Professional Documents

Culture Documents

Performance Sheet Drill Pipe: Pipe Body: Tubular Assembly

Uploaded by

Garcia C L AlbertoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Performance Sheet Drill Pipe: Pipe Body: Tubular Assembly

Uploaded by

Garcia C L AlbertoCopyright:

Available Formats

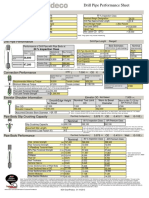

Drill Pipe Performance Sheet

Asset Number: 19212

Pipe Body:

Size and Weight: 4.000'' 14.00 ppf 0.330'' wall IU

Grade: CYX-105

Range: 2

Tool Joint: 4.875'' x 2.688'' XT39

Tubular Assembly:

Nominal

100% RBW

95% RBW

Ultra Class

90% RBW

Premium

80% RBW

4.000

0.330

3.340

3.967

0.314

3.340

3.934

0.297

3.340

3.868

0.264

3.340

Tensile Strength (lbs):

Torsional Strength (ft-lbs):

399,502

32,603

377,820

30,789

356,319

28,996

313,854

25,474

Burst Capacity (psi):

Collapse Capacity (psi):

15,159

15,896

16,459

15,199

15,593

14,026

13,860

11,622

OD (in):

Wall Thickness (in):

Nominal ID (in):

Adjusted Weight (lbs/ft): 16.34

Approximate Length (ft): 31.9

Box TJ Length (in): 15

Pin TJ Length (in): 12

Upset Type: IU

Max Upset OD (in): 4.188

Drift Size (in): 2.563

Fluid Displacement (gal/ft): 0.25

Fluid Displacement (bblsl/ft): 0.0059

Fluid Capacity w/IPC (gal/ft): 0.43

Fluid Capacity w/IPC (bbls/ft): 0.0102

Fluid Capacity w/o IPC (gal/ft): 0.43

Fluid Capacity w/o IPC (bbls/ft): 0.0103

18

0

Notes: Body properties are calculated based on uniform OD and wall thickness.

Burst capacity for Nominal (100% RBW) based on 87.5% RBW per API.

Note: These are OEM values that may vary with actual values due to mill tolerances, IPC tolerances, OEM rounding, and other

factors. Pipe is purchased at a guaranteed 95% RBW. IPC is applied to a nominal thickness of 0.009''. Pipe will have an ID of

3.285'', which is smaller than pipe purchased at 87.5%.

Connection: XT39

Elevator Shoulder:

TJ OD (in): 4.875

TJ ID (in): 2.688

MYS (ksi): 120

Maximum MUT (ft-lbs):

Tension at Shoulder Separation @ Max MUT (lbs):

Tension at Connection Yield @ Max MUT (lbs):

21,200

Tensile Limited

553,300

Minimum MUT (ft-lbs):

Tension at Shoulder Separation @ Min MUT (lbs):

Tension at Connection Yield @ Min MUT (lbs):

17,700

647,200

662,200

Smooth Edge Height (in): N/A

Smooth Edge OD (in): N/A

SE Elevator Shoulder Capacity (lbs): N/A

Nominal TJ OD (in): 4.875

Nominal TJ OD Elevator Shoulder Capacity (lbs): 470,100

Assumed Elevator Bore (in): 4.281

N/A

N/A

Tool Joint Torsional Strength (ft-lbs): 35,300

Tool Joint Tensile Strength (lbs): 662,200

XT39 is a trademark of NOV Grant-Prideco.

Note: MUT values are based on a friction factor of 1.0. There is no published pressure rating for this connection.

Note: Elevator capacity based on assumed elevator bore, no wear factor, and contact stress of 110, 100 psi. An increased

elevator shoulder OD increases elevator capacity without affecting make-up torque.

