Professional Documents

Culture Documents

Performance Sheet Drill Pipe: Pipe Body: Tubular Assembly

Uploaded by

Garcia C L AlbertoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Performance Sheet Drill Pipe: Pipe Body: Tubular Assembly

Uploaded by

Garcia C L AlbertoCopyright:

Available Formats

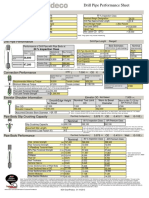

Drill Pipe Performance Sheet

Asset Number: 18929

Pipe Body:

Tubular Assembly:

Nominal

100% RBW

95% RBW

Ultra Class

90% RBW

Premium

80% RBW

2.875

0.362

2.151

2.839

0.344

2.151

2.803

0.326

2.151

2.730

0.290

2.151

Tensile Strength (lbs):

Torsional Strength (ft-lbs):

300,082

16,176

283,025

15,203

266,183

14,250

233,149

12,401

Burst Capacity (psi):

Collapse Capacity (psi):

23,137

23,112

25,120

22,358

23,798

21,574

21,153

19,912

OD (in):

Wall Thickness (in):

Nominal ID (in):

Size and Weight: 2.875'' 10.40 ppf 0.362'' wall IU

Grade: G-105

Range: 2

Tool Joint: 3.125'' x 1.500'' 2 7/8" HTPAC

Adjusted Weight (lbs/ft): 10.98

Approximate Length (ft): 31.5

Box TJ Length (in): 13

Pin TJ Length (in): 9

Upset Type: IU

Max Upset OD (in): 3.000

Drift Size (in): 1.375

Fluid Displacement (gal/ft): 0.17

Fluid Displacement (bblsl/ft): 0.0040

Fluid Capacity w/IPC (gal/ft): 0.17

Fluid Capacity w/IPC (bbls/ft): 0.0041

Fluid Capacity w/o IPC (gal/ft): 0.18

Fluid Capacity w/o IPC (bbls/ft): 0.0042

18

0

Notes: Body properties are calculated based on uniform OD and wall thickness.

Burst capacity for Nominal (100% RBW) based on 87.5% RBW per API.

Note: These are OEM values that may vary with actual values due to mill tolerances, IPC tolerances, OEM rounding, and other

factors. Pipe is purchased at a guaranteed 95% RBW. IPC is applied to a nominal thickness of 0.009''. Pipe will have an ID of

2.093'', which is smaller than pipe purchased at 87.5%.

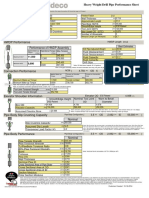

Connection: 2 7/8" HTPAC

Elevator Shoulder:

TJ OD (in): 3.125

TJ ID (in): 1.500

MYS (ksi): 120

Maximum MUT (ft-lbs):

Tension at Shoulder Separation @ Max MUT (lbs):

Tension at Connection Yield @ Max MUT (lbs):

5,100

Tensile Limited

213,300

Minimum MUT (ft-lbs):

Tension at Shoulder Separation @ Min MUT (lbs):

Tension at Connection Yield @ Min MUT (lbs):

4,300

Tensile Limited

263,200

N/A

N/A

Smooth Edge Height (in): N/A

Smooth Edge OD (in): N/A

SE Elevator Shoulder Capacity (lbs): N/A

Nominal TJ OD (in): 3.125

Tool Joint Torsional Strength (ft-lbs): 8,500

Tool Joint Tensile Strength (lbs): 266,300

2 7/8" HTPAC is a trademark of NOV Grant-Prideco.

Note: MUT values are based on a friction factor of 1.0. There is no published pressure rating for this connection.

This asset must be handled with a lift nubbin. For more information, please consult Workstrings Operations.

