Professional Documents

Culture Documents

TPM Manufacturing Skills Training Rozne Techniki Lean

Uploaded by

Sandro SouzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TPM Manufacturing Skills Training Rozne Techniki Lean

Uploaded by

Sandro SouzaCopyright:

Available Formats

Todays manufacturing companies have to achieve

operational excellence to succeed in business. This drives the

need to do things faster, better and at reduced cost and

requires a continuous improvement in skills.

The translation of thought leadership into practical action

underpins all of Peras manufacturing offerings. We

understand the challenges facing manufacturing companies

and have a strong track record in developing skills that

enable participants to deliver tangible business

improvements in the workplace.

All of our clients have one thing in common, they want to

develop their skills to deliver rapid operational improvement

in a sustainable manner. The content and style of our

training and the opportunity to interact with people from

other manufacturing companies delivers this.

Our approach to training

Through our practical industry experience and training

know-how, we demystify jargon, integrate practical and

relevant exercises and encourage feedback and full

participation. This makes our programmes highly interactive

and enjoyable. Most importantly, however, our courses focus

on delivering results. In this context we build participants

knowledge and confidence to implement the lessons learnt

and encourage them to identify specific actions that they

will take away as a result of the training. In this way, the

training acts directly as a catalyst as well as a means of

generating improvement.

Free with every course

Your delegates can order

any one of these books

absolutely free for each and

every public manufacturing

skills course that they

attend with Pera.

These book titles have been

selected by our course

leaders as being both

stimulating and practical - a

perfect complement to the

training.

manufacturing skills

Manufacturing skills training excellence in action

New for this year is a series of one day manufacturing

seminars. These key insights will build participants awareness

of cutting edge issues, helping them to see the relevance

and application of these issues to their business.

We are also repeating our successful Lean Manufacturing

programme this year. This series of workshops enables

participants to identify and eliminate waste in the

manufacturing workplace. It is an especially useful

programme when run on an in-house basis as participants

then address issues that are directly relevant to their business

and develop specific action plans that achieve measurable

improvement.

Pera we know how to align knowledge, people and

technology for manufacturing competitive advantage.

Book on www.pera.com or call 01869 340361 or fax 01869 340659

35

manufacturing seminar series

The Manufacturing Seminar Series

NE

W

Last year we regularly received requests for information about key manufacturing topics from people who werent

at the stage of needing training but who wanted to learn more about a topic and its application in their business.

In response we are presenting a new programme of seminars at our Middle Aston House facility. These seminars

are targeted at senior executives and are designed to provide attendees with insights into organisational benefits

and implementation issues.

Lean manufacturing

Lean Manufacturing is a well established approach used by leading practice organisations. It focuses on the

identification and elimination of all forms of waste in the manufacturing process. The approach uses a range of

tools and techniques combined with the development of empowered work teams to deliver impressive operational

results. This seminar will cover:

Seminar outline

What is Lean Manufacturing?

What are the benefits?

An overview of the tools and techniques

How to implement Lean Manufacturing.

Seminar Information

Dates: 21 Jan, 8 Apr, 23 Sept

Cost: 250 Venue: Middle Aston House

Blitz Kaizen

Blitz Kaizen events are a very effective tactical Lean tool for delivering accelerated improvements. Often

companies need to achieve rapid results in response to a specific problem. They also often want to achieve early

tangible success as part of a wider lean implementation. The use of Blitz Kaizen events is a highly effective way

of achieving this. This seminar will cover:

Seminar outline

What is a Blitz Kaizen event and where does it fit in Lean? Seminar Information

Examples and case studies

Dates: 4 Feb, 22 Apr, 7 Oct

Planning for Blitz Kaizens

Cost: 250 Venue: Middle Aston House

Running Blitz Kaizens.

Six Sigma

Six Sigma is gaining a high profile in many leading manufacturing companies. It is a structured, statistically based,

improvement methodology that targets the identification and reduction of variation within the manufacturing

process. Six Sigma is proven to reduce the level of defects and errors and consequently delivers significant bottom

line benefits.

Seminar outline

What is Six Sigma?

What are the benefits?

An overview of Six Sigma tools

How to implement Six Sigma.