The technical information containted herein, including the product performance sheet and other attached documents, has been extracted from information available from the manufacturer and is for reference only and not a recommendation. The user is fully responsible for the accuracy and suitability of use of the technical

information. Workstrings International cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various

inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable operation limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices,

and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.workstringsinternational.com

Download the Workstrings International Pipe Specification App on the App Store or Google Play

08-Sep-15

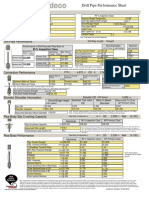

Operational Limits of Drill Pipe

Connection

Pipe Body

XT39

80 % Inspection Class

Tool Joint OD

(in)

4.875

Tool Joint ID

Pipe Body OD

(in)

Wall Thickness (in) 0.330

(in)

2.688

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

Pipe Body Grade

CYX105-120

(ft-lbs)

(lbs)

(ft-lbs)

0

1,000

2,000

3,100

4,100

5,100

6,100

7,200

8,200

9,200

10,200

11,200

12,300

13,300

14,300

15,300

16,400

17,400

18,400

19,400

313,900

313,600

312,900

311,500

309,800

307,500

304,700

301,100

297,100

292,700

287,600

281,900

274,800

267,700

259,700

250,900

240,200

229,200

217,100

203,100

(lbs)

(ft-lbs)

(ft-lbs)

(lbs)

(lbs)

(lbs)

(lbs)

313,900

553,300

313,900

313,900

647,200

313,600

553,300

800

313,700

313,700

647,200

312,900

553,300

1,600

313,200

313,200

647,200

311,500

553,300

2,400

312,500

312,500

647,200

309,800

553,300

3,300

311,200

311,200

647,200

309,800

309,800

647,200

308,000

308,000

647,200

305,900

305,900

647,200

303,500

303,500

647,200

300,700

300,700

647,200

647,200

307,500

304,700

301,100

297,100

292,700

287,600

281,900

274,800

267,700

259,700

250,900

240,200

229,200

217,100

203,100

4,100

553,300

4,900

553,300

5,700

553,300

6,500

553,300

7,300

553,300

553,300

8,200

297,100

297,100

553,300

9,000

293,600

293,600

647,200

553,300

9,800

289,700

289,700

647,200

553,300

10,600

285,400

285,400

647,200

553,300

11,400

280,700

280,700

647,200

553,300

12,200

275,500

275,500

647,200

553,300

13,100

269,200

269,200

647,200

553,300

13,900

263,000

263,000

647,200

553,300

14,700

256,300

256,300

647,200

553,300

15,500

248,900

248,900

647,200

Connection

Make-up Torque Range

(ft-lbs)

17,700

18,100

18,500

18,900

19,300

19,600

20,000

20,400

20,800

21,200

(lbs)

647,200

661,800

648,500

634,400

620,300

609,700

595,600

581,500

567,400

553,300

Note: Recommended MUT should always be used when possible. If not possible, MUT should be as close to Recommended MUT as possible.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

06-17-2015

You might also like

- 5 7/8" 23.4 PPF S135 Pipe SpecsDocument2 pages5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- 5 7/8" VM-165 R2 Pipe SpecsDocument2 pages5 7/8" VM-165 R2 Pipe SpecsTiffany DacinoNo ratings yet

- 4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BDocument3 pages4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BjohangomezruizNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohann ZabaletaNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular Assemblymsm.ele2009No ratings yet

- 5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BDocument3 pages5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BJeaneth HerreraNo ratings yet

- Xt39 Spec SheetDocument3 pagesXt39 Spec SheetjdcomptonNo ratings yet

- Landing String 6.625 .938 v150 FH Slip Proof 95rbw PDFDocument4 pagesLanding String 6.625 .938 v150 FH Slip Proof 95rbw PDFMarcelo VeronezNo ratings yet

- LandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)Document3 pagesLandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- Trispiral XT39Document1 pageTrispiral XT39Cerón Niño SantiagoNo ratings yet

- Drill Pipe Configuration: 95 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 95 % Inspection ClassSaurav SenguptaNo ratings yet

- Drill Pipe Performance Sheet 5.875 XT57 G105Document3 pagesDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.750Document3 pagesDrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.750Инженер Луис А. ГарсиаNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance Sheetjinyuan74No ratings yet

- HeavyWeight 3.5 25.58lbs NC-38Document3 pagesHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаNo ratings yet

- DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFDocument3 pagesDrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFGarcia C L Alberto100% (1)

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- 1000 SB Fast Clamp Sway Brace AttachmentDocument1 page1000 SB Fast Clamp Sway Brace AttachmentANTONIO GUTIERREZ MIRANDANo ratings yet

- 2.500 X 1.375 DC With MW20 SlickDocument1 page2.500 X 1.375 DC With MW20 SlickHadi Bapir SlemanNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- Beam End Connection ReportDocument6 pagesBeam End Connection ReportHibri HalimNo ratings yet

- Pipe Rack Hilti Bolt CalculationsDocument6 pagesPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVNo ratings yet

