Professional Documents

Culture Documents

Teoria Factores de Guthrie (N)

Uploaded by

Susana Avalos LazoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Teoria Factores de Guthrie (N)

Uploaded by

Susana Avalos LazoCopyright:

Available Formats

www.PDHcenter.com PDH Course G127 www.PDHonline.

org

Process Equipment Cost Estimating by Ratio and Proportion

Copyright © 2007

Randall W. Whitesides, P.E.

Course Overview

Students of this one-hour course will be provided with two simple methods to arrive at approximate

equipment costs during preliminary estimate preparation.

Learning Objective

At the conclusion of this course the student will:

• Understand the applicability of ratio and proportion estimating methods;

• Learn the technique to factor costs to correspond to varying equipment sizes and capacities;

• Learn the technique to escalate or otherwise adjust historical costs.

Intended Audience

This course is intended for anyone involved with cost estimate generation.

Benefits for Attendees

This course will provide new methods of estimating for some and refresher information for others.

The course material can be used as a reference source for actual future situations.

The course includes a true-false test at the end.

Introduction

This course provides the student with an understanding of the estimating technique known as The

Rule of Six-tenths and when appropriate, use of this rule in combination with cost indices. The

various types of estimates are discussed as prerequisite background. Equations are provided to

enable the student to escalate or otherwise adjust historical equipment cost data.

Content

Cost Estimate Types and Accuracy

Regardless of accuracy, capital cost estimates are typically made-up of direct and indirect costs.

Indirect costs consist of project services, such as overhead and profit, and engineering and

administrative fees. Direct costs are construction items for the project and include property,

equipment, and materials. This course deals with the equipment component of direct cost.

Process Equipment Cost Estimating by Ratio and Proportion 1

© 2007 Randall W. Whitesides, CPE, PE

www.PDHcenter.com PDH Course G127 www.PDHonline.org

In order for the student to fully understand the applicability of ratio and proportion estimating, it

will be helpful to list the types of estimates that exist. Cost estimates fall into the following

categories and generally accepted accuracy:

• Order of Magnitude (OME) estimate ± 50%

• Study estimate ± 30%

• Preliminary (budget, scope) estimate ± 20%

• Definitive estimate ± 10%

• Detailed estimate ± 5%

As the names imply, the main difference between these types of estimates is their accuracy. The

first three types serve as a cost indicator at a very early stage of the project design stage. They are

developed with a minimum amount of detailed engineering and advise a client or a

management group of that first look at project cost. The preparation of a

preliminary estimate is done by an estimator based on his assessment of the design,

past cost estimates, in-house estimating information, and previous contracts and

purchase orders. It is not normal to obtain formal quotations from equipment

manufactures in support of a preliminary estimate. Informal telephone budget quotations on

±

identified major equipment such as vessels, filters, etc. are acceptable. However, even these types

of Aexpedient@ quotations can prove to be time restrictive to obtain sometimes. Even with the

advent of sophisticated estimating software it is sometimes simply easier to manually approximate

an equipment cost. That is the subject of this course.

Definitive and detailed cost estimates are full-blown exercises that are undertaken to produce a

competitive bid submission or otherwise produce an accurate (plus or minus 10% or better) cost

estimate, for say, a corporation’s management approval for appropriation of funds. The ratio and

proportion methods presented in this course would not be normally suitable for inclusion in a

definitive estimate.

The equipment cost estimating methods that will be outlined in this course are suitable for use with

the first three types of estimates; definitive and detail estimates require formal, firm equipment cost

quotations from equipment manufacturers and suppliers.

Process Equipment Cost Estimating by Ratio and Proportion 2

© 2007 Randall W. Whitesides, CPE, PE

www.PDHcenter.com PDH Course G127 www.PDHonline.org

Ratio and proportion estimating

A ratio indicates the relationship between two (or more) things in quantity, amount, or size.

Proportion implies that two (or more) items are similar, differing only in magnitude. Using these

well-known mathematical tools is a simple process.

