Professional Documents

Culture Documents

2E-1103 Final Report Train-2 MI April-2013

Uploaded by

jasmineammaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2E-1103 Final Report Train-2 MI April-2013

Uploaded by

jasmineammaCopyright:

Available Formats

Oman LNG Train-2 MI April-2013

2E-1103Final Report

__________________________________________________________________________________

FINAL REPORT FOR 2E-1103

Scope of Inspection

Remove channel box cover

Replace bolts and nuts for channel box vent and drain flanges

Carry out 100% tube hydro jetting and clean clogged tubes.

Inspect tubes and components

Anticipate Baroscopic of tubes internal

Box up and service test shell side

Inspection Findings & Recommendations

Channel Box Cover( inlet)

Observed to be in good condition with no sign of pitting or any other

corrosion

Gasket face and flange face found in sound condition.

Inlet Channel Box

In as found condition, channel box surface found clean without any pitting or

corrosion.

The vent and drain bolts found corroded and were replaced with new ones

and found satisfactory.

Gasket face and flange face found in sound condition.

Channel Box Cover( out let)

Observed to be in good condition with no sign of pitting or any other

corrosion

Gasket face and flange face found in sound condition

Out let channel box

__________________________________________________________________________________

Page 1 of 4

Prepared by: Andiappan.s

Oman LNG Train-2 MI April-2013

2E-1103Final Report

__________________________________________________________________________________

In as found condition, channel box surface found clean without any pitting or

corrosion.

Approximately about 5 -8 kgs of shell shell deposits were observed in the

channel box, and re After removal of sea shells underneath found

satisfactory with out any corrosion.

The vent and drain bolts found corroded and were replaced with new ones

and found satisfactory

Gasket face and flange face found in sound condition.

Tube Sheet

Both the side tube sheets found to be in sound condition without any

mechanical damage or any corrosion. minor black material deposits were

observed on the tube sheets were cleaned and found satisfactory.

5 Nos of internal tubes were found to be clogged were cleaned by hydro

jetting and found satisfactory..

100% Hydrojet cleaning was carried out to clean all the internal of tubes and

the cleaning found satisfactory..

External inspection

No sign of external damage or paint failure was noticed.

Box Up

The new Gasket were found good and accepted after verification with the

material list. Fasteners were serviced and Nickel Anti-Seize compound is

applied on bolts for proper torqueing and seal tightening. Box up certificate

was issued after ensuring the requisite cleanliness is achieved on Flange and

Gasket face.

Recommendations next SD

100 % tubes needs to be hydro jet cleaned during next outage.

__________________________________________________________________________________

Page 2 of 4

Prepared by: Andiappan.s

Oman LNG Train-2 MI April-2013

2E-1103Final Report

__________________________________________________________________________________

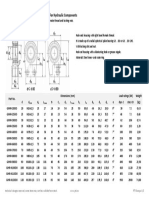

Tubes on inlet side partially clogged

Close up view of clogged tubes

Corroded vent bolts

Sea shell deposits at outlet channel box

__________________________________________________________________________________

Page 3 of 4

Prepared by: Andiappan.s

Oman LNG Train-2 MI April-2013

2E-1103Final Report

__________________________________________________________________________________

__________________________________________________________________________________

Page 4 of 4

Prepared by: Andiappan.s

You might also like

- Short Shut Down ReportDocument4 pagesShort Shut Down ReportMuhammad Ahmed AltafNo ratings yet

- TUV India HEAT EXCHANGER InspectionDocument43 pagesTUV India HEAT EXCHANGER InspectionParthiban NCNo ratings yet

- APE Vibro Checklist for ShipmentDocument1 pageAPE Vibro Checklist for ShipmentDiego Ignacio Arancibia CarrascoNo ratings yet

- 120V40 Demin Storage TankDocument2 pages120V40 Demin Storage TankPutumbaka BharatNo ratings yet

- ISOLATED PHASE BUS DUCT INSPECTION REPORT - OAHE DAMDocument34 pagesISOLATED PHASE BUS DUCT INSPECTION REPORT - OAHE DAMmersiumNo ratings yet