Seminar Information

Dates: 18 Feb, 6 May, 21 Oct

Cost: 250 Venue: Middle Aston House

Overall Equipment Effectiveness and Total

Productive Maintenance

A foundation for effective Just-in-Time manufacture is process reliability. TPM is a structured approach to maximise

the non-machine interface by ensuring that processes operate consistently at optimum condition. OEE is the

measure for TPM and can be used to monitor performance and, more importantly, identify areas for improvement.

Seminar outline

The five pillars of TPM

Benefits of TPM

How to calculate OEE

Tips for TPM implementation.

36

Seminar Information

Dates: 20 May, 4 Nov

Cost: 250 Venue: Middle Aston House

All courses can be tailored or run in-house. Call 01869 340361

Waste Elimination and

Value Stream Mapping

The Lean Manufacturing Programme

The identification of waste and the elimination of

non-value adding activities is the foundation of Lean

Manufacturing. This workshop provides the tools

required to capture the various forms of waste and to

implement effective countermeasures.

Course Objectives

Each course in this programme can be attended as a

stand-alone event or grouped together in a logical

sequence to show how the various techniques work

to support one another. The courses are ideal for a

company team based programme in which the

material and presentation is tailored to your specific

needs. A package fee and accredited certificate are

available for attendance of the whole series.

The Lean Manufacturing series is designed to meet a

wide range of attendee expectations. Whether you

are setting up a green-field site or looking to

improve your existing manufacturing practices,

whether you are looking for a practical explanation

of the terminology or looking for proven tips on

shop-floor implementation the Lean Manufacturing

Programme is a must for anyone who is serious

about Manufacturing Improvement.

Understand the essence of Lean Thinking

Build a different and wider perspective on waste

Be able to spot waste within the work environment

Be able to map current and future Value Stream

Maps

Know how to measure waste and monitor the

success of improvement activities

Identify a back at work project plan.

Course Content

5 principles of Lean Thinking

What is a business process?

Value adding and non-value adding activities

Definitions of waste - spot the worker!

The 7 classic wastes

Waste measurement

Practical Process Mapping

Maximising The Value Stream Mapping.

The Lean Manufacturing Programme includes the

following series of workshops.

Waste Elimination and Value Stream

Mapping

5S and Visual Management

Kaizen and Successful Shop-Floor

Improvement

One Piece Flow and Optimising Layouts

manufacturing skills

Based on the success of the 2002 programme we

continue to offer our Lean manufacturing series of

complementary training courses for 2003 which

cover all aspects of Lean Manufacturing Best

Practice. Through this programme participants will

build up knowledge and skills in the various methods

that can be employed to eliminate waste from their

products or services and in so doing boost

profitability and exceed customer expectations.

Course Information

Reducing Changeover and Set-Up TImes SMED

JIT Manufacturing and Introduction to Pull

Control

Duration:

1 day

Dates:

4 Feb, 3 Jun

Cost:

275 + VAT

Implementing Kanban Systems and

Smoothed Production

Location:

Team price

6-9 delegates

10 + delegates

225 per person

200 per person

Middle Aston House, Oxfordshire

Book on www.pera.com or call 01869 340361 or fax 01869 340659

37

manufacturing skills

5S and Visual Management

Kaizen and Successful Shop-Floor

Improvement

Significant improvements can be made to operational

performance by creating a work area which

instinctively feels right. This workshop provides a step

by step, team-based approach to create such an

environment and introduces a range of visual

methods to sustain improvement.

A literal translation of the Japanese word Kaizen is

continuous change for the better.

This workshop explores the people aspects of

Continuous shop-floor improvement and provides a

range of techniques to ensure effective

implementation within Western organisations.

Course Objectives

Course Objectives

Understand how workplace organisation supports

health and safety, operational performance and

customer impact

Be able to facilitate workplace organisation

projects

Understand the step-by-step 5S methodology

Know how to sustain and build upon the

improvements made

Identify a back at work project plan.

Course Content

Illustration of the benefits of good workplace

organisation

Categorisation of work into Runners, Repeaters

and Strangers

The 5S improvement methodology

Sort

Set locations

Stop contamination

Standardise

Sustain

Awareness of visual techniques in a range of

relevant applications.