When preparing preliminary estimates, two methods for estimating the cost of equipment are the

Rule of Six-tenths and the use of cost indices to adjust historic costs to current prices. Each will be

discussed and a single example will be offered to demonstrate the use of both.

The Rule of Six-tenths

Approximate costs can be obtained if the cost of a similar item of different size or capacity is

known. A rule of thumb developed over the years known as the rule of six-tenths gives very

satisfactory results when only an approximate cost within plus or minus 20% is required. An

exhaustive search in conjunction with the development

of this course left this author with no indication of any

0.6

(ratio) single individual who developed this concept. One is

forced to assume that the relationship naturally evolved

in the public domain after large quantities of actual cost

data were analyzed retrospectively. The earliest

mention of this concept was found in a reference accredited to a December 1947 Chemical

Engineering magazine article by Roger Williams, Jr. entitled “Six-tenths Factor Aids in

Approximating Costs”.

At any rate, the following equation expresses the rule of six-tenths:

0 .6

⎛S ⎞

CB = CA ⎜ B ⎟

⎝ SA ⎠

Where CB = the approximate cost ($) of equipment having size SB (cfm, Hp, ft5, or whatever)

B B

CA = is the known cost ($) of equipment having corresponding size SA (same units as SB), B

and SB/SA is the ratio known as the size factor, dimensionless.

B

Process Equipment Cost Estimating by Ratio and Proportion 3

© 2007 Randall W. Whitesides, CPE, PE

www.PDHcenter.com PDH Course G127 www.PDHonline.org

The “N” exponent

An analysis of the cost of individual pieces of equipment shows that the size factor’s exponent will

vary from 0.3 to unity, but the average is very near to 0.6, thus the name for the rule of thumb. If a

higher degree of sophistication is sought, Table 1 below can be used. It lists the value of a size

exponent for various types of process equipment. The Table 1 values have been condensed from a

vast, comprehensive tabulation of estimating cost data presented in the March 24, 1969 issue of

Chemical Engineering magazine. This article by K.M. Guthrie is entitled “Data and Techniques for

Preliminary Capital Cost Estimating”. While the source for the concept and the presented

exponential data is somewhat dated, i.e.1947 and 1969 respectively, there is indication that this

material is still relevant and valid.

Using Table 1 size exponents transforms the previously presented formula into,

N

⎛S ⎞

CB = CA ⎜ B ⎟

⎝ SA ⎠

Where the symbols are identical to those already described and N is the size exponent,

dimensionless, from Table 1:

PROCESS EQUIPMENT SIZE EXPONENT (N) - TABLE 1

EQUIPMENT NAME UNIT SIZE EXPONENT (N)

Agitator, propeller Hp 0.50

Agitator, turbine Hp 0.30

Air compressor, single stage cfm 0.67

Air compressor, multiple stage cfm 0.75

Air dryer cfm 0.56

Boiler, industrial, all sizes lb/hr 0.50

Boiler, package lb/hr 0.72

Centrifuge, horizontal basket dia (inches) 1.72

Centrifuge, solid bowl dia (inches) 1.00

Conveyor, belt feet 0.65

Conveyor, bucket feet 0.77

Process Equipment Cost Estimating by Ratio and Proportion 4

© 2007 Randall W. Whitesides, CPE, PE

www.PDHcenter.com PDH Course G127 www.PDHonline.org

Conveyor, screw feet 0.76

Conveyor, vibrating feet 0.87

Crystallizer, growth ton/day 0.65

Crystallizer, forced circulation ton/day 0.55

Crystallizer, batch gallons 0.70

Dryer, drum and rotatory sq. ft. 0.45

Dust collector, cyclone cfm 0.80

Dust collector, cloth filter cfm 0.68

Dust collector, precipitator cfm 0.75

Evaporator, forced circulation sq. ft. 0.70

Evaporator, vertical and horizontal tube sq. ft. 0.53

Fan Hp 0.66

Filter, plate and press sq. ft. 0.58

Filter, pressure leaf sq. ft. 0.55

Heat exchanger, fixed tube sq. ft. 0.62

Heat exchanger, U-tube sq. ft. 0.53

Mill, ball and roller ton/hr 0.65

Mill, hammer ton/hr 0.85

Pump, centrifugal carbon steel Hp 0.67

Pump, centrifugal stainless steel Hp 0.70

Tanks and vessels, pressure, carbon steel gallons 0.60

Tanks and vessels, horizontal, carbon steel gallons 0.50

Tanks and vessels, stainless steel gallons 0.68

Cost Indices

The names and purpose of today’s cost indices are too numerous to mention. Probably the most

widely known cost index to the general public is the Consumer Price Index (CPI) generated by the

