Professional Documents

Culture Documents

Performance Sheet Drill Pipe: Pipe Body: Tubular Assembly

Uploaded by

Garcia C L AlbertoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Performance Sheet Drill Pipe: Pipe Body: Tubular Assembly

Uploaded by

Garcia C L AlbertoCopyright:

Available Formats

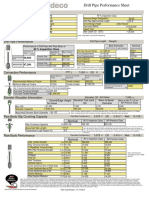

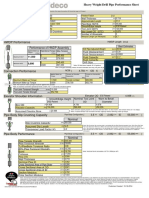

Drill Pipe Performance Sheet

Asset Number: WS42-20

Pipe Body:

Tubular Assembly:

Nominal

100% RBW

95% RBW

Ultra Class

90% RBW

Premium

80% RBW

5.875

0.415

5.045

5.834

0.394

5.045

5.792

0.374

5.045

5.709

0.332

5.045

1,067,779

131,016

1,010,535

123,863

953,697

116,779

841,238

102,815

18,543

15,976

20,132

14,447

19,072

12,897

16,953

9,728

OD (in):

Wall Thickness (in):

Nominal ID (in):

Tensile Strength (lbs):

Torsional Strength (ft-lbs):

Size and Weight: 5.875'' 26.30 ppf 0.415'' wall IEU

Grade: V-150

Range: 3

Tool Joint: 7.000'' x 4.250'' CTM57

Burst Capacity (psi):

Collapse Capacity (psi):

Adjusted Weight (lbs/ft): 29.69

Approximate Length (ft): 44.5

Box TJ Length (in): 18

Pin TJ Length (in): 14

Upset Type: IEU

Max Upset OD (in): 6.000

Drift Size (in): 4.125

Fluid Displacement (gal/ft): 0.45

Fluid Displacement (bblsl/ft): 0.0108

Fluid Capacity w/IPC (gal/ft): 0.99

Fluid Capacity w/IPC (bbls/ft): 0.0236

Fluid Capacity w/o IPC (gal/ft): 1.00

Fluid Capacity w/o IPC (bbls/ft): 0.0238

18

0

Notes: Body properties are calculated based on uniform OD and wall thickness.

Burst capacity for Nominal (100% RBW) based on 87.5% RBW per API.

Note: These are OEM values that may vary with actual values due to mill tolerances, IPC tolerances, OEM rounding, and other

factors. Pipe is purchased at a guaranteed 95% RBW. IPC is applied to a nominal thickness of 0.009''. Pipe will have an ID of

4.981'', which is smaller than pipe purchased at 87.5%.

Connection: CTM57

Elevator Shoulder:

TJ OD (in): 7.000

TJ ID (in): 4.250

MYS (ksi): 135

Maximum MUT (ft-lbs):

Tension at Shoulder Separation @ Max MUT (lbs):

Tension at Connection Yield @ Max MUT (lbs):

51,500

Tensile Limited

1,301,300

Minimum MUT (ft-lbs):

Tension at Shoulder Separation @ Min MUT (lbs):

Tension at Connection Yield @ Min MUT (lbs):

42,900

1,163,500

1,350,600

Smooth Edge Height (in): 3/32

Smooth Edge OD (in): 7.188

SE Elevator Shoulder Capacity (lbs): 1,223,100

Nominal TJ OD (in): 7.000

Nominal TJ OD Elevator Shoulder Capacity (lbs): 993,000

Assumed Elevator Bore (in): 6.125

Internal Pressure Rating (psi): 15,000

External Pressure Rating (psi): 10,000

CTM57 is a trademark of NOV Grant-Prideco.

Note: MUT values are based on a friction factor of 1.0.

Tool Joint Torsional Strength (ft-lbs): 96,600

Tool Joint Tensile Strength (lbs): 1,350,600

Note: Elevator capacity based on assumed elevator bore, no wear factor, and contact stress of 110, 100 psi. An increased

elevator shoulder OD increases elevator capacity without affecting make-up torque.