Understand the people implications of the Kaizen

philosophy

Appreciate the importance of appropriate targets

and measures

Benchmark performance through a variety of

proven models

Understand how and when to apply suitable

problem solving techniques

Introduce a simple shop-floor tool for

effective project management

Identify a back at work project plan.

Course Content

Building effective teams

The importance of targets, measures and

benchmarking

Problem solving roadmap

Practical project management on the shop-floor.

Course Information

Course Information

Duration:

1 day

Duration:

1 day

Dates:

3 Mar, 1 Jul

Dates:

1 Apr, 4 Aug

Cost:

275 + VAT

Cost:

275 + VAT

Location:

38

Team price

6-9 delegates

10 + delegates

225 per person

200 per person

Middle Aston House, Oxfordshire

Location:

Team price

6-9 delegates

10 + delegates

225 per person

200 per person

Middle Aston House, Oxfordshire

All courses can be tailored or run in-house. Call 01869 340361

One Piece Flow and Optimising

Layouts

Reducing Changeover and Set-Up

TImes - SMED

Small batch manufacture is one of the drivers to

achieve low cost, responsive supply.

Small batches mean more changeovers and more

changeovers usually mean more down-time. This

workshop investigates a proven methodology to

reduce changeover and set-up times and encourages

the small batch mindset.

Course Objectives

Course Objectives

Understand the reasons for, and benefits of, one

piece flow production

Distinguish the needs of standard and special lines

Appreciate the risks of super machine capital

investments

Build an awareness of virtual simulation

applications

Identify a back at work project plan.

Understand the benefits of small batch

manufacture

Understand the step by step process of Set-Up

reduction

Build confidence in facilitating Set-Up reduction

projects

Identify a back at work project plan.

Course Content

Course Content

One piece flow and close coupled cells

Line layout best practices

Multi-skilling line personnel

Bottleneck management

Case study: Witness line simulation.

The definition of a change-over

The 7 steps of Set-Up reduction

The distinction between Internal and External

activities

Changeover process analysis

Poka Yoke and standard operating procedures

Case study examples.

Course Information

Course Information

Duration:

1 day

Duration:

1 day

Dates:

6 May, 2 Sept

Dates:

2 Jun, 6 Oct

Cost:

275 + VAT

Cost:

275 + VAT

Location:

Team price

6-9 delegates

10 + delegates

225 per person

200 per person

Middle Aston House, Oxfordshire

Location:

Team price

6-9 delegates

10 + delegates

manufacturing skills

In order to be able to respond to ever-changing

customer demands, manufacturers need to rise to

the challenge of building flexibility into their

production processes. This workshop explores the

application of the concepts behind cellular

manufacturing to either existing or green-field sites.

225 per person

200 per person

Middle Aston House, Oxfordshire

Book on www.pera.com or call 01869 340361 or fax 01869 340659

39

manufacturing skills

JIT Manufacturing and Introduction T

to Pull Control

Just In Time Manufacturing is about pulling customer

requirements through the production process. It has

demonstrated significant benefits in a wide range of

industries, typically in reducing inventory and defect

levels as well as improving internal communication.

Through interactive presentation and a table-top

simulation game, this workshop investigates the

principles behind JIT, and explains exactly how

Kanban systems work. N.B. A minimum of six

attendees is required to run the JIT simulation.

Implementing Kanban Systems and T

Smoothed Production

Kanban systems are at the heart of Just in Time

manufacture. This workshop outlines practical

aspects of designing and introducing robust Kanban

systems that work. We also investigate Takt time as a

means of regulating output to meet customer

demand and establishing a smoothed production

sequence to level any erratic pull on line-side

supplies.

Course Objectives

Course Objectives

See how all the Lean principles work together to

meet customer needs

Understand the benefits of Just in Time manufacture

Gain an exposure to a number of successful Kanban

applications

Be enthused to apply the lessons learned to their

own production lines

Identify a back at work project plan.

Course Content

Course Content

Linking Lean principles to Just in Time manufacture

Comparing Push and Pull control systems

Introduction to Kanban systems

Card and call based Kanban systems

Preferred environment, rules and implications of

Kanban

Table-top, Just in Time simulation game.

Kanban design decisions

Calculating Kanban quantities

Step by step methodology to successfully

implement Kanban

The law of industrial dynamics Forresters Law

Introduction to and calculation of Takt time

Practical applications of Takt time

Implementation case study.