U.S. Department of Labor, Bureau of Labor Statistics. While the CPI could probably serve our

needs, more specific data is available for use in engineering and technical applications.

Process Equipment Cost Estimating by Ratio and Proportion 5

© 2007 Randall W. Whitesides, CPE, PE

www.PDHcenter.com PDH Course G127 www.PDHonline.org

Cost indices are useful when basing the approximated cost on other than current prices. If the

known cost of a piece of equipment is based on, for instance 1998 prices, this cost must be

multiplied by the ratio of the present day index to the 1998 base index in order to proportion the

value to present day dollars. (Incidentally, the inverse of this operation can be performed to

estimate what a given piece of equipment would have cost in some prior time). Mathematically,

this looks like,

⎛ I ⎞

C = CO ⎜ ⎟

⎝ IO ⎠

Where C = current cost, dollars

CO = base cost, dollars

I = current index, dimensionless

IO = base index, dimensionless

Many sources exist for technical indices but two of the more popular ones which are readily

available are those published monthly in Chemical Engineering magazine under “Economic

Indicators, Marshall and Swift Equipment Cost Index” and weekly in Engineering News Record

magazine under “Market Trends”. Both work equally well but as with other indices, they cannot be

used interchangeably. Incidentally, current Engineering New Record cost information is accessible

on the Internet at www.enr.com. Scroll down to the Construction Economics file tab and click on

recent cost indexes. Unfortunately no cost index information is offered at the Chemical

Engineering magazine website.

Process Equipment Cost Estimating by Ratio and Proportion 6

© 2007 Randall W. Whitesides, CPE, PE

www.PDHcenter.com PDH Course G127 www.PDHonline.org

MARSHALL & SWIFT EQUIPMENT COST INDEX

(1926 =100) 4thQ 3rdQ 4thQ

2006 2006 2005

M & S INDEX 1353.8 1333.4 1274.8

Annual Index

2001 = 1093.9 2003 = 1123.6 2005 = 1244.5

2002 = 1104.2 2004 = 1178.5 2006 = 1302.3

Example Tabulation of Magazine Cost Index Data

Let us take an illustrative example:

The following example illustrates a combined use of both of these ratio and proportion methods to

produce an approximate cost. Please note that the costs presented here are purely hypothetical and

should not be used as a basis for anything other than an illustration.

Let us assume that a rough estimate is being prepared for a project in which a 5,000-gallon capacity

stainless steel pressure vessel is involved. Let us further assume that our past project purchasing

data shows that a 2,000-gallon stainless steel pressure vessel, very similar to that currently required,

was purchased in 2001 for $15,000.

We now have all of the necessary components to approximate the present day cost (CB ) of a 5,000-

B

gallon vessel. We have, two dates, past and of course current; two known capacities (SB and SA );

and one historical cost (CO ) (that of the 2001 purchased

vessel).

The first step is to determine the cost index for our two

dates. Consulting a recent issue of Chemical Engineering

magazine, the M & S Equipment Cost Index for 2001 is

found to be 1093.9 (our base index for this example). In

like fashion, the 2006 4th Quarter index is found to be

1353.8 (the current index). The student may be interested to

know that the M & S Cost Index’s base is 1926 = 100; this

provides an astonishing indication of the amount of inflation that has taken place.