- Prevent MaintenanceDocument15 pagesPrevent Maintenancemecanico_ipnNo ratings yet

- Underground Pipe CertDocument2 pagesUnderground Pipe CertnomarblesNo ratings yet

- Maintenance Schedule For BOP - 5131086 - 01Document4 pagesMaintenance Schedule For BOP - 5131086 - 01franko guddiNo ratings yet

- #5 Scope of WorkDocument32 pages#5 Scope of Workrohit_me083No ratings yet

- Heat Exchanger InspectionDocument7 pagesHeat Exchanger InspectionHamid Albashir100% (1)

- Preparing A Prover For A Water Draw CalibationsDocument3 pagesPreparing A Prover For A Water Draw CalibationsLeonel NavaNo ratings yet

- Heat Exchanger Inspection PDFDocument8 pagesHeat Exchanger Inspection PDFreezmanNo ratings yet

- Maintaining and Repairing Heat Exchanger TubesDocument14 pagesMaintaining and Repairing Heat Exchanger TubesMicheal Brooks100% (1)

- List Defects With Ballast Tanks:: Yes NoDocument4 pagesList Defects With Ballast Tanks:: Yes Nosailor21316No ratings yet

- TDI43 Tank Inspection Examination & Testing API 653 Sec 12Document7 pagesTDI43 Tank Inspection Examination & Testing API 653 Sec 12Faizal SattuNo ratings yet

- Rei Vol IiDocument142 pagesRei Vol IiDineshNo ratings yet

- Bam 800 M800 RepairDocument3 pagesBam 800 M800 Repairapi-3752216No ratings yet

- DWR March 2021Document22 pagesDWR March 2021Mario MilicevicNo ratings yet

- Operation & Maintenance Manual For Bolted Steel Tanks: Complete InstallationDocument6 pagesOperation & Maintenance Manual For Bolted Steel Tanks: Complete InstallationIrvansyah RazadinNo ratings yet

- Technical Evaluation S.No - File Status: To: PTM & Mi From: Inspection Engineers SubDocument6 pagesTechnical Evaluation S.No - File Status: To: PTM & Mi From: Inspection Engineers SubMuhAli_No ratings yet

- Answers (1) (2) (1) (1) (1) (1) 1Document3 pagesAnswers (1) (2) (1) (1) (1) (1) 1tirunehdefaru1No ratings yet

- Man HoursDocument34 pagesMan HoursMocha Oreoo100% (1)

- Skybird Sigma 33 SurveyDocument16 pagesSkybird Sigma 33 SurveyMarkNo ratings yet

- Re-Welding, Expansion & HT ProcedureDocument6 pagesRe-Welding, Expansion & HT Proceduresuria qaqcNo ratings yet

- SOP R-301 Carbon Steel Refrigerant Piping - Rev.1Document3 pagesSOP R-301 Carbon Steel Refrigerant Piping - Rev.1iplaruffNo ratings yet

- Advanced Oilfield Technology Company Work Procedure for Control ValvesDocument6 pagesAdvanced Oilfield Technology Company Work Procedure for Control ValvesJustin Joy0% (1)

- Insp Checklist BALLONSDocument10 pagesInsp Checklist BALLONSAnonymous yCpjZF1rFNo ratings yet

- Marine Survey PracticeDocument10 pagesMarine Survey PracticeKurupath Sidharthan100% (1)

- CPP UNIT AIR PREHEATER GUIDE BEARING FAILUREDocument5 pagesCPP UNIT AIR PREHEATER GUIDE BEARING FAILUREParmeshwar Nath Tripathi0% (1)

- Repair STD March 2008 Ballot ApprovedDocument31 pagesRepair STD March 2008 Ballot ApprovedAhmed Ben NoumaNo ratings yet

- Jones Hydrant OM 8-21-09Document6 pagesJones Hydrant OM 8-21-09RktBatamNo ratings yet

- Boiler Survey & ConstDocument18 pagesBoiler Survey & ConstAmit ChouguleNo ratings yet

