Professional Documents

Culture Documents

Liebert Refrigerant Sizing

Uploaded by

coolth2Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liebert Refrigerant Sizing

Uploaded by

coolth2Copyright:

Available Formats

How to use the Liebert Refrigerant Line Sizing Program

This dialog window is used to enter the data used for the analysis.

At the top of the dialog window the title for the analysis can be entered. The date can also be

entered, but the program will default this to the current date if nothing is entered.

You may select English or Metric units for the inputs and results.

The analysis data is entered in the middle of the dialog window.

For the suction, discharge (hot gas), and liquid lines the equivalent length and, optionally, the outside

diameter are entered. The required line diameter will be calculated for any of the lines where a length

is entered and the diameter is set to 0. You must enter the equivalent length for the type of line you

are using. For split systems with condensing units enter the suction and liquid lines. For self

contained systems with condensers enter the discharge and liquid line. The program will calculate the

size of the line needed based on a maximum refrigerant temperature drop, listed on page 2, and

show the details on the output page. As an alternative, you may enter a desired line size in the

Outside Diameter boxes. The program will calculate the pressure drops and velocities based on the

input diameters.

The appropriate temperatures are entered for the evaporator, condensing and liquid. These should be

for the design operating conditions of the system (i.e. 75F/45 or 50% RH at 95F ambient). The

difference between the condensing temperature and liquid temperature is the system sub-cooling. 10o

F is a typical value for sub-cooling. We have chosen typical values but these may be changed if you

have more specific values to use.

Finally the cooling capacity is entered. This is the net cooling effect from the compressor. For multiple

compressor units, each with their own line sets, enter the capacity per compressor. Values for Liebert

systems based on 75F return air temps, may be found at the blue circle question mark.

Pressing the "Output" button will display the results of the analysis.

Pressing the "Exit" will quit the program without performing any analysis.

Output Screen

The outputs echo the inputs plus the results.

Included: Line size outside diameter, Pressure drop, Temperature drop, Refrigerant velocity and flow

rate.

Warnings are also output if the results are beyond accepted values.

For further study please refer to the ASHRAE Refrigeration Handbook. Additional information on

refrigerant line sizing may be found in ARI and RSES publications.

SAFM-7820-29

Rev. 7; 08/11/11

1 of 2

Line Sizing Guide

(R22 & R407C)

Typical Design Values:

Suction Line

Liquid Line

< 2 degree (1.1C) temperature drop

< 3 psi (20kPa) pressure

< 1 degree (.6C) temperature drop

< 3 psi (20kPa) pressure drop

Hot Gas (Discharge Line)

Vertical risers may be sized separate from horizontal runs in order to maintain sufficient velocity to

move oil up the riser.

< 2 degree (1.1C) temperature drop

< 6 psi (40kPa) pressure drop (6-10 psi (40-70 kPa) drop will experience a loss in capacity)

Equivalent lengths: The equivalent length of a line consists of the linear distance plus the addition of

equivalent lengths of fittings and specialty items whose values may be found in Table 1.

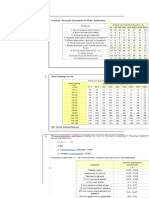

Table I: Equivalent Lengths, Feet (m) for Various Pipe Fittings

Copper Pipe 90 Degree Elbow

45 Degree

O.D. in.

Copper

Cast

Elbow

1/2

0.8 (.24)

1.3 (.4)

0.4 (.12)

5/8

0.9 (.27) 1.4 (.43) 0.5 (.15)

3/4

1.0 (.3)

1.5 (.46) 0.6 (.18)

7/8

1.45 (.44) 1.8 (.55) 0.8 (.24)

1 1/8

1.85 (.56) 2.2 (.67)

1.0 (.3)

1 3/8

2.4 (.73) 2.9 (.88)

1.3 (.4)

1 5/8

2.9 (.88) 3.5 (1.0) 1.6 (.49)

Tee

2.5 (.76)

2.5 (.76)

2.5 (.76)

3.6 (1.1)

4.6 (1.4)

6.4 (2.0)

7.2 (2.2)

Gate

Valve

0.26 (.08)

0.28 (.085)

0.3 (.09)

0.36 (.11)

0.48 (.15)

0.65 (.2)

0.72 (.22)

Globe

Valve

7.0 (2.1)

9.5 (2.9)

12.0 (3.7)

17.2 (5.2)

22.5 (6.9)

32.0 (9.8)

36.0 (11)