The technical information containted herein, including the product performance sheet and other attached documents, has been extracted from information available from the manufacturer and is for reference only and not a recommendation. The user is fully responsible for the accuracy and suitability of use of the technical

information. Workstrings International cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various

inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable operation limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices,

and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.workstringsinternational.com

Download the Workstrings International Pipe Specification App on the App Store or Google Play

08-Sep-15

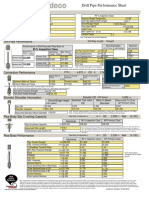

Operational Limits of Drill Pipe

Connection

Pipe Body

HT 2-7/8 PAC

80 % Inspection Class

Tool Joint OD

(in)

3.125

Tool Joint ID

Pipe Body OD

(in)

2.875

Wall Thickness (in) 0.362

(in)

1.500

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

Pipe Body Grade

G-105

(ft-lbs)

(lbs)

(ft-lbs)

0

200

400

700

900

1,100

1,300

1,600

1,800

2,000

2,200

2,500

2,700

2,900

3,100

3,400

3,600

3,800

4,000

4,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

(lbs)

(ft-lbs)

(ft-lbs)

(lbs)

(lbs)

(lbs)

(lbs)

233,100

213,300

233,100

233,100

263,200

233,100

213,300

200

233,100

233,100

263,200

233,000

213,300

400

233,000

233,000

263,200

232,800

213,300

500

233,000

233,000

263,200

232,500

213,300

700

232,800

232,800

263,200

232,500

232,500

263,200

232,200

232,200

263,200

231,900

231,900

263,200

231,700

231,700

263,200

231,200

231,200

263,200

263,200

232,200

231,900

231,200

230,700

230,100

229,500

228,400

227,600

226,700

225,700

224,200

223,100

221,900

220,700

219,000

900

213,300

1,100

213,300

1,300

213,300

1,400

213,300

1,600

213,300

213,300

1,800

230,700

230,700

213,300

2,000

230,100

230,100

263,200

213,300

2,200

229,500

229,500

263,200

213,300

2,300

229,100

229,100

263,200

213,300

2,500

228,400

228,400

263,200

213,300

2,700

227,600

227,600

263,200

213,300

2,900

226,700

226,700

263,200

213,300

3,100

225,700

225,700

263,200

213,300

3,200

225,300

225,300

263,200

213,300

3,400

224,200

224,200

263,200

Connection

Make-up Torque Range

(ft-lbs)

4,300

4,400

4,500

4,600

4,700

4,700

4,800

4,900

5,000

5,100

(lbs)

263,200

257,600

251,900

246,300

240,700

235,700

230,100

224,500

218,900

213,300

Note: Recommended MUT should always be used when possible. If not possible, MUT should be as close to Recommended MUT as possible.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

06-17-2015

You might also like

- 5 7/8" 23.4 PPF S135 Pipe SpecsDocument2 pages5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular Assemblymsm.ele2009No ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohann ZabaletaNo ratings yet

- 5 7/8" VM-165 R2 Pipe SpecsDocument2 pages5 7/8" VM-165 R2 Pipe SpecsTiffany DacinoNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance Sheetjinyuan74No ratings yet

- 4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BDocument3 pages4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BjohangomezruizNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- Drill pipe performance and operational limitsDocument3 pagesDrill pipe performance and operational limitsGarcia C L AlbertoNo ratings yet

- Drill Pipe Performance Sheet 5.875 XT57 G105Document3 pagesDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- Trispiral XT39Document1 pageTrispiral XT39Cerón Niño SantiagoNo ratings yet

- HeavyWeight 3.5 25.58lbs NC-38Document3 pagesHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаNo ratings yet

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaNo ratings yet

- Drill Pipe Performance and SpecificationsDocument3 pagesDrill Pipe Performance and SpecificationsИнженер Луис А. ГарсиаNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Drill Pipe Performance Data SheetDocument3 pagesDrill Pipe Performance Data SheetGarcia C L Alberto100% (1)

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetSaurav SenguptaNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- 5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BDocument3 pages5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BJeaneth HerreraNo ratings yet

- Xt39 Spec SheetDocument3 pagesXt39 Spec SheetjdcomptonNo ratings yet

- Drill CollarDocument1 pageDrill CollarGuillermo Rangel AvalosNo ratings yet

- 2.500 X 1.375 DC With MW20 SlickDocument1 page2.500 X 1.375 DC With MW20 SlickHadi Bapir SlemanNo ratings yet