- Boiler setup and installation guideDocument5 pagesBoiler setup and installation guideGuillermo LumbrerasNo ratings yet

- Above Ground Storage Tank Inspection GuidelinesDocument7 pagesAbove Ground Storage Tank Inspection GuidelinesTina Miller100% (1)

- Feild Inspection of Shell and Tube Heat ExchangersDocument4 pagesFeild Inspection of Shell and Tube Heat ExchangersMatthew BennettNo ratings yet

- The API 653 InspectionDocument4 pagesThe API 653 InspectionYousuf Memon100% (1)

- In-Service Storage Tank Inspection and Verification ChecklistDocument9 pagesIn-Service Storage Tank Inspection and Verification ChecklistAshif Khan100% (1)

- Project Standard Specification: Jacuzzi 15491 - Page 1/5Document5 pagesProject Standard Specification: Jacuzzi 15491 - Page 1/5adel rihanaNo ratings yet

- Failure Analysis of Ball Valves WorcesterDocument12 pagesFailure Analysis of Ball Valves Worcestercvishwas1159No ratings yet

- Failure Analysis of Ball ValvesDocument12 pagesFailure Analysis of Ball ValvesGhiyat FarisNo ratings yet

- #5 Guide To Ship's Piping (Black & White)Document25 pages#5 Guide To Ship's Piping (Black & White)Dony Eko Cahyadi100% (2)

- Boiler Installation and SetupDocument30 pagesBoiler Installation and Setupcakhokhe100% (1)

- Sandia National Laboratories API-653 In-Service Tank Inspection and Evaluation TANK ID: 981-A2-T0 (West)Document80 pagesSandia National Laboratories API-653 In-Service Tank Inspection and Evaluation TANK ID: 981-A2-T0 (West)Manokaran RamalingamNo ratings yet

- Aljac Catg On Closed SamplerDocument2 pagesAljac Catg On Closed SamplervuongNo ratings yet

- Hydrostatic and Settlement Tests ProcedureDocument12 pagesHydrostatic and Settlement Tests Procedureツ ツ100% (1)

- Copper Pipes InstallationDocument6 pagesCopper Pipes InstallationrkssNo ratings yet

- Exp Fire Hydrants 929Document3 pagesExp Fire Hydrants 929Cesar CoronelNo ratings yet

- Windlass Bearing 1Document5 pagesWindlass Bearing 1Gaurav MaithilNo ratings yet

- Above Ground Storage Tanks PresentationDocument28 pagesAbove Ground Storage Tanks PresentationRamesh sivanNo ratings yet

- ASME CODE Requirements - Heat ExchangerDocument9 pagesASME CODE Requirements - Heat ExchangerJithin FrancizNo ratings yet

- Docking Survey Checklist: Name of The Ship: IR. Number: Port of Registry: Report No.Document3 pagesDocking Survey Checklist: Name of The Ship: IR. Number: Port of Registry: Report No.capone55No ratings yet

- Series 808Y Installation InstructionsDocument4 pagesSeries 808Y Installation InstructionsFEBCONo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- A Guide to Ship Repair Estimates in Man-hoursFrom EverandA Guide to Ship Repair Estimates in Man-hoursRating: 4.5 out of 5 stars4.5/5 (5)

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Surface Preparation StandardsDocument4 pagesSurface Preparation StandardsjasmineammaNo ratings yet

- BGas Painting Multiple Choice 2Document7 pagesBGas Painting Multiple Choice 2jasmineammaNo ratings yet

- Blasting & Coating Procedure For Fabricated Steel StructureDocument8 pagesBlasting & Coating Procedure For Fabricated Steel Structurejasmineamma100% (1)

- API 653 Study GuideDocument19 pagesAPI 653 Study GuideSubramaniam Ramasamy86% (7)

- External Pipe CoatingsDocument15 pagesExternal Pipe Coatingsupesddn2010100% (3)