Angle

Typical

Valve

Trap

4.0 (1.2)

3.2 (.96)

5.0 (1.5) 3.6 (1.08)

6.5 (2)

4.0 (1.2)

9.5 (2.9) 5.8 (1.76)

12.0 (3.7) 7.4 (2.24)

16.0 (4.9) 9.6 (2.92)

19.5 (5.9) 11.6 (3.52)

Limitations Guides and Precautions:

Small Systems and Challenger split systems:

Maximum equivalent length

200 feet (60m)

Vertical Rise (Condensing unit high,3, 5 & 8 ton)

50 feet (15m)

Vertical Rise (Condensing unit high, 1, 1.5 & 2 ton)

40 feet (12m)

Condensing units must not be located more than 15 feet (4.5m) below the evaporator

Small system runs over 50 (15m) equivalent feet (vertical) require installation of a Liquid Line solenoid valve. (reference SFA:

E7300-01)

When below 15 feet (4.5m) Small Systems require a field installed Suction/Liquid heat exchanger (supplied by others)

Liebert DS and Challenger self contained systems:

Maximum equivalent length (single compr or 2-step)

Maximum equivalent length (4-step or digital)

Vertical Rise (Condenser high, single compr or 2-step)

Vertical Rise (Condenser high, 4-step or digital)

280 feet (85m)

260 feet (79m)

70 feet (21m)

60 feet (18m)

Horizontal suction and hot gas line velocities must be greater than 700 FPM (3.6m/s)and pitched (1.3cm) per every 10 feet

(3m) of horizontal run

Vertical lifts (H.G. risers) must exceed 1000 FPM (5m/s) up to 3000 FPM (15m/s) but may be noisy

Trapping must be practiced at bottom of riser with any rise over 5 feet high. If rise exceeds 25 feet (7.5m), then we require a trap

in 20 foot (6m) increments or evenly divided

Scenarios involving condenser located below evaporator; condenser can not be greater than 15 feet (4.5m) below evaporator

with FSC. Condenser with Lee-Temp should be on the same level

Additional liquid lift will require the installation of a sub-cooler on Liebert DS and Challenger

(Application will be good for 30 feet (9m) with this optional equipment)

2 of 2

You might also like

- Line Sizing File (No Password)Document18 pagesLine Sizing File (No Password)Montian LuangsakultongNo ratings yet

- Nordyne Line SizeDocument4 pagesNordyne Line SizeRay RavelNo ratings yet

- Ashrea Duct WorkDocument55 pagesAshrea Duct WorkHaja MydeenNo ratings yet

- ACCA Manual D SpreadsheetDocument96 pagesACCA Manual D SpreadsheetEdNo ratings yet

- RIM20 Rotor Insertion Flowmeter-Technical InformationDocument9 pagesRIM20 Rotor Insertion Flowmeter-Technical InformationnprashanNo ratings yet

- Control Valve Sizing-Engineering DataDocument21 pagesControl Valve Sizing-Engineering DatapalindapcNo ratings yet

- The equal friction method for sizing ductsDocument8 pagesThe equal friction method for sizing ductsRamil BelmonteNo ratings yet

- Guide To CADREFlow SamplesDocument20 pagesGuide To CADREFlow SamplesWashington RodriguesNo ratings yet

- Tecumseh Refrigerant PipingDocument24 pagesTecumseh Refrigerant Pipingaries26marchNo ratings yet

- Solvent Flow Meter Catalogue PDFDocument6 pagesSolvent Flow Meter Catalogue PDFJR DadisNo ratings yet

- 04 ColumnDynamicsDocument18 pages04 ColumnDynamicsabhmarsNo ratings yet

- HR E577rDocument6 pagesHR E577rAnton RenaldoNo ratings yet

- Rexworth Hydraulic MotorDocument28 pagesRexworth Hydraulic MotorSorin-Adrian Learschi100% (1)

- What Is Instrument Hook Up Diagram ? Instrument Hook Up Diagram Is Also Called Installation Drawing, Specifies The ScopeDocument31 pagesWhat Is Instrument Hook Up Diagram ? Instrument Hook Up Diagram Is Also Called Installation Drawing, Specifies The ScopevrajakisoriDasiNo ratings yet

- Rexroht PumpDocument45 pagesRexroht PumpmanualdeutsNo ratings yet

- Aeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramDocument4 pagesAeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramAshraf KamalNo ratings yet

