effective Maintenance Program

VI. MAINTENANCE PLANNING

Major maintenance outages are usually scheduled well in advance of the actual outage date, and

preparation for the outage should begin early. An important part of that is to review operational logs,

previous inspection reports for any indication of work needed, and review recommendations from GE

communicated by Technical Information Letters, Engineering Change Notices, etc. to integrate those

items into your plans. Materials you expect to need should be ordered to have available at the start of the

outage to avoid the risk of costly delays waiting for material.

The operational log should include the type of duty, any known incidents of disoperation. Operational

events which should be carefully noted are:

a.

Errors in synchronizing

b.

Under or over frequency operation

c.

Lightning surges or other transients

d.

Faults (such as short circuits) on system or adjacent machines

e.

Unbalanced load, including single phase operation (Negative Sequences and Motoring)

f.

Overload

g.

Over voltage or under voltage

h.

Loss of field

i.

Loss of cooling water without load run-back

j.

Out of synchronism operation.

Each of these events would have a different impact on the necessary planning for maintenance and

inspection. Depending on the circumstances, some of them might dictate that the machine is shut down

for immediate inspection, whereas with other events it would be reasonable to wait until the next

schedule inspection.

Your maintenance program should reflect the level of acceptable risk for the unit. That will probably vary

from unit to unit and plant to plant, and will change over time as the importance of the unit to the power

system changes. In addition, new technologies are constantly being developed to improve unit reliability,

performance, monitoring and inspection equipment, and otherwise provide more costeffective means for

maintaining the generator. The MAGIC Robot In-Situ Generator Inspection System is one example of a

new technology developed by GE to provide a more cost-effective means of inspecting your generator.

The owner/operator should be aware of these developments and modify the maintenance program

accordingly. While this should be a continuous process, the maintenance outage planning review is an

appropriate checkpoint.

Your local GE Field Service Office can assist you in your maintenance planning, and review of your

overall maintenance program, incorporating any appropriate new maintenance and upgrade technologies

available.

10

2012 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

Creating an Effective Maintenance Program

GEK 103566h

THIS PAGE INTENTIONALLY LEFT BLANK

2012 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

11

GEK 103566h

Creating an Effective Maintenance Program

GE Energy

General Electric Company

www.ge-energy.com

12

2012 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

You might also like

- Til 1755-R3 Lci Water - Cooled Bus LeaksDocument8 pagesTil 1755-R3 Lci Water - Cooled Bus LeaksMichael SanchezNo ratings yet

- EMX - 11 - G - MB - EN - GS - 016 - En-Gas Turbine Functional Description, 7HA.02Document21 pagesEMX - 11 - G - MB - EN - GS - 016 - En-Gas Turbine Functional Description, 7HA.02RichardLemus100% (3)

- TIL 1108-R1: Cast Segmented Turbine Nozzle Acceptance GuidelinesDocument10 pagesTIL 1108-R1: Cast Segmented Turbine Nozzle Acceptance GuidelinesAkramNo ratings yet

- Technical Information Letter: GE PowerDocument6 pagesTechnical Information Letter: GE PowerHashim BukhariNo ratings yet

- Technical Information Letter: Thermal Engineering Product Service TIL 1108-R1Document7 pagesTechnical Information Letter: Thermal Engineering Product Service TIL 1108-R1Heryanto SyamNo ratings yet

- T 2024Document4 pagesT 2024ashok100% (1)

- Generator VOL 8ADocument18 pagesGenerator VOL 8AEmadAlhosien AlhosienNo ratings yet

- TIL 1819 ImplementationDocument4 pagesTIL 1819 ImplementationManuel L LombarderoNo ratings yet

- Sb-Lm2500-Ind-303 R1Document11 pagesSb-Lm2500-Ind-303 R1Daniil SerovNo ratings yet

- Nic 13.05Document14 pagesNic 13.05BouazzaNo ratings yet

- Til 1566-R2 Hazardous Gas Detection System RecommendationsDocument4 pagesTil 1566-R2 Hazardous Gas Detection System RecommendationsMichael Sanchez100% (2)

- Megger Test Procedure Explained With Transformer ExampleDocument4 pagesMegger Test Procedure Explained With Transformer ExamplesamsungloverNo ratings yet