Process Equipment Cost Estimating by Ratio and Proportion 7

© 2007 Randall W. Whitesides, CPE, PE

www.PDHcenter.com PDH Course G127 www.PDHonline.org

This complied data allows us to substitute,

⎛ I ⎞ ⎛ 13538

. ⎞

C = CO ⎜ ⎟ = ($15,000) ⎜ ⎟ = $18,565

⎝ IO ⎠ ⎝ 1093.9 ⎠

Therefore, the 4th Quarter 2006 cost of the 2,000-gallon capacity vessel is estimated to be $18,565.

Now, having determined the current estimated cost of the smaller capacity vessel, we need to adjust

this amount to correspond to the larger volume (5,000 gallons). Referring to Table 1, we find a size

exponent corresponding to stainless steel vessels equal to 0.68. Substituting in the equation

presented earlier results in,

N

⎛S ⎞

0.68

⎛ 5,000 ⎞

CB = C A ⎜ B ⎟ = ($18,565) ⎜ ⎟ = $34,617

⎝ SA ⎠ ⎝ 2,000 ⎠

The unit, ten, and hundred places in this figure are irrelevant. A “rough” estimate of $34,617 is

ridiculous and implies a degree of accuracy that has no basis in this case; $35,000 is more sensible

and just as likely to be correct in the context of a plus or minus 20% estimate.

Therefore, the approximate 4th Quarter 2006 cost of the 5,000-gallon capacity vessel is $35,000.

Summary

While there may be sophisticated software available to generate accurate cost estimates, we should

never loose sight of the importance of understanding the basis for costs. Never let computer output

cloud simple estimating judgment.

It is novel to be armed with simple, quick, easy to understand techniques to arrive at approximate

equipment costs. The Rule of Six-tenths and the use of cost indices are two readily available and

easy to use ratio and proportion methods to quickly estimate equipment costs.

Process Equipment Cost Estimating by Ratio and Proportion 8

© 2007 Randall W. Whitesides, CPE, PE

You might also like

- Six Tenth RuleDocument8 pagesSix Tenth Ruleusman_hafeez86No ratings yet

- Capital Cost Estimate Rule of ThumbDocument9 pagesCapital Cost Estimate Rule of ThumbParallaxster100% (1)

- Est01 - So You Think You'Re An EstimatorDocument6 pagesEst01 - So You Think You'Re An Estimatormechanical_engineer11No ratings yet

- Energies: Cost Engineering Techniques and Their Applicability For Cost Estimation of Organic Rankine Cycle SystemsDocument18 pagesEnergies: Cost Engineering Techniques and Their Applicability For Cost Estimation of Organic Rankine Cycle SystemssilencruzNo ratings yet

- EST.01 So You Think You're An Estimator?: Mr. Larry R. Dysert, CCCDocument6 pagesEST.01 So You Think You're An Estimator?: Mr. Larry R. Dysert, CCCdanish_1985No ratings yet

- Development OF Factored Cost Esti Mates - AS Appli ED I N Engi Neeri NG, Procurement, AND Constructi ON FOR THE Process I Ndustri ESDocument6 pagesDevelopment OF Factored Cost Esti Mates - AS Appli ED I N Engi Neeri NG, Procurement, AND Constructi ON FOR THE Process I Ndustri ESRi A PeNo ratings yet

- Formularios para La Gestión de Los CostesDocument10 pagesFormularios para La Gestión de Los CostesVerónica Restrepo GiraldoNo ratings yet

- Suitable Method For Capital Cost Estimation in Chemical Processes IndustriesDocument5 pagesSuitable Method For Capital Cost Estimation in Chemical Processes IndustriesAfiq JohariNo ratings yet

- 2 Cost Concept and Design EconomicsDocument27 pages2 Cost Concept and Design EconomicsMuhammad Adnan, 180021217No ratings yet

- Depreciation D V Vs N $ 3000/ YearDocument3 pagesDepreciation D V Vs N $ 3000/ Yearumair saleemNo ratings yet

- PICE Cost Estimating LECTURE FinalDocument44 pagesPICE Cost Estimating LECTURE FinalAaRichard ManaloNo ratings yet

- Parametric Cost Deployment Dean NasaDocument8 pagesParametric Cost Deployment Dean Nasamosros123No ratings yet