- DFJKDocument12 pagesDFJKDickson ChongNo ratings yet

- SS2 Agv200 0001 13Document28 pagesSS2 Agv200 0001 13Thoriq Septa VallahanggaNo ratings yet

- Application Bulletin 140Document12 pagesApplication Bulletin 140Maria DazaNo ratings yet

- Carrier Air Con 38QRR ManualDocument30 pagesCarrier Air Con 38QRR ManualYorkistNo ratings yet

- 05 PumpsDocument80 pages05 PumpsRoberto O'ConnorNo ratings yet

- One Company Unlimited SolutionsDocument20 pagesOne Company Unlimited SolutionsjobinjsNo ratings yet

- 1-5 Steam Temperature - QuestionnaireDocument3 pages1-5 Steam Temperature - QuestionnairesdiamanNo ratings yet

- PIPESYS Training SupplementDocument7 pagesPIPESYS Training Supplementahad_shiraziNo ratings yet

- HYD. PumpDocument40 pagesHYD. Pumprohitbhat2345No ratings yet

- Ch20-Variable Air VolumeDocument14 pagesCh20-Variable Air VolumeperezismaelNo ratings yet

- Axial Piston Pump CatalougeDocument36 pagesAxial Piston Pump Catalougemrkadu_61No ratings yet

- Gas Line Sizing Rev1Document11 pagesGas Line Sizing Rev1Sermsak LimpadapunNo ratings yet

- 633LS ProdspecDocument14 pages633LS ProdspecAdrian AbellaNo ratings yet

- PressureDrop CalculatorDocument7 pagesPressureDrop CalculatorHomer SilvaNo ratings yet

- Reznor HandbookDocument72 pagesReznor Handbookethen223100% (1)

- A6 VDocument40 pagesA6 VWesame Shnoda100% (1)

- Alicat Scientific MFCs-Technology & BenefitsDocument6 pagesAlicat Scientific MFCs-Technology & BenefitsyuvionfireNo ratings yet

- Fan Curve BasicsDocument4 pagesFan Curve BasicsSze Yan LamNo ratings yet

- ASTM D1250-04 For PC Manual - ROFA SoftwareDocument8 pagesASTM D1250-04 For PC Manual - ROFA SoftwareSeeker168No ratings yet

- Dimensionamiento de Lineas de GasDocument10 pagesDimensionamiento de Lineas de GasHugo Narvaez FuentesNo ratings yet

- Cooling Coil 01Document15 pagesCooling Coil 01Sam Wang Chern Peng100% (3)

- Oil Coolers: Air CooledDocument12 pagesOil Coolers: Air CooledHenry RogersNo ratings yet

- HSN 7461-70Document11 pagesHSN 7461-70codymasterNo ratings yet

- Linde Hydraulics - HPV-02Document0 pagesLinde Hydraulics - HPV-021antonio100% (1)

- Om004 Om008 Integral ManualDocument9 pagesOm004 Om008 Integral ManualistopiNo ratings yet

- How to use AutoSPRINK features for pressure reducing valvesDocument7 pagesHow to use AutoSPRINK features for pressure reducing valvesIvan Lizarazo100% (1)

- Bomba Rexroth A4SGCDocument32 pagesBomba Rexroth A4SGCEdgarRetuertoNo ratings yet

- Liquid Line SizingDocument12 pagesLiquid Line Sizinglolofm25No ratings yet

- Liquid Pressure Drop CalculationDocument9 pagesLiquid Pressure Drop CalculationMichaelMahonyNo ratings yet

- A3H37 Performance Characteristics of A3H Series Variable Displacement Piston PumpsDocument4 pagesA3H37 Performance Characteristics of A3H Series Variable Displacement Piston PumpsEdson LeandroNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Power Boilers & Heat Exchangers World Summary: Market Values & Financials by CountryFrom EverandPower Boilers & Heat Exchangers World Summary: Market Values & Financials by CountryNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Fluid Power Valves & Hose Fittings World Summary: Market Values & Financials by CountryFrom EverandFluid Power Valves & Hose Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Air & Gas Compressors World Summary: Market Values & Financials by CountryFrom EverandAir & Gas Compressors World Summary: Market Values & Financials by CountryNo ratings yet

- Technical specs for fire protectionDocument11 pagesTechnical specs for fire protectioncoolth2No ratings yet

- NL Master Specification Guide For Public Funded Buildings: Re-Issued 2017/05/31Document7 pagesNL Master Specification Guide For Public Funded Buildings: Re-Issued 2017/05/31coolth2No ratings yet