- Series: Safety, Operation, and Procedure Instructions For The PTS Series of DC Hipot/MegohmmetersDocument37 pagesSeries: Safety, Operation, and Procedure Instructions For The PTS Series of DC Hipot/MegohmmetersBarajiux100% (1)

- V7x DatasheetDocument4 pagesV7x DatasheetReginald D. De Guzman100% (1)

- TIL 1420-2r1 Lube Oil Logic EnhancementDocument4 pagesTIL 1420-2r1 Lube Oil Logic EnhancementManuel L LombarderoNo ratings yet

- TIL 1880 Trip Risk When Liquid Fuel Recirculation Is Turned Off While Running On Gas PDFDocument5 pagesTIL 1880 Trip Risk When Liquid Fuel Recirculation Is Turned Off While Running On Gas PDFManuel L LombarderoNo ratings yet

- T 1918Document4 pagesT 1918esutjiadiNo ratings yet

- T 2055 R 1Document6 pagesT 2055 R 1srinivasNo ratings yet

- Til 1886 Inspection of Low Pressure Rotor Wheel Dovetails On Steam Turbines With Fossil Fueled Drum Boilers PDFDocument6 pagesTil 1886 Inspection of Low Pressure Rotor Wheel Dovetails On Steam Turbines With Fossil Fueled Drum Boilers PDFManuel L LombarderoNo ratings yet

- Til 2191 - 9e S2B Tip Shroud DistressDocument3 pagesTil 2191 - 9e S2B Tip Shroud DistressMichael SanchezNo ratings yet

- Til 1213 R1Document6 pagesTil 1213 R1Hernan GirautNo ratings yet

- t1961r1 - Steam Turbine Governor Setting To Help Meet Nerc Frequency Reponse AdvisoryDocument17 pagest1961r1 - Steam Turbine Governor Setting To Help Meet Nerc Frequency Reponse AdvisoryHung NgoNo ratings yet

- Technical Information Letter: Ge Power TIL 2445 Product ServiceDocument4 pagesTechnical Information Letter: Ge Power TIL 2445 Product ServiceMinhajur Rahman100% (1)

- Til 1236-R2Document5 pagesTil 1236-R2makarov.olegNo ratings yet

- Technical Information Letter: Thermal Engineering Product Service TIL 1881Document11 pagesTechnical Information Letter: Thermal Engineering Product Service TIL 1881Ignacio Moratinos Castañeda100% (1)

- Technical Information Letter: Energy Services Engineering Product Service TIL 1713Document5 pagesTechnical Information Letter: Energy Services Engineering Product Service TIL 1713ankarao69No ratings yet

- Technical Procedures: Numerical Listings of Support Equipment and Consumable Materials (Level 1 and 2 Maintenance)Document28 pagesTechnical Procedures: Numerical Listings of Support Equipment and Consumable Materials (Level 1 and 2 Maintenance)exergicNo ratings yet

- Til 1509 R4 F-Class Front End (R0, S0, and R1) Compressor InspectionsDocument9 pagesTil 1509 R4 F-Class Front End (R0, S0, and R1) Compressor InspectionsMichael Sanchez100% (1)

- F Technology StoryDocument16 pagesF Technology StoryTufail Memon100% (1)

- TIL 1237-1: Potential Flexible Hose Installation Errors: Technical BulletinDocument6 pagesTIL 1237-1: Potential Flexible Hose Installation Errors: Technical BulletinAkramNo ratings yet

- GEK103623 DDocument18 pagesGEK103623 DNouman Saeed100% (1)

- Gek 116689Document32 pagesGek 116689HANo ratings yet

- GEA31503e PGP Product E-Catalog 2015 R10Document47 pagesGEA31503e PGP Product E-Catalog 2015 R10juagamsar100% (1)

- Technical Specifications, Fuel Nozzle GR 127 PDFDocument8 pagesTechnical Specifications, Fuel Nozzle GR 127 PDFMadhan KumarNo ratings yet

- 01 Tab01 130916060639 Phpapp02 PDFDocument36 pages01 Tab01 130916060639 Phpapp02 PDFajo zinzoNo ratings yet

- Ge F-Class Gek111895Document2 pagesGe F-Class Gek111895gopinathsampath0% (2)