- Cost Estimate Classification System - As Applied in Engineering, Procurement, and Construction For The Process IndustriesDocument13 pagesCost Estimate Classification System - As Applied in Engineering, Procurement, and Construction For The Process IndustriesmohamedNo ratings yet

- Paper Dimensionless GroupsDocument6 pagesPaper Dimensionless GroupsAnonymous np9S6omhMlNo ratings yet

- Competitive Pricing of Process PlantsDocument8 pagesCompetitive Pricing of Process Plantsvazzoleralex6884No ratings yet

- Cost Engineering Techniques and Their Applicability For Cost Estimation of Organic Rankine Cycle SystemsDocument19 pagesCost Engineering Techniques and Their Applicability For Cost Estimation of Organic Rankine Cycle Systemskanbur.191No ratings yet

- 1966 BenstonDocument17 pages1966 BenstonstephanbubeckNo ratings yet

- WEBBER & CLINTON / RCA Applied / The Clopay Case / LongDocument14 pagesWEBBER & CLINTON / RCA Applied / The Clopay Case / LongAnastasiaNo ratings yet

- Expert Systems With Applications: Wei-Chih Wang, Shih-Hsu Wang, Yu-Kun Tsui, Ching-Hsiang HsuDocument9 pagesExpert Systems With Applications: Wei-Chih Wang, Shih-Hsu Wang, Yu-Kun Tsui, Ching-Hsiang HsuHema Chandra IndlaNo ratings yet

- Handout Group 6Document5 pagesHandout Group 6api-3831834No ratings yet

- PMBOK Cost (6th Edition) - 268-307-5Document3 pagesPMBOK Cost (6th Edition) - 268-307-5Nathan yemaneNo ratings yet

- Overview of Cost EstimatingDocument17 pagesOverview of Cost EstimatingEli Ferreira100% (1)

- Cost EstimatingDocument27 pagesCost EstimatingArief Budiman Hermani100% (1)

- Key Components of A Cost EstimateDocument11 pagesKey Components of A Cost EstimatedevikaNo ratings yet

- Esm570 04Document32 pagesEsm570 04abdalrahim mattarNo ratings yet

- Cost EstimatingDocument27 pagesCost EstimatingAndrew Ugoh100% (1)

- COSTandVALUE Artikel Carlo Holvoet Oktober 2013 PDFDocument4 pagesCOSTandVALUE Artikel Carlo Holvoet Oktober 2013 PDFVictor VazquezNo ratings yet

- Initiating Step of ADocument7 pagesInitiating Step of ANayan RathodNo ratings yet

- PEB4102 Chapter 3Document46 pagesPEB4102 Chapter 3LimNo ratings yet

- Project IntroDocument7 pagesProject IntroAkash DasNo ratings yet

- ReportESTIMATION OF PROJECT TIMES AND COSTSDocument51 pagesReportESTIMATION OF PROJECT TIMES AND COSTSa_m_shihaNo ratings yet

- 56r-08 Cost Estimate Classification System - As Applied For The Building and General Construction IndustriesDocument16 pages56r-08 Cost Estimate Classification System - As Applied For The Building and General Construction IndustriesWalter100% (4)

- Module 3Document55 pagesModule 3Holy666 TokNo ratings yet

- Fundamentals of Cost Accounting 5th Edition Lanen Solutions Manual 1Document36 pagesFundamentals of Cost Accounting 5th Edition Lanen Solutions Manual 1brittanymartinezdknybgqpes100% (27)

- The Lean Project Delivery System An UpdateDocument19 pagesThe Lean Project Delivery System An UpdateDavidNo ratings yet

- Chapter 10 Solutions Horngren Cost AccountingDocument43 pagesChapter 10 Solutions Horngren Cost AccountingAnik Kumar Mallick100% (2)

- Hussam Estimation1Document19 pagesHussam Estimation1Abdo England100% (1)

- A New Concept for Tuning Design Weights in Survey Sampling: Jackknifing in Theory and PracticeFrom EverandA New Concept for Tuning Design Weights in Survey Sampling: Jackknifing in Theory and PracticeNo ratings yet