The technical information containted herein, including the product performance sheet and other attached documents, has been extracted from information available from the manufacturer and is for reference only and not a recommendation. The user is fully responsible for the accuracy and suitability of use of the technical

information. Workstrings International cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various

inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable operation limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices,

and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.workstringsinternational.com

Download the Workstrings International Pipe Specification App on the App Store or Google Play

30-Nov-15

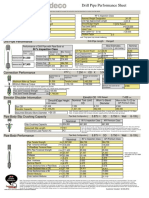

Operational Limits of Drill Pipe

Connection

Pipe Body

CTM57

80 % Inspection Class

Tool Joint OD

(in)

7.000

Tool Joint ID

Pipe Body OD

(in)

5.875

Wall Thickness (in) 0.415

(in)

Combined Loading for Drill Pipe at

(ft-lbs)

0

2,200

4,500

6,700

9,000

11,200

13,500

15,700

18,000

20,200

22,500

24,700

26,900

29,200

31,400

33,700

35,900

38,200

40,400

42,700

(lbs)

841,200

841,000

840,400

839,500

838,000

836,200

834,000

831,400

828,200

824,800

820,800

816,600

811,900

806,600

801,000

794,800

788,300

781,000

773,600

765,400

V-150

Minimum Make-up Torque = 42,900

(ft-lbs)

Connection Max

Pipe Body

Max Tension Tension

(lbs)

Pipe Body Grade

Combined Loading for Drill Pipe at

Maximum Make-up Torque = 51,500

Operational Assembly

Torque

Max Tension

Tool Joint Specified Minimum

135,000

(psi)

Yield Strength

4.250

Operationa Assembly

l Torque

Max Tension

(ft-lbs)

(lbs)

Pipe Body

Max Tension

(lbs)

(lbs)

(ft-lbs)

Connection

Max Tension

(lbs)

841,200

841,200

1,163,500

841,200

1,301,300

841,000

1,301,300

1,800

841,100

841,100

1,163,500

1,301,300

3,600

840,700

840,700

1,163,500

1,163,500

840,400

839,500

1,301,300

5,300

840,100

840,100

838,000

1,301,300

7,100

839,200

839,200

1,163,500

836,200

1,301,300

8,900

838,100

838,100

1,163,500

834,000

1,301,300

10,700

836,700

836,700

1,163,500

1,301,300

12,400

835,100

835,100

1,163,500

1,301,300

14,200

833,200

833,200

1,163,500

1,301,300

16,000

831,000

831,000

1,163,500

1,163,500

831,400

828,200

824,800

820,800

1,301,300

17,800

828,500

828,500

816,600

1,301,300

19,500

826,000

826,000

1,163,500

811,900

1,301,300

21,300

823,000

823,000

1,163,500

806,600

1,301,300

23,100

819,700

819,700

1,163,500

1,301,300

24,900

816,200

816,200

1,163,500

1,301,300

26,600

812,600

812,600

1,163,500

808,500

808,500

1,163,500

1,163,500

801,000

794,800

788,300

28,400

1,301,300

781,000

1,301,300

30,200

804,100

804,100

773,600

1,301,300

32,000

799,500

799,500

1,163,500

765,400

1,301,300

33,700

794,700

794,700

1,163,500

Operational drilling torque is limited by the Make-up Torque.

Operational drilling torque is limited by the Make-up Torque.

Connection

Make-up Torque Range

Make-up Torque

(ft-lbs)

Min MUT

Max MUT

42,900

43,900

44,800

45,800

46,700

47,700

48,600

49,600

50,500

51,500

Connection Max

Tension

(lbs)

1,163,500

1,190,600

1,215,000

1,242,200

1,266,600

1,293,700

1,318,100

1,345,200

1,330,200

1,301,400

Note: Recommended MUT should always be used when possible. If not possible, MUT should be as close to Recommended MUT as possible.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

11-18-2015

You might also like

- Drill Pipe Performance Sheet 5.875 XT57 G105Document3 pagesDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoNo ratings yet

- 5 7/8" VM-165 R2 Pipe SpecsDocument2 pages5 7/8" VM-165 R2 Pipe SpecsTiffany DacinoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular Assemblymsm.ele2009No ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.750Document3 pagesDrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.750Инженер Луис А. ГарсиаNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohann ZabaletaNo ratings yet

- DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFDocument3 pagesDrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFGarcia C L Alberto100% (1)

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance Sheetjinyuan74No ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Drill Pipe Configuration: 95 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 95 % Inspection ClassSaurav SenguptaNo ratings yet

- HeavyWeight 3.5 25.58lbs NC-38Document3 pagesHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaNo ratings yet

- LandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)Document3 pagesLandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- 5 7/8" 23.4 PPF S135 Pipe SpecsDocument2 pages5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoNo ratings yet