- Landing String 6.625 .938 v150 FH Slip Proof 95rbw PDFDocument4 pagesLanding String 6.625 .938 v150 FH Slip Proof 95rbw PDFMarcelo VeronezNo ratings yet

- 2.875 N80 6.51ppf EUEDocument1 page2.875 N80 6.51ppf EUEANSARAKUNo ratings yet

- TB 00700001 eDocument9 pagesTB 00700001 eRicardo LopezNo ratings yet

- Application Example: Pneumatic 2-Finger Parallel GripperDocument35 pagesApplication Example: Pneumatic 2-Finger Parallel GripperBaltazar EspinosaNo ratings yet

- 2183R TechdataDocument2 pages2183R TechdataNelson NeriNo ratings yet

- 8761 TechdataDocument3 pages8761 TechdataAndie SiahaanNo ratings yet

- 1.-1032A TechdataDocument2 pages1.-1032A TechdataJORGE ALOR RODRIGUEZNo ratings yet

- 1030A TechdataDocument2 pages1030A TechdataSamuel C. HernándezNo ratings yet

- 8777 Techdata PDFDocument3 pages8777 Techdata PDFNestor-leoNo ratings yet

- 8770 TechdataDocument2 pages8770 TechdataAl Wahdani RambeNo ratings yet

- Belden Cables Data 8777Document3 pagesBelden Cables Data 8777AnandNo ratings yet

- Dep 22 1680 QD GDR217BS4371 - 20231212105031.905 - XDocument10 pagesDep 22 1680 QD GDR217BS4371 - 20231212105031.905 - XoswaldovbNo ratings yet

- Indicaodres Atex Marca PeperDocument56 pagesIndicaodres Atex Marca PeperArmaders GonzAlezNo ratings yet

- Polyethylene Gas Pipe 2007Document10 pagesPolyethylene Gas Pipe 2007asgharkhanNo ratings yet

- 2097 In002 - en PDocument8 pages2097 In002 - en PCarlosOtinianoNo ratings yet

- P&B Push To Reset OnlyDocument3 pagesP&B Push To Reset Onlypablo_bas99No ratings yet

- PV Elite Vessel Analysis Program: Input DataDocument90 pagesPV Elite Vessel Analysis Program: Input DatajahiranazriNo ratings yet

- TBE Inlet Separator V 2100 FLNG2Document6 pagesTBE Inlet Separator V 2100 FLNG2halipzramlyzNo ratings yet

- Grinnell Figure 772 Grooved Rigid CouplingDocument4 pagesGrinnell Figure 772 Grooved Rigid CouplingJuanNo ratings yet

- Vessel Design CalculationDocument54 pagesVessel Design CalculationPohn Myint Han50% (2)

- Rociadores STD TycoDocument86 pagesRociadores STD TycoIvAldreteNo ratings yet

- Split stream dearator vessel design calculationsDocument26 pagesSplit stream dearator vessel design calculationsArt G. EnziNo ratings yet

- For More Information Please Call 1-800-Belden1: DescriptionDocument3 pagesFor More Information Please Call 1-800-Belden1: DescriptionMohammed KhalilNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DPPS PDFDocument2 pagesDPPS PDFStowartNo ratings yet

- DPPSDocument2 pagesDPPSGarcia C L AlbertoNo ratings yet

- WS36-01 DPPSDocument2 pagesWS36-01 DPPSGarcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- Drill Pipe Performance Data SheetDocument3 pagesDrill Pipe Performance Data SheetGarcia C L Alberto100% (1)

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, X-95.. XT57 (7.000 X 4.250)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, X-95.. XT57 (7.000 X 4.250)Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- Drill Pipe Performance Data SheetDocument3 pagesDrill Pipe Performance Data SheetGarcia C L Alberto100% (1)

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance Sheetjinyuan74No ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance Sheetjinyuan74No ratings yet

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- Sprinkler Items (TPMC)Document21 pagesSprinkler Items (TPMC)duleesha oshanNo ratings yet

- Regulators 92b PDFDocument12 pagesRegulators 92b PDFAlberto CastellanosNo ratings yet