- Presentation-Ship Repair, Maintenance & Modernization Cost ModelDocument33 pagesPresentation-Ship Repair, Maintenance & Modernization Cost ModelFerdinand Tiongson HechanovaNo ratings yet

- Presentation-Ship Repair, Maintenance & Modernization Cost ModelDocument33 pagesPresentation-Ship Repair, Maintenance & Modernization Cost ModelJulio Mario De CastroNo ratings yet

- IT Project Management-Cost Estimation Process.J.nicholos.08Document9 pagesIT Project Management-Cost Estimation Process.J.nicholos.08kksbabu05No ratings yet

- Cost EstimationDocument7 pagesCost EstimationManoj EkNo ratings yet

- Cost Estimation and Analysis1Document49 pagesCost Estimation and Analysis19819143966No ratings yet

- Measuring The Efficiency of Decision Making Units: CharnesDocument16 pagesMeasuring The Efficiency of Decision Making Units: CharnesnnleNo ratings yet

- Journal of Computing in Civil Engineering, 7 (1993) ,: Crespi, I.Document2 pagesJournal of Computing in Civil Engineering, 7 (1993) ,: Crespi, I.Cristina PanaitNo ratings yet

- Cost Estimation in Project ManagementDocument4 pagesCost Estimation in Project ManagementAsad Ullah0% (1)

- 4918 Module 2 Conception Feasibility Specifications Data AcquisitionDocument30 pages4918 Module 2 Conception Feasibility Specifications Data AcquisitionAshlyn CicilyNo ratings yet

- Klasifikasi Akurasi EstimasiDocument4 pagesKlasifikasi Akurasi EstimasiAdwina DesyandriNo ratings yet

- Cost Concepts and Design EconomicsDocument19 pagesCost Concepts and Design EconomicsReian Cais SayatNo ratings yet

- Mathematical and Computer Modelling: Minjae Park, Hoang PhamDocument16 pagesMathematical and Computer Modelling: Minjae Park, Hoang PhamMubashir UnnissaNo ratings yet

- Btech ReportDocument4 pagesBtech ReportRyuuichi KishimaNo ratings yet

- Pricing and Estimating: B.Sravanthi Ced, KitswDocument25 pagesPricing and Estimating: B.Sravanthi Ced, KitswKandagatla KamalNo ratings yet

- 41R-08 Risk Analysis and Contingency Determination Using Range EstimatingDocument10 pages41R-08 Risk Analysis and Contingency Determination Using Range EstimatingDody Bdg100% (1)

- Cost Estimation: True / False QuestionsDocument216 pagesCost Estimation: True / False QuestionsElaine GimarinoNo ratings yet

- BAYESDocument29 pagesBAYESjosephpogba360No ratings yet

- Jurnal AsingDocument2 pagesJurnal AsingHero BirawanNo ratings yet

- Bsce-2a - Case Study 2 - Sato - March 16, 2024Document19 pagesBsce-2a - Case Study 2 - Sato - March 16, 2024Gawa GawaNo ratings yet

- Improving the User Experience through Practical Data Analytics: Gain Meaningful Insight and Increase Your Bottom LineFrom EverandImproving the User Experience through Practical Data Analytics: Gain Meaningful Insight and Increase Your Bottom LineNo ratings yet

- Economic Multi Agent Systems: Design, Implementation, and ApplicationFrom EverandEconomic Multi Agent Systems: Design, Implementation, and ApplicationRating: 4 out of 5 stars4/5 (1)

- C 14Document26 pagesC 14pfylNo ratings yet

- Cracks in Buildings PDFDocument50 pagesCracks in Buildings PDFSanjay ShelarNo ratings yet

- Class 7 - 9 State Space Representation To Transfer Function and Vice VersaDocument13 pagesClass 7 - 9 State Space Representation To Transfer Function and Vice Versaapi-26676616No ratings yet

- Four Bar Mechanism and Analysis in CreoDocument9 pagesFour Bar Mechanism and Analysis in CreoJigneshNo ratings yet