- TB Maintenance Concept PDFDocument16 pagesTB Maintenance Concept PDFhamedia83No ratings yet

- GEK116771Document12 pagesGEK116771Korneev MaximNo ratings yet

- TIL 1132 2R1 - VIGV Inspection, Thrust WasherDocument5 pagesTIL 1132 2R1 - VIGV Inspection, Thrust WasherHernan Giraut100% (2)

- Frame 9001E Combustion PDFDocument2 pagesFrame 9001E Combustion PDFfrdnNo ratings yet

- 9fa ProbsDocument12 pages9fa ProbsMarbz Al MonteNo ratings yet

- Gas Turbine Combustion SystemDocument14 pagesGas Turbine Combustion Systemrohit u100% (1)

- t10682r1-Fr-5,6,9 VIGVDocument2 pagest10682r1-Fr-5,6,9 VIGVJEORJE100% (1)

- Scope of Work Gas TurbineDocument13 pagesScope of Work Gas TurbinePhong le100% (2)

- GE 7FA Flex Seal Upgrade USDocument2 pagesGE 7FA Flex Seal Upgrade USPeter_Phee_341100% (1)

- GT Fuel Nozzle Refurbishment PDFDocument3 pagesGT Fuel Nozzle Refurbishment PDFJJ100% (1)

- Alstom Gas-Turbines-Technical-Performance PDFDocument2 pagesAlstom Gas-Turbines-Technical-Performance PDFPoull SteeadyNo ratings yet

- Service Experiences With The World Record Gas Turbine SGT-8000HDocument16 pagesService Experiences With The World Record Gas Turbine SGT-8000HabelsgNo ratings yet

- GE Gas Turbine Extendor Combustion SystemDocument2 pagesGE Gas Turbine Extendor Combustion SystemRaden Mas100% (1)

- Til 1214-3R3Document7 pagesTil 1214-3R3Hernan Giraut100% (2)

- Psib 20160225a-R3Document6 pagesPsib 20160225a-R3Léandre Ettekri NdriNo ratings yet

- DDocument18 pagesDMahmoud El-abdNo ratings yet

- 06 UCH GT 9001E - Inlet Filter & Duct SystemsDocument113 pages06 UCH GT 9001E - Inlet Filter & Duct SystemsHassan Mahmood100% (1)

- M&M at DLN1Document8 pagesM&M at DLN1Muralimohan MolabantiNo ratings yet

- Proven Solutions GE-EvuletDocument48 pagesProven Solutions GE-EvuletmohamedhasNo ratings yet

- NIC - 07-37 - Rev-01 Technical Updates Web Portal GEDocument47 pagesNIC - 07-37 - Rev-01 Technical Updates Web Portal GEManuel L LombarderoNo ratings yet

- SBLM2500 Ind 217Document5 pagesSBLM2500 Ind 217Daniil SerovNo ratings yet

- IGV AssamblyDocument31 pagesIGV AssamblyPhong le100% (1)

- LM TM2500 Upgrade Solutions PDFDocument2 pagesLM TM2500 Upgrade Solutions PDFLibyanManNo ratings yet

- T48 SpreadDocument1 pageT48 SpreadKarim MuhammedNo ratings yet

- TIL 1879 - TIL 1879 Installation and Maintenance Recommendations For Exhaust ThermocouplesDocument26 pagesTIL 1879 - TIL 1879 Installation and Maintenance Recommendations For Exhaust ThermocouplesBouazzaNo ratings yet

- Til 1576-R1Document4 pagesTil 1576-R1Bouazza100% (1)

- UPS Manual OperacionesDocument21 pagesUPS Manual Operacionesjose Alberto uribe MinierNo ratings yet

- Reportes Lecturas de CampoDocument2 pagesReportes Lecturas de Campojose Alberto uribe MinierNo ratings yet

- Check The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001Document5 pagesCheck The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001jose Alberto uribe Minier100% (1)

- Condenser Surface: Hotwell Condensate SumpDocument54 pagesCondenser Surface: Hotwell Condensate Sumpjose Alberto uribe MinierNo ratings yet

- Hipot TestDocument5 pagesHipot TestSanjeet Saud100% (2)