- T3802-Z-DS-001 - Rev. 3 - Technical DocumentDocument5 pagesT3802-Z-DS-001 - Rev. 3 - Technical DocumentpetricamafteiNo ratings yet

- EUROPLUS New System TYPPR EN 2005-09Document12 pagesEUROPLUS New System TYPPR EN 2005-09Christian BenitezNo ratings yet

- Screen Sand ControlDocument20 pagesScreen Sand ControlsaptagunungNo ratings yet

- Hydromation Filter MHydromation FilterDocument26 pagesHydromation Filter MHydromation FilterArt G. EnziNo ratings yet

- BARTEC Engineers ManualDocument12 pagesBARTEC Engineers ManualMd Nazir HussainNo ratings yet

- Imbinari Tevi Tyco-GrinnelDocument41 pagesImbinari Tevi Tyco-GrinnelSorin StanNo ratings yet

- List of The Equipments (R)Document12 pagesList of The Equipments (R)Rubel RanaNo ratings yet

- 8761 TechdataDocument3 pages8761 TechdataAndie SiahaanNo ratings yet

- SB Sway Brace AttachmentDocument2 pagesSB Sway Brace Attachmentrvalentino2012No ratings yet

- Section 19 - Appendix C - FormsDocument52 pagesSection 19 - Appendix C - Formsfivehours5No ratings yet

- CHT4000 Series Hydraulic Universal Testing Machine: ConfigurationDocument5 pagesCHT4000 Series Hydraulic Universal Testing Machine: ConfigurationMuhammad TausifNo ratings yet

- Final Report, NarayanganjDocument125 pagesFinal Report, NarayanganjNaim ParvejNo ratings yet

- WAW-600F Single Space Servo Universal Testing MachineDocument13 pagesWAW-600F Single Space Servo Universal Testing MachineXavier Kate GalvanNo ratings yet

- Rolatube Defence and Capabilities Brief 03 SeptDocument21 pagesRolatube Defence and Capabilities Brief 03 SeptThinkDefenceNo ratings yet

- QUOTATION For WINORAC 12 12 23Document4 pagesQUOTATION For WINORAC 12 12 23Kasarachi AmadiNo ratings yet

- 8770 TechdataDocument2 pages8770 TechdataAl Wahdani RambeNo ratings yet

- 8777 Techdata PDFDocument3 pages8777 Techdata PDFNestor-leoNo ratings yet

- PROFIS Anchor 2.2.0: WWW - Hilti.deDocument6 pagesPROFIS Anchor 2.2.0: WWW - Hilti.deCollin NguNo ratings yet

- 104 - . Accessories For Buoyancy Transmitter: Product SpecificationsDocument22 pages104 - . Accessories For Buoyancy Transmitter: Product SpecificationsTreeNo ratings yet

- HUT-A Hydraulic Universal Testing Machine 2018.6.26 PDFDocument6 pagesHUT-A Hydraulic Universal Testing Machine 2018.6.26 PDFSoup PongsakornNo ratings yet

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFDocument3 pagesDrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFGarcia C L Alberto100% (1)

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, X-95.. XT57 (7.000 X 4.250)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, X-95.. XT57 (7.000 X 4.250)Garcia C L AlbertoNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFDocument3 pagesDrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFGarcia C L Alberto100% (1)

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- DPPS PDFDocument2 pagesDPPS PDFStowartNo ratings yet

- Course Outline Grade 8 ScienceDocument7 pagesCourse Outline Grade 8 SciencePrincess Mae LumawagNo ratings yet

- Review of Byrne's Signal Processing - A Mathematical Approach (1st Ed) - Goras (???)Document1 pageReview of Byrne's Signal Processing - A Mathematical Approach (1st Ed) - Goras (???)Linden JavaScriptNo ratings yet

- 2013 Catalog KabeldonCA 1-420 KV SOT 7,2-36 KV Pages3-4!3!10 EnglishDocument7 pages2013 Catalog KabeldonCA 1-420 KV SOT 7,2-36 KV Pages3-4!3!10 Englishiyilmaz1No ratings yet

- ASCE 7 Wind Load CalculationDocument22 pagesASCE 7 Wind Load Calculationani145yadavNo ratings yet

- Rotation RollingDocument14 pagesRotation RollingMinh HuỳnhNo ratings yet

- Review 2 ElectricalWiringDocument11 pagesReview 2 ElectricalWiringPriyaranjan DasNo ratings yet