- Project Name:: Falcon URIDocument2 pagesProject Name:: Falcon URIcoolth2No ratings yet

- Daily Time Record for Richard MacapagalDocument1 pageDaily Time Record for Richard Macapagalcoolth2No ratings yet

- Concrete Design Excel SheetDocument4 pagesConcrete Design Excel Sheetcoolth2No ratings yet

- And So It Goes: Life According To Kurt VonnegutDocument2 pagesAnd So It Goes: Life According To Kurt Vonnegutcoolth2No ratings yet

- Concrete Design Excel SheetDocument16 pagesConcrete Design Excel SheetCleth Hiren Santos25% (4)

- Installation, Operation and Maintenance Manual: Model BCSW-FRPDocument12 pagesInstallation, Operation and Maintenance Manual: Model BCSW-FRPcoolth2No ratings yet

- Motion Control Engineer - Lexmark Research - Development CorporationDocument2 pagesMotion Control Engineer - Lexmark Research - Development Corporationcoolth2No ratings yet

- Kitchen VentDocument5 pagesKitchen Ventcoolth2No ratings yet

- DWG TrueView DWG Convert Conversion ReportDocument1 pageDWG TrueView DWG Convert Conversion ReportCosmin CinciNo ratings yet

- ASHRAE Chilled Water Systems GuideDocument4 pagesASHRAE Chilled Water Systems Guidecoolth2No ratings yet

- Sims4 CheatsDocument2 pagesSims4 Cheatscoolth2No ratings yet

- Bs Electrical Engineering CurriculumDocument2 pagesBs Electrical Engineering Curriculumcoolth2No ratings yet

- Expansion Vessel Sizing GuideDocument1 pageExpansion Vessel Sizing Guidecoolth2No ratings yet

- Acoustic CalculationDocument14 pagesAcoustic Calculationcoolth2No ratings yet

- Fan Coil Units, AHUs Sequence of OperationDocument18 pagesFan Coil Units, AHUs Sequence of OperationRa Ar100% (2)

- Air Handling Unit Noise Generation - Original AttenuatorDocument4 pagesAir Handling Unit Noise Generation - Original Attenuatorcoolth2No ratings yet

- Ventilation Brochure ECPEN11-203 Ventilation Catalogue UK Tcm511-252287Document39 pagesVentilation Brochure ECPEN11-203 Ventilation Catalogue UK Tcm511-252287coolth2No ratings yet

- Essential HVAC Calculations Spreadsheet for Load Estimation, Psychrometrics, Duct DesignDocument52 pagesEssential HVAC Calculations Spreadsheet for Load Estimation, Psychrometrics, Duct DesignSyed ShahbazNo ratings yet

- Reading Guitar Tablature II - Guitar Lessons at Ultimate-GuitarDocument6 pagesReading Guitar Tablature II - Guitar Lessons at Ultimate-Guitarcoolth2No ratings yet

- Ref Pipe Sizing Ver 02 21 11Document12 pagesRef Pipe Sizing Ver 02 21 11coolth2No ratings yet

- VR FDocument1 pageVR Fcoolth2No ratings yet

- Product Data 23XRV en PDFDocument32 pagesProduct Data 23XRV en PDFMarianela MasyRubiNo ratings yet

- 40LM 120-200 Model CarrierDocument12 pages40LM 120-200 Model CarrierEngr.Mmosaad100% (1)

- OAPU SizingDocument2 pagesOAPU Sizingcoolth2No ratings yet

- Ordinary Song TabDocument2 pagesOrdinary Song Tabcoolth2No ratings yet

- The World Leader in Air Conditioning - 40LM Chilled Water Ceiling Ducted Fan Coil UnitsDocument2 pagesThe World Leader in Air Conditioning - 40LM Chilled Water Ceiling Ducted Fan Coil UnitsprokjongNo ratings yet

- Vav SystemsDocument4 pagesVav Systemscoolth2No ratings yet

- Vav SystemsDocument4 pagesVav Systemscoolth2No ratings yet

- Damage To Stern Tube Bearing and SealsDocument4 pagesDamage To Stern Tube Bearing and SealsJoão Henrique Volpini MattosNo ratings yet

- Slurry Flo BrochureDocument4 pagesSlurry Flo BrochureChristian Andres Campa HernandezNo ratings yet

- Value-Instruments Cat2012 enDocument58 pagesValue-Instruments Cat2012 enAnonymous C6Vaod9No ratings yet