- Solid Dispersion PolymorphismDocument37 pagesSolid Dispersion PolymorphismAmey KamtheNo ratings yet

- Ari Faba Plus - Kvs Diagram PDFDocument32 pagesAri Faba Plus - Kvs Diagram PDFgiuseppe.timpone1100% (1)

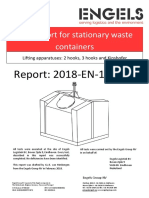

- Report 2018-En-1 en 13071-1-3 Aero EnglishDocument16 pagesReport 2018-En-1 en 13071-1-3 Aero EnglishSlikCostaNo ratings yet

- 3 Phase Electrical Wiring InstallationDocument3 pages3 Phase Electrical Wiring Installationsofyan_shah100% (2)

- MSQE Program: With Tracks in Economics, Finance, and MarketingDocument20 pagesMSQE Program: With Tracks in Economics, Finance, and MarketingSimone MarrettaNo ratings yet

- Derrick Scott Van Heerden - Mathemagical Music Scales, 2013Document54 pagesDerrick Scott Van Heerden - Mathemagical Music Scales, 2013Tiago Ramos100% (1)

- QTMS Brochure Rev2Document8 pagesQTMS Brochure Rev2ManibalanNo ratings yet

- J Euromechsol 2020 104041Document13 pagesJ Euromechsol 2020 104041Son NguyenNo ratings yet

- Year 6 - EclipsesDocument7 pagesYear 6 - EclipsesHani BakarNo ratings yet

- IBA Test Prep MaterialDocument3 pagesIBA Test Prep MaterialAmmar Hassan67% (9)

- Borzone Et Al 1996Document13 pagesBorzone Et Al 1996Daiane Evangelista AvizNo ratings yet

- Chemistry: Pearson EdexcelDocument28 pagesChemistry: Pearson EdexcelNyraStardollNo ratings yet

- Failure Analysis by Means of MicrosDocument31 pagesFailure Analysis by Means of Micros28192175100% (1)

- SPM General CatalogDocument40 pagesSPM General CatalogNailuth García100% (1)

- School of Basic Sciences and Research, Sharda University Physics Laboratory ManualDocument5 pagesSchool of Basic Sciences and Research, Sharda University Physics Laboratory ManualNiboli ZhimomiNo ratings yet

- CSL361 Programming Assignment 2:: March 9, 2014Document2 pagesCSL361 Programming Assignment 2:: March 9, 2014Jam SinghNo ratings yet

- Shear Wave Velocity: Comparison Between Centrifuge and Triaxial Based MeasurementsDocument6 pagesShear Wave Velocity: Comparison Between Centrifuge and Triaxial Based MeasurementsLuciano JuniorNo ratings yet

- Able BrochureDocument8 pagesAble BrochureravensarcillaNo ratings yet

- Long Welded Rails-6Document21 pagesLong Welded Rails-6vpmohammedNo ratings yet

- Elementary Linear Algebra: Howard Anton Chris RorresDocument78 pagesElementary Linear Algebra: Howard Anton Chris Rorresdeandra isabelleNo ratings yet

- PC PilesDocument12 pagesPC PilesBobby SetiawanNo ratings yet

- ASTM D5147 - Sampling and Testing Modified Bituminous Sheet Material1Document5 pagesASTM D5147 - Sampling and Testing Modified Bituminous Sheet Material1jothi vel muruganNo ratings yet

- Pressure Rating For SSII Float EquipmentDocument2 pagesPressure Rating For SSII Float EquipmentMahmoud Ahmed Ali AbdelrazikNo ratings yet

- R. Angeline Prabha & J.Lavina Mary: Jacsi College of Engg. NazarethDocument17 pagesR. Angeline Prabha & J.Lavina Mary: Jacsi College of Engg. NazarethRose EdwardNo ratings yet

- LogiComm Pattern ControlDocument2 pagesLogiComm Pattern ControlNordson Adhesive Dispensing SystemsNo ratings yet

- Prilling TowerDocument29 pagesPrilling TowerMuhammad Saleem SukheraNo ratings yet