- A. Atoms: Engineering MaterialsDocument36 pagesA. Atoms: Engineering MaterialsAmpolNo ratings yet

- New Iguzzini Products 2009-2010Document252 pagesNew Iguzzini Products 2009-2010iGuzzini illuminazione SpANo ratings yet

- Jastram Rudder Angle Indicators 300 RAIDocument2 pagesJastram Rudder Angle Indicators 300 RAIbenson8pyNo ratings yet

- C03-001-Structural Steel CalculationsDocument166 pagesC03-001-Structural Steel CalculationsNguyễnBìnhPhươngNo ratings yet

- LAS No. 2Document8 pagesLAS No. 2Eddie Lumaras Jr.No ratings yet

- 5 Measurement of Water-Holding Capacity and Juiciness: K.O. Honikel and R. HammDocument37 pages5 Measurement of Water-Holding Capacity and Juiciness: K.O. Honikel and R. HammFrancisco QuiñonesNo ratings yet

- Hd4 / Uniair (Withdrawable, Removable, Fixed Versions) Hd4 / R, Hd4 / S, Hd4 / Unimix (Fixed Version)Document10 pagesHd4 / Uniair (Withdrawable, Removable, Fixed Versions) Hd4 / R, Hd4 / S, Hd4 / Unimix (Fixed Version)Raffaele RattiNo ratings yet

- Steam Condensate Pot SizingDocument1 pageSteam Condensate Pot SizingSaeid Rahimi Mofrad100% (1)

- Assessment 3 API 570Document12 pagesAssessment 3 API 570Mohamed ZainNo ratings yet

- Wind LoadDocument34 pagesWind LoadArah Louise ApostolNo ratings yet

- S6 Bat 8.2kWhDocument2 pagesS6 Bat 8.2kWhZhang EthanNo ratings yet

- Difference Between MCB, MCCB, RCCB, ELCBDocument3 pagesDifference Between MCB, MCCB, RCCB, ELCBJaved HasanNo ratings yet

- Low-Cost Non-Destructive Inspection by Simplified Digital Speckle InterferometryDocument8 pagesLow-Cost Non-Destructive Inspection by Simplified Digital Speckle InterferometryLuis Pujay MateoNo ratings yet

- PHY4003 Modern Optics (Class 21) : Joon I. Jang Department of Physics, Sogang University Spring Semester 2022Document22 pagesPHY4003 Modern Optics (Class 21) : Joon I. Jang Department of Physics, Sogang University Spring Semester 2022김지수No ratings yet

- Objective Questions Bank On Engineering Drawing For EseDocument53 pagesObjective Questions Bank On Engineering Drawing For EseHisham Feroz100% (1)

- Radiation Protection in Digital Radiology: Optimisation of Digital Fluoroscopy L04Document60 pagesRadiation Protection in Digital Radiology: Optimisation of Digital Fluoroscopy L04Valantina ShapelNo ratings yet

- International Studies Final Exam-BumuloDocument22 pagesInternational Studies Final Exam-BumuloBielan Fabian GrayNo ratings yet

- Monorail Design CS 0089 (FINAL)Document8 pagesMonorail Design CS 0089 (FINAL)asvenk309No ratings yet

- HYT Series: Fixing Type Terminal BlockDocument12 pagesHYT Series: Fixing Type Terminal BlockcoronaqcNo ratings yet

- Upute Casio Pro Trek Prg340Document33 pagesUpute Casio Pro Trek Prg340tempera999No ratings yet

- CE405 - Experiment 3 - Determination of Specific Gravity and Water Absorption of AggregatesDocument5 pagesCE405 - Experiment 3 - Determination of Specific Gravity and Water Absorption of AggregatesMel CoderesNo ratings yet

- KamachoThunderbus' Spell Stat Cheat SheetDocument44 pagesKamachoThunderbus' Spell Stat Cheat Sheetaxl3foley100% (1)

- JZBFJZBS Series Semi Hermetic Compressor Condensing Units (Bitzer Compressor)Document9 pagesJZBFJZBS Series Semi Hermetic Compressor Condensing Units (Bitzer Compressor)Coolequipment CeeNo ratings yet

- Super WoW 1 - DeMO - Student S BookDocument11 pagesSuper WoW 1 - DeMO - Student S BooksunnyNo ratings yet