Course Information

Course Information

Duration:

1 day

Duration:

1 day

Dates:

28 July, 3 Nov

Dates:

21 Aug, 8 Dec

Cost:

275 + VAT

Cost:

275 + VAT

Location:

40

Gain an exposure to a wide range of practical

Kanban signals

Learn a step by step methodology to design and

implement Kanban systems

Understand how to calculate required Kanban

quantities

Understand the practical application of Takt time

Build confidence in introducing Kanban systems

within the work environment

Identify a back at work project plan.

Team price

6-9 delegates

10 + delegates

T

225 per person

200 per person

Middle Aston House, Oxfordshire

Location:

Team price

6-9 delegates

10 + delegates

225 per person

200 per person

Middle Aston House, Oxfordshire

All courses can be tailored or run in-house. Call 01869 340361

Total Productive Maintenance

and OEE

This course conveys a practical and implementable

understanding of production planning and control

concepts to those in your organisation who have to

make it work.

The course will equip them to assess, evaluate and

develop the systems back in their working life with

the aim of contributing effectively to the

improvement of business performance.

Course Objectives

Course Objectives

Understand the principles of Total Productive

Maintenance

Build confidence in facilitating process

improvement workshops

Be able to measure the OEE of particular processes

Identify a back at work plan of action.

Course Content

Introduce delegates to

techniques in manufacturing control

practical applications of these techniques.

With particular emphasis on MRP and JIT and how

they can be complimentary.

Course Content

TPM concepts

5 pillars of TPM

Introducing Overall Equipment Effectiveness (OEE)

Autonomous & planned maintenance

People training & skills

Early equipment management

Linking TPM and Lean Manufacturing

Targeting TPM improvement areas

Your TPM implementation plan.

The role of manufacturing within the business

Forecasting tools and techniques

Stock management

MRPI & MRPII

Scheduling tools and techniques

Mathematical models and simulation

Computerised planning tools

Line balancing and Takt time

Just In Time.

Course Information

Course Information

Duration:

1 day

Duration:

2 days

Dates:

28 Jan, 24 Jun

Dates:

4-5 Feb, 13-14 May, 12-13 Aug,

4-5 Nov

Cost:

275 + VAT

Cost:

550 + VAT

Location:

Melton Mowbray, Leicestershire

Location:

Team price

6-9 delegates

10 + delegates

manufacturing skills

The key to effective Manufacturing is process

reliability. Total Productive Maintenance (TPM) aims

to maximise the man-machine interface by ensuring

that processes are consistently operating at their

optimum condition. Overall Equipment Effectiveness

(OEE) is the measure of TPM and can be used to

monitor process performance or more importantly

identify areas for process improvement.

Effective Production Planning &

Control

225 per person

200 per person

Middle Aston House, Oxfordshire

Book on www.pera.com or call 01869 340361 or fax 01869 340659

41

manufacturing skills

Design for Manufacture and

Product Customisation

An estimated 80% of manufacturing cost is decided

on the drawing board, for this reason breaking down

the barriers between Design and Manufacture is

essential in todays marketplace. Further competitive

advantage can be derived from offering products

which are tailored to meet specific customer

requirements without incurring the premium prices

which are usually associated with the supply of

Specials. This workshop provides a range of design

methods to facilitate efficient manufacture and a

design framework in which last minute product

configuration offers customised products within the

cost and lead-time expectations of mass production.

Geometric Dimensioning and

Tolerancing

This course is compiled for those who need an

understanding of Geometric Dimensioning and

Tolerancing and the fundamentals of applying it. It is

not specific to a single standard but includes the

difference between the two common standards, ISO

and ASME Y14.5 1994.

Course Objectives

Course Objectives

Understand the concepts behind design efficiency

Be able to apply some simple design rules for

effective manufacture

Gain exposure to the principles of Late Product

Configuration

Examine products in order to identify areas for

improvement

Identify a back at work plan of attack.

Course Content

Understand the latest developments in Geometric

Dimensioning and Tolerancing

Know the use and the meaning of the Geometric

symbols

Read and apply GD&T to drawings and concepts

Develop an understanding of design concepts.

Course Content

Co-ordinate drawings

Symbols and terms

Datum system

Form controls

Position controls

Introduction to MMC concept

Orientation controls

Profile controls

Co-axial controls

Co-planar controls.