- Method of MomentsDocument114 pagesMethod of MomentsankladhaNo ratings yet

- Sean Dickerson ResumeDocument3 pagesSean Dickerson ResumeSeanNo ratings yet

- Turkle Sherry What Does Simulation Want PDFDocument11 pagesTurkle Sherry What Does Simulation Want PDFmonterojuNo ratings yet

- Alpema Standerd For Brazed Aluminium Plate-Fin Heat ExchDocument78 pagesAlpema Standerd For Brazed Aluminium Plate-Fin Heat ExchBilal NazirNo ratings yet

- Tda 1526Document15 pagesTda 1526Adilcio Melo0% (1)

- Engine Service Tool ReferenceDocument4 pagesEngine Service Tool ReferenceandrzejNo ratings yet

- MCQ in Services MarketingDocument83 pagesMCQ in Services Marketingbatuerem0% (1)

- DIMENSIONAL TOLERANCES FOR COLD CLOSE RADIUS PIPE BENDINGDocument11 pagesDIMENSIONAL TOLERANCES FOR COLD CLOSE RADIUS PIPE BENDINGpuwarin najaNo ratings yet

- Vantio CacheServe 7.2.0 Administrators Manual 20161208 PDFDocument577 pagesVantio CacheServe 7.2.0 Administrators Manual 20161208 PDFPaulette Servin100% (1)

- Write Like An Academic: Designing An Online Advanced Writing Course For Postgraduate Students and ResearchersDocument9 pagesWrite Like An Academic: Designing An Online Advanced Writing Course For Postgraduate Students and ResearchersLexi TronicsNo ratings yet

- Analytic DeviceDocument4 pagesAnalytic DeviceuiuiuiuNo ratings yet

- AOE - FormDocument8 pagesAOE - FormBimal GuptaNo ratings yet

- Item No. Specification Requested Offered Specifications 1.1. 1.1 Law and CertificatesDocument23 pagesItem No. Specification Requested Offered Specifications 1.1. 1.1 Law and CertificatesSaša StankovićNo ratings yet

- Suparco+ KRL Test Ques For Electrical EngrzDocument5 pagesSuparco+ KRL Test Ques For Electrical Engrzمحمد فصیح آفتابNo ratings yet

- Adhokshaj Mishra: Thwarting The Surveillance in Online CommunicationDocument24 pagesAdhokshaj Mishra: Thwarting The Surveillance in Online CommunicationGauravRajNo ratings yet

- Application for Assistant Engineer PostDocument3 pagesApplication for Assistant Engineer PostKandasamy Pandian SNo ratings yet

- Prepositions-Of-place Worksheet Azucena SalasDocument3 pagesPrepositions-Of-place Worksheet Azucena SalasAndreia SimõesNo ratings yet

- Volvo 850 GLT Owners Manual 1993Document176 pagesVolvo 850 GLT Owners Manual 1993jpaulorosado2186No ratings yet

- Indus Water Treaty & Emerging Water IssuesDocument24 pagesIndus Water Treaty & Emerging Water Issuesu1umarNo ratings yet

- Aksin Et Al. - The Modern Call Center - A Multi Disciplinary Perspective On Operations Management ResearchDocument24 pagesAksin Et Al. - The Modern Call Center - A Multi Disciplinary Perspective On Operations Management ResearchSam ParkNo ratings yet

- I) CentrifugesDocument46 pagesI) Centrifugesiahim87No ratings yet

- Christianity and Online Spirituality Cybertheology As A Contribution To Theology in IndonesiaDocument18 pagesChristianity and Online Spirituality Cybertheology As A Contribution To Theology in IndonesiaRein SiraitNo ratings yet

- Assessment of Groundwater Quality Using GIS - A Case Study of The Churu District of RajasthanDocument9 pagesAssessment of Groundwater Quality Using GIS - A Case Study of The Churu District of RajasthanSivaShankarNo ratings yet

- Module 8 SAHITA ConcreteDocument11 pagesModule 8 SAHITA ConcreteHarrybfnNo ratings yet

- OceanPixel Abundo Marine Renewable Energy An Emerging OptionDocument96 pagesOceanPixel Abundo Marine Renewable Energy An Emerging OptionjopaypagasNo ratings yet

- A134 PDFDocument4 pagesA134 PDFJarbas MoraesNo ratings yet

- Assign 1Document5 pagesAssign 1Aubrey Camille Cabrera100% (1)