- Upload Download 4-Wire Cable Tester 8700Document2 pagesUpload Download 4-Wire Cable Tester 8700HaLeNo ratings yet

- Hipot Cable TestingDocument13 pagesHipot Cable Testingsofyan_shah100% (4)

- PRO Series 100 - 400V2 Pre-Service and Calibration Manual: (Models 110 - 410)Document42 pagesPRO Series 100 - 400V2 Pre-Service and Calibration Manual: (Models 110 - 410)quankddNo ratings yet

- Equipos Pruebas VLF Marca High Voltage (English)Document2 pagesEquipos Pruebas VLF Marca High Voltage (English)ValentinaNo ratings yet

- Electrical Safety ProcedureDocument33 pagesElectrical Safety ProcedurePraful E. Pawar100% (1)

- Model 19032-19032-P Data SheetDocument8 pagesModel 19032-19032-P Data SheetmanchuricoNo ratings yet

- Mining Equipment Testing: Application GuideDocument8 pagesMining Equipment Testing: Application Guiderk6482100% (1)

- IotaITS 75C SwitchDocument4 pagesIotaITS 75C SwitchJohn Melanathy IINo ratings yet

- Evaluation of Electrical Insulation in Three-Phase Induction Motors and Classification of Failures Using Neural NetworksDocument11 pagesEvaluation of Electrical Insulation in Three-Phase Induction Motors and Classification of Failures Using Neural NetworksIsrael ZamudioNo ratings yet

- Megger Hi-Pot Procedure 8-6-09Document2 pagesMegger Hi-Pot Procedure 8-6-09Mark HaizlipNo ratings yet

- Hi Pot Test DetailsDocument7 pagesHi Pot Test Details2003vinay100% (1)

- What Is HIPOT Testing (Dielectric Strength Test) - EEPDocument7 pagesWhat Is HIPOT Testing (Dielectric Strength Test) - EEPmahmoud fawzyNo ratings yet

- ThumperDocument8 pagesThumperJohan DiscoBiscuit PrinslooNo ratings yet

- Hi-Pot Test Instructions, Hipotronics Models HD-103 and HD-106Document10 pagesHi-Pot Test Instructions, Hipotronics Models HD-103 and HD-106sreekanthbammidiNo ratings yet

- Is 10418 Technical Specification of XLPE Insulated LT CablesDocument4 pagesIs 10418 Technical Specification of XLPE Insulated LT CablesManoj AgarwalNo ratings yet

- Philips 170c6fs Chassis Sh6Document78 pagesPhilips 170c6fs Chassis Sh6videosonNo ratings yet

- Bakers Surge Tester - ST 203aDocument76 pagesBakers Surge Tester - ST 203aPrabhu sankarNo ratings yet

- Technical Specification For 33 KV Aerial Bunched Cable - 2Document7 pagesTechnical Specification For 33 KV Aerial Bunched Cable - 2BijuNo ratings yet

- Megger Cable Fault Finding SolutionsDocument44 pagesMegger Cable Fault Finding SolutionsMudassarHashmi100% (3)

- AWA - Advanced Winding Analyzer: Specifications and Electrical RequirementsDocument4 pagesAWA - Advanced Winding Analyzer: Specifications and Electrical RequirementsIslam FawzyNo ratings yet

- Ieee 400.2-2013 Guide For Field Testing of Shielded Power Cable Systems Using Very Low Frequency VLF PDFDocument60 pagesIeee 400.2-2013 Guide For Field Testing of Shielded Power Cable Systems Using Very Low Frequency VLF PDFJorge Rivera100% (2)

- 5-Power & Control Cables PDFDocument11 pages5-Power & Control Cables PDFAnonymous ufMAGXcskMNo ratings yet

- Philips 104s Cm23 Gs IIIDocument53 pagesPhilips 104s Cm23 Gs IIIadrianrossosjNo ratings yet

- Electrical System TestingDocument10 pagesElectrical System TestingoritasNo ratings yet

- Surge Comparison Test - Electrom InstrumentsDocument6 pagesSurge Comparison Test - Electrom InstrumentsJoe Dirta0% (1)

- Testing Methods Required To Maintain Electrical-Equipment PDFDocument104 pagesTesting Methods Required To Maintain Electrical-Equipment PDFIrfan AshrafNo ratings yet