- Estimating Your API Test Score Eliminate 8 Weeks of Fretting While You Wait For Your API Exam Score! MSTSDocument3 pagesEstimating Your API Test Score Eliminate 8 Weeks of Fretting While You Wait For Your API Exam Score! MSTSqazi12No ratings yet

- Third Party Inspection Guidelines-Section 9.0Document30 pagesThird Party Inspection Guidelines-Section 9.0kostas.micha100% (1)

- BGas Painting Multiple Choice 2Document17 pagesBGas Painting Multiple Choice 2Abdul Gafoor86% (14)

- Corrosion Revision QuestionsDocument2 pagesCorrosion Revision QuestionsjasmineammaNo ratings yet

- Coating FormulaDocument4 pagesCoating Formulajasmineamma100% (1)

- Tank - Design and AnalysisDocument4 pagesTank - Design and Analysissammar_10No ratings yet

- API Test Taking TipsDocument6 pagesAPI Test Taking TipsSripathyNo ratings yet

- TLVD002 GF Material Expeditor Visit MOMDocument10 pagesTLVD002 GF Material Expeditor Visit MOMjasmineammaNo ratings yet

- Inspector Calc Part 1Document10 pagesInspector Calc Part 1Abbas RizviNo ratings yet

- 13 01 15 Expediting Report GoodrichGasketsDocument2 pages13 01 15 Expediting Report GoodrichGasketsjasmineamma100% (1)

- EXPEDITING REPORT STATUS AND ACTIONSDocument2 pagesEXPEDITING REPORT STATUS AND ACTIONSjasmineamma100% (1)

- 13 01 15 Expediting Report GoodrichGasketsDocument2 pages13 01 15 Expediting Report GoodrichGasketsjasmineamma100% (1)

- Iob 06-Feb-2017 10-17-19 PDFDocument1 pageIob 06-Feb-2017 10-17-19 PDFjasmineammaNo ratings yet

- Ipg Exp Report 2-20 May17Document1 pageIpg Exp Report 2-20 May17jasmineammaNo ratings yet

- Ready List 1 20-May-2017 15-31-06Document3 pagesReady List 1 20-May-2017 15-31-06jasmineammaNo ratings yet

- Choose Your CityDocument9 pagesChoose Your CityjasmineammaNo ratings yet

- RTJ Mail 20-May-2017 15-13-48Document1 pageRTJ Mail 20-May-2017 15-13-48jasmineammaNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Level 2 Workbook-Print EditionDocument38 pagesLevel 2 Workbook-Print EditionjasmineammaNo ratings yet

- Expediting Report MIL-18AugDocument3 pagesExpediting Report MIL-18AugjasmineammaNo ratings yet

- Book of Wisdom - Workbook and JournalDocument20 pagesBook of Wisdom - Workbook and JournalBlack ChiNo ratings yet

- MIL CONTROL EXPEDITING REPORT FOR RAPP 7 & 8 PROJECTDocument2 pagesMIL CONTROL EXPEDITING REPORT FOR RAPP 7 & 8 PROJECTjasmineamma100% (1)

- Expense SheetDocument1 pageExpense SheetjasmineammaNo ratings yet

- V CgartDocument1 pageV CgartjasmineammaNo ratings yet

- SECTION 2 - Commmunicating Checklist PDFDocument3 pagesSECTION 2 - Commmunicating Checklist PDFjasmineamma100% (1)

- Case Study On Structure Collapse: Jacklin Mary - J 121901040Document12 pagesCase Study On Structure Collapse: Jacklin Mary - J 121901040Crazy MechonsNo ratings yet

- PVCPressPipeSteelA 24Document1 pagePVCPressPipeSteelA 24Mustafa AlluhaibiNo ratings yet

- Cold-Formed Steel Shear Wall DesignDocument8 pagesCold-Formed Steel Shear Wall DesignjmiguelmenaNo ratings yet

- Fencing, Compound Wall and Gate: by Ar. Pranoti LadDocument49 pagesFencing, Compound Wall and Gate: by Ar. Pranoti Ladbishal dasNo ratings yet