- Product Data Sheet Keystone Figure 360 362 370 372 K Lok High Performance Butterfly Valve en 5430886Document16 pagesProduct Data Sheet Keystone Figure 360 362 370 372 K Lok High Performance Butterfly Valve en 5430886NanDo Wandi SaputraNo ratings yet

- Inst Manual Engine General 47706356Document164 pagesInst Manual Engine General 47706356giri_placid100% (1)

- Riddhi Steel & Tube Pvt. LTD.: Contact DetailsDocument4 pagesRiddhi Steel & Tube Pvt. LTD.: Contact DetailsRohit AgrawalNo ratings yet

- A 335 - A 335M - 03 QTMZNS9BMZM1TQ - PDFDocument8 pagesA 335 - A 335M - 03 QTMZNS9BMZM1TQ - PDFYssel Hernandez BautistaNo ratings yet

- Astm A 691 .98Document6 pagesAstm A 691 .98FrengkiNo ratings yet

- K To 12 Rac FinalDocument220 pagesK To 12 Rac FinalHari Ng Sablay80% (5)

- Service Parts List: Diesel EngineDocument44 pagesService Parts List: Diesel Enginepedro perezNo ratings yet

- Sajid Khan.: Mechanical EngineerDocument2 pagesSajid Khan.: Mechanical EngineerShankker KumarNo ratings yet

- ASTM Ferrous Castings FerroalloysDocument3 pagesASTM Ferrous Castings FerroalloysMAX ALBERTO JUAREZ AVALOSNo ratings yet

- 2013 - 2020 Yuhong Group Export AchievementDocument27 pages2013 - 2020 Yuhong Group Export AchievementAhmed ItoeNo ratings yet

- DS-1 4th Ed - Volume 3 - Addendums 1 To 6Document77 pagesDS-1 4th Ed - Volume 3 - Addendums 1 To 6Aashid Ps83% (6)

- Guide For Welding Ferritic/Austenitic Duplex Stainless Steel Piping and TubingDocument29 pagesGuide For Welding Ferritic/Austenitic Duplex Stainless Steel Piping and Tubingarnoldbatista55100% (2)

- PFP by MorganDocument20 pagesPFP by Morgansajid aslamNo ratings yet

- 5.4.2 Engineering Spec Pressure Vessel - NewDocument52 pages5.4.2 Engineering Spec Pressure Vessel - Newandrieysyah2525No ratings yet

- CW S Series ManualDocument32 pagesCW S Series ManualDoger DudeskyNo ratings yet

- Understanding SCC in PipelinesDocument14 pagesUnderstanding SCC in Pipelinesalmgdb1453No ratings yet

- Preheater Installation Check List: PlantDocument11 pagesPreheater Installation Check List: PlantJCSNo ratings yet

- Ground Movement Associated With Trench Excavation and Their Effect On Adjacent ServicesDocument3 pagesGround Movement Associated With Trench Excavation and Their Effect On Adjacent ServicesEnri05No ratings yet

- Design Tank-2Document4 pagesDesign Tank-2evrim77No ratings yet

- Insertion Vortex S V Bar TI 8 602 USDocument8 pagesInsertion Vortex S V Bar TI 8 602 USMarcos AndréNo ratings yet

- Pipe Stress Analysis Scope and Specifications For Clients, Engineers and ContractorsDocument4 pagesPipe Stress Analysis Scope and Specifications For Clients, Engineers and ContractorsUmesh TiwariNo ratings yet

- DB EKHVH-BB EN tcm135-184347 PDFDocument20 pagesDB EKHVH-BB EN tcm135-184347 PDFdino_pNo ratings yet

- Customer CareDocument26 pagesCustomer Carenike_y2kNo ratings yet

- Piping Class - AT70Document2 pagesPiping Class - AT70Дмитрий РыбаковNo ratings yet

- SHURflo Pump Brochure PDFDocument28 pagesSHURflo Pump Brochure PDFOscar Muñoz ValeroNo ratings yet

- ZW Brochure V2 PDFDocument37 pagesZW Brochure V2 PDFCarlos SimoesNo ratings yet

- Technical SpecificationDocument42 pagesTechnical SpecificationHadisupriadiNo ratings yet