- 5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BDocument3 pages5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BJeaneth HerreraNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Trispiral XT39Document1 pageTrispiral XT39Cerón Niño SantiagoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- 4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BDocument3 pages4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BjohangomezruizNo ratings yet

- Drill CollarDocument1 pageDrill CollarGuillermo Rangel AvalosNo ratings yet

- 2.500 X 1.375 DC With MW20 SlickDocument1 page2.500 X 1.375 DC With MW20 SlickHadi Bapir SlemanNo ratings yet

- Xt39 Spec SheetDocument3 pagesXt39 Spec SheetjdcomptonNo ratings yet

- Landing String 6.625 .938 v150 FH Slip Proof 95rbw PDFDocument4 pagesLanding String 6.625 .938 v150 FH Slip Proof 95rbw PDFMarcelo VeronezNo ratings yet

- BC547 PDFDocument7 pagesBC547 PDFToño ParodNo ratings yet

- Structural Bolting GuideDocument24 pagesStructural Bolting GuideJoseph BookerNo ratings yet

- Beam End Connection ReportDocument6 pagesBeam End Connection ReportHibri HalimNo ratings yet

- AA SPEC 371001 - Conveyor Pulleys and ShaftsDocument14 pagesAA SPEC 371001 - Conveyor Pulleys and Shaftsjonodo89No ratings yet

- Pipe Rack Hilti Bolt CalculationsDocument6 pagesPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVNo ratings yet

- 2.875 N80 6.51ppf EUEDocument1 page2.875 N80 6.51ppf EUEANSARAKUNo ratings yet

- Wedge Thread Tool Joints Applications and EconomicsDocument9 pagesWedge Thread Tool Joints Applications and EconomicsalexintelNo ratings yet

- Application Example: Pneumatic 2-Finger Parallel GripperDocument35 pagesApplication Example: Pneumatic 2-Finger Parallel GripperBaltazar EspinosaNo ratings yet

- Steel Kract Cid-28t-C (Pe) - 1 (SMJ 8224) K60101cid-Page 1-130Document130 pagesSteel Kract Cid-28t-C (Pe) - 1 (SMJ 8224) K60101cid-Page 1-130Giovanny100% (1)

- Autopilot Interface Unit: Deklin Technologies IncDocument24 pagesAutopilot Interface Unit: Deklin Technologies Incraphael EliasNo ratings yet

- Final Report, NarayanganjDocument125 pagesFinal Report, NarayanganjNaim ParvejNo ratings yet

- 4.5 15.1ppf P110EC DWC-C-SR Spec SheetDocument3 pages4.5 15.1ppf P110EC DWC-C-SR Spec SheetsaadNo ratings yet

- PV Elite Vessel Analysis Program: Input DataDocument90 pagesPV Elite Vessel Analysis Program: Input DatajahiranazriNo ratings yet

- Offcon DNV Zorro SkidDocument7 pagesOffcon DNV Zorro SkidRAMSINGH CHAUHANNo ratings yet

- Pad LEEA-048 Guidance On The Design Testing and Inspection of Fabricated Pad EyesDocument3 pagesPad LEEA-048 Guidance On The Design Testing and Inspection of Fabricated Pad EyesAnirudh S. Goel83% (6)

- Flang ManegmentDocument12 pagesFlang ManegmentYasser Abd El Fattah100% (1)

- Sample4 PVEliteDocument66 pagesSample4 PVEliteSourav Hait100% (1)

- BE ProdBulletin AD1250AirMeasDocument6 pagesBE ProdBulletin AD1250AirMeasMaria Gabriela BusteloNo ratings yet

- Datasheet BombaDocument4 pagesDatasheet BombasaculNo ratings yet

- Knighten Machine &: Proforma Invoice Customer: Knighten Machine & Proposal No: H-156086Document26 pagesKnighten Machine &: Proforma Invoice Customer: Knighten Machine & Proposal No: H-156086Guillermo FigueroaNo ratings yet

- 2097 In002 - en PDocument8 pages2097 In002 - en PCarlosOtinianoNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersFrom EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersRating: 3.5 out of 5 stars3.5/5 (19)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFDocument3 pagesDrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFGarcia C L Alberto100% (1)

- DrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, X-95.. XT57 (7.000 X 4.250)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, X-95.. XT57 (7.000 X 4.250)Garcia C L AlbertoNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFDocument3 pagesDrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFGarcia C L Alberto100% (1)