- Tripura Building Amendnent Rules 2019Document13 pagesTripura Building Amendnent Rules 2019RupakDasNo ratings yet

- SB Brace Frame For Single Sided Walls Instructions For Assembly and UseDocument84 pagesSB Brace Frame For Single Sided Walls Instructions For Assembly and UseYaser IsmailNo ratings yet

- Tests For Workability of Concrete at Construction Site and Its ValuesDocument3 pagesTests For Workability of Concrete at Construction Site and Its ValuesAvinash LalNo ratings yet

- CFY 2011-2012 List of ContractorsDocument235 pagesCFY 2011-2012 List of ContractorsVivian Sy83% (12)

- Hyundai Dash 9 Posi - Nega SytemDocument70 pagesHyundai Dash 9 Posi - Nega SytemRobert Zehender99% (76)

- BLDG TECH Juson Assignment Lecture 2Document11 pagesBLDG TECH Juson Assignment Lecture 2Ma. Janelle GoNo ratings yet

- Hvac Ducting FundamentalDocument56 pagesHvac Ducting Fundamentalzafarbadal100% (2)

- Is 13935Document26 pagesIs 13935Ashaprava MohantaNo ratings yet

- Stress and Strain - Axial Loading2Document33 pagesStress and Strain - Axial Loading2Clackfuik12No ratings yet

- BuchananandGardner2019 Metal3Dprintinginconstruction AreviewDocument37 pagesBuchananandGardner2019 Metal3Dprintinginconstruction AreviewJoão PraganaNo ratings yet

- CKE6150 Spare Parts ManualDocument74 pagesCKE6150 Spare Parts ManualVanessa RiveraNo ratings yet

- Structural Calculation Design Criteria SummaryDocument2 pagesStructural Calculation Design Criteria Summarykate denoyaNo ratings yet

- Sprinkler Head Spacing and Location GuideDocument7 pagesSprinkler Head Spacing and Location GuideWarry SolivenNo ratings yet

- Isocope KROVDocument4 pagesIsocope KROVEjub ČelikovićNo ratings yet

- Innvo8 Squash Court Panel System: Specification InformationDocument5 pagesInnvo8 Squash Court Panel System: Specification InformationDaniil TriznoNo ratings yet

- TEST YOUR KNOWLEDGE - WELDED JOINTS QUIZDocument2 pagesTEST YOUR KNOWLEDGE - WELDED JOINTS QUIZkalpanaadhi100% (1)

- Fabrication EnquiryDocument180 pagesFabrication Enquiryvinod23456100% (1)

- DXB SHJ Freezone ListDocument444 pagesDXB SHJ Freezone ListFaiza KhalidNo ratings yet

- TOYOTA Yaris 1.33 VVT-i 1NR-FE: Timing Chain: Removal/installationDocument17 pagesTOYOTA Yaris 1.33 VVT-i 1NR-FE: Timing Chain: Removal/installationMapaqui Mapaqui100% (1)

- 56r 08Document21 pages56r 08manojsingh4allNo ratings yet

- Catalogo BuildexDocument2 pagesCatalogo BuildexRaciel Ivan CanoNo ratings yet

- GIHR-K..DO - Rod Ends For Hydraulic ComponentsDocument1 pageGIHR-K..DO - Rod Ends For Hydraulic ComponentsQuintrae DelfinNo ratings yet

- National Building Code ReviewerDocument16 pagesNational Building Code ReviewerZoeNo ratings yet

- Impact Sound Reduction and Decoupling System for FloorsDocument4 pagesImpact Sound Reduction and Decoupling System for FloorsParashuram ChauhanNo ratings yet

- Bill Mosley John Bungey & Ray Hulse: Reinforced Concrete Design To EC2Document17 pagesBill Mosley John Bungey & Ray Hulse: Reinforced Concrete Design To EC2xavierlthNo ratings yet

- DFH00191 - RAUTHERM SPEED HKV P - TI - EN - LayoutDocument4 pagesDFH00191 - RAUTHERM SPEED HKV P - TI - EN - LayoutRENSO BirouClujNo ratings yet