Estimating design efficiency

10 golden rules of design for manufacture

Introduction to Late Product Customisation

Customer value

Product configuration

Modular design

JIT manufacture

Table-top exercise to illustrate the best design

practices.

Course Information

Course Information

Duration:

1 day

Duration:

3 days

Dates:

20 May, 18 Nov

Dates:

10-12 Feb, 7-9 May, 4-6 Aug,

17-19 Nov

Cost:

275 + VAT

Cost:

750 + VAT

Location:

Melton Mowbray, Leicestershire

Location:

42

Team price

6-9 delegates

10 + delegates

225 per person

200 per person

Middle Aston House, Oxfordshire

All courses can be tailored or run in-house. Call 01869 340361

Electrical Engineering for NonElectrical Personnel

Course Objectives

Demonstrate a knowledge of the fundamental

laws governing Electrical Engineering

Recognise common electrical components,

including relays, contactors and motors

Understand how common electrical components

function

Understand the terminology used in Electrical

Engineering

Be aware of the dangers and safety procedures

associated with Electrical Engineering

Effectively converse on electrical topics with

electrical personnel.

This course is aimed at personnel who, as part of

their job function, will be exposed to, or who will be

expected to work in, an electrical environment with

a minimum of supervision. It will suit mechanically

biased maintenance staff, supervisors, technicians

and managers.

In the interests of safety and to ensure maximum

benefit from this course, delegates must have a good

grounding in electrical theory which can be gained

on the `Electrical Engineering for Non-Electrical

Personnel course.

This is a hands on course where delegates will be

using a variety of industrial grade test instruments to

perform functional tests on electrical components

and circuits, reading standard electrical drawings and

completing fault finding exercises on a 240/415

(230/400) volt system.

Course Objectives

Course Content

Generation of electricity

Inductors and transformers

Personal safety

The electro magnet

Relays

Solonoids

Contractors

Electric motors

Motor controls

Wiring and distribution

IEE regulations

Correction equipment

City & Guilds exam.

Understand safety implications

Demonstrate a knowledge of analogue/digital

multimeters

Apply insulation, clampmeter and voltage testers

Know how to read and use electrical

drawings/symbols

Understand how to test AC/DC motors.

Course Content

manufacturing skills

This is a theoretical based course with extensive

demonstrations to illustrate how electrical

components function with examples of common

components, and how they are combined to form

electrical circuits. It has been designed to cover all

the major aspects of Electrical Engineering, which

may be found in a manufacturing environment.

Practical Electrical Engineering

Safety issues

Analogue and digital multimeters

Clampmeters

Electrical diagrams

Electrical symbols

Fault finding exercises

Motor control systems

City & Guilds exam.

In the interests of safety, delegates should have a

basic training in electrical engineering or have

completed Electrical Engineering for Non Electrical

Personnel.

Course Information

Course Information

Duration:

3 days

Duration:

3 days

Dates:

21-23 Jan, 18-20 Mar, 20-22 May

22-24 Jul, 23-25 Sept, 11-13 Nov

Dates:

18-20 Feb, 15-17 Apr, 17-19 Jun,

19-21 Aug, 21-23 Oct, 9-11 Dec

Cost:

800 + VAT

Cost:

850 + VAT

Location:

Melton Mowbray, Leicestershire

Location:

Melton Mowbray, Leicestershire

Book on www.pera.com or call 01869 340361 or fax 01869 340659

43

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Weibull Analysis in ExcelDocument2 pagesWeibull Analysis in ExcelEduardo Cunha100% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Practical Reliability EngineeringDocument246 pagesPractical Reliability EngineeringSandro SouzaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Mcgraw Hill - The Project Manager's Desk Reference 2Nd Edition A Comprehensive Guide To Project Planning, Scheduling, Evaluation, and Systems (2002)Document585 pagesMcgraw Hill - The Project Manager's Desk Reference 2Nd Edition A Comprehensive Guide To Project Planning, Scheduling, Evaluation, and Systems (2002)Sandro SouzaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- TPM - Developing Performance Indicators For Managing Maintenance (1998) - WiremanDocument108 pagesTPM - Developing Performance Indicators For Managing Maintenance (1998) - WiremanSandro SouzaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Supplier Evaluation and Performance Monitoring (SL4 - DE)Document19 pagesSupplier Evaluation and Performance Monitoring (SL4 - DE)AllwynRajkumarNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- International CV Wiring Diagrams PDFDocument1,039 pagesInternational CV Wiring Diagrams PDFiskandarmustafa100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Diplexer K 782106xxDocument2 pagesDiplexer K 782106xxplanning toolsNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Bs Iso 4190 LiftDocument9 pagesBs Iso 4190 LiftVivien John100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- TP0027-9 Masterload Gantry PDFDocument104 pagesTP0027-9 Masterload Gantry PDFtmaail698150% (2)