- DPPS PDFDocument2 pagesDPPS PDFStowartNo ratings yet

- Mod 3Document3 pagesMod 3Kevin ArnaizNo ratings yet

- Practice 4ADocument22 pagesPractice 4ACamha NguyenNo ratings yet

- BRIVO CT315/325 Theory of Operation: GE HealthcareDocument114 pagesBRIVO CT315/325 Theory of Operation: GE HealthcareManuel Saenz100% (1)

- Unit 3 Sessionwise ProblemsDocument5 pagesUnit 3 Sessionwise ProblemsNilay ShahNo ratings yet

- PDS FF IODocument9 pagesPDS FF IODaniel GarciaNo ratings yet

- Odelling A Cassette Tape Rewinding ProcessDocument5 pagesOdelling A Cassette Tape Rewinding Processbruno marquesi quentinNo ratings yet

- 1.temperature Indicating SystemsDocument15 pages1.temperature Indicating SystemsVedanta NairNo ratings yet

- Hager PDFDocument36 pagesHager PDFMihai RacaruNo ratings yet

- Brosur Sand PumpDocument2 pagesBrosur Sand PumpRektorUnitelNo ratings yet

- Rotor Dynamics of Aircraft Gas Turbine EnginesDocument5 pagesRotor Dynamics of Aircraft Gas Turbine EnginesfengrotorNo ratings yet

- Wind Load Design NSCP 2015 PDFDocument6 pagesWind Load Design NSCP 2015 PDFJoshua Espanto MorenNo ratings yet

- Chapter 14 PolynomialsDocument20 pagesChapter 14 PolynomialsOzzy PingBoi100% (2)

- Physics 2P - Specimen PaperDocument20 pagesPhysics 2P - Specimen PaperHan Thi Win KoNo ratings yet

- Deformable Bodies (Thermal Stress)Document11 pagesDeformable Bodies (Thermal Stress)Kristelle GinezNo ratings yet

- % Steel RCC STRDocument9 pages% Steel RCC STRVenkata Raju KalidindiNo ratings yet

- 4.1/4.2 Scale Factor and Similarity Review Name: - ClassDocument5 pages4.1/4.2 Scale Factor and Similarity Review Name: - Classapi-5034094710% (1)

- Avo Analysis and Impedance Inversion For Fluid Prediction in Hoover Field, Gulf of MexicoDocument124 pagesAvo Analysis and Impedance Inversion For Fluid Prediction in Hoover Field, Gulf of MexicoJuan DelgadoNo ratings yet

- Corona Discharge - Wikipedia, The Free EncyclopediaDocument8 pagesCorona Discharge - Wikipedia, The Free EncyclopediavagoliyoNo ratings yet

- How To Calculate and Draw Bending Moment and Create BMD Diagram in Four StepsDocument10 pagesHow To Calculate and Draw Bending Moment and Create BMD Diagram in Four Stepsvinod kumarNo ratings yet

- Techniques For Quadcopter Modelling & Design: A Review: ArticleDocument11 pagesTechniques For Quadcopter Modelling & Design: A Review: Articlenguyễn namNo ratings yet

- Chapter - 1 (1) كاملDocument24 pagesChapter - 1 (1) كاملFaisal ZanoomNo ratings yet

- Tinius Film TestingDocument3 pagesTinius Film TestingHafiani HichamNo ratings yet

- Recrystallization of AcetanilideDocument6 pagesRecrystallization of AcetanilideButterlesstoastNo ratings yet

- CIE L A B Color Scale: BackgroundDocument4 pagesCIE L A B Color Scale: BackgrounddnzoltanNo ratings yet

- Schwichtenberg & Wainer - Proofs and ComputationsDocument384 pagesSchwichtenberg & Wainer - Proofs and ComputationsYan Mikhlin100% (1)

- Elements of Seismic Surveying PDFDocument51 pagesElements of Seismic Surveying PDFShawki BsatNo ratings yet

- Ball Lightning Fusion ReactorsDocument43 pagesBall Lightning Fusion ReactorsGavin O'rourke-SoccorsoNo ratings yet

- 19EC402 QK-Signals and SystemsDocument34 pages19EC402 QK-Signals and SystemsSaranya AthipatlaNo ratings yet

- Experiment 7-Forced Oscillation-Pohl's PendulumDocument4 pagesExperiment 7-Forced Oscillation-Pohl's Pendulumdiyana889450% (2)