Professional Documents

Culture Documents

Shoring Design & Calculation PDF

Uploaded by

Hamdy Taha Khedr100%(2)100% found this document useful (2 votes)

4K views6 pagesOriginal Title

SHORING DESIGN & CALCULATION.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(2)100% found this document useful (2 votes)

4K views6 pagesShoring Design & Calculation PDF

Uploaded by

Hamdy Taha KhedrCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

Darras

FOUNDATIONS L.L.C.

2S >

(pps ge) obwlws

Tel. : 00971 4 3934337

Fax : 00971 4 3934778

P.O. Box: 20605, Dubai - U.A.E.

E- mail: dallas @emirates.net.ae

vavig-rarerey: dale

SAVIE-FATEWA: Qu

PEI aga tetea: “Gye

dallas @emirates.net.ae : 45/9! a0!

CONSULTANTS:

MAIN CONTRACTOR

‘SHORING DESIGN

PROPOSED B+G+6+R RESIDENTIAL BUILDING

FOR

MR. MOHD. NOOR MAHMOOD MOHD. MASHROOM.

PLOT NO. 421-194, AL WARQA FIRST, DUBAI, UA.

MIS. AL AJMI ENGINEERING CONSULTANTS

MIS, DUBAI EURO CONTRACTING CO.

SHORING CONTRACTOR M/S. DALLAS FOUNDATIONS L.L.C.

Revision

D

c

8

A

Zea

JOB No : PL-610

‘GEO FOUNDATION GROUP LL.C.AAQ2013 Date : 7/9204

CA ea HSE pa

DALLAS FOUNDATIONS L.L¢,

PO. box 20605 Dube, LAE

Prepared)

Trial

Checked By

‘Signature | tial Signature | inal

MIS.AL AJMI ENGINEERING CONSULTANTS.

‘Approved BY

Signature

(C:\PLS10_SH_DUBAL_EURO :front-cover

DALLAS rouornonsice (pps do clstass _paahes

CONTENTS :

A. INTRODUCTION

A Scope of Work

A2 Shoring Details

B. COMPUTER ANALYSIS USING ReWaRD 2.5

c. DESIGN OF H-BEAM

C.1 DESIGN OF CONCRETE PLANKS

D. SOIL REPORT

D.1 Extract from soil report

E. REFERENCES

F. REPORT FORMS

F.1— Third Party Insurance

F.2 Trade Licence

(GEO FOUNDATION GROUP L.L.¢.AAG2013 Date : 7/5/2014 ©: \PL-610_SH_OUBAL_EURO : Contents

DALLAS rowosnonsice lppigh obubwes (p2t >

METHOD STATEMENT FOR SHORING WORKS:

1.0 INTRODUCTION:

The Excavation required for the Proposed B+G+6 Residential Building for Mr.

Mohd. Noor Mahmood Mohd. Mashroom Plot no. 421-194 Al Warga First, Dubai

requiring permanent shoring system for protection of basement area @ neighbor

construction side 5.0 m away from the shoring limit. Overall excavation depth will

be -3.80 m.

For the above shoring works, we are proposing permanent Soldier Piles shoring

system using 457x191x74kg /m @ 1.60 m c/e from which our scope of work

covers the only installation of shoring using Beams for an approximate excavation

depth -3.80 m.

1.1. LOCATION AND PROTECTION OF EXISTING SERVICES BY

MAIN CONTRACTOR:

All the underground services falling in line the shoring system will be located by

carrying out trial trenches up to max. 2.0 m below ground level. If any

underground informed for future instruction.

1.2. WORKING PLATEFORM:

Prior to the installation of the B-Beams, the site should be excavated and leveled as

per requirements by the main contractor. The excavation should be sufficient to

allow the shoring equipment access to each and every location.

1.3. SURVEY WORKS:

A qualified survey by would carry out setting out surveying works. The plot line

(building line) will be marked and the shoring line will be established as per Dubai

Municipality approved shop drawings. Facility will be provided to the engineer for

checking the points.

DALLAS sounosronsitc (ppd) slolws (p>

2.0 INSTALLATION OF H-BEAM:

2.1 GENERAL:

The shoring system with section 457 x 191 x 74kg/m @ 1.60me/e (beams

length 8.0m) is proposed for retaining the excavation starting from 0.0m to a

toe level at -8.0 m is required for a safe excavation depth up to -3.80m. Center

-to-center distance between the adjacent H-Beams shall be 1.60 m as per the

submitted design.

2.2. METHOD OF INSTALLTION: (For beam driving insertion)

The H-Beam will be driven by ABI machine with Vibro hammer, beams are

lifted in vertical position using ABI Machine. Beams location is to be set as per

approved design at site. Leveling of beams is to be done prior to beam driving

to ensure the verticality of each driven pile.

2.3. INSTALLATION OF CONCRETE PANELS:

‘The installation of concrete panels between the H-Beams walls to be done by

main contractor following appropriate procedure. After the installation of all

the beams is completed, excavation shall be carried out up to the required level

on several stages, after each stage, for the stability of the H- beams wall, itis

important that the panel will be install in steps directly after the excavation

(high free stands of the soil especially over a longer period must be avoided).