- Delta SOLIVIA Inverter 2.5APG3 Installation GuideDocument148 pagesDelta SOLIVIA Inverter 2.5APG3 Installation Guidekselvan_1No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Low Molecular PVC HomopolymerDocument1 pageLow Molecular PVC HomopolymerHuynh Nam QuangNo ratings yet

- 8cab & Covering Parts System - ENGLISG-G9165Document68 pages8cab & Covering Parts System - ENGLISG-G9165George Jhonson100% (5)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Aro Pump Pd30r XXX XXX C enDocument8 pagesAro Pump Pd30r XXX XXX C enhrpenleyNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- ASP Page Life CycleDocument20 pagesASP Page Life CycleRaghu GowdaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- TIA Guidelines York RegionDocument24 pagesTIA Guidelines York RegionTahmidSaanidNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Interline 1012+ds+eng PDFDocument4 pagesInterline 1012+ds+eng PDFSUBHOMOY100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Japan: EDI CT OF GovernmentDocument17 pagesJapan: EDI CT OF GovernmentfatimahNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Iaa 2010Document84 pagesIaa 2010KarlitosmanNo ratings yet

- EOI Notice No 6)Document5 pagesEOI Notice No 6)Chandeshwor ShahNo ratings yet

- SQF Audit Checklist: Module A7Document59 pagesSQF Audit Checklist: Module A7Maruan MuhammadNo ratings yet

- Cable Tray Installation Method StatementDocument5 pagesCable Tray Installation Method StatementSandeep KumarNo ratings yet

- ANSI B16.5 - Maximum Pressure and Temperature RatingsDocument2 pagesANSI B16.5 - Maximum Pressure and Temperature RatingsKalpana BansalNo ratings yet

- LogDocument11 pagesLogLiz ZieNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Siemens s7 TcpipDocument22 pagesSiemens s7 TcpipEdward NezatlenseNo ratings yet

- ModemLog - ZTE Proprietary USB ModemDocument2 pagesModemLog - ZTE Proprietary USB ModemGilang RamadhanNo ratings yet

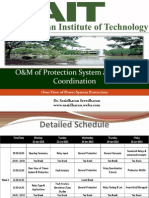

- O&M of Protection Systems and Relay Coordination GuideDocument72 pagesO&M of Protection Systems and Relay Coordination GuideAlejandro Ramirez Benites100% (2)

- Master List of Documents As Per Qms & LMS: Quality Annexure ManualDocument4 pagesMaster List of Documents As Per Qms & LMS: Quality Annexure Manualbabu541No ratings yet

- Silentknight FACP Farenhyt IFP-1000 PDFDocument220 pagesSilentknight FACP Farenhyt IFP-1000 PDFwendy vegaNo ratings yet

- DFMA OverviewDocument75 pagesDFMA Overviewanwar anwaryNo ratings yet

- Nessus Scan Report for 192.168.1.7Document7 pagesNessus Scan Report for 192.168.1.7Jyoti DahaleNo ratings yet

- 3Ph 3wire CTPT Trivector Meter With PPMB For 11KV Boundary Metering 24.09.10 PDFDocument14 pages3Ph 3wire CTPT Trivector Meter With PPMB For 11KV Boundary Metering 24.09.10 PDFStephen BridgesNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- 42Document8 pages42Syed Ali KhanNo ratings yet

- Job Description: Non-Clinical Support AssociateDocument2 pagesJob Description: Non-Clinical Support AssociateMia AbayonNo ratings yet

- Coordinator JDDocument6 pagesCoordinator JDFrans KutumelaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)