The concrete panels must be fixed tight to the H-beams and pressed against the

undisturbed soil. Any soil movements behind the wall from over excavation or

too high free stands are refilled in compacted layer.

3.0 DESIGN OF SHORING SYSTEM:

The design is based on the available soil report and according to our submitted

calculations.

‘SHEET #07

a DALLAS rounosnonsice (pps) sluluws (pts

/ PROJECT : PROPOSED B+G+6+R RESIDENTIAL BUILDING

LOCATION PLOT NO. 421-194, AL WARQA FIRST, DUBAI, UAE.

CONSULTANTS —_: M/S.AL AJMI ENGINEERING CONSULTANTS

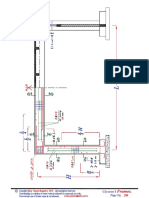

SOLDIER PILE DESIGN FOR PLOT SIDE

SHORING WITH SOLDIER PILES AT 1.6 M C/C FOR A MAX. EXC. DEPTH 3.8 M

L ‘SURCHARGE 20 KN/M2

DESIGN OF SECTION

Excavation Depth . 3,80 m (from EGL 0.0M )

‘Maximum Spacing of H-Beam . 1.60 m cle

‘Maximum Moment per section = 169.9 kN-m/m (ReWARD 2.5)

Ultimate Factor . 14

Ultimate Moment per section = 380.6 kNm

Sx required . 380.6 x 1000

25

= 1,384 om?

Sx Provided a 1,458 om? > 4,384 om?

OK,

DEPTH OF EMBEDMENT

(With reference to Elev 0.0)

Zero BM at Elev. . -6.00 m (ReWARD 2.5)

Embedment . 6.00 - 3.60

. 2.20 m

Factor of safety : 14

Embedment Required . 220 x14

. 3.08 m

Length of section required - 3.08 +3.80

: 6.88 m

|1- Beam 8.0 m ong

GEO FOUNDATION GROUP LL AAQI2013 Date: 7/3/2014 (G1PL.610_SH_DUBA_EURO:Des of Section (S201-1)

SHEET #08,

a DALLAS rowoxronsicc (pp db) olulwaa parts

PROJECT : PROPOSED B+G+6+R RESIDENTIAL BUILDING

LOCATION + PLOT NO. 421-194, AL WARQA FIRST, DUBAI, U,

CONSULTANTS : —MIS.AL AJMI ENGINEERING CONSULTANTS.

DESIGN OF CONCRETE PLANKS @ 1,6 M SPACING CIC

SHORING WITH SOLDIER PILES AT 1.6 M CIC FOR A MAX. EXC. DEPTH 3.8 M

SURCHARGE 20 KN/M2

Maximum Horizontal Pressure

at Excavation Depth 3.8 m = 23.65 kN/m2 (ReWARD 2.5)

Span 1.60

Uniform load on the planks = 14.78 kNim?

Plank Height = 500 mm

Maximum Moment/Span = 44.78 x0.50x2.56

8

= 3.78 kNm

Ultimate Moment = 378 x14

= 5.30 KNm

Using Precast Panels of size 500 mm width x 100 mm thicki

Man 5.30 kN

b 500 mm

h 100 mm

Cover 30 mm

bar dia 12mm

¢ 64 mm

fo . 30 Nimm*

f, 425 Nimm?

M. 0.086

dha,

z 57.4 mm

085d = = =~ 60.8 mm

z 57.4 mm

As req 251 mm?

No of bars 3.00

Spacing Require: 443 mm

Use T 12 atspacing of 130 mm cic - ong direction

Use T8 at spacing of 130 mm cic - short direction

GEO FOUNDATION GROUP LL.C.AA@2013 Date : 7192014 C:APL-510_SH_DUBAL_EURO Plank Design (Sec 1-1)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Soil Report PDFDocument30 pagesSoil Report PDFHamdy Taha KhedrNo ratings yet

- Hinged Frames RFTDocument2 pagesHinged Frames RFTHamdy Taha Khedr100% (1)

- Earthwork Support ShoringDocument3 pagesEarthwork Support Shoringabdella.whateverNo ratings yet

- Rules of Email EtiquetteDocument2 pagesRules of Email EtiquetteAdid Adep DwiatmokoNo ratings yet

- 3 Hinge FrameDocument2 pages3 Hinge FrameHamdy Taha KhedrNo ratings yet

- Dewatering PDFDocument21 pagesDewatering PDFHamdy Taha KhedrNo ratings yet

- Dewatering For ConstructionDocument14 pagesDewatering For ConstructionpabulumzengNo ratings yet

- Fixed Frames PDFDocument2 pagesFixed Frames PDFHamdy Taha KhedrNo ratings yet

- Demarcation Certificate: Temp. Demarcation For Soil TestDocument0 pagesDemarcation Certificate: Temp. Demarcation For Soil TestHamdy Taha KhedrNo ratings yet

- Pmbok 5th Edition PDFDocument42 pagesPmbok 5th Edition PDFAli AbdurrahmanSungkar0906631036No ratings yet